Tech Type

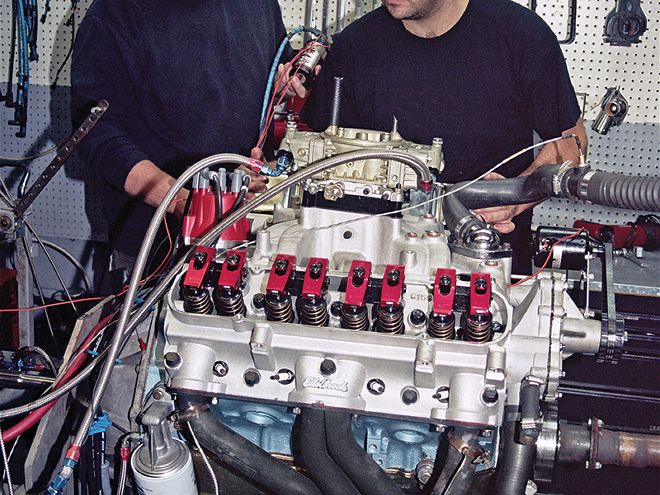

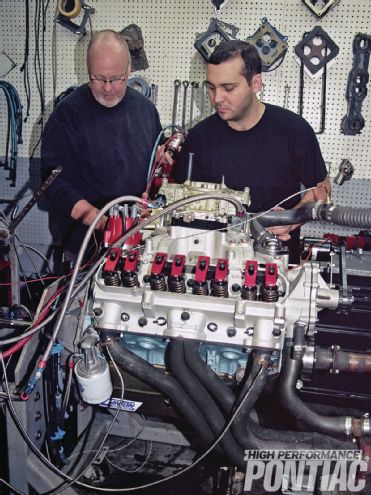

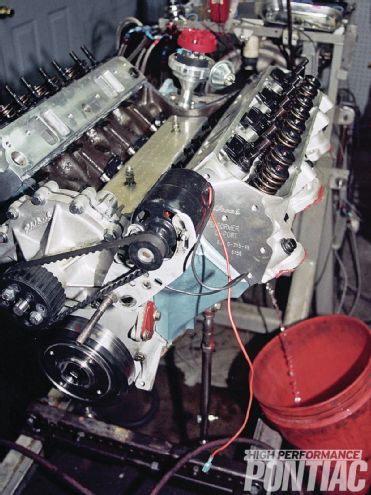

Craig Wise and Corey Porter prepare The Mule for dyno testing with the Edelbrock Performer D-Port heads and 92-octane pump gas.

Craig Wise and Corey Porter prepare The Mule for dyno testing with the Edelbrock Performer D-Port heads and 92-octane pump gas.

With the supercharger testing complete, HPP felt it was time for The Mule to explore some new horizons. Up until now, the stroker 455 retained all of its original build parts and we worked within those confines. In every instance, including the rocker arm ratio and cam phase test, we discovered that our original combination yielded the best results and thus, the engine was returned to that state for the next phase of research and development.

Within the traditional Pontiac community there are two schools of justifiable thought when it comes to cylinder heads. These are: retain and fully port the stock castings or switch to an aftermarket aluminum design, such as the Edelbrock offerings or others. We chose the first ideology, since it made the most sense. The 6X castings used in the mid ’70s have become well respected and widely used, so it was a logical place to start our engine build.

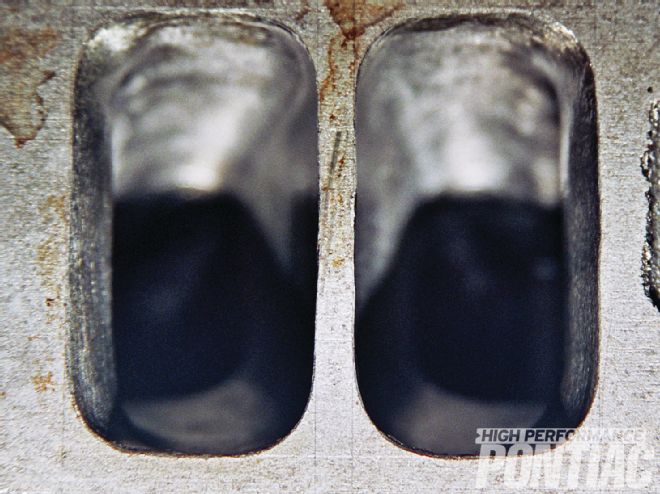

1 With the 6X cylinder head removed, an examination of the combustion chamber reveals that it displayed excellent flame travel, as determined by the discoloration. Note the spark plug bias toward the intake valve. Combustion chamber volume is 96 cc.

1 With the 6X cylinder head removed, an examination of the combustion chamber reveals that it displayed excellent flame travel, as determined by the discoloration. Note the spark plug bias toward the intake valve. Combustion chamber volume is 96 cc.

These factory heads when treated to RaceKrafters’ porting expertise and state-of-the-art equipment produced stunning results. The Mule consistently returned dyno numbers of between 492 and 494 hp and was very insensitive to octane. We were able to make that power on regular grade gasoline, though at times we did try higher-octane fuels with little to no gain.

In addition, the combustion event when qualified for efficiency by the amount of ignition lead required was also quite impressive. With a 9.1:1 compression ratio, the Poncho with the 6X cylinder heads only required a maximum spark timing of 32 degrees BTDC. By any measure The Mule was an impressive engine. But we knew that the cylinder heads were at their maximum power potential, if the dyno needle were to move upwards, we needed to increase the volumetric efficiency of the engine.

Volumetric efficiency (VE) is a measure of cylinder fill. On our test level we cannot confirm or accurately assign a number for it. But the more air throughput the engine has, the greater the VE will be. In an engine, peak cylinder fill coincides with peak torque and in most applications the VE is around 80 percent. A simple way to understand this is that at the most the bore is 80 percent filled to capacity with charge. That is defined as the combustible mixture. A well-defined race engine can experience VE nearer 100 percent and beyond. Once forced induction is applied, the VE potential becomes almost limitless depending on the airflow of the power adder and the pressure realized.

There is a simple equation to calculate power from airflow that HPP has introduced in previous installments of this series, but it bears repeating.

Horsepower = flow at 28 inches/H2O x 0.257 x number of cylinders.

Our RaceKrafters modified 6X cylinder heads flowed 236 cfm at 0.500-inch lift and 250 cfm at 0.600-inch lift. The cam with the 1.65:1 rockers lifted the valve to around 0.550 inch. If we average the airflow between those two lift points, we come up with around 243 cfm, which then calculates to 499 hp to our 492 hp actual reading. Extremely close, especially since we are not taking into consideration any flow loss from the intake manifold.

2 The piston crowns were evenly discolored and showed no signs of carbon accumulation. Crosshatch on the bore looked as if it just came off the hone.

2 The piston crowns were evenly discolored and showed no signs of carbon accumulation. Crosshatch on the bore looked as if it just came off the hone.

As an aside, it proves that the 6X cylinder heads and the potential horsepower are at their maximum with no room to improve the VE. We could potentially find more power with a higher compression ratio and a more aggressive cam profile, but the gains would be minimal since the engine can only ingest so much air through the cylinder heads. If we wanted to make more power, The Mule required better-flowing cylinder heads.

When Edelbrock introduced its first Pontiac cylinder head in the early ’90s, it was with a round exhaust port (laid-over D in appearance in Edelbrock’s case) and not the more commonly employed D-port design with the Siamesed center ports. There is no denying that it was an excellent casting with the ability to make huge power, but that came with a complication— either Round-Port exhaust manifolds or less-common-than-D-Port Round-Port headers were required. This added expense, and in some cases, required custom headers to be made for cars that weren’t originally offered with Round-Port heads. Recognizing that the Pontiac community had varied needs, Edelbrock created a replacement D-port cylinder head a couple of years ago. This is the design we wanted to try on The Mule: D-port versus D-port.

The Edelbrock Advantage

When choosing which cylinder head route to go with for your Pontiac, factors beyond airflow need to be considered.

If your 6X cylinder heads are in good shape and are not cracked then RaceKrafters can duplicate what they did to The Mule for a charge of $2,500 including parts and labor. This entails cleaning, surfacing, porting, valve job, new 2.11/1.77 stainless steel valves (larger than stock exhaust valves), 7⁄16 studs, and new valvesprings, retainers, and locks.

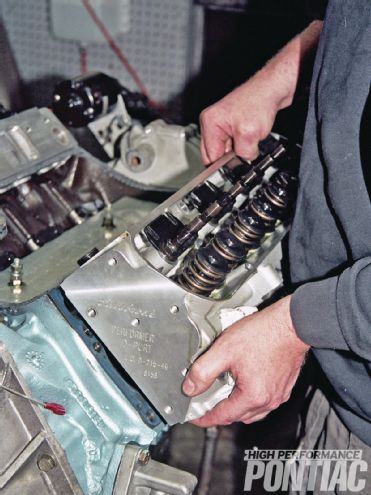

3 The Edelbrock cylinder head is a direct bolt on, but does require different head bolts. There are some stanchions that are higher than on the 6X heads. Summit Racing Equipment provided the needed ARP bolts under part number EDL-8561.

3 The Edelbrock cylinder head is a direct bolt on, but does require different head bolts. There are some stanchions that are higher than on the 6X heads. Summit Racing Equipment provided the needed ARP bolts under part number EDL-8561.

The Edelbrock D-port fully assembled castings can be purchased from many retailers. Summit Racing has them under part number EDL-61575 for hydraulic roller cam for $2,319 or EDL-61579 for hydraulic flat-tappet cam for $2,199 per pair. They come with 87cc chambers, 2.11/1.66 stainless steel valves, valvesprings, retainers, locks, 7⁄16-inch studs, and pushrod guide plates. Bare 87cc chamber castings and bare or fully assembled 72cc chamber castings are also available.

When examining a cylinder head, it is very important to study the combustion chamber design and spark plug orientation. By all standards, the Pontiac factory casting employs a combustion chamber that undeniably works well, but is about 50 years old in design. We all know that engine technology has advanced quite a bit during that time. Also, the 6X head has the spark plug biased toward the intake valve. That is in contrast to the modern trend.

In theory, the plug should be in the center of the bore, which is the most turbulent. If it cannot reside there then the next best location is facing the exhaust valve. This is the hottest part of the combustion chamber and will allow for the reaction zone to be more efficient. This describes the heat transfer from the burned to unburned mixture, which is required to speed up the flame travel across the bore.

A benefit of the Edelbrock casting is that it employs a modern combustion chamber design and has the spark plug biased toward the exhaust valve instead of the intake valve like a Pontiac factory casting does. In some vintage Pontiac literature, the division claimed that by placing the electrode near the intake valve a leaner mixture could be ignited. That may have been the theory then, but it is not the trend over the last 30 years.

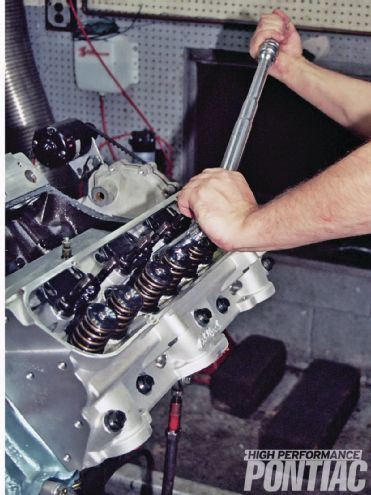

4 Prior to installation the valvesprings were checked to ensure that they were up to task of controlling valvetrain with our hydraulic roller cam. The valvesprings on the 6Xs measured 130 psi at the 1.685-inch installed height and 275 psi at 1.175 inches. The spring rate is 284 psi. On the E-heads they checked in at 110 psi at the 1.780-inch installed height and 275 psi at 1.210 inch. The spring rate is 289 psi. Shown here, the head bolts were torqued to 100 ft-lb in the proper sequence.

4 Prior to installation the valvesprings were checked to ensure that they were up to task of controlling valvetrain with our hydraulic roller cam. The valvesprings on the 6Xs measured 130 psi at the 1.685-inch installed height and 275 psi at 1.175 inches. The spring rate is 284 psi. On the E-heads they checked in at 110 psi at the 1.780-inch installed height and 275 psi at 1.210 inch. The spring rate is 289 psi. Shown here, the head bolts were torqued to 100 ft-lb in the proper sequence.

Another consideration is that the Edelbrock aluminum cylinder heads will remove 42 pounds from the front of your Pontiac, since the fully dressed pair of 6X heads weighs 108 pounds and the E-heads weigh 66 pounds. This is a huge benefit to a drag car, since it allows for more weight transfer to the rear tires. On a street Pontiac, the weight reduction will allow for more nimble handling and better braking. That is something that cannot be seen on an engine dyno or flowbench. In addition, the Edelbrock castings are a better jumping off point, since they allow for improved flow when massaged, while our 6X heads are now at their maximum.

To assign hard numbers to the flow potential, RaceKrafters tested the out-of-the-box Edelbrock castings and this was what they found.

The Edelbrock cylinder head outflowed the modified 6X casting at every lift point on the intake side, but the Pontiac casting did a substantially better job on the exhaust side, which we found interesting. At 0.500-inch lift, the Edelbrock head had an intake to exhaust ratio of 63 percent, while at the same lift the 6X enjoyed a ratio of 77 percent. For years the industry has debated the value of the intake/exhaust ratio with convincing arguments on both sides of the isle and we are not going to get involved in that. Here HPP is only providing an observation from our test data.

Employing our equation and averaging the flow on the Edelbrock heads between 0.500 inch and 0.600 inch, we come up with approximately 263 cfm. This would translate to a potential 540 hp in stock form. Saving you the trouble of referencing the dyno sheet, The Mule produced 502 hp with the new heads. Simply put, the engine was not using the newfound airflow potential to the maximum.

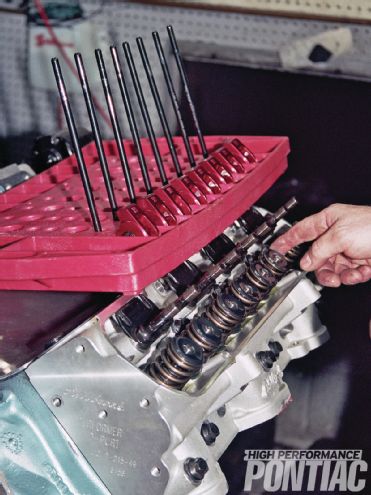

5 RaceKrafters set up the guide plates on the 6X heads for 3⁄8-inch-diameter pushrods, but the Edelbrock casting uses 5⁄16-inch pushrods, so a set of Hi-Tech 8.900-inch long pushrods was ordered from Comp Cams under part number 7781-16. They feature one-piece construction from 0.080-inch-wall, seamless chrome-moly; are heat-treated for durability and guide-plate usage; and have reinforced ends.

5 RaceKrafters set up the guide plates on the 6X heads for 3⁄8-inch-diameter pushrods, but the Edelbrock casting uses 5⁄16-inch pushrods, so a set of Hi-Tech 8.900-inch long pushrods was ordered from Comp Cams under part number 7781-16. They feature one-piece construction from 0.080-inch-wall, seamless chrome-moly; are heat-treated for durability and guide-plate usage; and have reinforced ends.

The Test Data

With the Edelbrock castings, the smaller combustion chamber raised the compression ratio to 9.98:1 from 9.1:1. When going from cast-iron to aluminum, even with the exact same chamber design, the compression ratio needs to be at least one point higher to maintain the same thermal efficiency. Aluminum transfers more heat to the coolant and thus, has a lower thermal energy conversion. So in theory, forgetting about the different combustion chamber design and spark plug orientation, the just shy of one point more compression ratio almost makes things equal in that sense.

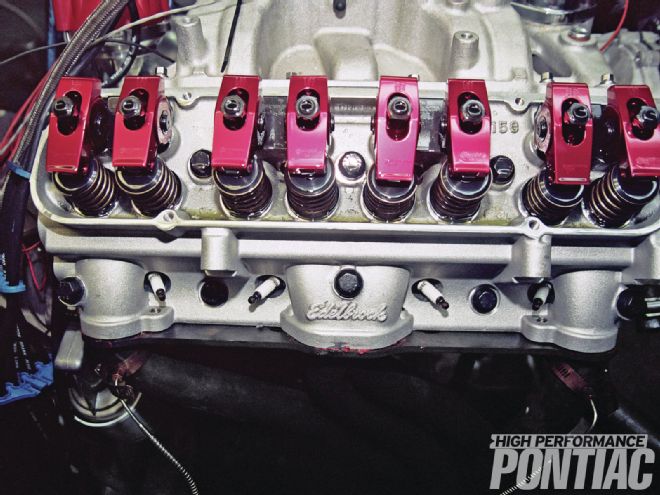

6 The same Comp Cams 1.65:1 full roller rockers were employed from the 6X heads.

6 The same Comp Cams 1.65:1 full roller rockers were employed from the 6X heads.

With the increased intake flow, the aluminum heads did reward us with a nice gain in torque. The Pontiac picked up 15 lb-ft on the average between 3,300 and 5,300 rpm. Average horsepower in the same engine speed range increased by about 12. Reference the dyno sheet and graphs for the complete test data.

What did confuse us was the Edelbrock cylinder head wanted two degrees additional advance (34 versus 32). Also, the Edelbrock heads with the current engine configuration had the power ramp down quickly after 5,000 rpm, while the 6X pulled more evenly to about 5,300 rpm. This is more apparent when viewing the dyno graph than the raw data, since a projected trajectory can be seen. By 5,400 rpm the aluminum heads only had an advantage of 2.7 hp.

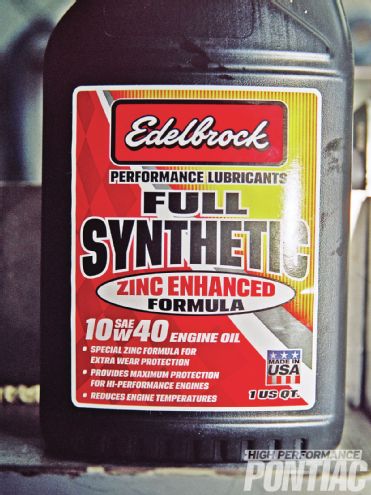

10 Edelbrock now offers a full synthetic oil with the necessary zinc for a performance camshaft. We used the Brad Penn for this cylinder head test, but the Edelbrock 10W/40 oil will be used in a future test.

10 Edelbrock now offers a full synthetic oil with the necessary zinc for a performance camshaft. We used the Brad Penn for this cylinder head test, but the Edelbrock 10W/40 oil will be used in a future test.

There is no denying that the Edelbrock cylinder heads in as-shipped form made more power than the 6X casting, but something was going on that we did not fully understand. In theory, the more advanced combustion chamber design and exhaust valve biased spark plug should not have required more ignition advance. It appeared as if The Mule was balking at the additional airflow. Was the cam too small for the better-flowing heads?

A Possible Analysis

The following theory is the author’s alone and is only conjecture. It’s based upon a search to assign reason as to why the engine did not fully use the additional airflow and its need for more spark advance.

If one were to compare the intake port flow at approximately 0.550-inch lift you would see that the Edelbrock cylinder head flows about eight percent more when on the test bench. It must be understood that the flowbench, though the industry standard, cannot replicate the true dynamics of cylinder filling and emptying that goes on in an engine. It is only a static test. In addition, the airflow equation is only an estimator and it leaves many important facts out, but can be used to get you into the ballpark. With the 6X heads the equation came very close to the actual horsepower produced, but it now indicates that the engine when equipped with the better flowing cylinder heads is not putting the additional air to work.

11 After testing, the process of removing the heads ensued to examine the flame travel.

11 After testing, the process of removing the heads ensued to examine the flame travel.

Now let’s use the equation backwards. Let us predict airflow from horsepower. It now becomes:

Horsepower / # cylinders/ 0.257 = cfm

502/8/0.257= 244 cfm that is being used with the Edelbrock heads

Now for the 6X calculation:

492/8/0.257= 239 cfm that is being used with the 6X castings

If you divide the 6X airflow by the Edelbrock airflow, the result is a difference of 0.020 percent. Now take the 492 (6X hp) and multiply it by 1.020 = 501.84 hp. It is almost the exact number we saw on the dyno for the E-head (502.8).

15 Intake port volume for the 6X heads is 172 cc; for the Edelbrock D-port heads it is 205 cc. The Edelbrock casting has a larger intake runner and a similar exhaust runner when measured in volume. Runner volume is only an indicator and not all-inclusive to the port design or potential. The volume can be manipulated in area and shape, so the cc reading is only an indicator of what is really going on. This holds true for both the intake and exhaust ports.

15 Intake port volume for the 6X heads is 172 cc; for the Edelbrock D-port heads it is 205 cc. The Edelbrock casting has a larger intake runner and a similar exhaust runner when measured in volume. Runner volume is only an indicator and not all-inclusive to the port design or potential. The volume can be manipulated in area and shape, so the cc reading is only an indicator of what is really going on. This holds true for both the intake and exhaust ports.

A possible explanation may lie with the larger intake port volume that may create lower port velocity as the valve starts to lift along with the lower exhaust flow rate. In theory if the port velocity at low lift is lower then the VE will suffer in the beginning stages of the cylinder fill.

The other wild card is the exhaust flow. If I had to guess, I would say that it had a minimal impact on the pumping losses in the engine, but would help to limit the engine’s ability to fill the cylinder bore with charge if energy is being used to push the inert gases out.

In my final analysis, the Edelbrock cylinder head right out of the box has the ability to produce around 535 hp when matched with a more aggressive cam profile and a slightly higher compression ratio. I may be wrong, but the cam grind may need the intake valve opened a little earlier and the duration increased along with the overlap to help scavenging. But this is only a guess on my part.

Regardless, the D-Port E-heads performed well and contain even more potential to be tapped. It’s impressive that a docile street Pontiac makes this kind of power.

Port Flow

Edelbrock D-Port As Shipped Flow in cfm at 28-in/H2O

Lift Intake Exhaust 0.100 67 54 0.200 139 106 0.300 203 138 0.400 240 154 0.500 258 162 0.600 268 164

Ported 6X Flow in cfm at 28-in/H2O

Lift Intake Exhaust 0.100 66 55 0.200 133 106 0.300 191 149 0.400 224 170 0.500 236 182 0.600 250 186

If you divide the 6X airflow by the Edelbrock airflow, the result is a difference of 0.020 percent. Now take the 492 (6X hp) and multiply it by 1.020 = 501.84 hp. It is almost the exact number we saw on the dyno for the E-head (502.8).

A possible explanation may lie with the larger intake port volume that may create lower port velocity as the valve starts to lift along with the lower exhaust flow rate. In theory if the port velocity at low lift is lower then the VE will suffer in the beginning stages of the cylinder fill.

The other wild card is the exhaust flow. If I had to guess, I would say that it had a minimal impact on the pumping losses in the engine, but would help to limit the engine’s ability to fill the cylinder bore with charge if energy is being used to push the inert gases out.

In my final analysis, the Edelbrock cylinder head right out of the box has the ability to produce around 535 hp when matched with a more aggressive cam profile and a slightly higher compression ratio. I may be wrong, but the cam grind may need the intake valve opened a little earlier and the duration increased along with the overlap to help scavenging. But this is only a guess on my part.

Regardless, the D-Port E-heads performed well and contain even more potential to be tapped. It’s impressive that a docile street Pontiac makes this kind of power.

HPP Engine Buildup Worksheet

Engine Displacement: 467 ci

Bore/Stroke: 4.185 / 4.250-in

Bore/Stroke ratio: 0.98:1

Rod/Stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Deck height: 10.205-in

Crank: Butler/Eagle forged

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Bearings: Clevite, plain shell, tri-metal

Pistons: Butler/Ross forged flat-top with valve reliefs

Piston-to-deck height: 0.010-in below

Piston pins: Ross, 0.990-in floating, 0.155-in wall

Method used to retain pins in pistons: Spiro Locks

Rings: Total Seal, moly top, ductile second, 3-piece oil, 1⁄16, 1⁄16, 3⁄16-in

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in-pan

Crank scraper: Canton in-pan

Oil pan: Canton Racing Road Race Series 5 quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2 ccs

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job

Intake 45, 60, 75, and 82-deg, 82 is hand-blended into 75-deg.,

Exhaust 45-deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valveguides: K-line bronze liner

Valve Seals: Steel/Viton

Rocker Studs: ARP 7⁄16-in

Rocker Arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 3⁄8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration At 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe Separation Angle 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 130 psi

Open Pressure: 275 psi

Timing Chain: Cloyes double roller

Induction

Carb: Holley 750-cfm HP

Intake Manifold: Edelbrock Torker II

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5mm

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32-in

Collector Size: 3.00-in

Gaskets

Brand: Fel-Pro

Parts Sources

Engine Components: Summit Racing Equipment

Reciprocating Assembly: Butler Performance, www.butlerperformance.com

Dyno results

Ported 6X Heads

32-degrees total timing and #79

jets, square

RPM TQ HP BSFC 3300 544.0 341.8 0.40 3400 547.6 354.5 0.40 3500 550.5 366.8 0.39 3600 550.0 377.0 0.38 3700 548.5 386.4 0.39 3800 547.4 396.1 0.39 3900 546.4 405.7 0.39 4000 545.8 415.7 0.38 4100 547.0 427.0 0.40 4200 547.3 437.7 0.38 4300 545.9 447.0 0.38 4400 545.0 456.6 0.39 4500 544.0 466.1 0.39 4600 539.1 472.1 0.40 4700 536.8 480.4 0.41 4800 531.7 485.9 0.41 4900 523.0 488.0 0.43 5000 514.8 490.1 0.43 5100 507.3 492.6 0.43 5200 496.2 491.3 0.44 5300 482.5 486.9 0.44

Edelbrock D-port Heads

34 degrees total timing and #79

jets, square

RPM: TQ: HP: BSFC 3300 566.7 356.1 0.38 3400 569.5 368.7 0.38 3500 570.7 380.4 0.38 3600 569.3 390.3 0.38 3700 566.9 399.4 0.38 3800 565.1 408.8 0.39 3900 564.2 418.9 0.39 4000 563.4 429.1 0.39 4100 562.9 439.4 0.39 4200 563.3 450.5 0.40 4300 563.2 461.1 0.37 4400 563.3 471.9 0.36 4500 559.7 479.6 0.37 4600 556.7 487.6 0.37 4700 554.1 495.8 0.38 4800 547.3 500.2 0.38 4900 538.5 502.4 0.40 5000 528.1 502.8 0.41 5100 506.2 491.5 0.44 5200 491.2 486.4 0.45 5300 487.2 491.7 0.45