The last time Project Pure Pontiac (aka The Mule) was on the dyno at RaceKrafters it made approximately 647 horsepower with the 3.6-inch (medium sized) pulley on the Gear Head Designs supercharger. If you recall we had no luck getting the engine to run with the intercooler. The carburetor went very lean and thus, the engine bucked and could not take the load. Bob Wise was running the dyno and quickly aborted the pull.

Since the concept of cooler charge air is valid, we wanted to go back to the dyno and try again with another CX Racing intercooler. Before we get into what HPP found during our latest test session, it would be prudent to apply some theory as to what was happening with the engine.

Carburetor 101

Much to the chagrin of the EFI crowd, in many ways the lowly carburetor is the ultimate air flow meter. When calibrated properly it does a remarkable job of delivering the proper amount of fuel in lock step with the incoming air throughput. As airflow increases so does fuel flow.

When discussing carburetor theory, the term signal is often used. It describes the low-pressure region that is created in the booster that allows fuel to flow from the float bowl and through the delivery circuits. The greater the difference in the atmospheric pressure, or in the case of a blow-through carburetor such as our Quick Fuel unit boost pressure on the float bowl and the low-pressure region in the booster, the stronger the signal. A strong signal allows for more fuel to be delivered but more important, improved atomization. A weak signal usually means less fuel delivered for a given jet and air bleed size, and poor atomization, a term that describes the fuel being broken into small particles but still in a liquid form. A practical example of this is the discharge from a spray bottle or aerosol canit is still in liquid form but very minute particles.

The best example of a poor signal is an engine with too large a carburetor. Contrary to what many believe, if the carburetor throttle plates and venturi are too large, the engine will go lean and not rich. This is due to the area being too great for the airflow into the engine and the resultant poor signal quality. Thus, little fuel is discharged.

What usually happens is the enthusiast does not have a full grasp on what is occurring and keeps increasing the jet size to fuel the engine. They then make the false assumption that the fuel pump is too small since no matter how large a jet is installed, the mixture can never be made rich enough under full power. So a 400 horsepower Pontiac ends up with huge jets and a fuel pump that can support a Pro Stock engine to compensate for too large a carburetor and poor signal strength. This was not the case with The Mule, but a twist on the theory.

When the original intercooler was installed the engine ran poorly and the air/fuel ratio went to 16:1. The key was the leaning of the mixture. That meant the signal in the carburetor went away. We knew exactly what was happening but not why, and the printing presses were waiting. The mystery would need to be solved another day.

In subsequent discussions with Gear Heads, we came to understand that we were actually performing the beta test for the possible integration of an intercooler into the companys Pontiac supercharger kit. To this point, the system was only offered with a chemical intercooler (methanol injection).

When our results were presented, the theory of using a smaller CX Racing intercooler, along with the smallest supercharger pulley (more boost), was suggested. We had refrained from going to the smaller pulley since the author was concerned with the load on the snout of the crankshaft. To reiterate, Craig Wise, who built the engine, did not share that concern. As we had mentioned in the previous installment, The Mule was not broken, and 647 hp at a mild boost level was quite an accomplishment.

But as hot rodders, we wanted to push the envelope. So a smaller intercooler was sent from Gear Heads to RaceKrafters. HPP made travel plans to be there when The Mule would once again be bolted to what was becoming an old friendthe Stuska water brake.

More Numbers

Craig filled the dyno fuel cell with what was left of our 100-octane Rockett Brand unleaded gasoline. It was the same fuel we used when we aborted our testing previously. HPP and RaceKrafters wanted to keep as many aspects of the test constant as possible.

The one thing we could not control was the weather. Whereas the last session had the dyno room ambient temperature at nearly 96 degrees F on our test day the weather was much better. The dyno cell was about twenty degrees cooler at around 74 degrees F.

Our protocol would be to attach the smaller intercooler with the medium size pulley and no methanol injection. Then based upon the results we would make a decision from there.

The Mule made a full pull with this combination but did not sound as clean, and was a little on the choppy side. Its mixture did lean out to an average of 13.483:1 for the entire run. That was about three air/fuel ratios leaner than the best previous pull (647 hp) without any intercooler. This was pointing to a loss of signal, but was much richer than the 16:1 we experienced with the larger intercooler. No jet changes were made to the carburetor.

With this setup, the engine was down substantially from the previous Snow Performance chemical-only intercoolerwe lost about 72 hp. The average boost pressure throughout the run was now 3.02 psi; before it was 4.84 psi.

With confidence that the engine would take the load, Craig now switched to the 3.25-inch pulley, the smallest one (we had not used this one before) and made a pull. The Mule had the small intercooler with the highest boost pulley. This would be the most aggressive combination we could employ while still using an intercooler.

The average boost pressure went to 4.40 psi and the peak horsepower climbed to 59255 ponies shy of the chemical intercooler and lower boost pulley. The average air/fuel ratio was about the same at 13.63:1, showing a flow loss.

Since that was the best we could do with the intercooler, the wrenches came out and the system was restored to its previous best state but this time with the high-boost pulley and Snow Performance methanol injection with the #3 nozzle. The Mule really liked this with the average boost pressure going to 6.648 psi and a peak of 8.62 psi at 5,100 rpm. Our Pontiac with factory casting ported 6X cylinder heads, a smog block with an over bore, and a cast-aluminum intake manifold rewarded us with an astounding 673 hp and 740 lb-ft of torque! The average air/fuel ratio was 10.03:1. And the best part of the whole thing was The Mule sung like an opera star. No muss, no fuss 673 hp from a pure Pontiac with no signs of discontent in any way whatsoever.

Where Did The Signal Go?

With the results now in hand, we can explore where the signal to the carburetor went along with the boost pressure.

To a student of engineering, air is considered a gas and follows some basic laws. The most dominant one being that it does not like to make turns, and the longer the flow path the greater the frictional loss. A simple tape measure solved the mystery of the lost signal and boost.

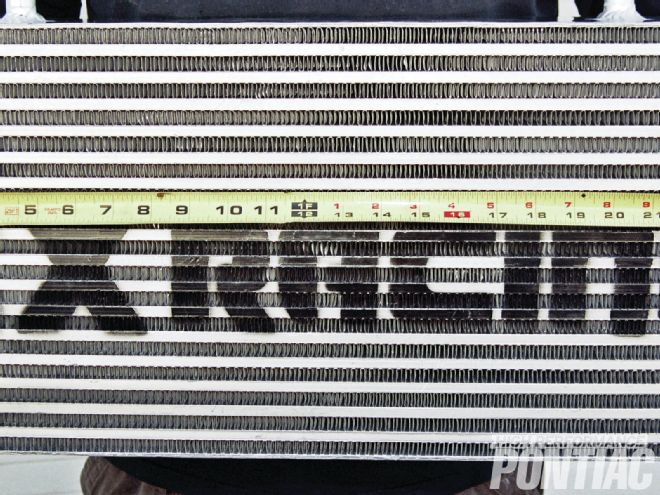

1 The original intercooler measured 24 inches across and was 12 inches high. It was not too large, but the amount of pipe to install it made it an excessive flow loss.

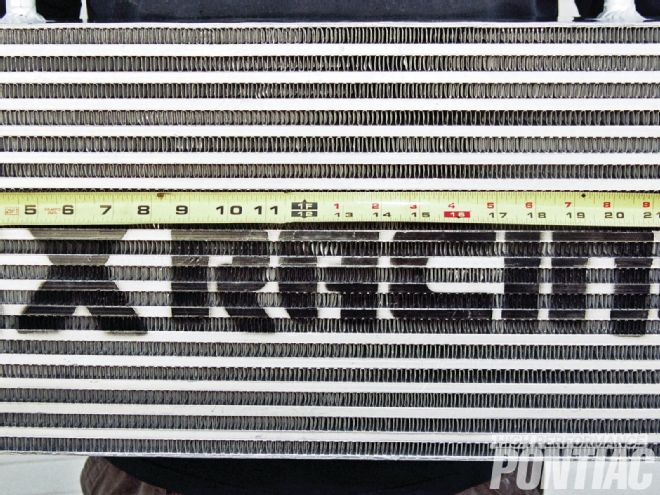

2 The replacement intercooler shared the same height but was 7-inches narrower.

3 The three pulley overall outside diameters offered by Gear Heads are 3.25-inch, 3.6-inch, and 4.00 inch. Where the belt actually rides on the grooves the diameters are 2.95-, 3.25-, and 3.8-inch respectively. For this story and last months, the pulleys are identified by their overall outside diameters. In the last issue, we mistakenly referred to the middle-sized pulley as having an overall diameter of 3.25-inch. We apologize for the confusion.

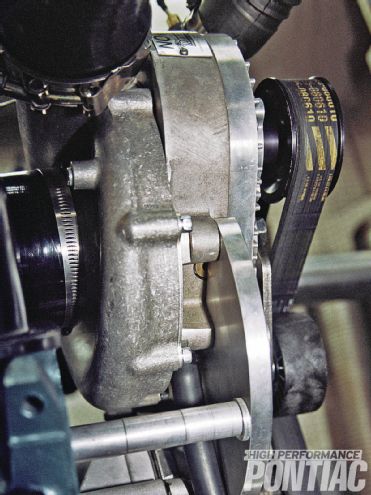

4 Craig confirmed the pulley diameter before each test, since it would have been easy to grab the wrong one.

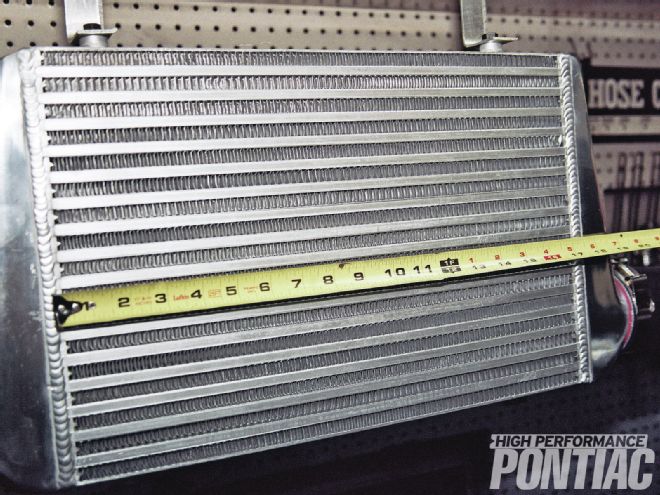

5 The intercooler was hung on the wall and the dyno exhaust fan drew a good deal of air across it.

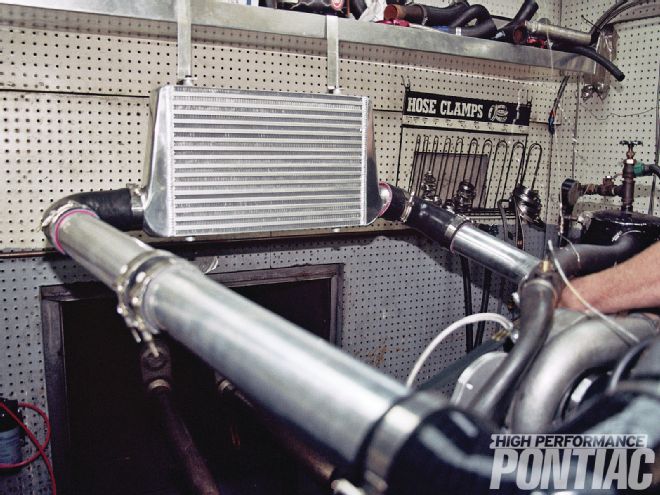

6 As you can clearly see, the pipe length to include the intercooler was very long.

7 The Mule loved the high-boost pulley and Snow Performance methanol injection, and produced 673 horsepower.

8 A larger supercharger would be required for a big cubic-inch Pontiac engine if the intercooler were desired.

With no intercooler, the distance from the discharge of the supercharger to the carburetor inlet was through approximately 25 inches of piping. Once any intercooler was added, the necessary pipe length jumped to an additional 70 inches for a total distance of 95 inches. But there is more. The larger intercooler measured 24 inches long and 12 inches high. This meant that a total around 119 inches of length were added to the airflow path. With the smaller intercooler, which was 17 inches long and 12 inches high, that distance was shortened slightly to around 112 inches. In either case, its an extremely long distance for air to travel before reaching the carburetor. Simply put, the travel distance was way too far, and the boost pressure and airflow dropped off, filling all of the piping. In retrospect, HPP believes there wasnt a manufacturing defect in the first (larger) intercooler the system was just too long to have the carburetor deliver the necessary fuel for our application.

As an aside to this, the chemical intercooler, in this case a Snow Performance Stage 2 Boost Cooler, still did a more efficient job of dropping the intake temperature. With the cooler dyno-room air compared to the last session, and the high-boost pulley, the discharge temperature at the blower was around 153 degrees F. With the intercooler, it only dropped to 90 degrees F in the plenum, but with the methanol injection, the air cooled to 65 degrees F.

It must be recognized that when installed in a Pontiac, the intercooler will be even less effective, since the piping will be absorbing underhood heat and transferring it to the air the engine is breathing. Also, the methanol injection makes for a much cleaner and simpler installation over the piping and issues that would be present with an intercooler. The chemical system does not become heat-soaked as an intercooler would, and should remain just as effective regardless of the underhood temperature. The air the engine will be digesting will be hotter under those conditions, but the drop in temperature should remain constant or nearly so.

To get the intercooler to match the power The Mule made with the methanol injection, a substantially larger blower would be required, and a corresponding gain in crankshaft load and parasitic drain for no net positive result.

Our results are a true bonanza for the Pontiac owner who wants the power a Gear Head Designs supercharger kit delivers. The simpler and easier-to-install chemical intercooler out-performed the air-to-air intercooler for our application. The only question that remains is, what pulley size do you want?

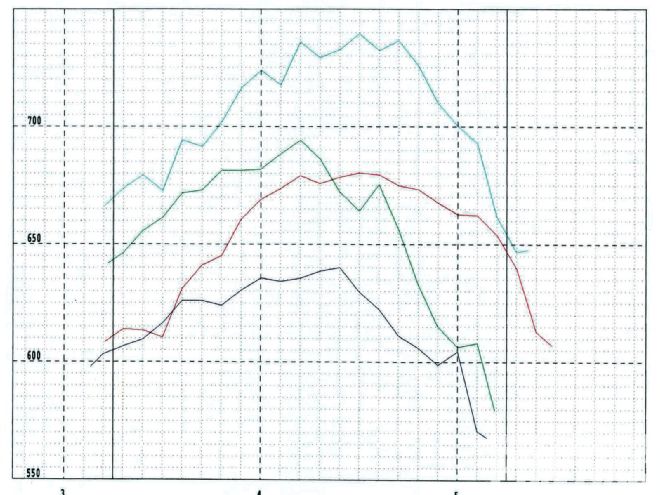

Corrected Torque

Red is without an intercooler, and with methanol injection and the 3.6-inch pulley. Dark blue represents the smaller intercooler with the 3.6-inch pulley. Green is the small intercooler with the 3.25-inch pulley. Aqua is without an intercooler with the 3.25-inch pulley, plus methanol injection.

Red is without an intercooler, and with methanol injection and the 3.6-inch pulley. Dark blue represents the smaller intercooler with the 3.6-inch pulley. Green is the small intercooler with the 3.25-inch pulley. Aqua is without an intercooler with the 3.25-inch pulley, plus methanol injection.

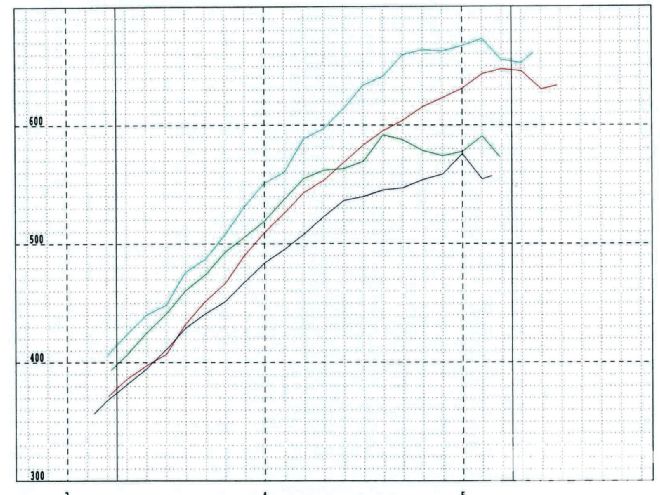

Corrected Horsepower

Red is without an intercooler, and with methanol injection and the 3.6-inch pulley. Dark blue represents the smaller intercooler with the 3.6-inch pulley. Green is the small intercooler with the 3.25-inch pulley. Aqua is without an intercooler with the 3.25-inch pulley, plus methanol injection.

Red is without an intercooler, and with methanol injection and the 3.6-inch pulley. Dark blue represents the smaller intercooler with the 3.6-inch pulley. Green is the small intercooler with the 3.25-inch pulley. Aqua is without an intercooler with the 3.25-inch pulley, plus methanol injection.

Small intercooler, 3.6-inch pulley, no methanol (dark blue on graph) RPM TQ HP PSI A/F 3,300 606.6 381.1 1.88 13.01 3,400 609.5 394.6 1.99 12.90 3,500 616.3 410.7 2.08 12.86 3,600 625.8 429.0 2.18 12.92 3,700 626.0 441.0 2.33 13.06 3,800 623.9 451.4 2.41 13.11 3,900 630.4 468.1 2.56 13.26 4,000 635.6 484.1 2.69 13.32 4,100 634.1 495.0 2.81 13.48 4,200 635.4 508.1 2.85 13.55 4,300 638.5 522.7 2.99 13.74 4,400 640.0 536.1 3.10 13.71 4,500 629.6 539.5 3.29 13.65 4,600 622.4 545.1 3.44 13.64 4,700 611.1 546.9 3.53 13.93 4,800 605.9 553.7 3.71 14.21 4,900 598.6 558.5 3.85 14.26 5,000 604.4 575.4 4.00 14.32 5,100 570.7 554.2 4.29 14.41

Small intercooler, 3.25-inch pulley, no methanol (green on graph) RPM TQ HP PSI A/F 3,300 646.2 406.0 2.90 13.46 3,400 655.5 424.4 3.03 13.00 3,500 661.2 440.6 3.19 12.87 3,600 671.6 460.3 3.39 12.76 3,700 672.9 474.0 3.54 12.91 3,800 681.2 492.9 3.72 13.13 3,900 681.2 505.8 3.96 13.10 4,000 681.8 519.2 4.09 13.14 4,100 688.3 537.3 4.26 13.31 4,200 694.1 555.1 4.47 13.41 4,300 686.1 561.7 4.72 13.49 4,400 672.1 563.1 4.84 13.79 4,500 664.2 569.1 4.98 13.95 4,600 675.3 591.5 5.07 14.24 4,700 656.3 587.3 5.22 14.29 4,800 632.7 578.2 5.32 14.22 4,900 614.9 573.7 5.28 14.38 5,000 606.4 577.3 5.36 14.46 5,100 608.0 590.4 5.36 14.34

No intercooler; 3.25-inch pulley; Snow Performance Stage 2 Boost Cooler#3 methanol nozzle (aqua on graph) RPM TQ HP PSI A/F 3,300 673.6 423.2 4.13 10.22 3,400 679.2 439.7 4.38 10.10 3,500 672.5 448.2 4.63 9.96 3,600 694.3 475.9 4.90 9.88 3,700 691.4 487.1 5.19 9.93 3,800 701.7 507.7 5.48 9.97 3,900 716.2 531.8 5.75 9.93 4,000 723.7 551.2 6.06 9.90 4,100 717.5 560.2 6.36 9.89 4,200 735.7 588.4 6.66 10.00 4,300 729.1 596.9 6.90 10.00 4,400 732.5 613.7 7.21 10.03 4,500 739.4 633.5 7.48 9.98 4,600 732.2 641.3 7.71 9.98 4,700 736.4 659.0 7.97 10.01 4,800 725.7 663.3 8.14 10.08 4,900 709.8 662.2 8.32 10.19 5,000 700.3 666.7 8.52 10.24 5,100 692.8 672.7 8.62 10.25

HPP Engine Buildup Worksheet

Engine Displacement: 467 ci

Bore/Stroke: 4.185 / 4.250-in

Bore/Stroke ratio: 0.98:1

Rod/Stroke ratio: 1.6:1

Bottom End

Block: Stock 75 455

Deck height: 10.205-in

Crank: Butler/Eagle forged

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Bearings: Clevite, plain shell, tri-metal

Pistons: Butler/Ross forged flat-top with valve reliefs

Piston-to-deck height: 0.010-in below

Piston pins: Ross, 0.990-in floating, 0.155-in wall

Method used to retain pins in pistons: Spiro Locks

Rings: Total Seal, moly top, ductile second, 3-piece oil, 116, 116, 316-in

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road Race Series 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2 ccs

Maximum flow at 28 inches of pressure

LiftIntake Flow CFMExhaust Flow CFM 0.1006655 0.200133106 0.300191149 0.400224170 0.500236182 0.600250186

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job

Intake: 45, 60, 75, and 82-deg, 82 is hand-blended into 75-deg.

Exhaust: 45-deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 1132-in

Valve Guides: K-line bronze liner

Valve Seals: Steel/Viton

Rocker Studs: ARP 716-in

Rocker Arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 38x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration At 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe Separation Angle: 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 137-lb/in

Open Pressure: 290-lb/in

Timing Chain: Cloyes double roller

Induction

Carb: Quick Fuel Technology 750-cfm, set up for blow-through supercharger

Intake Manifold: Edelbrock Torker II

Supercharger: . . Gear Head Designs Paxton Novi 1500

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5 mm

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32-in

Collector Size: 3.00-in

Gaskets

Brand: Fel-Pro

Parts Sources

Engine Components:

Summit Racing Equipment www.summitracing.com

Reciprocating Assembly:

Butler Performance www.butlerperformance.com