Readers who follow our annual engine building competition, the AMSOIL Engine Masters Challenge, are likely familiar with the efforts of the late Dan Miller and his incredible early Hemi. Dan was a regular at the event, and his innovative modifications always placed his engines in the thick of competition. Dan did not work in seclusion, favoring instead to involve numerous talented and enthusiastic individuals from across the nation, using their input and expertise to help hone his engine building craft. Dan was well on his way to building a new early Chrysler Hemi for the 2011 EMC competition when the unthinkable occurred. Dan Miller died from a sudden heart attack on the May 9, 2011.

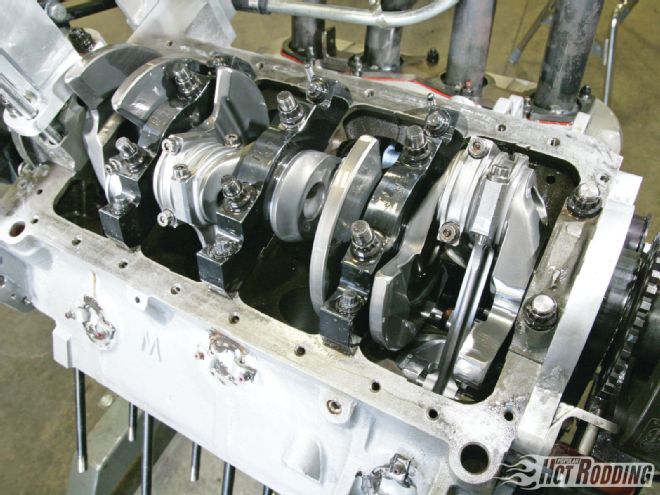

Few engine families have been the subject of as much modification as that seen by the early Chrysler Hemi. This ’56 factory casting is filled with the right stuff to make it competitive some 55 years later, including a Bryant billet crank, Pauter rods, and Hot Heads steel main caps secured by ARP bolts to hold it together.

Few engine families have been the subject of as much modification as that seen by the early Chrysler Hemi. This ’56 factory casting is filled with the right stuff to make it competitive some 55 years later, including a Bryant billet crank, Pauter rods, and Hot Heads steel main caps secured by ARP bolts to hold it together.

News of Dan’s death represented a personal shock to friends, family, and Engine Masters teammates alike. As team member John Beck of Pro Machine (where Dan did all his dyno testing) remembers: “Dan was the driving force behind the whole deal. He got it going and did most of the engineering. He was 90 percent of the effort. I saw him at my shop no less than an hour before he passed; then I heard he had the heart attack.” Dan had already put a tremendous amount of time and effort in the engine, and it seemed as though the project had come to an end, however, as the team members contemplated the events and conferred, it was decided that the engine should be completed as a tribute to their departed friend. Dan’s widow, Elaine Miller, agreed, and the result is the engine featured here.

The Build

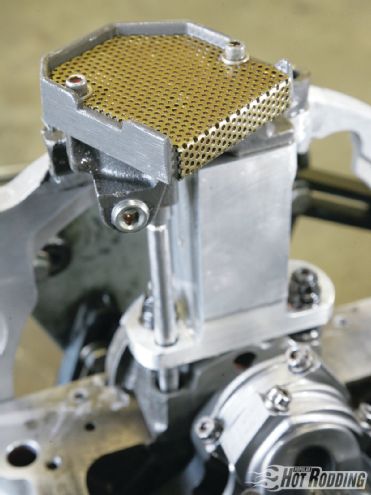

A replacement Melling oil pump circulates the AMSOIL 10-30 synthetic lubricant. The pump is modified with a custom pickup arrangement, and is mounted to an aluminum spacer to drop it into the deep oil pan.

A replacement Melling oil pump circulates the AMSOIL 10-30 synthetic lubricant. The pump is modified with a custom pickup arrangement, and is mounted to an aluminum spacer to drop it into the deep oil pan.

Naturally, without Dan, the central figure of the project was gone, leaving a scattered group of individual team members across seven states. Each had played a role in Dan’s overall vision, but only in their own isolated specialty. Bob Holmes of Wilton, California, took the reins, taking it upon himself to become the project coordinator to see the engine through to completion. Bob would be the glue that would bind the team together, setting deadlines, assigning work goals, and working out the scheduling and logistics of the build.

Nick Smithberg of Smithberg Racing of Fort Calhoun, Nebraska, would take on the responsibility of modeling the airflow and building the unique upper intake and ram tubes. Scott Clark of Omaha, would build the ECU and take the point position in the areas of engine management system development and tuning, with Scott Courtney providing additional expertise in the area of electronics. Beck of Pro Machine in Chico, California, would handle the block machining, final engine assembly, and dyno tuning. Bob Walker and Hot Heads Research of Lowgap, North Carolina, was on board to fund the project and provide the necessary specialty early Hemi components. Gene Adams and Ron Pratt of Northern California would provide their expertise in component selection and consultation.

Although Dan had competed with an early Hemi in previous Engine Masters Challenge competitions, when the group decided to take on the task of completing Dan’s project, there was plenty of work to do. Holmes tells us, “It was a pile of parts and a collection of ideas. Job one was to organize the effort, delegating responsibly and rounding up parts in progress all over the country.” Ground zero of the project was Beck’s shop. Beck set about the task of building the short-block using primarily components that had already been earmarked for the project.

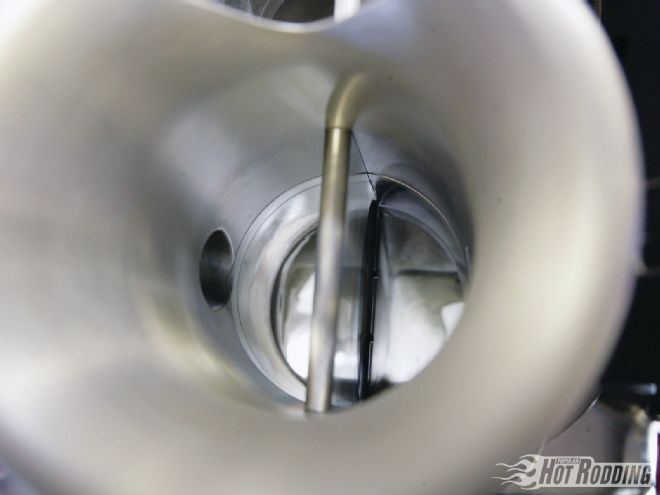

Beck handled machining the factory ’56 Chrysler early Hemi block, installing a 3.825-inch stroke Bryant billet crankshaft, filling the 4.015-inch bores with custom Ross pistons for a displacement of 388 ci. The internals are linked by Pauter rods, and Federal-Mogul bearings were used throughout. Beck relates that the short-block assembly was relatively straightforward: “Assembling the bottom end was academic, really, once the deck height was set and the piston-to-head clearance was worked out.” The high-dome Ross pistons were drilled for gas ports to load a .043/.043/3mm Total Seal ring package, and were targeted at producing massive squeeze. The compression ratio of the completed engine assembly topped 15:1. Beck disclosed that this setup was not without its compromises: “The piston dome proved to be just too high, and it compromised flame travel. A shorter dome and less ratio would have likely resulted in better combustion efficiency and more power.”

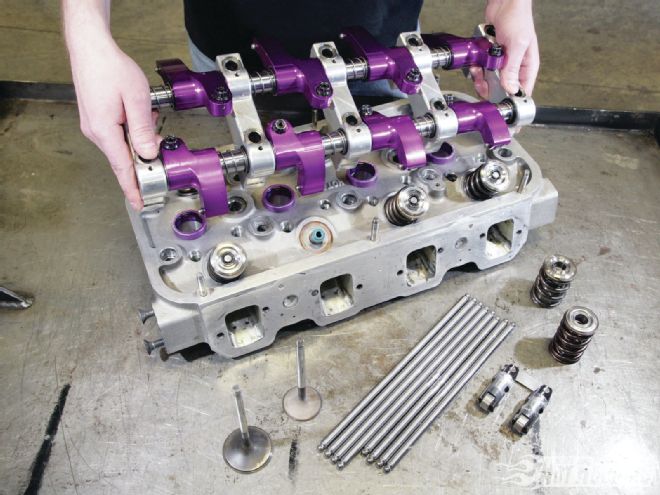

A signature characteristic of the Chrysler Hemi is the rocker arrangement featuring separate shafts for the intake and exhaust valves, suspended on opposite sides of the cylinder head. This opposed valve layout minimizes bore shrouding due to the valve orientation towards the center of the cylinder.

A signature characteristic of the Chrysler Hemi is the rocker arrangement featuring separate shafts for the intake and exhaust valves, suspended on opposite sides of the cylinder head. This opposed valve layout minimizes bore shrouding due to the valve orientation towards the center of the cylinder.

The camshaft choice was on the large side of extreme, with a custom Engle solid-roller profile that measured 280/280 degrees duration, with a whopping .950-inch lift on the intake, and .750-inch on the exhaust. The very high intake valve lift was courtesy of the 1.9:1 ratio of the Rocker Arm Specialists rocker arms. The combination did present some problems, as Beck described: “We found the high lift was really hard on the valvesprings, and maintaining the lash adjustment proved problematic. We developed a routine for readjusting the lash after every few pulls.” There was little doubt that these guys were pushing the limits in regard to valve opening intensity, and as a result the entire valvetrain was being tortured to the bone.

The four-hole Hilborn injection and Hot Heads manifold comprise an induction system that would be considered exotic strictly on the basis of the components used. The internal modifications take the system to another level.

The four-hole Hilborn injection and Hot Heads manifold comprise an induction system that would be considered exotic strictly on the basis of the components used. The internal modifications take the system to another level.

With time being a critical factor in making the 2011 AMSOIL Engine Masters Challenge event, there was little time for ongoing cylinder head development. The team largely carried over the cylinder heads from Dan’s previous competition engine. The Hot Heads castings featured Ferrea 2.200/1.750-inch valves with peak flow in the mid 300-cfm range. Holmes relates, “Several different people worked on the heads over the previous few years, including Gene Adams and fellow Engine Masters competitor Brett Miller. The big focus was on the induction system, ram tubes, and EFI.”

The task of working out the elaborate induction system was put into the capable hands of Smithberg. Smithberg literally shut down his shop and focused entirely on the development of this one-of-a-kind induction. Starting with a Hot Heads manifold mated to a four-hole Hilborn injection unit converted to EFI, the components underwent intensive internal modifications. The result was to effectively create an individual-runner induction. Inside the Hot Heads manifold, the plenum area was epoxy-filled to transform what would normally comprise the plenum into eight runners right up to the injector base. From there, the four-pot Hilborn was bisected vertically along the axis of the throttle shafts, effectively creating eight separate induction paths once the throttles were fully opened. The throttle plates actually nest into the divider wall above and below the throttle plates at wide-open throttle, presenting one streamlined surface to incoming airflow.

Inside the induction tract the manifold and injector are divided to effectively create eight individual runners. A properly designed, sized, and tuned individual runner arrangement takes distinct advantage of wave tuning, often resulting in a substantial gain in torque.

Inside the induction tract the manifold and injector are divided to effectively create eight individual runners. A properly designed, sized, and tuned individual runner arrangement takes distinct advantage of wave tuning, often resulting in a substantial gain in torque.

Topping the Hilborn unit are the air horn stacks, which beyond their airflow capabilities, qualify as works of art. These units were the creation of Smithberg, who explains, “I believed there was room for improvement in the design of the stacks, and decided that an elliptical shape would be optimal. There was also the consideration of injector placement and angle, two design aspects we experimented with. The steep injector angle required a thick stock to CNC-machine the finished pieces from. Luckily, I managed to find a very thick-walled aluminum tubing to have them machined from.” Smithberg tells us the divider wall configuration was critical to making the system function as an individual runner induction, “There was cross talk between the runners that made the tune very uneven in terms of cylinder-to-cylinder distribution. The final arrangement of the divider and injector placement isolated the runners and eliminated that problem.”

Nick Smithberg of Smithberg Racing worked to size the manifold’s runner cross-section and length to maximize the tuning effect of the system.

Nick Smithberg of Smithberg Racing worked to size the manifold’s runner cross-section and length to maximize the tuning effect of the system.

Of course, an elaborate EFI induction system such as the unit developed by Smithberg would need equally elaborate tuning and control capabilities. This is where Scott Clark fits into the puzzle. Clark has earned a reputation as a highly skilled tuner and calibration man, but his ability goes beyond simply keying the laptop. Clark’s skills in electronics and knowledge of engine management led him to build the custom Mega Squirt ECU controlling the timing of the pack ignition and fuel delivery. Trading knowledge for a wide-open checkbook, Clark employed salvaged and OEM components, from GM coil packs and Ford trigger wheel, to the cam synchronization created from a modified Chrysler distributor.

Injector placement and angle were the subject of intensive experimentation, balancing power output, induction stand-off, and air/fuel ratio balance, factors that proved often at odds.

Injector placement and angle were the subject of intensive experimentation, balancing power output, induction stand-off, and air/fuel ratio balance, factors that proved often at odds.

To the Challenge

With so many people involved and a short time frame to work with, it was an achievement for the team to simply make a showing at the AMSOIL Engine Masters Challenge. As Holmes put it: “I’d like to say we had a grand plan, but it was such a scramble to put this together.” The engine’s exotic induction system certainly captivated the interest of all at the event, making the running of this engine a “must see” affair. The Hemi didn’t disappoint, willfully loading the dyno to deliver a peak of 689 hp and 572 lb-ft of torque. The electronics package and tuning action alone was worth the price of admission. In the control room, Clark worked the tune in a virtual Vulcan mind meld with the electronics, as he fixed his attention to the onrush of data coming in via eight display channels carrying data individually from each cylinder. In attendance was Dan’s widow, Elaine, who took a leap of faith in agreeing to see the engine project completed, and was rewarded by a heartfelt kinship to the individuals who made it happen.

The crown jewel of the engine assembly had to be the air horn assemblies designed by Smithberg. The elliptical profile was machined for optimal airflow, and the look is pure horsepower.

The crown jewel of the engine assembly had to be the air horn assemblies designed by Smithberg. The elliptical profile was machined for optimal airflow, and the look is pure horsepower.

388ci Chrysler Gen I Hemi Bore: 4.015 inches Stroke: 3.825 inches Displacement: 388 ci Compression ratio: 15:1 Camshaft: COMP Cams solid roller Camshaft duration: 280 degrees at .050-inch tappet rise Valve lift: .950-/.750-inch Rocker ratio: Rocker Arm Specialists; 1.9:1 ratio Piston rings: Total Seal Piston: Ross Block: ’56 Chrysler Production Hemi Crankshaft: Bryant Rods: Pauter Cylinder head: Hot Heads Intake valve diameter: 2.20 inches Exhaust valve diameter: 1.75 inches Intake manifold Hot Heads EFI: Hilborn Header: Hot Heads Engine Management: Mega Squirt, EMS Pro Damper: Fluidampr Fuel: VP Q16

The (late) Dan Miller, Hot Heads, Gene Adams team was well represented at the 2011 Engine Masters Challenge. That this group was able to accomplish their goal and bring the project to fruition is a fitting tribute to their departed friend.

The (late) Dan Miller, Hot Heads, Gene Adams team was well represented at the 2011 Engine Masters Challenge. That this group was able to accomplish their goal and bring the project to fruition is a fitting tribute to their departed friend.

388ci Chrysler Gen I Hemi

RPM TQ HP 3,500 414.8 276.4 3,700 432.1 304.4 3,900 448.1 332.7 4,100 462.1 360.7 4,300 482.8 395.3 4,500 509.2 436.3 4,700 531.7 475.8 4,900 547.6 510.9 5,100 556.3 540.2 5,300 565.5 570.7 5,500 571.7 598.7 5,700 569.8 618.4 5,900 564 633.6 6,100 556.6 646.5 6,300 547.8 657.1 6,500 540.6 669 6,700 532.4 679.2 6,900 521.4 685.1 7,100 509.5 688.7 7,300 494.6 687.5 7,200 502.9 689.4 7,500 467.9 668.1