Over more years than we care to count, our 460-powered ’73 Ford has served us well, but time and an odometer that has spun all the way around several times have taken their toll. Considering how long we’d been flogging the F-350 and the number of miles racked up with the bed full and an obscene amount of weight hooked to the rear bumper, we’ve got nothing to complain about. However, the time had come to replace the truck or rebuild it—we chose the latter.

Just about ready for the dyno, our 545-inch Ford looks almost stock thanks to the painted Weiand manifold, Ford Racing and Performance Parts SCJ heads, and Edelbrock water pump. We’ll be using FAST EZ-EFI to supply the fuel.

Just about ready for the dyno, our 545-inch Ford looks almost stock thanks to the painted Weiand manifold, Ford Racing and Performance Parts SCJ heads, and Edelbrock water pump. We’ll be using FAST EZ-EFI to supply the fuel.

To turn our tired truck into the Hot Rod Hauler we envisioned, some chassis and cosmetic enhancements were added and an E4OD overdrive automatic from Gearstar was installed—now we’re putting the finishing touches on a freshened 460. Bored .030-inch oversize and stuffed with a ½-inch stroker crank, the result is a bigger big-block—a 545-inch powerplant for our Hot Rod Hauler.

As we’ve done many times in the past, we turned to John Beck and Pro Machine for his engine-building expertise. A Bonneville legend, one of John’s engines propelled the Cummins-Beck-Davidson-Thornsberry/Pro Machine Blown Fuel Roadster to over 300 mph at Bonneville (setting a record of 301.150 mph), but he’s just adept at putting together an engine for a sprint car, drag racer, boat, or a utilitarian truck like ours.

The heart of the Eagle 545 kit is a cast-steel crank with 4.500-inch stroke, said to be good for up to 700 horsepower. Main and rod journal dimensions are stock and standard bearings are included.

The heart of the Eagle 545 kit is a cast-steel crank with 4.500-inch stroke, said to be good for up to 700 horsepower. Main and rod journal dimensions are stock and standard bearings are included.

Some time ago (in the July issue of CCT), we documented the machine work required to build a first-class engine like our big-block Ford. Unfortunately our scheduling conflicts (read editor Manson’s unreasonable demands about turning out a magazine more or less on time every month rather than spend time working in the shop) kept us from getting back to John’s digs until recently.

With the machine work done, John went about stuffing all the parts into our blueprinted block. For the rotating assembly we turned to our one-stop shopping center for performance parts—Summit Racing.

For our needs we chose Mahle forged pistons with 38cc dished heads. Rods are Eagle H-beams with full floating pins and ARP bolts.

For our needs we chose Mahle forged pistons with 38cc dished heads. Rods are Eagle H-beams with full floating pins and ARP bolts.

Crank, Rods, Pistons, Rings

For the parts we needed to build our big Ford’s short-block, we didn’t have to look farther than the Summit Racing catalog for a complete Eagle stroker kit that included a crank, rods, pistons, rings, and bearings.

Eagle offers a wide variety of cast and forged crankshafts for applications ranging from stock replacements to all-out racing. For our purposes, we selected a cast-steel crank with a 4.500-inch stroke. Although not as strong as Eagle’s forged version, the cast-steel crank is very affordable and capable of handling 700 horsepower. As the steel casting is stronger than a typical OEM cast crank (as well as many factory forgings) and our engine won’t see sustained high-rpm use, we decided to go with the more economical route.

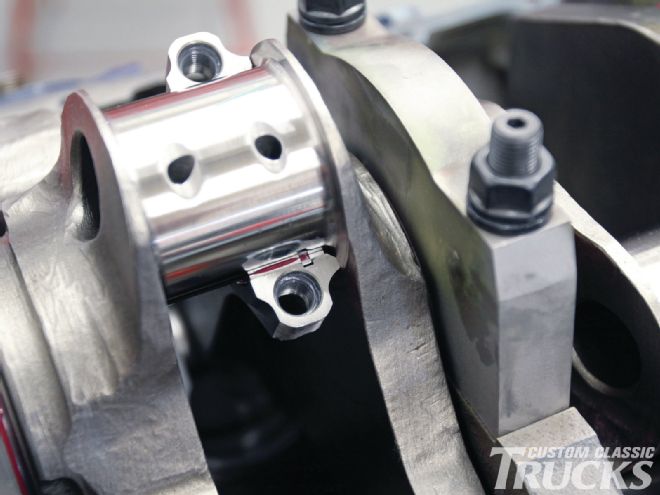

Note the wide chamfer between the edge of the bearing and the side of the connecting rod. It’s necessary to clear the fillet radii on the crankpins.

Note the wide chamfer between the edge of the bearing and the side of the connecting rod. It’s necessary to clear the fillet radii on the crankpins.

Like the stock crank, the Eagle crankshaft has 2.200-inch rod journals and 3.00-inch mains, the journals are highly polished and the oil holes are blended. These cranks are internally balanced and custom balancing to specific bobweights is available.

Included in the Eagle stroker kit are H-beam rods forged from certified 4340-chromoly steel. Manufactured from a two-piece forging (one for the rod, the other for the cap) the result is a stronger part, as the “grain” of the metal can be oriented in the direction of stress (the stress exerted on the cap is perpendicular to the stress on the beam). These rods are stock length at 6.700 inches, weigh approximately 800 grams, and are bushed for full-floating piston pins. Holding on the caps are 7⁄16-inch ARP 12-point bolts.

A large radius (arrow) on the crank pins increases strength, but special narrow bearings are often required.

A large radius (arrow) on the crank pins increases strength, but special narrow bearings are often required.

Due to the bore size and increased stroke, custom pistons from Mahle are required. Forged from aluminum, these premium pistons come with Grafal anti-friction coating on the skirts and are phosphate coated to aid break-in. Lightweight, full floating piston pins are retained with round wire locks and low drag rings are included (1.5mm compression rings and 3.0mm oil rings).

While there is no substitute for checking clearances and individual components, much can be told by how the crankshaft in an assembled short-block rotates. Our 545 turned easily and smooth, indicating there was very little drag.

Camshaft and Valvetrain

We called on our friends at Comp Cams, told them our goals for the truck, and supplied all the pertinent information. Shortly afterward, they responded with a split-duration roller cam. Lift is .601-inch, while duration at .050 lift is 214 degrees on the intake, 224 degrees on the exhaust, and lobe centers are at 110 degrees.

Distributor gear wear can be a problem with steel roller cams so a bronze gear was installed on our MSD distributor.

Distributor gear wear can be a problem with steel roller cams so a bronze gear was installed on our MSD distributor.

The decision to go with hydraulic lifters was based on two considerations. First was the reduced friction between flat tappets and cam lobes. With today’s oils, accelerated wear can be an issue, particularly during break-in—roller tappets eliminate that problem. The second consideration was performance. According to the folks at Comp Cams, in nearly all circumstances, a good roller camshaft design will outperform its flat tappet counterpart. They add that the benefits of roller cams are higher tappet velocity, more lift and more area, along with reduced valvetrain friction (often a 15-plus hp increase), and higher engine rpm with little effect on low-speed drivability and power.

Continuing the friction-fighting theme, we ordered a set of Comp Cams High Energy roller rockers. Featuring a die-cast aluminum body, they have a needle bearing fulcrum and roller tip to decrease friction and lower oil temperatures. To ensure a long service life, the pushrod sockets are fitted with steel inserts.

Ford 460 distributors can be found with two different shaft sizes: .500 and .530-inch. Comp Cams offers bronze gears for both. Composite gears are also available for some engines.

Ford 460 distributors can be found with two different shaft sizes: .500 and .530-inch. Comp Cams offers bronze gears for both. Composite gears are also available for some engines.

Heads

Internal combustion engines are basically air pumps, which means one of the keys to improving performance is to move air in and out more efficiently. To that end, the team at Ford Racing and Performance Parts got together with Jon Kaase and the results of that collaboration can be found in the new aluminum Super Cobra Jet heads.

Lots of research resulted in revised valve angles and locations to reduce cylinder-wall shrouding and improve flow, and the combustion chambers were redesigned. While there were significant changes, these heads use the same valves, valve springs, retainers, and 7⁄16-inch stud-mounted rockers as the earlier Cobra Jet heads, and the same intake and exhaust manifolds fit.

To dress up our new engine we opted for a complete fastener kit from Totally Stainless. A variety of styles are available; we chose socket heads.

To dress up our new engine we opted for a complete fastener kit from Totally Stainless. A variety of styles are available; we chose socket heads.

We could have spent hours porting our stock cast-iron heads and not come close to the power potential of the new SCJ heads. Add to that our stock heads needed all the guides and valves replaced, had to be surfaced, and would require machine work to install studs and guide plates, the SCJ heads were a logical choice.

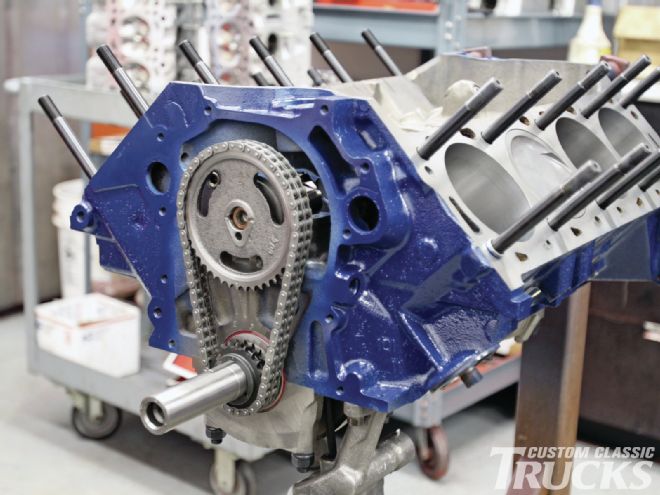

Comp Cams provided the timing chain and sprockets. The crank sprocket has multiple keyway slots to advance or retard cam timing.

Comp Cams provided the timing chain and sprockets. The crank sprocket has multiple keyway slots to advance or retard cam timing.

Induction and Ignition

Topping off our stroker motor is a Weiand intake manifold and a FAST EFI fuel-injection system. An MSD distributor will provide spark. In our next installment we’ll detail the operation of the fuel injection, dial in the ignition’s advance curve, and have a full report on the dyno test and tune session. CCT

Super Cobra Jet Aluminum Cylinder Heads (heads are sold individually)

Ford Racing part number 397-M-6049-SCJ

Fits 429/460ci engines (except BOSS 429)

Valve size: 2.200-inch intake/1.760-inch exhaust

Intake ports: 290cc

Exhaust ports: 148cc

Combustion chambers: 72cc

With the pan full of oil, John primed the system by spinning the oil pump with an air drill.

With the pan full of oil, John primed the system by spinning the oil pump with an air drill.