Our everyday driver Flathead is a little grungy on the outside, but the oil stays nice and clean, thanks to a Speedway Motors beehive filter with a NAPA 1006 element, fresh oil every 2,000, and a magnet epoxied to the drain plug.

Our everyday driver Flathead is a little grungy on the outside, but the oil stays nice and clean, thanks to a Speedway Motors beehive filter with a NAPA 1006 element, fresh oil every 2,000, and a magnet epoxied to the drain plug.

Of all the engines that have powered hot rods over the years the Flathead Ford is in a class by itself. Certainly not because it’s the most powerful, or the most reliable, they can’t even be described as cheap to build. I can hear Brennan saying, “Yeah, double the horsepower and normally aspirated and you’ve got 200 ponies if you’re lucky, why bother?” As much as I hate to agree with Brennan on any subject, he makes a valid point. The most basic crate engine currently available will make more horsepower, last longer, and cost less overall than a Flathead V-8. So why are so many hot rodders, young and old, intrigued by an engine that went out of production nearly 60 years ago? Certainly in this age of advanced automotive technology there’s no logical basis for building a Flathead—but when did hot rodding and logic have much in common? The fact is the Flathead Ford is a link to the past, a connection to our hot rodding roots—in a word they are traditional.

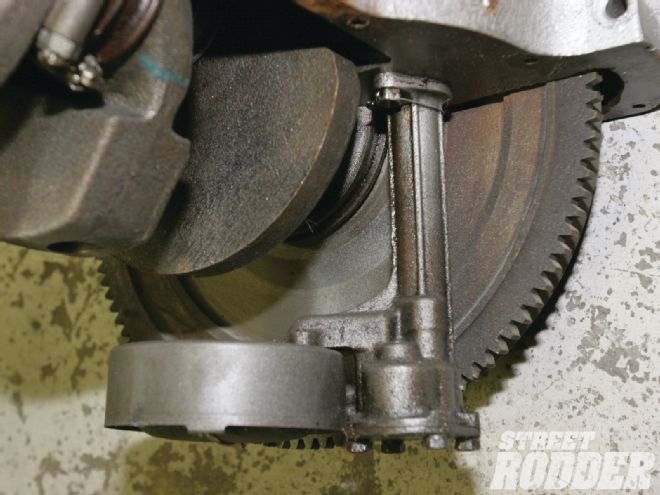

Shown here is an early long-body oil pump; there’s really no good reason to use one. Note the pickup bolts directly to the pump.

Shown here is an early long-body oil pump; there’s really no good reason to use one. Note the pickup bolts directly to the pump.

Although many of the same time-honored techniques that have always been used to hop-up Flatheads are still valid today, there are those who continue to look for new ways to make these old engines better. One of the common contemporary modifications is adding an oil filter.

This is a ’49-53-style short-body pump that is available from Speedway Motors. The oil pressure bypass is under the hex cover.

This is a ’49-53-style short-body pump that is available from Speedway Motors. The oil pressure bypass is under the hex cover.

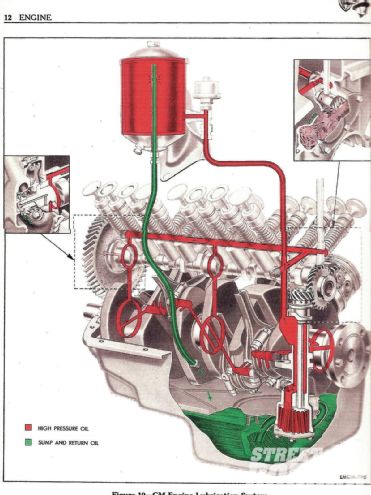

Stock Oiling System

The Flathead V-8 oiling system was basically the same from 1932-53. Oil is delivered by a gear-style pump driven off the cam (which runs at half crankshaft speed). During its production run the design of the Flathead’s oil pump was changed several times. The early long-body pumps were rated at 30 psi at 30 mph (there was also a second revised long-body pump), then in 1948 the short-body pump was introduced, which, like all its predecessors, had straight-cut gears and produced around 60 psi.

From late 1949-53 a short-body pump with helical gears was used. Another change made in 1949 was the relocation of the pressure relief valve. From 1932-48 the pressure relief valve was in the valley at the front of the block while the ’49-53 pumps have the pressure relief built into the pump. Today the most commonly used pumps are the late-style standard pump and the high-volume version available from Melling and others.

The Melling high-volume pump is recognizable by the extended bottom cover. These pumps are also available from Speedway Motors.

The Melling high-volume pump is recognizable by the extended bottom cover. These pumps are also available from Speedway Motors.

After the oil leaves the Flathead’s pump it’s delivered to a cavity with two passages, one leads to the rear main bearing, which also supplies the lubrication through the crankshaft to the rearmost rod bearings (numbers 4 and 8), and the other passage leads to an outlet on the back of the block for the oil pressure sender as well as the distribution tube that runs the length of the block and supplies the cam bearings, the front and center main bearings, which again supply the rod bearings through passages in the crankshaft.

While Flatheads did not have a factory oil filter until one became optional equipment in 1940, they did have another unique method of trapping some contaminants—sludge traps in the crankshaft. As the ’shaft spun centrifugal force tossed all kinds of “stuff” into the hollow crank pins where it collected (unfortunately all that “stuff” had already been pumped through the engine). The crankpins have holes in each end that are sealed with soft plugs and it is an absolutely critical step in rebuilding any Flathead that these plugs are removed and the passages and sludge traps are thoroughly cleaned.

This oil pump pickup (PN 91016259) from Speedway Motors is used to convert ’49-53 pumps for use in earlier Flatheads.

This oil pump pickup (PN 91016259) from Speedway Motors is used to convert ’49-53 pumps for use in earlier Flatheads.

All things considered, Flathead Fords had a pretty good oiling system. With a late-style pump, proper clearances, and the correct oil, adequate lubrication is not an issue for street-driven engines, however a filter of some sort should be included. Here are three methods of doing that:

Bypass Filters

Flatheads have a tube running the length of the block to distribute oil. Pre-’49 engines have a pressure bypass under the hex cap at the front of the valley. When using a late oil pump it’s common to shim the spring under the cap and rely on the relief valve in the pump.

Flatheads have a tube running the length of the block to distribute oil. Pre-’49 engines have a pressure bypass under the hex cap at the front of the valley. When using a late oil pump it’s common to shim the spring under the cap and rely on the relief valve in the pump.

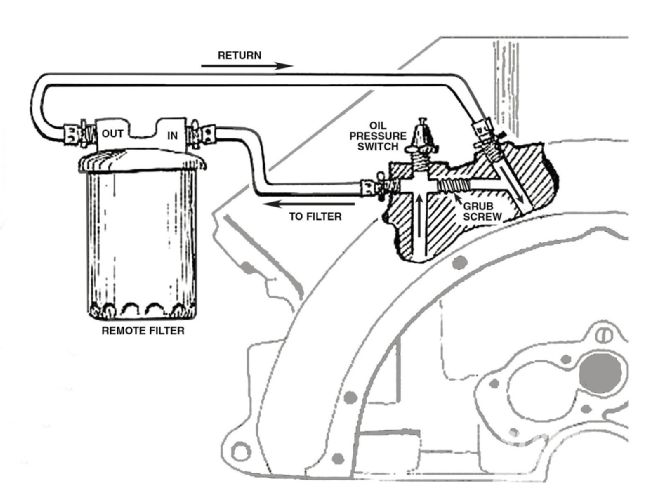

When Ford did introduce an oil filter it was the bypass style, which meant only a portion of the oil was filtered. Oil was delivered to the filter from a boss at the back of the block where the oil pressure gauge sender was located. From the filter oil was returned to the pan. A simple arrangement, it’s always been said that 10 percent of the engine’s oil passes through this style filter, which Joe Abbin’s recent testing confirmed (see his sidebar on page 83 for more information).

Partial Filtration

A popular oil filter conversion is the partial flow style. Basically the oil is rerouted at the back of the block. On the pad where the oil pressure sender is found there are two holes with 1/4-inch pipe threads (one is horizontal and normally plugged, the other is vertical and is for the oil pressure sender). To add a filter the vertical passage from the pump to the oil pressure sender is drilled to 9/16-inch for increased flow and both outlets are drilled and tapped for a 3/8-inch NPT fittings. Oil will be taken out of the engine at this point and routed to a remote spin-on filter bracket (do not use a Ford canister or beehive filter with this conversion).

To return oil to the engine a hole is drilled into the block to intersect the oil galley. Some blocks have a raised, round protrusion from the casting core that marks the spot. In others a wooden dowel slipped into the horizontal passage can be used to determine the depth of the passage and the spot to drill.

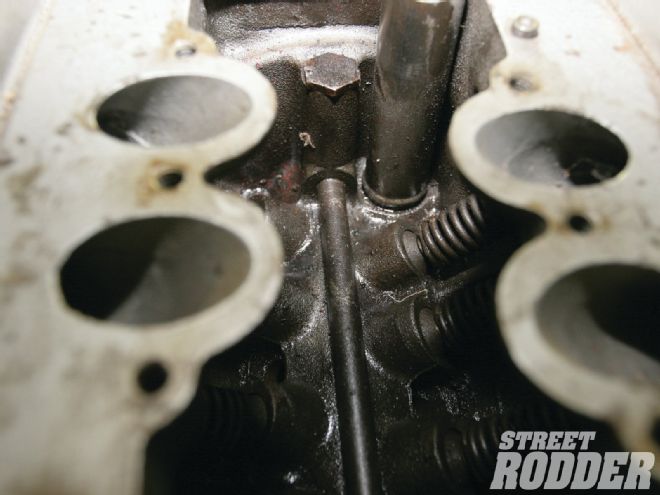

This is the oil pressure sender boss at the back of the block—one hole is used for the sender, the other can be used for a bypass filter. Note the raised round spot? That’s where the block is drilled for a partial flow conversion.

This is the oil pressure sender boss at the back of the block—one hole is used for the sender, the other can be used for a bypass filter. Note the raised round spot? That’s where the block is drilled for a partial flow conversion.

The final step is to block the connection between the two internal oil passages in the block. Just past the vertical passage from the pump, the horizontal passageway leading to the oil distribution tube is plugged by drilling a tapping for a 7/16-inch set screw. Oil will now leave the block, pass through the filter, and return to the distribution tube. However, the rear main and rods, numbers 4 and 8, will still receive unfiltered oil directly from the pump.

It should go without saying that these modifications should be done with the engine disassembled to allow for through removal of all the debris from drilling and tapping.

Full Flow Filters

Adding a partial flow filter requires plugging the internal passageway between the sender boss and the oil distribution tube. A new hole must also be drilled in the block to return oil from the filter to the distribution tube.

Adding a partial flow filter requires plugging the internal passageway between the sender boss and the oil distribution tube. A new hole must also be drilled in the block to return oil from the filter to the distribution tube.

A system to filter 100 percent of the oil flowing through a Flathead is available from Phil Goller. Originally developed by Mark Kirby (formerly from Motor City Flatheads, now Motor City Speed Equipment), a collaboration of the two Flathead gurus has resulted in the complete filter kit that is available from Goller’s Hot Rods.

This system uses a modified pump with a line that exits the side of the pan, delivers the oil to a remote filter, after which it returns to the engine through a fitting in the back of the block. Oil is no longer delivered directly from the pump and back rods. Filtered oil is now fed “backward” to the rear main down through the passage that runs from the pump to the oil distribution tube.

Installing the full-flow system couldn’t be easier. Other than the installation of the pump, the only required modifications to the engine are a bulkhead fitting in the pan and the installation of the 1/4-inch pipe return fitting in the oil pressure sender boss. Which is Best?

Goller’s Hot Rods offers a full-flow filter system for Flatheads. Oil is taken from a new bottom plate on the modified pump (the internal passage is plugged) and delivered directly to a remote filter. The filter mount, hose, and fittings are included in the kit.

Goller’s Hot Rods offers a full-flow filter system for Flatheads. Oil is taken from a new bottom plate on the modified pump (the internal passage is plugged) and delivered directly to a remote filter. The filter mount, hose, and fittings are included in the kit.

There are pros and cons to all the choices we’ve talked about. The bypass style filters the least amount of oil but is the cheapest and easiest to install, the full-flow version filters all the oil all the time, is easy to install, but is the most expensive, retailing for around $350, and the partial flow is in the middle; it filters most of the oil, is the most labor intensive to install, but the parts are cheap.

Which you use is up to you, however we suggest using some sort of filter, changing the oil regularly, and your Flathead will lead a long, healthy life.

Joe Abbin is a mechanical engineer with over 50 years of experience in analyzing, testing, and racing high-performance vehicles of all kinds. His fascination with Ford Flatheads led him to found Roadrunner Engineering and do a monumental amount of experimentation with these engines, all of which he has documented with scientific accuracy.

From the filter oil is returned to the back of the block where it is fed to the distribution tube and down past the pump shaft to the rear main and back rod bearings.

From the filter oil is returned to the back of the block where it is fed to the distribution tube and down past the pump shaft to the rear main and back rod bearings.

We asked Joe to comment on Flathead oil filters.

Thoughts on Flathead Ford Oil Filtration

By Joe Abbin

Every engine benefits from clean oil! A major requirement to provide clean oil is an oil filter. Ford was slow to provide a real oil filter for the Flathead V-8. One did not become available until 1936, when an early design oil filter was offered as a dealer-installed accessory. It was recommended for service in dusty areas. The most commonly seen Flathead oil filter with a replaceable element first became available as an accessory in 1940 and later as standard equipment in 1946. These units were commonly retrofitted on earlier engines for longer engine life.

The stock filter does not filter all the oil, all the time. Most of the oil pump output goes to the engine without filtering and the remainder goes to the oil filter in a parallel flow arrangement. While 100 percent of the oil is not filtered in one pass, the stock filter is effective nevertheless, filtering all of the oil in about five minutes at highway speeds. Various options for converting to full-flow or other systems, which filter more of the oil more of the time, in my view is not generally worth the effort.

Flatheads have a simple but effective lubrication system; including a filter makes it better.

Flatheads have a simple but effective lubrication system; including a filter makes it better.

How much oil does the Ford Flathead oil pump circulate and how much gets filtered?

The stock Flathead oil pump is a positive displacement gear type, capable of circulating about 15 quarts per minute under ideal conditions when the engine is spinning at 2,000 rpm (the high-volume version pumps approximately 20 percent more). A recent test at Roadrunner Engineering demonstrated that a stock ’46-53 oil filter with restrictor flows about a quart and a half of oil per minute through a clean filter under meaningful conditions of oil pressure (55 psi), temperature (180 degrees F), and viscosity (15W-40). This means that about 10 percent of the oil pumped by the stock pump goes through the filter under these conditions and the rest goes unfiltered to the engine. Therefore, under these same conditions, I estimate that all the oil in a 5- or 6-quart system is filtered in less than five minutes at highway speeds. Not bad and certainly worthwhile!

Additional notes/ cautions

When using the stock oil filter system, it is important to retain the oil restrictor at the inlet to the filter canister. This is a brass fitting with about a 0.060-inch-diameter hole to prevent too much flow through the filter, particularly if the filter element is not installed (ouch!). The Eaton/Weatherhead catalog still shows a similar part available under catalog number 1215. The ’49-53 engines incorporated the restrictor into a tee fitting (8CM-6073 or 1BA-6073) that also mounted the oil pressure sending.

With any type of full-flow conversion, a filter cartridge designed for full flow or a bypass loop must be installed for adequate oiling. No oil flows if the filter inlet/outlet lines are simply plugged. Also, a stock parallel flow-type filter system or beehive type that uses a stock-type filter cartridge will not flow enough oil for a full-flow conversion and will result in almost instant engine destruction.

For additional Flathead Ford building tips get a copy of Joe’s latest book, 335 HP Flathead Ford V-8 Performance Handbook available on the Roadrunner website.