There is no denying that crate engines have changed the racing landscape-possibly forever. Maybe it was just the tip of the economic iceberg, but we've noticed tracks and engine builders offering more options than ever before for racers looking to pinch every last penny.

Take, for example, the recent development of spec racing engines. Spec motors that require a certain combination of parts have been around for decades, but until recently most were usually limited to a specific cylinder head or intake mandated by the track promoter. But now we're seeing engine builders putting together some pretty ingenious engine packages in order to stay competitive with the crate onslaught.

This newest generation of spec motors are capable of providing big horsepower on a budget. And unlike most crates that are built from mainly stock OEM components and must be treated with kid gloves, these specs are built from the ground up with racing in mind. They may cost more up front than a crate motor, but the idea is that they should be able to provide good, raceable power and do it for a season or more without needing a rebuild. It's just one way to help save the racer money in the long term to help keep the sport healthy.

"I've been on both sides of this deal," says Comp Cams' Scooter Brothers, who has consulted on several different new spec motor projects and understands the difficulty of helping racers save some money in an environment where-let's face it-money can often buy speed. "I've been a racer, a promoter, an engine builder, and now I'm a parts supplier. One thing I've learned is that a racer will compete at 100 percent of his ability and spend about 110 percent of what he can afford to spend.

"I'm not sure we can ever change that or make racers believe they can perform better when spending less. However, if they can be shown how to spend the right amount in the right places, it might free them up to last longer, race more, or win more, and be more successful. As long as they can feel competitive and feel that there is a way to exploit some tiny loophole to make themselves better than the next guy they will find a reason to compete and be happy. It makes very little difference how fast they go or how much power they make as long as they are competitive."

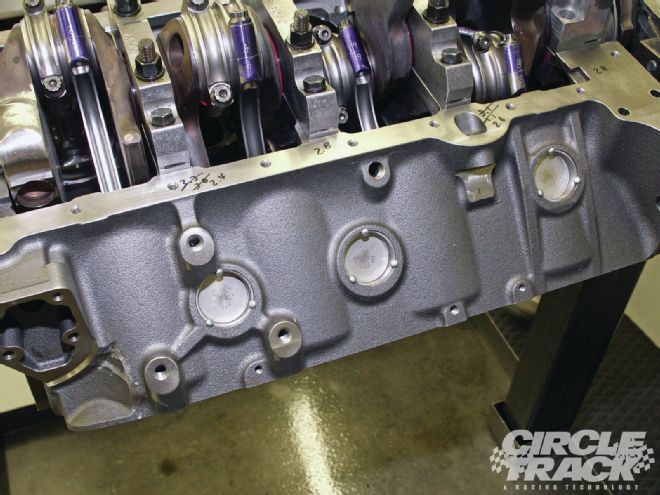

Dorton says that he chose his components very carefully for his 387ci small-block. The Dart SHP block is incredibly strong and durable yet still cheaper than a Chevy Bow Tie block. Notice the expanded water jackets around the cylinder bores for exceptionally consistent cooling. The crank is a tough Callies forged unit with 3.625 inches of stroke.

Dorton says that he chose his components very carefully for his 387ci small-block. The Dart SHP block is incredibly strong and durable yet still cheaper than a Chevy Bow Tie block. Notice the expanded water jackets around the cylinder bores for exceptionally consistent cooling. The crank is a tough Callies forged unit with 3.625 inches of stroke.

But what is also interesting is that a few forward-thinking engine builders have taken the reins from the promoters and instead of simply building to a rulebook have produced their own spec engine designs and made them available for any track promoter or series that would like to give them a shot.

To give you a better idea of just what's available out there, we've taken three very different examples from three different engine builders. Keith Dorton of Automotive Specialists is a longtime stock car racer who can trace his roots all the way back to Holman and Moody and has built winning race engines for the late, great Dale Earnhardt. His spec engine design most closely resembles the classic stock car formula with a few key differences that make it quite interesting. Meanwhile, Mast Motorsports has a more road-oriented heritage and has developed a range of spec motors utilizing tuned port fuel injection. And finally, Sprint Car racing icon Ron Shaver has developed a spec motor for the Sprint guys that keeps the traditional elements that makes the engines so unique while mixing in some key low-cost components. Shaver has also taken a unique step when it comes to dealing with the age-old issue of cheating.

A hydraulic roller cam is a consistent feature with almost all the new spec motors we are seeing. Rollers eliminate the need to the special lubricants that flat tappet cams require and make easy power. Hydraulic lifters help absorb some of the shock that can damage valvetrain components and, in addition to being nearly maintenance free, help the entire valvetrain run smoother longer.

A hydraulic roller cam is a consistent feature with almost all the new spec motors we are seeing. Rollers eliminate the need to the special lubricants that flat tappet cams require and make easy power. Hydraulic lifters help absorb some of the shock that can damage valvetrain components and, in addition to being nearly maintenance free, help the entire valvetrain run smoother longer.

There's something here for just about everyone, and this is certainly only the first wave of the new generation of spec racing engines. It's going to be exciting to watch how this all will develop.

Traditional but with a Twist "I've been pretty up front all along that I don't think crate engines are a good idea for racing long-term," Dorton says of developing a spec motor that's an alternative to crates. "But it's obvious that you had to either get on board in some manner or get left behind-and I had no doubt that we could do something better than what's out there."

Dorton's answer is a spec motor that remains easily recognizable as a small-block stock car racing engine. But because he's not restrained by the typical rulebook, he can make some changes that improves durability while keeping costs down.

"The problem is we had painted ourselves into a bit of a box," he explains. "Even though everyone's rulebook is a little bit different, they all follow the same principles. And the only way to continue making more power is to increase the rpm. But anytime you push the rpm levels, your expenses go up and rebuild intervals go down. So with the new spec motor instead of chasing rpm we simply added displacement."

Instead of the usual 358 cubic inches, Dorton chose a Dart SHP Chevrolet-style block than is lightweight, relatively inexpensive compared to a Bow Tie block and can easily handle a 4.125-inch bore with 3.625 inches of stroke for 387 total cubic inches. Dorton also outfitted the drivetrain with a hydraulic roller cam and lifters. The hydraulic system combined with a cam lobe designed to make a broad torque curve while being gentle on the valves, puts the redline at a respectable 7,800 rpm. Dorton says that while he wouldn't recommend it for extended periods, one of the test engines has been run as high as 8,200 rpm safely.

Dorton points out that a lot of work went into the valvetrain to produce good power at just the right rpm levels. "A motor with lots of consistent torque is not only easier to drive, but they also produce better racing. Plus, these motors produce enough rpm that they really sound like a race motor should," he adds.

Horsepower can be adjusted between 600 to 650, to suit the needs of the cars and the desires of the series director, with just a carb change. Currently, Dorton expects this package to sell for approximately $26,000, which includes everything from the ignition and wiring harness, to the carburetor, and even the power steering pump. "The crate motors are typically only a long-block," he says, "so when you add in all that's required to get one running, the costs get a lot closer than you might think. Plus, you still don't get anywhere near the horsepower that this spec motor is capable of. Here, we're talking the equivalent horsepower of a NASCAR Nationwide engine at 1/3 the price. And our test motors have shown that we can race these between four and five thousand laps between rebuilds, which should get most racers through an entire season no problem."

A look at the rod and piston combination reveals another clue to just how much thought Dorton put into his engine package. A 6-inch rod helps maintain a good rod/stroke ratio with a 3.625-inch stroke crank. The Mahle pistons are custom forgings with coatings throughout for good durability and use a 1.5 mm, 2 mm, 3 mm ring package. But notice the symmetrical valve pockets. Dorton says having the pistons made this way allows him to cut down on cost by reducing the piston inventory needed.

A look at the rod and piston combination reveals another clue to just how much thought Dorton put into his engine package. A 6-inch rod helps maintain a good rod/stroke ratio with a 3.625-inch stroke crank. The Mahle pistons are custom forgings with coatings throughout for good durability and use a 1.5 mm, 2 mm, 3 mm ring package. But notice the symmetrical valve pockets. Dorton says having the pistons made this way allows him to cut down on cost by reducing the piston inventory needed.

Join the LS Revolution It has been quite a few years since a first generation small-block that is the staple of stock car racing has appeared in any new GM vehicle, but that doesn't mean that the cam-in-block small-block is dead. It's just grown up a bit.

The GM LS series of engines is carrying on the pushrod engine tradition and has been around long enough that some of the exotic feel of the motor has worn off. In fact, many feel that time has come to see the LS engine widely accepted in stock car racing.

Mast Motorsports has been working with the LS engine package for years and has experience designing a lot of their own parts for the engine-and the engine builder believes it can bring an effective spec motor to the racing market based on LS technology. Of course, NASCAR has been doing that for years with its spec motor that is legal for a few different touring series, including the Camping World Truck Series, but the Mast version includes a lot more race-ready components. We used one of Mast Motorsports' own creations to power our own Project G.R.E.E.N. Late Model, Circle Track's science experiment to see how stock car racing might look running alternative fuels.

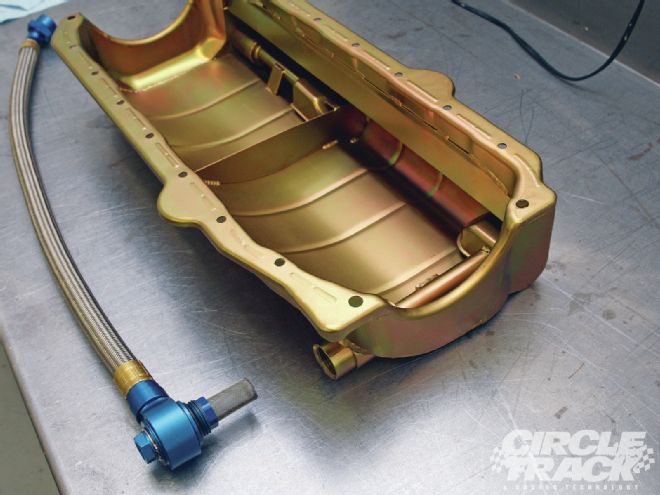

Milodon came up with a custom dry sump oil pan design for the project to meet Dorton’s specifications. Screens integrated into all the pickup tubes help protect the engine, and the pan dimension have been massaged so that it will fit in just about any chassis.

Milodon came up with a custom dry sump oil pan design for the project to meet Dorton’s specifications. Screens integrated into all the pickup tubes help protect the engine, and the pan dimension have been massaged so that it will fit in just about any chassis.

"Basically, what we're offering is anything from about 500 horsepower to 700 horsepower and above," explains engine builder Horace Mast. "We we do different from anybody else is we feature electronic fuel injection and we like to use our own cylinder heads to help control the power curve. We have about 11 different cylinder heads that we can choose from."

One of the reasons that fuel injection technology has been slow to catch on in circle track racing is because of fears that it can be a new avenue for cheaters to gain an unfair advantage. The electronic computers can potentially be hacked for a number of nefarious purposes. Depending on your preference, it can be possible to do anything from adjusting the fuel curves to make more power to actually installing traction control. But after extensive research and development, Mast believes he has a solution for all that.

"We have developed our own ECM (electronic control module) that's very secure and well protected," he says. "It's not like a GM or some other control that wasn't designed explicitly for racing and doesn't require the same safeguards to keep someone from cracking into it.

"Our electronic control is heavily safeguarded and single-password protected, which means that you would have to know the password specifically for that serial number and that ECM for it to work. The other thing we've developed with our ECM is we can control which parameters the team or racing series has the ability to change. So we can control specifically what is allowed to be adjusted and lock out everything else if the racing series wants."

Mast says that the ECM actually protects his spec engines from cheating more than the traditional carburetor as well. He explains the engine is tuned so that if a team tries to make external changes to the engine to the electronic ignition, it will almost always hurt power instead of helping it.

Mast's spec design is also unique because it utilizes a drive-by-wire throttle instead of a direct linkage with the intake manifold. This adds in an extra level of control for the engine builder that Mast says he takes advantage of to make the engine more driveable.

"Our main goal with these spec engines is to provide the most energy possible to the rear wheels," he says. "And that's not necessarily accomplished by making the biggest peak horsepower number that a lot of other guys like to brag about. We concentrate on the torque curve and also the throttle response to make the engine more raceable. The throttle system helps us because we can use it as a tuning tool to improve how quickly any change the driver makes with his right foot until he feels it in at the rear wheels. The car becomes more responsive to his inputs so he becomes more comfortable racing it."

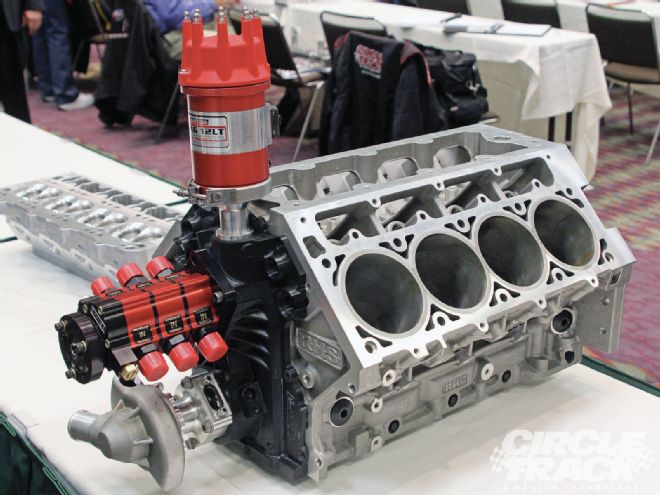

The A4MP Sprint motor isn’t currently legal with the RHS LS race block that you see here, but this photo does help illustrate how the modern design can be adapted to work with the front mounted components that help make a Sprint Car racing motor unique.

The A4MP Sprint motor isn’t currently legal with the RHS LS race block that you see here, but this photo does help illustrate how the modern design can be adapted to work with the front mounted components that help make a Sprint Car racing motor unique.

When making the switch from a traditional carbureted race engine to a fully electronic spec engine, Mast says the switchover isn't as difficult as you might imagine. The LS block uses the same bellhousing pattern, so engine mounts will be the only change you have to make to the chassis-and that's not even necessary if you're using mounting plates. You will, however, have to add a return fuel line, a higher pressure fuel pump capable of at least 60 psi, and the rest is wiring. The ECM is fully self contained, so wiring it up isn't difficult, and the rest is the same with any carbureted car.

The Next Generation Sprint Ron Shaver was the lead development engine builder for a new spec engine design is purpose-built for Sprint Car racing. Like Mast Motorsports, he starts with an LS block, but the end result is quite unlike any LS engine we've ever seen.

Dubbed the A4MP engine (for Alternative 410 Motor Program), this spec motor isn't intended to race in a class all its own. "There's already enough classes out there for Sprint Car racing," says Donny Schatz, four-time World of Outlaws Champion, who worked closely with Shaver on the motor's development. "The last thing we need to do is create another class that's going to split the fields even further. We already have the 305s, the 360s and the 410 racing classes. This A4MP motor is designed to be able to race alongside the 410's and give racers an option that's a lot more affordable. Should it put out into its own class all by itself, our goals have failed. But if we can use this motor package to get more people to the track racing each other then the sport as a whole will be healthier."

The basis for the A4MP motor is an LS block and cylinder heads, but to keep it looking and feeling like a real Sprint Car motor, the design retains the iconic Sprint mechanical fuel injection and oil pump hung off the front of the engine. It does, however, ditch the magneto ignition for a more standard unit that provides a full 12 amps all the way down to idle.

Schatz says that the A4MP motor can be built by any engine builder and will sell for somewhere around $20,000 complete. Comparing that to a full-blown 410 motor at anywhere between $40,000 to $55,000 makes it quite a steal. And like all the other spec motors we've talked about, the A4MP can go quite a bit longer between rebuilds. Schatz says this design should be able to race 20 to 30 full events before requiring a rebuild. On the other end of the spectrum is the current state-of-the-art World of Outlaw Sprint Car motor that Schatz says has to go back to the engine builder for a rebuild after just eight races.

Sprint Car racing icons Donny Schatz and Ron Shaver played a large role in the development of the A4MP motor and both say that on small to medium sized tracks the spec motor can be very competitive with fully built traditional 410 racing engines.

Sprint Car racing icons Donny Schatz and Ron Shaver played a large role in the development of the A4MP motor and both say that on small to medium sized tracks the spec motor can be very competitive with fully built traditional 410 racing engines.

But even though there is quite a bit of cost difference, the A4MP can be competitive against the fully built 410s. "The torque curve is just tremendous," Schatz says. "The rpm is limited to about 8,300 because of the hydraulic lifters, but on the smaller tracks (1/2-mile and under) this thing can really run with any of the 410s out there. On the bigger tracks it has trouble keeping up but you're not on those very often.

"The goal," he continues, "is to provide the weekly racer with a sound alternative that is competitive and fun to race. He doesn't have to spend as much to buy one and he doesn't have to rebuild it nearly as often, so he can afford to race more. And then when the travelling series come to town, it's still competitive against them so your local racers can go out and compete against the name guys to see how they stack up."

You may have noticed that earlier we mentioned that anyone will be allowed to build the A4MP engine. Instead of going with a single builder and an elaborate sealing system like many spec and crate motor's have resorted to, the A4MP has a unique plan to control cheating. Any engine builder that wishes to build his own motor will have to put up a $300 bond. Once bonded he can build all the A4MP engines he can sell, but if any engine is found to be illegal that bond will come due in the form of a $10,000 fine.

Yes, that's right: ten grand for cheating. We'll be interested to see how well this works but we can't imagine a better way to keep engine builders from going outside the rulebook than hitting them where it hurts-the checkbook.