If you go to as many cars shows as I do, you happen to notice the trends and modern technology in our classic vehicles. Modern fuel injection in our classic trucks is one of those trends that simply cannot be ignored. I will go out on a limb and say that within five years you will see twice as many fuel injected vehicles than in previous years. With that said, you might not ever see the Chevy 350 go away any time soon but, lucky for us, the older power plants can be adapted to EFI. Modern EFI technology can bring plenty of food to the table and is hard to argue when it comes to fuel savings, drivability, and reliable horsepower. For the most part, we are going to be talking about upgrading older and newer Chevy and Ford motors to aftermarket EFI systems such as TBI, multi-port, and tune-port-style injection systems.

Lets talk about the different types of fuel injection and how they can improve your performance plus add savings at the pump.

Throttle Body Injection (TBI)

A TBI consists of a carb-like throttle-body with two or four injectors that will increase or decrease the amount of fuel into the intake manifold depending on the vehicle’s demand for fuel. Most TBI systems calculate fuel increase and decrease with what is called a speed density system. The speed density system uses a RPM signal, via tach signal on the distributor, that measures how fast the engine speed is in RPMs. A manifold absolute pressure (MAP) sensor that is mounted on the intake, or inside the body, measures the manifold pressure inside the intake and also the incoming air temperature. An O2 sensor is also used on one side of the exhaust to determine the oxygen ratio of the escaping exhaust. A throttle position sensor (TPS) determines the throttle-body’s throttle position depending on how much throttle your right foot is giving it. Last thing is the vehicle’s computer; the computer calculates all of the above sensors and constantly adjusts by increasing and decreasing the pulse width of the injectors to increase or decrease the amount of fuel entering the engine. EFI eliminates the need to change the jets inside a carburetor and the hassle of servicing the carb. TBI systems like (FAST) Fuel Air Spark Technologie’s EZefi, Holley Avenger, Edelbrock, and Howell TBI all offer an easy plug-and-play-style fuel injection that anyone can install without the need for a laptop.

Edelbrock Pro-Flo XT EFI systems are ideal for converting carbureted engines to EFI. They offer more efficiency and drivability in street high performance engines, and is ideal for small-block Chevys.

Edelbrock Pro-Flo XT EFI systems are ideal for converting carbureted engines to EFI. They offer more efficiency and drivability in street high performance engines, and is ideal for small-block Chevys.

Multi-port fuel injection (MPFI) and Sequential fuel injection (SFI)

Multi-port fuel injection has a slightly different way of letting fuel enter the combustion chamber. Instead of the injectors being on top of the intake like TBI, there are eight injectors placed inside the intake pointed down at the intake valve. Multi-port systems will allow the fuel to bypass the hot intake runners to help with better fuel atomization. Rather than having fuel sprayed on top of the intake and sit until the motor pulls it in with one of the intake valves opening, MPFI systems allow the fuel a cool, straight shot to the combustion chamber.

Often overlooked, fuel pressure regulators are very important to a fuel injected motor because you can dial in the correct amount of fuel pressure depending on the manufactures recommendations. Shown is an Aeromotive fuel pressure regulator that can adjust from 40-70 psi and most EFI systems fall somewhere in the middle of that pressure.

Often overlooked, fuel pressure regulators are very important to a fuel injected motor because you can dial in the correct amount of fuel pressure depending on the manufactures recommendations. Shown is an Aeromotive fuel pressure regulator that can adjust from 40-70 psi and most EFI systems fall somewhere in the middle of that pressure.

There are several ways to control eight injectors inside the intake. One example is batch fire; as the engine spins, the computer will add fuel by opening several fuel injectors at a time (batch fire). The fuel then sits above the intake valves until the motor is ready to open the intake valves via the firing order. The MPFI system has slightly better fuel control over a (TBI) style system because it is not dumping fuel inside the intake and reacting to rich or lean command by the O2 sensor.

(SFI) or sequential fuel injection uses the same eight injectors and placed in the same spot on the intake but it has a slightly different way to control the engine fuel demand. The SFI system has better timing than that of a MPFI and will open only one fuel injector at a time right before the intake valve is opening. As the engine rotates a crank and/or cam sensor will tell the vehicle’s computer where the number one cylinder is. The computer then calculates where the rest of the cylinders are placed via a programmed firing order and determines when to open each injector. SFI has an advantage because fuel can be added into the engine’s combustion chamber with more precision than that of TBI or MPFI.

So how do I adapt all this EFI stuff to my truck?

Depending on what system you find suits your truck and budget depends on what you will need to purchase. Most of the aftermarket EFI manufactures make a small kit that gets you close to street ready and a full-on kit that has everything you need to be driving down the road. If you are going to pull a Chevy LS motor from a junkyard then make sure to grab everything like engine harness to fuses, etc., if you are brave enough to wire it yourself. If you are not the type that wants to spend countless hours messing with your EFI system, then a full kit is definitely the way to go.

Lokar’s drive-by-wire electronic throttle control pedal assembly is pre-programmed at the factory for specific applications. Included is an application specific pedal wiring harness that works in conjunction with the OEM wiring harness. Pedal calibration optimizes throttle response to eliminate pedal lag. The electronic throttle control/harness requires one of Lokar’s drive-by-wire pedal sets, which are offered in a variety of styles. Each item is sold separately for versatility.

Lokar’s drive-by-wire electronic throttle control pedal assembly is pre-programmed at the factory for specific applications. Included is an application specific pedal wiring harness that works in conjunction with the OEM wiring harness. Pedal calibration optimizes throttle response to eliminate pedal lag. The electronic throttle control/harness requires one of Lokar’s drive-by-wire pedal sets, which are offered in a variety of styles. Each item is sold separately for versatility.

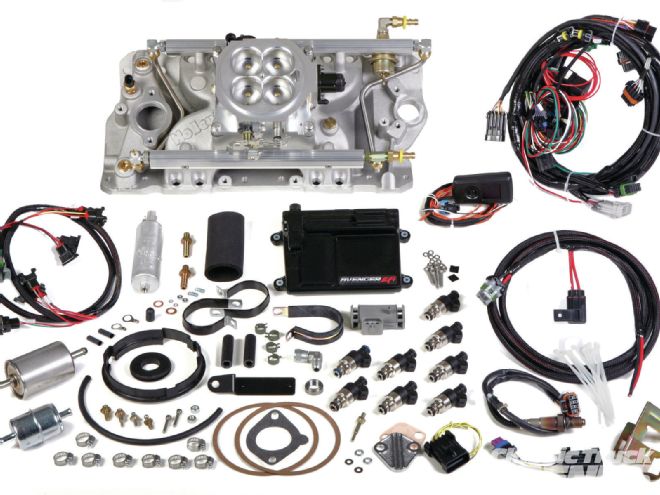

Holley Avenger Multi port EFI systems for small- or big-block Chevy. They feature the same simple plug-and-play computer system as the TBI Avenger, and will support up to 500 hp with the 36 pounds-per-hour injectors and 650 hp with the use of 48 pounds-per-hour injectors.

Holley Avenger Multi port EFI systems for small- or big-block Chevy. They feature the same simple plug-and-play computer system as the TBI Avenger, and will support up to 500 hp with the 36 pounds-per-hour injectors and 650 hp with the use of 48 pounds-per-hour injectors.

The future is here with the next gen GM small-block in the form of the LS motor. Considered by Chevy fans to be the cream of the crop this LS7 may not be affordable for all of us but luckily GM made several versions of the LS platform. Part of what makes this engine desired is the electronic fuel injection. Since GM made several different LS style engines you have plenty to chose from at GMPP dealers or junkyard cars and trucks.

The future is here with the next gen GM small-block in the form of the LS motor. Considered by Chevy fans to be the cream of the crop this LS7 may not be affordable for all of us but luckily GM made several versions of the LS platform. Part of what makes this engine desired is the electronic fuel injection. Since GM made several different LS style engines you have plenty to chose from at GMPP dealers or junkyard cars and trucks.

Ron Francis Wiring offers a complete line of fuel injection harnesses for GM and Ford including GM LS-1 and Ford 302, 4.6 & 5.4 engines. You get everything you need for your engine to run like factory. Based on their Telorvek panel, the system allows you to install the computer just about anywhere in the vehicle. Here’s how is works: The sensor connectors are factory installed to 20-foot lengths of wire. Once you plug the connector into the sensor, run the wires back to the Telorvek panel. The Telorvek panel has factory installed connectors to then plug into the factory computer. This allows the installer to choose the location of components and the wires can be dressed for a neat, professional look.

Ron Francis Wiring offers a complete line of fuel injection harnesses for GM and Ford including GM LS-1 and Ford 302, 4.6 & 5.4 engines. You get everything you need for your engine to run like factory. Based on their Telorvek panel, the system allows you to install the computer just about anywhere in the vehicle. Here’s how is works: The sensor connectors are factory installed to 20-foot lengths of wire. Once you plug the connector into the sensor, run the wires back to the Telorvek panel. The Telorvek panel has factory installed connectors to then plug into the factory computer. This allows the installer to choose the location of components and the wires can be dressed for a neat, professional look.

Tank you very much

Gas tanks are a huge part of the equation and need to be addressed. Companies like Aeromotive, Rock Valley Antique Auto Parts and Tanks Inc. all offer several choices of fuel tanks that can adapt to whatever EFI system you choose. For the average lower horsepower EFI swap, you can get away with using a stock-style fuel tank with a stock pickup tube but you will have to run a framerail mounted fuel pump. A stock-style pickup tube is very limited on the amount of fuel it can handle. Think of the stock fuel pickup tube as a small soda straw and a garden hose as the larger EFI fuel sump, the soda straw can only deliver so much fuel versus the much larger garden hose. So when the supply of fuel runs out or can’t deliver what the vehicles engine is demanding, the engine can go lean. The picture shows a Rock Valley tank that has been cut out. If you notice the fuel pump on the right has a sump around it to help the in-tank fuel pump to always be submerged in fuel. This also helps the fuel pump stay cool and also not suck any air when the tank gets below 1/8 on gas. Notice also the larger fuel inlet and return lines than that of a stock gas tank.

Fuel Lines

Since fuel pressure is much higher on fuel injected vehicles you will need to upgrade the fuel line to a larger diameter to maintain proper fuel volume. Stock fuel lines were designed for a much lower amount of fuel volume to travel through them, this is especially true for the six-cylinder vehicles that were often running smaller fuel line than that of a V-8. You can try to make your own fuel lines from an auto parts store, but I have run into length issues from not getting long enough line to compete the job to just plain cheap fuel line that will rust within a week. This is why I recommend that you look at companies like Inline tube and Classic Tube for fuel line that fits your vehicle. You will still need to tailor the fuel line to your liking if the EFI kit you choose does not provide the fuel line. Shown are some adapters from Aeromotive that will work on adapting the stock late model Chevy, Ford and Mopar fuel lines to the stock fuel rail.