In many respects it has become easier to restore and modify a classic Pontiac than when the subject vehicle was only a few years old. Though some parts are still hard to find, most are readily available, from the most obscure body clip to a crankshaft. This makes ownership much more rewarding and fun.

There is a fly in the ointment though—even the most meticulously restored Pontiac still has to run on modern gasoline. There simply is no place where we can turn the calendar back and fill our ride with the gas we grew up on (or at the old price). The days of High-Test fuel on every corner have long passed and will never return.

Will my finished car run well on modern pump gas? Though not enough of a concern that it would derail someone’s plan to own a classic Pontiac, it does weigh on every hobbyist’s mind. To further complicate this, the federal government is on the verge of implementing new rules for gasoline that will mean even more changes at the pump. Talks of increased ethanol content, up to 15 percent from the current 10 percent, along with other new chemistries are all on the table with no concern of how it will impact the collector-car hobby, let alone the Pontiac community.

As the author, I accept this premise because the efforts of the petroleum industry need to serve the good of the nation and not just the collector-car market. Yet it would be nice if our beloved Pontiac engines could gladly accept and perform well on today’s and possibly tomorrow’s fuel. This would be best for everyone—we can enjoy cleaner air and the possibility of a reduced dependence on foreign oil, and still enjoy the performance of a traditional Pontiac. That’s a win-win situation.

Craig and Bob Wise of Racekrafters are preparing the SD-455 engine for the dyno testing by removing the factory parts and installing the Edelbrock Performer RPM intake and MSD ignition while the engine is on the dyno cart.

Craig and Bob Wise of Racekrafters are preparing the SD-455 engine for the dyno testing by removing the factory parts and installing the Edelbrock Performer RPM intake and MSD ignition while the engine is on the dyno cart.

The opportunity to explore this concept required a test mule. HPP needed a strong-running Pontiac engine and Melvin Benzaquen of Classic Restoration Enterprises had just the right candidate. Robert J. Tomasetta and his son, Chris, own a ’73 Formula SD-455—an extremely rare car. Melvin was performing a complete restoration on the Formula and had contracted out to RaceKrafters Automotive Machine owners, Bob and Craig Wise, to rebuild and mildly tweak the Super-Duty mill.

To even a casual reader of HPP, these two shops are no strangers. Both businesses are well entrenched in the Pontiac community and respected for their ability. With the blessings of the Tomasetta family, HPP created a test protocol to examine the impact of fuel composition on one of the most respected Pontiac engines of all time.

Testing had to be done in incremental steps on RaceKrafter’s advanced and very accurate engine dyno with a Depac data acquisition system. Bob and Craig have over 30,000 dyno runs on the current data-collection system. This makes them an excellent choice for repeatable information and removing the potential of skewed results from an inexperienced operator.

As mentioned in the gasoline story, Rockett Brand Racing Fuel joined us in the endeavor. Not only did it provide the fuel, but it also performed an analysis of it to remove any possibility of corrupting the test. This is important so that there is no debate as to the validity—the variables have been removed.

In the chart above, AKI is the anti-knock index. This is a measure of the octane as derived from the method R+M/2=AKI. SG is the weight of the fuel measured as specific gravity. The amount of ethanol is listed as a function of volume, so it’s read in percentage.

Fuel Specifications

The specifications on the fuel from Rockett are:

Product

AKI

SG

Ethanol%

O2 Weight%

A/F

Base

92

0.743

0.0

0.0

14.7

E10

93.5

0.749

10.0

3.5

14.2

E15

94.0

0.753

15.0

5.2

13.9

E85

112

0.789

85.0

29.0

9.8

Ethanol contains oxygen; it replaced MTBE as an oxygenate for a reduction in emissions. Rockett provided the amount of oxygen in each test fuel using the industry standard, a percentage of the total weight of the fuel. As ethanol is added, the octane improves slightly.

Air/fuel ratio in the last column is the stoichiometric value. This describes the mixture strength for the best chemical-energy release, which is not to be confused with the ratio for the most power, since there are energy losses inside every engine and some inert exhaust gas is always present in the cylinder bore due to overlap of the camshaft. The exhaust gas effectively dilutes the mixture.

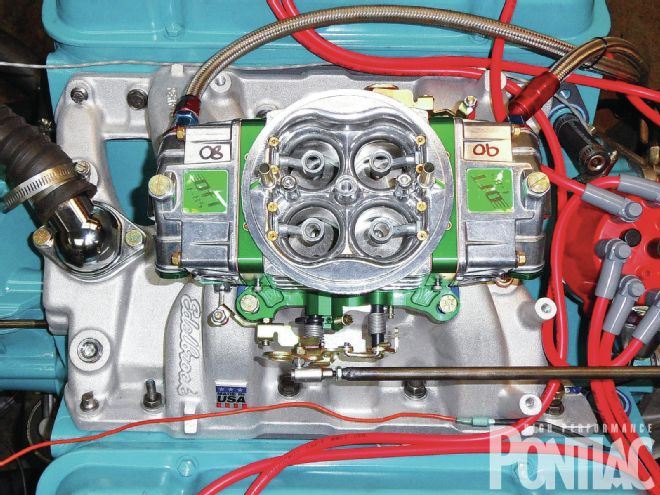

The assembled-in-the-USA Quick Fuel Technology 750-cfm carb on the left is calibrated to run on the non-oxygenated base, E10, and E15 fuels, while the E85-specific carb is calibrated for E85 characteristics. All Q-Series carburetors feature an aluminum main body and billet metering blocks and throttle body to provide positive sealing between circuits. The aluminum fuel bowls incorporate QuickSet sight windows on both sides to facilitate easy float adjustment. Along with many tuneable features, for drag racing jet extensions and notched floats are included; for the street, built-in vacuum tubes and a four-corner idle system are employed.

The assembled-in-the-USA Quick Fuel Technology 750-cfm carb on the left is calibrated to run on the non-oxygenated base, E10, and E15 fuels, while the E85-specific carb is calibrated for E85 characteristics. All Q-Series carburetors feature an aluminum main body and billet metering blocks and throttle body to provide positive sealing between circuits. The aluminum fuel bowls incorporate QuickSet sight windows on both sides to facilitate easy float adjustment. Along with many tuneable features, for drag racing jet extensions and notched floats are included; for the street, built-in vacuum tubes and a four-corner idle system are employed.

The base gasoline was kept as a constant and Rockett mixed in the prescribed amount of ethanol to produce the blends. This removed variability in the base gasoline, which otherwise could skew the results.

When gasoline is mixed with ethanol, the amount of alcohol is described by the letter E with a value. Thus, E10 is 90 percent gasoline and 10 percent ethanol. This is the current standard fuel in most parts of the country, especially near major metropolitan areas. In some rural areas, straight gasoline without ethanol is still offered. It is the equivalent to the first fuel in the chart, identified as Base. E15 is currently not offered to the public but is part of a major debate going on in Washington, D.C., as well as in the auto and petroleum industry. Its intent is to add more ethanol and reduce the amount of crude oil in gasoline. It is a political “hot potato” that HPP will avoid discussing, but we include it in the test since it may be forced upon the public in the near future.

E85 is only 15 percent gasoline and 85 percent ethanol. Any newer vehicle that has a badge saying Flex-Fuel or any other similar term has the ability to use this fuel. Those vehicles have a fuel-composition sensor, which has the ability to detect the amount of ethanol in the gas and adjust the engine calibration accordingly. Often a flex-fuel vehicle will run on a mix of fuel that is less than E85, if the owner doesn’t always purchase the same type of gas. They may have a tank of E85 and top it off with E10 or base fuel. That is why a fuel-composition sensor is required.

Aside from the fact that E85 will allow for much more compression to make more power—an avenue that we could not explore for this test as it would have required complete engine teardown and a piston swap—no other internal changes needed to be made to the fresh Pontiac mill for the varied fuels. However, there were some required bolt-on parts.

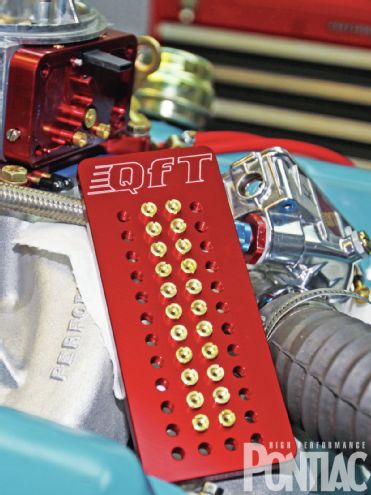

Adjusting the size and placement of bleeds or plugs in the emulsion passages are advanced tuning techniques and are determined by many factors, such as the size of the emulsion passage, the idle feed restrict passage dimension, and the specific gravity of the fuel, and so on. For this reason, most manufacturers determine the fuel flow of the carburetor on a wet bench and then the end user/tuner only needs to modify the jets and low- and high-speed air bleeds. Very rarely do you see a tuner change emulsion hole size or position. The gasoline metering block is red and uses only one plug (looks like a bleed) in the emulsion passages. Note there are four possible locations. The E85 metering block is green and also has a plug, but only three emulsion passages.

Adjusting the size and placement of bleeds or plugs in the emulsion passages are advanced tuning techniques and are determined by many factors, such as the size of the emulsion passage, the idle feed restrict passage dimension, and the specific gravity of the fuel, and so on. For this reason, most manufacturers determine the fuel flow of the carburetor on a wet bench and then the end user/tuner only needs to modify the jets and low- and high-speed air bleeds. Very rarely do you see a tuner change emulsion hole size or position. The gasoline metering block is red and uses only one plug (looks like a bleed) in the emulsion passages. Note there are four possible locations. The E85 metering block is green and also has a plug, but only three emulsion passages.

Any variation in the composition of the gasoline, along with a change to the stoichiometric value, requires tuning of the ignition and fuel delivery. The distributor advance curve must be adjusted to the burn speed of the fuel blend. Huge differences in the stoichiometric values of the fuel as the ethanol is added, along with an increase in weight (reference the SG in the chart), meant the OE Rochester Quadra-Jet and Delco points distributor were not up to the task when it came to quick and easy tuning changes on the dyno.

Let’s discuss the ignition system first.

Having the ability to easily alter the amount of ignition advance not only as a total, but as a curve, would be essential to test each fuel. The fuel-burn rate affect on power is optimized by the timing of the arc across the spark plug. Even though the Delco distributor can be recurved, the adjustability we would require would not be within reach. It would be extremely burdensome to execute a small timing change. The ignition system is a place where modern technology can really help.

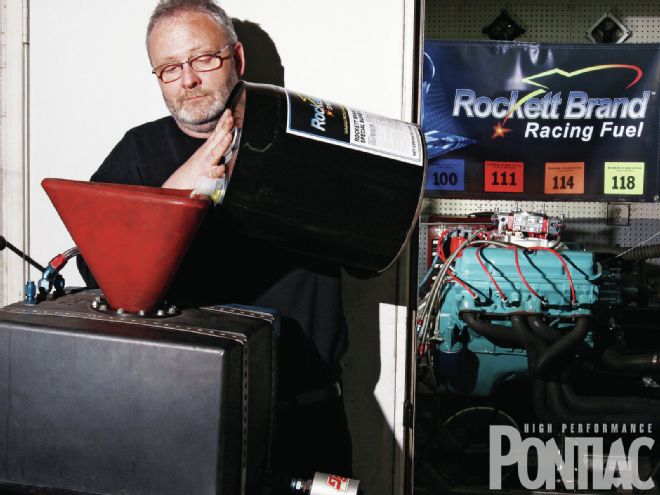

MSD was informed of our project and was quick to supply its Programmable 6AL-2 kit. We also used an MSD Ready-to-Run Distributor we had on hand, which Craig Wise made a sleeve for so it would fit the larger SD block hole. But the important part is that the system is completely programmable for timing changes as minute as 0.1 degree/100 rpm. This is accomplished though a dedicated software and cable that interfaces to a laptop PC.

A side benefit was the added spark energy of the MSD CD ignition/coil and multi-strike function below 3,000 rpm. We started our dyno pulls just around this engine speed, so the multi-strike did little for the results, but helped keep the engine running clean during minor carburetor tuning adjustments at idle.

The MSD Programmable 6AL-2 (PN 6530) was a key component to this test and is a worthwhile addition to any Pontiac engine. This system eliminates the weights and springs in the distributor, and is PC programmable with Windows-based Pro-Data +Software. It allows you to plot a timing curve down to a 0.1 degree every 100 rpm, program three rev limits in 100-rpm increments, set a step retard for nitrous applications, and employs capacitive discharge technology for high voltage and spark energy. We also ordered the Blaster HVC coil to augment the system.

The MSD Programmable 6AL-2 (PN 6530) was a key component to this test and is a worthwhile addition to any Pontiac engine. This system eliminates the weights and springs in the distributor, and is PC programmable with Windows-based Pro-Data +Software. It allows you to plot a timing curve down to a 0.1 degree every 100 rpm, program three rev limits in 100-rpm increments, set a step retard for nitrous applications, and employs capacitive discharge technology for high voltage and spark energy. We also ordered the Blaster HVC coil to augment the system.

The last obstacle was the need for a carburetor. Quick-Fuel Technology, a well-known supplier of both race and street carburetors, was just the source we required. It offers a wide variety of carburetors, and supplied a regular gasoline and an E85-calibrated carburetor, along with all of the necessary tuning parts for both gasoline- and alcohol-based fuels. RaceKrafters supplied all of the engine specifications to Quick-Fuel Technology, which suggested a pair of 750-cfm mechanical secondary carburetors—one for gasoline and the other for E85.

An E85 carburetor is built and modified with parts that can live with the corrosion and propensity to eat rubber that is a fact when using alcohol. But since E85 is a hybrid fuel, it is not strictly an alcohol carburetor with an E85 marking on it. Quick-Fuel Technology has done extensive research and tuning to develop the proper fuel curve for E85 by way of a higher flow rate power valve, larger fuel passages in the metering block, and properly sized jets and air bleeds. Other features include gaskets, floats, and a needle valve that will live with E85. The result is the carburetor is completely different than the gasoline or alcohol models it sells.

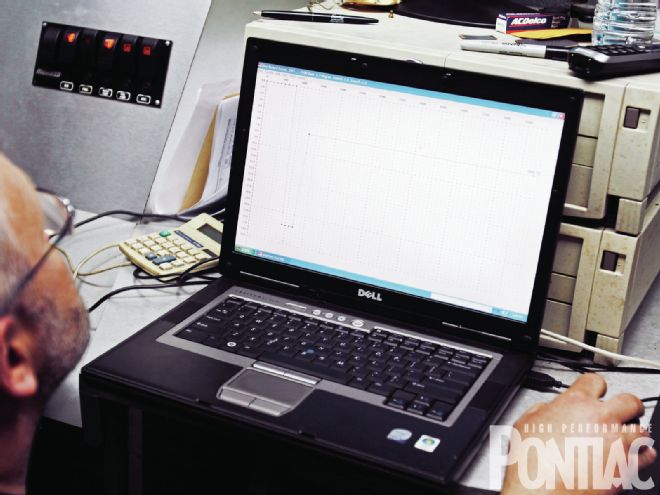

This is the home screen for the MSD system. It provides a dashboard and monitors for various aspects of the ignition system, and an ignition curve graph for tuning.

This is the home screen for the MSD system. It provides a dashboard and monitors for various aspects of the ignition system, and an ignition curve graph for tuning.

To accommodate the Quick Fuel carburetors, Bob installed an Edelbrock Performer RPM intake manifold he had on hand. A long-time favorite of Pontiac fans, the aluminum, made-in-the-USA intake has a power range of 1,500 to 6,500 rpm.

There is an aside to this test that needs to be mentioned. The Rockett brand E85 is a true 85 percent ethanol and is considered a race gasoline even though it is legal to pump into the tank of a flex-fuel vehicle, (If you own one, it will love this stuff!) Tim Wusz, technical consultant to Rockett, told us their testing has shown that many pump-dispensed E85-labeled products can test as low as 65-percent ethanol content. Even though E85 is not offered near the HPP offices, it was important for us to source this product from Rockett. Without the confirmation of the fuel’s integrity, the calibration of the E85 carburetor could have been far from ideal if we happened to get a batch of E65.

Each Rockett fuel can was identified with the HPP logo so that it could be tracked through the manufacturing process.

Each Rockett fuel can was identified with the HPP logo so that it could be tracked through the manufacturing process.

The question may come to mind: If the government is mandating E85, how does it allow lesser blends to be sold as that product? From our cursory investigation, it seems that during the winter months, the refinery is allowed to alter the ethanol content to aid in extreme cold starting—alcohol does not like to allow an engine to run at minus 10 degrees F. As the weather warms, the blend reverts back to the original specification.

The Testing

The subject SD is destined for a fully restored car and is designed to look stock under the hood. It will use a factory fuel and ignition system, but will hide a set of ported No. 16 casting cylinder heads and a Comp Cams 224/230 at 0.050-inch hydraulic roller bumpstick. The engine was completely rebuilt and fully machined, along with the cylinder heads (see HPP Engine Buildup worksheet).

It was broken in on the dyno in factory trim with the Rochester carburetor, Delco distributor, and factory exhaust manifolds. In this form it was quite potent. It made a peak of 406 hp and 504 lb-ft of torque while requiring 36 degrees of total timing.

The next step was to remove the exhaust manifolds and install a set of 1.875-inch headers with 3.00-inch collectors. The Q-Jet and Delco distributor were still in place. The free-flowing exhaust stepped the power up to 425 and the torque to 508 lb-ft. The engine still desired 36 degrees BTDC timing. This was the extent of the testing with OE parts. Stock-configured tests were performed with locally sourced 93-octane pump gas from a nearby station.

For our test, the intake manifold was removed and the Performer RPM was fitted, along with the MSD ignition system and the Quick-Fuel gasoline carburetor (all tuning notes are in the dyno charts). This was the first test with the base Rockett 92-octane fuel.

Craig ran the dyno for our test.

Craig ran the dyno for our test.

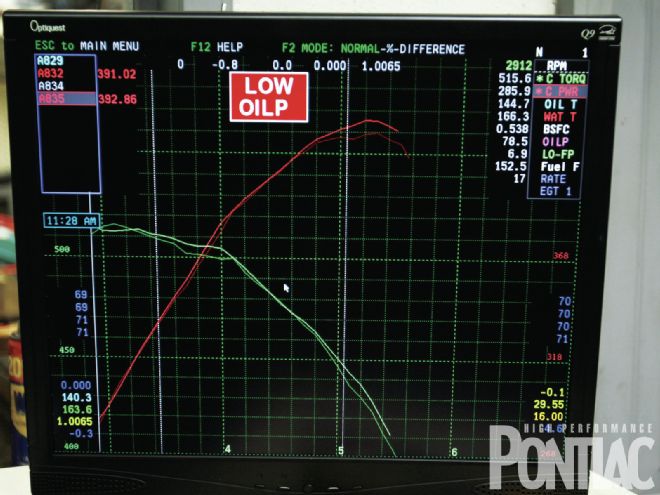

This pull is our control since the exhaust, intake manifold, carburetor, and ignition are all constant. Only the blend of fuel changes, along with carburetor tune and ignition lead to optimize each gasoline. With the control Rockett fuel in place, the baseline after multiple pulls was set at 438 hp and 529 lb-ft of torque and 32 degrees of ignition lead.

The fuel cell and carburetor were drained and filled with Rockett E10, the common type of gasoline in the majority of stations in America today. After some minute fiddling, the engine produced 438 hp and 528 lb-ft of torque. The engine wanted 30 degrees total timing.

With the gasoline carburetor still in place, the E15 prototype fuel blend was added. This emission reduction gasoline improved the power to 443 and torque to 545 lb-ft—so much for the government killing the power in an older engine with new gas! We were surprised the engine now only wanted 28 degrees of timing.

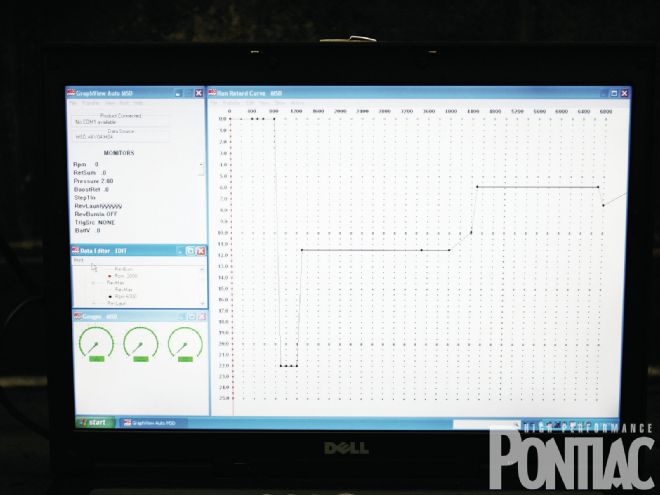

The key to optimizing a dyno session is the ability to collect accurate data at many rpm points. Here, after an early pull, Bob analyzes the power numbers down around the 2,900 rpm area to make a tuning decision.

The key to optimizing a dyno session is the ability to collect accurate data at many rpm points. Here, after an early pull, Bob analyzes the power numbers down around the 2,900 rpm area to make a tuning decision.

With the gasoline-biased fuels all tested, it was now time to remove the carburetor and install the E85 version. After some baseline pulls, Craig made slight jet and air-bleed alterations and we were rewarded with 445 hp and 549 lb-ft of torque, a gain of 7 hp and 20 lb-ft of torque from the base fuel. We fed the carburetor a fuel that Pontiac engineers could have never imagined, and the SD liked it! The engine wanted 32 degrees of advance with the E85.

Analyzing the Results

This exercise has proven without a doubt that as much as the hobbyist community is concerned about modern gasoline, it’s better than what we had years back, and is fully compatible with an older engine when the fuel system is updated to work with ethanol-enhanced fuels and the engine is properly tuned for them (more on that later).

There was one aspect of the subject engine that was less than ideal—the 8.35:1 compression ratio. Since this engine was built to live on the street in a restored Firebird, the compression ratio was calculated for that use and not as a fuel test subject. It is the consensus of everyone involved that the results would have been even more dramatic (a larger power increase over the base fuel) if the engine were around 10:1.

The other sticking point is the cylinder heads. In life you cannot help who or what you fall in love with, and there is certainly a lot to love about Pontiac engines. The only problem is the stock cylinder heads (even the SD version). Talk to any true engine guy and he’ll say the Pontiac combustion chamber, port design, and spark plug location all leave much to be desired when compared to modern engines or many modern aftermarket Pontiac heads. In their defense, the castings are somewhat typical of what is found on some other performance engines of that era.

With the MSD system, Bob was able to perform quick and easy timing adjustments via his laptop computer.

With the MSD system, Bob was able to perform quick and easy timing adjustments via his laptop computer.

A good benchmark for a combustion-chamber design is the octane tolerance it provides. We all know the compression ratio needs to be conservative on a street Pontiac or detonation will become a problem. A set of aftermarket heads with a more modern combustion chamber makes a world of difference. It allows a higher static-compression ratio, which improves the thermal efficiency of the engine.

One pitfall—it’s very easy for readers to assume the SD-455 liked the E10 and E15, and especially the E85, based on the higher octane. As mentioned in the fuel primer that needs to be read, octane has nothing to do with power. As long as an engine has enough octane to control abnormal combustion, the rest of it means nothing. The Pontiac made more power because of the chemical composition of the different fuels and the burn characteristics. As the author, I plead with you to ignore the octane trap. Burn rate and energy content are the keys to power.

What did really surprise all of us, including the people at Rockett, was the timing curve. It was assumed that as the ethanol amount was increased, the engine would want more ignition lead, but it followed no real trend. The gas station fuel purchased in Lancaster, Pennsylvania, required 36 degrees of timing, while the base Rockett blend wanted only 32 degrees. Then the E10 and E15 each wanted 2 degrees less, resulting in 32 and 30 degrees, respectively. Following that trend, we believed the E85 would have desired around 25 to 26 degrees of advance, but it didn’t. In fact, the demand went back up to 32 degrees BTDC.

HPP does not want you to get mired in the numbers, but it’s important to recognize that as stated in the fuel story, for the best performance the engine needs to be tuned to the fuel used, and if anything, this proves it. Fuel blends are complex—there are so many factors that impact burn speed, vaporization rate, heat transfer and cooling effect—there is no way to predict an actual number other than to try it on a dyno.

QFT provided all of the jets and supplies we would need to fine-tune for each fuel. With accurate data and Craig’s experience, we were able to achieve the best tune for each fuel without much effort.

QFT provided all of the jets and supplies we would need to fine-tune for each fuel. With accurate data and Craig’s experience, we were able to achieve the best tune for each fuel without much effort.

We don’t want to lead you astray—we were tuning for the best power. (You should also tune for part-throttle driveability.) We only found a few horsepower with each tune as the fuel was changed to the other blend with the previous gasoline’s calibration.

Other Findings

As great as the engine ran on the E85, its entire sound changed. The exhaust was choppy even when tuned to perfection, and it did not sound happy. That is why we were all so shocked when the dyno data came up—based upon the exhaust note, we believed it was going to be way down on power.

If E85 is offered in your area, there is a real benefit to building a dedicated engine for it. Given the option, we would do everything the same but bump the compression ratio up to 11.0:1 or better to take advantage of the Rockett brand product’s 112 octane. However, you would have to build the fuel system as you would for an alcohol application.

We were all excited to see how the Pontiac would run with the QFT E85 carburetor. It did not disappoint.

We were all excited to see how the Pontiac would run with the QFT E85 carburetor. It did not disappoint.

The OE flex-fuel vehicles have special fuel lines, injectors, gas tank, and so on. A new car has a very elaborate vapor-recovery system in the gas tank that does not allow in much air, and thus, moisture. This is done on gasoline and flex-fuel vehicles for evaporative emissions. An older Pontiac with an open-vent gas tank and carburetor bowl filled with E85 will wick in moisture at a much greater rate. This all needs to be considered if you decide to build an E85 engine.

And unlike a flex-fuel engine, your Pontiac will be forced to always run on E85 due to the carburetor calibration. You would need to have two carburetors and a fuel tank drain if you wanted to race on E85 and run on the street with gasoline. That’s not a major obstacle, but one that needs to be recognized. Some enthusiasts install a fuel cell in the trunk for the E85 and retain the stock gas tank for the street fuel. At the track they change carburetors and use a pickup-truck dual fuel-tank valve to feed the E85 to the engine.

Conclusion

Everyone who was at the dyno session that day came away with not only a new respect for modern gasoline, but also the adaptability of a true Pontiac engine. We all learned a lot, and we hope that you too will feel the same way.

HPP Engine Buildup Worksheet

Engine Displacement: 463 ci

Bore/Stroke: 4.185/4.210-in

Block/Crank Combo: Super-Duty / SCAT 4340 forged

Bore/Stroke Ratio: 0.994:1

Rod/Stroke Ratio: 1.57:1

Bottom End

Block Description: ’73 SD-455

Deck Height: 10.212-in

Crank: SCAT 4340 forged, 4.210-in stroke

Balancer: OEM

Rods: Eagle forged, 6.625-in

Bearings: Clevite

Pistons: SRP forged flattop, 4.185-in

Piston to Deck Height: 0.002-in

Piston Pins: SRP

Method Used to Retain Pins in Pistons: Spiro locks

Rings: Mahle 1⁄16, 1⁄16, 3⁄16-in

Rod Bolts and Head Bolts: ARP

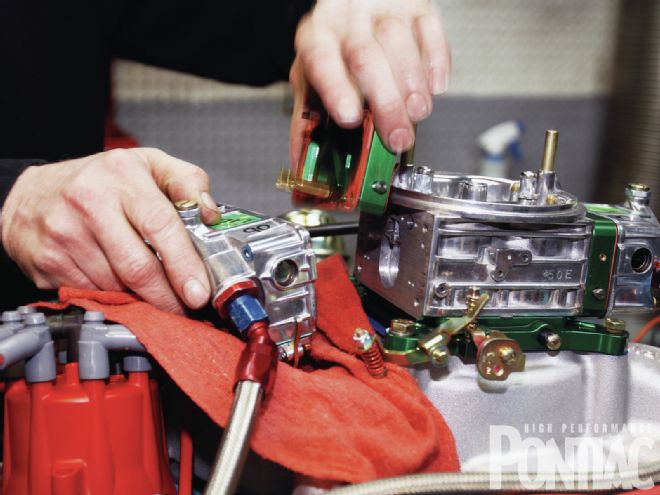

Craig removes the rear float bowl and metering block. The gaskets are specific for E85 applications so that ethanol doesn’t deteriorate the material. He swaps jets in the E85 carb in search of a few more horsepower.

Craig removes the rear float bowl and metering block. The gaskets are specific for E85 applications so that ethanol doesn’t deteriorate the material. He swaps jets in the E85 carb in search of a few more horsepower.

Oiling System

Windage Tray: OEM

Oil Pan: OEM

Oil Pump: Melling

Heads

Casting Number: 16

Head Mods: Super Mod porting

Combustion Chamber Volume: 111 cc’s

Maximum Flow at 28 Inches of Pressure, Int/Exh: . 240-cfm at 0.500-in lift / 190-cfm at 0.500-in lift

Compression Ratio: 8.35:1

Valves: Manley SS 2.11/1.77-in

Angles Used in Valve Job: 30, 45, 65-deg

Rocker Arms: Comp Cams roller, 1.52:1

Pushrods: Comp Cams 5⁄16-in stock length

Cam

Type: Comp Cams hyd. roller

Duration at 0.050: 224/230-deg

Lift: 0.502/0.510-in

Centerline: 107-deg

Lobe Separation Angle: 110-deg

Installed Position: 107-deg

Lifters: Comp Cams hyd. roller

Valvesprings: Comp Cams, dual

Timing Chain: Comp Cams

Induction

Carb: Quick Fuel 750-cfm

Intake Manifold: Edelbrock Performer RPM

With more than 35 pulls over our eight-hour test session, the SD-455 didn’t miss a beat.

With more than 35 pulls over our eight-hour test session, the SD-455 didn’t miss a beat.

Ignition

Distributor: MSD

Coil: MSD

Wires: MSD 8mm

Exhaust

Headers, Brand: Hooker

Primary Tube Diameter: 1.875-in SD

Primary Tube Length: 28.00-in

Collector Size: 3.00-in

Gaskets

Brand: Fel-Pro/B.O.P.

Dyno Charts

Please note the change in fuel consumption is measured by BSFC (lb/HpHr) is the result of the different stoichiometric values of the different fuels. As the stoichiometric value goes lower, more fuel volume is required to support the engine.

Rockett Brand Base Fuel

QFT carburetor, 69/79 jets, 32 degrees BTDC

Average power from 3,500 to 5,000 rpm is 399.78 hp and 496.29 lb-ft of torque

RPM

TQ

HP

BSFC

3,000

528.5

301.9

0.51

3,100

527.7

311.5

0.48

3,200

527.1

321.1

0.47

3,300

525.2

330.0

0.46

3,400

524.1

339.3

0.47

3,500

523.6

349.0

0.47

3,600

519.7

356.2

0.47

3,700

517.8

364.8

0.47

3,800

515.3

372.8

0.46

3,900

515.6

382.8

0.46

4,000

511.5

389.6

0.47

4,100

509.9

398.0

0.46

4,200

505.6

404.4

0.46

4,300

498.1

407.8

0.47

4,400

491.7

411.9

0.47

4,500

486.3

416.7

0.47

4,600

480.9

421.1

0.47

4,700

475.8

425.8

0.47

4,800

470.0

429.6

0.48

4,900

462.0

431.1

0.48

5,000

456.8

434.8

0.48

5,100

449.1

436.1

0.49

5,200

442.2

437.8

0.49

5,300

433.6

437.6

0.50

Rockett Brand E10

QFT carburetor 72/81 jets, 30 degrees BTDC

Average power from 3,500 to 5,000 rpm is 400.51 hp and 497.18 lb-ft of torque

RPM

TQ

HP

BSFC

3,000

528.1

301.6

0.49

3,100

528.0

311.6

0.48

3,200

527.1

321.3

0.48

3,300

527.2

331.3

0.47

3,400

526.3

340.7

0.47

3,500

523.0

348.5

0.47

3,600

521.7

357.6

0.48

3,700

518.0

364.9

0.49

3,800

517.3

374.3

0.48

3,900

515.5

382.8

0.47

4,000

513.2

390.9

0.47

4,100

509.9

398.0

0.47

4,200

505.9

404.6

0.47

4,300

499.6

409.0

0.48

4,400

493.2

413.2

0.49

4,500

487.8

417.9

0.49

4,600

481.2

421.5

0.49

4,700

476.7

426.6

0.49

4,800

471.1

430.5

0.48

4,900

463.0

431.9

0.49

5,000

457.8

435.8

0.48

5,100

451.1

438.0

0.49

5,200

451.1

438.2

0.50

5,300

434.4

438.4

0.51

Rockett Brand E15

QFT carburetor 70/79 jets, 28 degrees BTDC

Average power from 3,500 to 5,000 rpm is 407.54 hp and 506.07 lb-ft of torque

RPM

TQ

HP

BSFC

3,000

542.5

309.9

0.50

3,100

544.5

321.4

0.47

3,200

541.8

330.1

0.46

3,300

540.2

339.4

0.46

3,400

537.1

347.7

0.46

3,500

535.9

357.1

0.46

3,600

532.4

364.9

0.46

3,700

529.9

373.3

0.46

3,800

526.9

381.2

0.46

3,900

526.6

391.0

0.46

4,000

522.9

398.3

0.46

4,100

519.8

405.8

0.46

4,200

515.2

412.0

0.47

4,300

506.4

414.6

0.47

4,400

502.5

421.0

0.47

4,500

495.4

424.4

0.47

4,600

488.9

428.2

0.47

4,700

482.7

432.0

0.48

4,800

476.8

435.7

0.47

4,900

471.6

439.9

0.48

5,000

463.3

441.0

0.48

5,100

455.9

442.7

0.48

5,200

446.7

442.3

0.48

Rockett Brand E85

QFT E85 carburetor, 78/88 jets, 32 degrees BTDC

Average power from 3,500 to 5,000 rpm is 408.38 hp and 507.07 lb-ft of torque.

RPM

TQ

HP

BSFC

3,000

547.4

312.7

0.68

3,100

548.6

323.8

0.66

3,200

547.1

333.4

0.65

3,300

544.3

342.0

0.66

3,400

540.0

349.5

0.66

3,500

537.0

357.8

0.66

3,600

532.7

365.1

0.66

3,700

529.6

373.1

0.66

3,800

527.5

381.7

0.66

3,900

526.8

391.2

0.66

4,000

525.2

400.0

0.65

4,100

521.2

406.9

0.66

4,200

515.3

412.1

0.67

4,300

508.8

416.6

0.67

4,400

503.1

421.5

0.67

4,500

496.4

425.3

0.67

4,600

490.0

429.2

0.67

4,700

483.7

432.9

0.68

4,800

478.0

436.9

0.69

4,900

472.6

440.9

0.69

5,000

465.1

442.8

0.69

5,100

457.8

444.6

0.69

5,200

448.7

444.2

0.69