Nothing like the guttural roar of a turbo engine making 950 lb-ft at 4,000 rpm. It's like the last few seconds of a pool being drained or the chug of a tornado as it slurps up a lake. That kind of power tends to add stress to engine parts, and we've rolled the bones many times with the gods of physics, hoping they wouldn't fill the oil pan with flaming bits of crankshaft. To keep the noise and power and avoid the dry-cleaning bill, we've decided to assemble a long-block turbo engine that can take the load that a 1,000-plus horsepower pounding delivers with the Comp Turbo 67s on our Wrenchrat twin-turbo kit.

The Hammer was the last mule we built nearly five years ago. It was assembled by JMS Racing Engines in El Monte, California, with a Lunati rotator and Wiseco Pro Tru pistons. In a testament to JMS and the bullet-proof short-block, that turbo engine has seen the dyno whip more than 500 times without even a scuffed bearing. Why build another? Compression ratio. The Hammer has between 10.5-11.0:1 compression ratio depending on the combustion chamber and head gasket choices, so adding a lot of boost begs for race gas, taking the fun out of street thrashing.

The Animal will be stronger yet, with a compression ratio in the 8.5:1 area so we can try to control detonation. To add a little science to the mix, we'll explain why we chose each part of this turbo small block and what disaster we were trying to avoid. Since Ted Toki broke in the twin turbos on his '55 Chevy, he volunteered to assemble the new turbo engine at Westside Performance in Los Angeles, California.

Turbo Small Block: The Rotator

Our first plan was to build a 434-inch turbo small block, thinking bigger is always better. Except this time, that is. As the stroke gets longer, the piston gets shorter, and on a boosted engine you run out of dish room to get the compression down. For example, if you have a 9.020 deck and a 6-inch rod with a 4-inch stroke, you end up with a compression distance (CD) of only 1.025 inches from the wristpin location to the crown. Not only is that a bit too thin to hit with the boost hammer, the maximum dish is only 19 cc, since the small end of the rod is so close to the underside of the piston.

To get the 8.5:1 compression ratio we needed to pack in copious boost; we needed around 30 cc of dish, making the big-stroke/big-rod combo a no-go. We also looked at the 5.85-inch rod and 1.170-inch piston option. JE Pistons, for example, has a shelf piston for this combination called the Extreme Duty with a 23cc dish, but it still wasn't enough. Also, we didn't like the 5.70-inch rod and 1.320 CD piston for this application because of the piston's extra weight. Rod failures typically occur just after the piston reaches TDC on the exhaust stroke and the crankshaft is trying to pull it in the opposite direction. A big 4.155 bore combined with a tall piston creates a heavy slug on the end of the rod at 7,000 rpm. In this case, less is more, so we looked for something better.

We spoke to Sean Crawford at JE Pistons about our turbo small block to get his take on the situation. "I'd sacrifice the extra inches all day long to get a workable combination," Crawford says. "We should use thick lands, good rings, and don't compromise the piston [height] as much to make it work." The combo he recommended has a 3.875 stroke with a 5.85-inch rod for 420 inches. This piston has a 31cc inverted dome and a 1.227-inch CD. It represents a balance between the light-piston/long-rod and heavy-piston/short-rod combination and puts the piston 0.0055 below the deck on a 9.020 block. Using the Brodix 233 CNC heads with a 68cc chamber, it gave us 8.54:1 compression.

With the piston and rod combo handled, we spoke to Tom Molnar from K1 Technologies about a good crankshaft. Crankshaft quality is about strength and design. He told us that it is not the amount of horsepower you are making that fails a crank but rather the load and fatigue caused by the number of cycles at that load. "Look at it like bending a straightened out paper clip," says Molnar. "If you make small bends, it will last a lot longer than if you are making big bends. A higher load is a bigger bend failing to clip at the joint."

What fails in the crankshaft, besides lack of oil and spun bearings from assembly errors, is a failure in the area of the fillet in the main bearing journal. The K1 crankshaft has a full-radius fillet on the main and rod bearing journals that relieves the stress in this critical area. The crank is also a 4340 forging, with a tensile strength approximately three times as that of a cast crank. Basic metallurgy indicates the higher hardness, the higher the tensile strength, and the greater the resistance to fatigue.

The rods are billet H-beams and are made from the same 4340 steel as the crankshaft. Note the ARP rod bolts and bushed sleeve for the 0.927 wristpin.

The rods are billet H-beams and are made from the same 4340 steel as the crankshaft. Note the ARP rod bolts and bushed sleeve for the 0.927 wristpin.

The H-beam rods are also made from 4340 steel. As we mentioned previously, it's not horsepower loads that breaks a rod. If it were, you'd see more rods crushed from the cylinder pressure. Most rods are pulled apart by the forces generated by the crankshaft. The design of the H-beam in addition to the hardness of the steel resists this type of failure.

When you combine the materials in the forging, the design of the H-beam rod, and the stress-relieved crank, you get a rotator that will take more cycles under more load over a longer period of time than any cast assembly. This kind of insurance will allow us to focus on testing parts and making power without worrying about failures on dyno day.

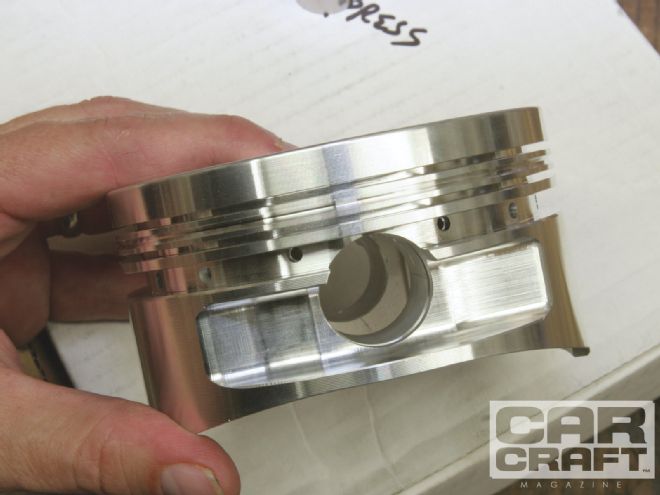

Note the smooth crown on the JE piston. All the edges are machined so there are no potential hot spots that can cause pre-ignition under boost. There is a lot more to this piston than meets the eye.

Note the smooth crown on the JE piston. All the edges are machined so there are no potential hot spots that can cause pre-ignition under boost. There is a lot more to this piston than meets the eye.

The Block

We all know Dart Machinery makes blocks, but what to choose? The SHP block is a stout piece at $1,500, but to use Dart's Jack McInnis' words, "The Little M is more suited to lots of power and lots of abuse." That sounds like us. We chose the Sportsman version because it is $400 cheaper than the Little M. It lacks four-bolt main caps on each end and it's made from ductile iron instead of billet steel, but it's stout enough for the kind of street/strip beating we will deliver.

Typical first-generation iron small-blocks are weak where the main caps meet the web in the block. If there is enough cylinder pressure and rpm, the webbing will crack and the crank bearings will turn to paste. Similarly, the main webbing can also separate from the crank, driving the entire rotator through the pan. To avoid these annoyances, the Little M Sportsman has more meat in the main webbing, more nickel alloy mixed in the casting of the block, and four-bolt splayed caps that don't squirm when you are at full throttle.

The rings are JE Pro Seal 1⁄16, 1⁄16, ductile iron with a 3⁄16 standard tension carbon-steel oil ring. It may look like there are four ring grooves, but the channel below the top ring is called the gas accumulator groove. Under boost, it collects combustion gas leaking past the top ring and helps prevent the equalization of the pressure that lifts the top ring and reduces ring seal.

The rings are JE Pro Seal 1⁄16, 1⁄16, ductile iron with a 3⁄16 standard tension carbon-steel oil ring. It may look like there are four ring grooves, but the channel below the top ring is called the gas accumulator groove. Under boost, it collects combustion gas leaking past the top ring and helps prevent the equalization of the pressure that lifts the top ring and reduces ring seal.

Another advantage to an aftermarket block is bore size. With a standard small-block, you get 4.030 or maybe 4.060 bore at best. Sure, you can go more with a 400 block, but at 1,000 hp, look for cracks that go from the steam holes to the head boltholes. The Little M can go all the way to 4.185 and still have 0.200 inch left in the cylinder wall.

Did You Know?

The cam journals in GM blocks are bored with three different inside diameters so the bearings can be loaded on a stepped tool and installed all at once to speed assembly and reduce cost. Dart bores all the cam journals to the same size so they can line-hone them to a finished dimension. This makes a more precise diameter and ensures true alignment of the journals. It also means all the cam bearings are the same size.

Big Small-Block Piston/Rod Combos

434

9.025 deck height/4.00 stroke

5.70 rod-1.320 piston

5.85 rod-1.170 piston

6.00 rod-1.020 piston

420

9.025 deck height/ 3.875 stroke

5.70-inch rod-1.375 piston

5.85-inch rod-1.225 piston

6.00-inch rod-1.075 piston

Two-Headed Specs

4.155 bore

3.875 stroke

5.850 rod

9.020 deck height

Compression distance: 1.227

-.0055 deck clearance

8.57:1 compression ratio

-31cc inverted dome

68cc combustion chamber volume

Head gasket: 0.061 thickness, 4.200 Bore: 13.9cc volume