The success of this project can be traced directly back to our starting point. Right out of the box, the GMPP LS3 crate motor is an impressive little small-block. Think about how cool it would have been to have an all-aluminum small-block that pumped 492 hp and 484 lb-ft of torque. Now toss in the fact that said small-block would idle with 20-plus inches of vacuum, deliver as much as 25 miles per gallon on the freeway, and run flawlessly for 100,000 miles or more. The modern LS motor is a real thing of beauty and makes for one heck of a starting point for even wilder buildups. We demonstrated this by replacing the factory heads and cam in the LS3 with ported heads from GMPP and a healthy Comp Xtreme Energy hydraulic roller cam. With these simple bolt-ons, the power jumped to 569 hp and 522 lb-ft of torque. The next upgrade came in the form of a 417 stroker assembly from Demon Engines. The additional displacement combined with a FAST LSXR intake improved the output of our LS3 to 608 hp and 570 lb-ft of torque. This was now officially one serious small-block, especially when you remember the all-aluminum construction (less weight is the same as more power).

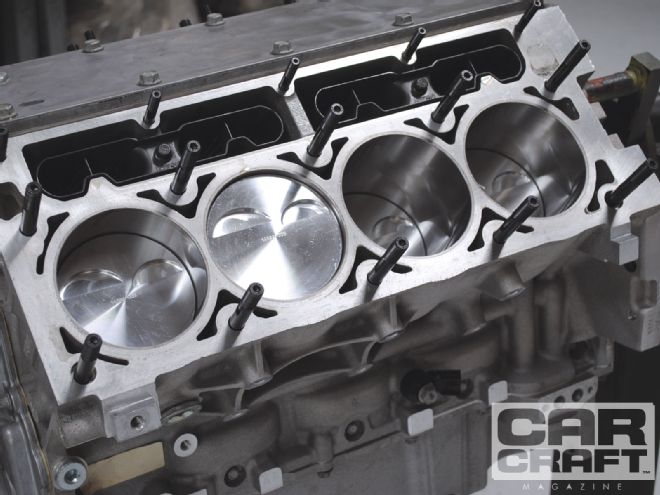

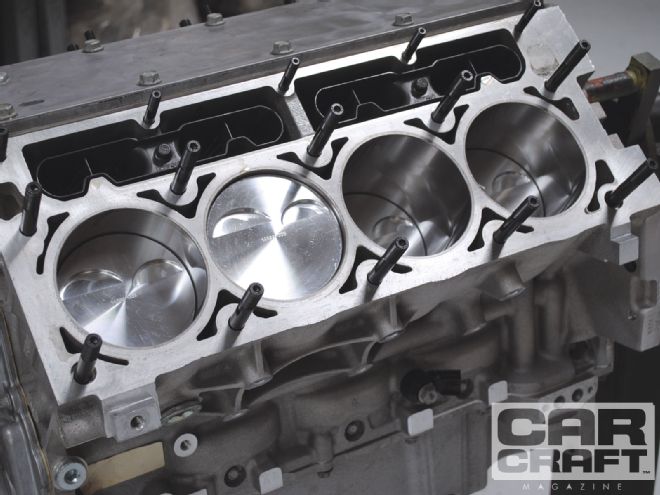

Last month, we equipped the LS3 aluminum block with a 417 stroker kit from Demon Engines. The flat-top pistons produced a static compression ratio of 11.1:1. While perfect for a normally aspirated operation, it was a tad on the high side for a boosted application.

Last month, we equipped the LS3 aluminum block with a 417 stroker kit from Demon Engines. The flat-top pistons produced a static compression ratio of 11.1:1. While perfect for a normally aspirated operation, it was a tad on the high side for a boosted application.

Having performed all the major upgrades on our normally aspirated motor, we were left with only one of two options: nitrous oxide or boost. Not to discount the impressive nature of the former, we chose the latter. There is only one thing better than a modified LS stroker, and that is a modified LS stroker on boost. Luckily for LS enthusiasts, their responsiveness to normally aspirated bolt-ons carries over to blowers and turbos.

You just haven't lived until you've been behind the wheel of a supercharged or turbocharged LS Camaro, GTO, or muscle car. Knowing this, we decided to live a little and subject our very own modified GMPP crate motor to some boost. Rather than go the usual route and run a centrifugal or twin-screw supercharger (that comes next), we opted to test a turbo. We liked the turbo option since the exhaust-driven impeller all but eliminated the parasitic losses associated with driving a supercharger. To the average enthusiast, this means a turbo will offer more horsepower per pound of boost than any other form of forced induction. The trade-off for this efficiency is that the turbo will not offer the same boost response as a positive-displacement blower, but the stroker already had more than enough low-speed power.

Rather than change the pistons, we opted to replace the cylinder heads. Off came the CNC-ported L92 heads from GMPP to make way for an equally impressive set from Procomp.

Rather than change the pistons, we opted to replace the cylinder heads. Off came the CNC-ported L92 heads from GMPP to make way for an equally impressive set from Procomp.

Equipped with flat-top pistons from Probe Racing, our 417 stroker was sporting a compression ratio just a hair more than 11.0:1. A turbo motor can be run at this compression ratio but would require careful attention to the timing curve and/or use of octane booster. Rather than reduce the boost, run octane booster, or lose power from retarded timing, we opted to drop the static compression ratio. Though we were committed to using the flat-top pistons, we found another way to drop the compression on our 417 stroker. The cure came from Procomp Motorsport. Not only did Procomp offer dedicated LS3 head castings in both as-cast and CNC form, but the company also offered a version with dramatically larger combustion chambers. Where the typical LS3 chambers measure 70 cc, the big-chamber, CNC-ported LS3 heads from Procomp featured chambers that checked in at a whopping 81 cc. The 11cc increase in chamber volume dropped the static compression ratio of our LS3 stroker down to 9.9:1 compression-much more boost friendly than the 11.1:1 produced by the GMPP heads. Thanks to a little love rub by the flow experts at Dr. J's Performance, the flow rates offered by the Procomp heads exceeded 360 cfm. The basic difference in performance between the Procomp and GMPP heads would be the drop in static compression.

The big-chamber Procomp LS3 heads were installed using new Fel-Pro MLS head gaskets and ARP heads studs. With the stroker now boost ready, we installed the turbo kit from HP Performance in Roswell, New Mexico. The kit was originally designed for use in a '10 Camaro, but we had to perform a few minor adjustments to tubing position to facilitate installation on the engine dyno. In the end, the turbo kit looked like a cross between the kits offered for the '10 Camaro and a late-model LS-powered Chevy truck. This had no effect on power or performance; it just made our life easier during testing. The intercooled turbo kit featured a Y-pipe designed to channel the exhaust from both sides of the motor to a single turbo mounted adjacent to (and slightly ahead of) the passenger-side cylinder head. The Y-pipe also featured a mount for the 45mm wastegate from Turbo Smart and a (very useful) oxygen sensor bung. Like the remainder of the kit, the Y-pipe was treated with a thermal barrier coating and featured V-band clamps to secure together sections of tubing for a leak-free seal. The Y-pipe was designed to bolt to the factory LS3 exhaust manifolds, but we employed a set of shorty headers from JBA. Also coated, the JBA headers looked right at home and obviously offered improved flow over the factory manifolds. Mounted to the Y-pipe using a T4 flange was a custom 67mm HPQ turbo from Precision Turbo. Capable of supporting 750 hp, the 67mm turbo featured Precision's unique, CEA (Competition Engineered Aerodynamics) forged-aluminum compressor wheel. The impressive turbo from Precision offered exceptional boost response. We employed a manual boost controlled from Turbo XS to regulate the boost beyond the wastegate spring setting.

Once again, we ran the FAST LSXR intake along with the 102mm Big Mouth throttle-body. Note also the FAST fuel rail and 60-pound injectors. The factory intake and fuel rail are cost-saving options here.

Once again, we ran the FAST LSXR intake along with the 102mm Big Mouth throttle-body. Note also the FAST fuel rail and 60-pound injectors. The factory intake and fuel rail are cost-saving options here.

Bolting on the turbo system was no more difficult than a typical header swap, but we made sure to drill and weld a fitting onto the steel Moroso oil pan to serve as an oil drain prior to installation. We ran a section of braided line equipped with -10 fittings from the oil drain on the bottom of the turbo to the oil pan. The oil feed for the turbo came from the fitting located just below the oil filter. The ultraefficient air-to-air intercooler was plumbed in line between the turbo and FAST LSXR intake. A dedicated fan was used to supply cool air to the intercooler during testing. Knowing the turbo kit offered plenty of potential, we installed a set of 60-pound injectors. The stock 42-pounders were obviously inadequate for our turbocharged stroker application. As we would soon find out, so were the 60-pounders. The idea was to run the small 67mm turbo on pump gas, then switch over to the larger 80mm turbo and run race fuel to see some big power numbers. Prior to running the motor under boost, we tuned the combination with the Procomp heads to see just how much power the drop in compression was worth. It lowered the peak power numbers from 608 hp and 570 lb-ft to 577 hp and 551 lb-ft of torque. These numbers were close to the general rule of 3 to 4 percent drop per point of compression.

The LS3 turbo kit from HP Performance was actually a mixture of systems for the '10 Camaro and a late-model, LS-powered truck. For dyno fitment, we employed a few sections of tubing from each kit, but none of the minor changes affected the power output.

The LS3 turbo kit from HP Performance was actually a mixture of systems for the '10 Camaro and a late-model, LS-powered truck. For dyno fitment, we employed a few sections of tubing from each kit, but none of the minor changes affected the power output.

With our 417 now ready for boost, we installed the turbo kit and proceeded to tune the combination at various boost levels. Using the manual wastegate controller (basically a bleed valve that tricks the wastegate into staying closed until a higher boost level is reached), we started out near 6 psi of boost. What was obvious from the first run was that the 67mm turbo was a tad on the small side of this application. Truth be told, we agreed to test this small turbo on our stroker to determine the maximum power it would support. Turns out that at 6.5 psi, the 417 produced 766 hp and 815 lb-ft of torque. The 67mm turbo was obviously a bit small for this powerful stroker, as the boost rose to a peak of nearly 9 psi then fell off rapidly. The response was impressive, but the 67mm turbo is more at home on a stock LS3 (or modified 5.3L or 5.7L). Despite the smallish turbo, the kit offered gains that exceeded 200 hp and 250 lb-ft of torque. This should give you and idea of how impressive turbo kits are on LS motors. Simply bolting on the turbo system improved the power output of the modified LS motor more than the heads, cam, and stroker kit combined. Such is the beauty of exhaust-driven forced induction, as it is entirely possible to more than double the power output of your motor, assuming all systems are capable of supporting the revised power level.

The small turbo worked well, but we had our eye on the larger 80mm Precision Turbo. After a cool-down period, we replaced the small turbo with its larger cousin. Now things were starting to get going. We were happy to have the control offered by the Turbo Smart wastegate, as the engine dyno seems to artificially load the motor and create boost control problems. The Turbo Smart wastegate kept things under control and allowed us to dial in the desired boost level. As expected, the larger 80mm turbo offered slightly less response than the smaller 67mm, but boy howdy did it make power. The 417 easily eclipsed the 900hp mark, but unfortunately, we were not able to break the magical 1,000hp barrier. The turbo kit and turbo itself were more than capable, but our 60-pound injectors called it quits at 913 hp at 12 psi. With no larger injectors at our disposal, we were forced to call it a day and officially put an end to the engine dyno portion of our LS3 upgrade series. Look for the LS3 stroker to be installed in the engine bay and run in a future issue, but know that the combination of inches and boost makes for one serious small-block.

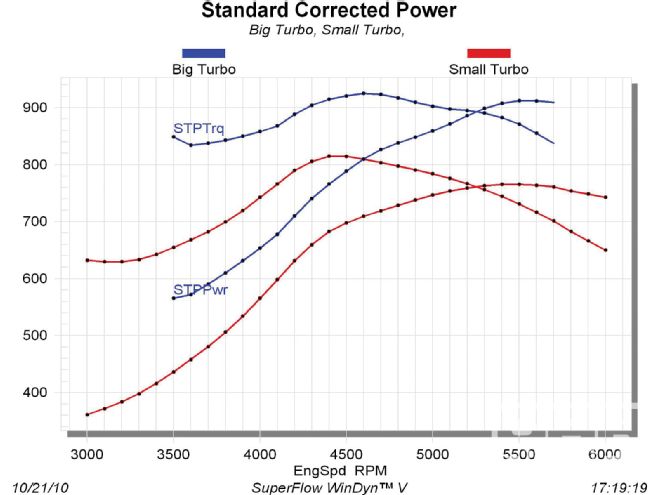

This graph illustrates two important aspects of the turbo kit: Turbos offer huge power gains, and the 67mm was (as indicated by the guys at HP and Precision Turbo) indeed too small for this application. Sized for a stock LS application, it managed to produce 766 hp and a whopping 815 lb-ft of torque. But, it is evident from the shape of the curve that the flow rate was falling off at the top of the rev range, as both boost and power production fell past 5,500 rpm. If you are looking to make 750 hp, this is a good turbo, but if you need more, you'd better step up to something larger.

The larger 80mm Precision turbo, made more than 900 hp, but we ran into another limiting factor. Despite increasing the static fuel pressure, our 60-pound injectors were no match for the demand, and we were forced to stop at 913 hp and 925 lb-ft of torque. The turbo and accompanying kit were clearly capable of supporting more than 1,000 hp, but we'd need larger injectors (75-pounders) to do so. Keeping the tune conservative, we were able to run roughly 12 psi of boost to reach the goal of 900 hp.