The performance and racing fuel-hose market is on the verge of its biggest transformation in the last 50 years. Ever since the '60s, when aircraft-derived, rubber-core, stainless steel-braided hose and the familiar red-and-blue aluminum fittings began to replace parts store black rubber hose and worm-drive clamps as the performance and racing fuel hose of choice, the hot rod fuel-hose market has been relatively stable. True, the hose and fittings have evolved incrementally, with different manufacturers featuring their own pet design innovations, but until recently, the basic appearance and system functionality have stayed pretty much the same. And now that's become a problem: Similar to the flat-tappet cam failure problem HOT ROD reported on a few years back, a perfect storm of diverse factors have combined that under certain conditions may seriously degrade the reliability and safety of traditional rubber-based hose formulations when used over extended time periods.

That old rubber hose, it ain't what it used to be. Today's aggressive fuel additives have greatly shortened the life span of traditional rubber-based hoses.

That old rubber hose, it ain't what it used to be. Today's aggressive fuel additives have greatly shortened the life span of traditional rubber-based hoses.

Developed in the early '50s for military aircraft, stainless steel-braided, chlorinated polyethylene (CPE) hose was designed to be reasonably compatible with a wide array of aircraft fluids, with fittings that could be installed using simple handtools. Descendents of it still constitute the mainstream of today's racing hose market, with slight manufacturer-specific compound variations (Aeroquip, for example, calls its CPE compound "AQP").

These Aeroquip Performance hoses represent the traditional hot rod hoses we've always used. From top: AQP-core, stainless braided racing hose with new black or classic red and blue hose ends; budget Socketless, AQP-core, textile-braid racing hose (both the black and blue hoses); and Teflon race hose with steel fittings, durable with a high pressure rating but stiff with a large bend radius.

These Aeroquip Performance hoses represent the traditional hot rod hoses we've always used. From top: AQP-core, stainless braided racing hose with new black or classic red and blue hose ends; budget Socketless, AQP-core, textile-braid racing hose (both the black and blue hoses); and Teflon race hose with steel fittings, durable with a high pressure rating but stiff with a large bend radius.

Even for aircraft, the specific hose compound was always a compromise-so it always degrades over time. For aviation, that's OK because the hose is always replaced after a prescribed interval before any serious harm can occur. But this also means that-even in the heyday of high-octane, leaded gas-CPE-based aircraft-style hose was never ideal for long-term, indefinite, highway use. If until recently it seemed to outperform parts store black hose even on a daily street driver, it was primarily due to high-quality, aerospace-type manufacturing techniques, the stainless braid's higher temperature resistance, and drastically lower operating pressures compared with the original aircraft applications (for example, up to 1,000 psi on an aircraft in the -6 or -8 hose sizes, compared with less than 100 psi even on an automotive fuel-injection application).

Gas Pains

But in the last decade, things started going downhill. Fuel chemistry has changed radically since the original hose was developed to resist high-octane aviation gas and jet fuels. Street gas was reformulated with weird additives and oxygenates. Reformulated gas can have up to 15 percent ethanol, and E85 (about 85 percent ethanol) is common in the Midwest. It's gotten to the point where there's at least 23 different regional street gas blends. The brew can also vary seasonally, and not every state imposes strict quality controls in the first place. Some blends have caused minimal problems, but others-particularly those with ethanol and other abrasive additives-cause drastic rubber compound degradation.

Although not as bad as street gas, many leaded, competition-only gas blends now have aggressive additives, that-while still allowing the blend to pass a sanctioning body's fuel check-are almost as caustic as alcohol fuels.

New-gen, ultralightweight, flexible PTFE (Teflon) hose is now the first choice of top-tier racers. Brown & Miller hoses

currently dominate NASCAR racing and many other pro racing series. Here, its hose was used to plumb a Sprint Car's fuel cell.

New-gen, ultralightweight, flexible PTFE (Teflon) hose is now the first choice of top-tier racers. Brown & Miller hoses

currently dominate NASCAR racing and many other pro racing series. Here, its hose was used to plumb a Sprint Car's fuel cell.

Whether with street or race gas, deterioration is accelerated when the car sits for a length of time. Some experts recommend purging the system, while others caution that the hose may dry rot if it doesn't remain wet. Knowing what to do is a real crapshoot. Definitely don't expect that bulk rubber-core racing hose bought years ago to still be viable even if it has just been sitting in storage. All rubber-based hose has a finite shelf life.

EFI Raises the Bar

Electronic fuel injection systems introduced yet more issues. Compared with carbureted systems, high-volume recirculation fuel injection setups have a serious effect on rubber-core hose due to the much greater amount of surface footage and volumes of fuel passing through them. Fuel returning to the tank on a recirculation-type system gets aerated, souring the gas and accelerating hose degradation because of increased oxidation and leaching of the tube elastomer. Additionally, more heat is transferred into the gas tank by fuel returning from the engine compartment, heating the fuel overall and further accelerating hose degradation. Today's engine compartments are also much hotter-at times approaching 400 degrees F-which impacts underhood hose big time. And fuel injection nozzles are easily clogged by rubber particles breaking loose from hose deteriorating on the inside.

Fuel vapors also permeate through rubber hose. If your car sits in an enclosed garage, that fuel-like smell is partially vapor evaporating through the hose.

Import Contamination

If reformulated fuel weren't bad enough, inferior Chinese hose and fittings have seriously contaminated the supply chain. These hoses and fittings may look like the real McCoy, but the hose compound may be the wrong formulation, the braid may not be correctly bonded or extruded through the rubber, the hose bore may not be concentric (causing eventual leakage or failure at the fittings), and the fittings themselves may be made from inferior alloys or have the wrong heat treat. There's no easy way to tell by looking at the outside. All we can say here is buy name brand parts from a reputable manufacturer or distributor.

Reusable, lightweight, aluminum fittings are becoming available for PTFE hose. These are Bonaco's rendition, which appear very similar to the traditional red-and-blue fittings we have always used. Pricing on smooth-bore, stainless-braid, PTFE hose has come way down.

Reusable, lightweight, aluminum fittings are becoming available for PTFE hose. These are Bonaco's rendition, which appear very similar to the traditional red-and-blue fittings we have always used. Pricing on smooth-bore, stainless-braid, PTFE hose has come way down.

One workaround is to inspect and replace rubber hoses in a timely manner, just like aircraft mechanics have always done. Savvy racers have known this for years, but on the street, the usual approach is to only replace on failure. That's not too big a deal with a generic parts store hose, but it's aggravating when it's a trick hose with expensive fittings. Still, if you are going to continue using CPE- or nitrile-based hoses, proactive maintenance needs to become as routine as an oil or fan belt change. Hose makers we talked to were reluctant to recommend a specific replacement interval, but empirical field experience suggests this may have to be done every 12 to 18 months. The ideal solution would be to just say no to traditional rubber-core hose-assuming there are better hoses available for substitution. Fortunately, modern technology has provided both low- and high-end alternatives.

Budget Solution: J30R9

If you just want reasonable longevity at a modest cost without regard to appearance, the budget, parts store solution is hose meeting SAE standard J30R9 or (just becoming available) the further improved J30R12. Although these hoses can operate at up to 180 psi, what really makes them better than generic parts store hoses are the improved materials they're made from, designed for contact with alcohols, diesel, oxygenate additives, and oxidized gas. Although the outer walls are usually still hydrogenated nitrile butadiene rubber (HNBR) or CPE, internally there's a thin fluoroelastomer, FKM, or Viton core. Collectively, the design also resists cracking caused by sour gas and reduces emissions because fuel can't evaporate through the hose. XRP is said to be working on a braided racing hose conforming to SAE J30R9 that may eventually replace traditional CPE-cored formulations. This would offer significantly improved durability but still keep down the price of race hose. We'll keep you updated on XRP's progress. While J30R9 is better than old-school fuel hose, like any rubber-based hose, it, too, eventually deteriorates. In fact, domestic OE new-car manufacturers have pretty much switched to Teflon-based hoses.

A new player in the lightweight hose market, TechAFX sells the same PTFE-core, stainless-braid hose used on new GM cars, but unlike the General it has both OE-style quick-disconnects and a large variety of field-installable, black-anodized, aluminum hose ends. So far, TechAFX hose is offered in -6 (3/8), -8 (1/2), or -10 (5/8) sizes; hose and hose-end pricing is within 10 percent of stainless/CPE-core hose.

A new player in the lightweight hose market, TechAFX sells the same PTFE-core, stainless-braid hose used on new GM cars, but unlike the General it has both OE-style quick-disconnects and a large variety of field-installable, black-anodized, aluminum hose ends. So far, TechAFX hose is offered in -6 (3/8), -8 (1/2), or -10 (5/8) sizes; hose and hose-end pricing is within 10 percent of stainless/CPE-core hose.

High-Tech

Solution: Teflon

We may call it Teflon, but that's actually DuPont's trade name for polytetrafluorethylene (PTFE), a synthetic fluoropolymer that is stable at very low and high temperatures and chemically inert to everything except acid. PTFE hose is so durable that, absent crash damage and assuming proper installation practices, it should outlast the life of the car.

About the same time the aerospace industry developed medium-pressure, rubber-cored hose, it began PTFE hose development for high-pressure, hydraulic-impulse systems that by the late '50s were pushing 3,000 psi. PTFE hose eventually found its way into racing applications, primarily for brakes, hydraulic clutches, and power steering systems. Originally, PTFE was much costlier than CPE. It was also very stiff, with a bend radius at least twice that of CPE-based stainless braided hose. The available mild steel or stainless steel PTFE-compatible hose ends were heavy and bulky in the larger dash sizes typically used for fuel systems, with only a limited selection of elbow angles available. More recently, Earl's, Goodridge, TechAFX, and others introduced a wider variety of fittings in aluminum, but that still didn't solve the bend radius or cost problems.

These Orme Brothers hoses illustrate today's wide variety of hose choices. From bottom: Stiff, high-pressure PTFE hydraulic hose; Brown & Miller flexible, lightweight, convoluted PTFE hose with black polymer braid, green/blue fire-retardant Nomex braid, or (in two different sizes) black/blue polyester cover; and XRP flexible PTFE dark gray/yellow Kevlar that's uniquely smooth on the inside but convoluted on the outside. Swivel-after-assembly elbow (arrow) eases double-elbow installations.

These Orme Brothers hoses illustrate today's wide variety of hose choices. From bottom: Stiff, high-pressure PTFE hydraulic hose; Brown & Miller flexible, lightweight, convoluted PTFE hose with black polymer braid, green/blue fire-retardant Nomex braid, or (in two different sizes) black/blue polyester cover; and XRP flexible PTFE dark gray/yellow Kevlar that's uniquely smooth on the inside but convoluted on the outside. Swivel-after-assembly elbow (arrow) eases double-elbow installations.

The picture started changing once the OEMs started to use PTFE-based hose for fuel systems. Original extreme high-pressure PTFE hose was way overkill for even an EFI system, so the new PTFE fuel hose developed at OEM instigation traded off unnecessary extreme high-pressure capability for a tighter bend radius-some high-end versions have less than half the radius of even traditional stainless braided CPE racing hose.

Professional racers then did the OEs one better, adding extreme light weight to their list of desired hose attributes. A stainless outer braid may have been a lightweight answer in the context of the '60s, but polyester, synthetic polymer, Kevlar, and other exotic new materials can save even more weight while still providing adequate abrasion protection and (with Kevlar) high-heat resistance on a par with stainless steel. Pioneers in the racing market such as Brown & Miller, Goodridge, XRP, and Earl's have also introduced ultralight PTFE hose that's now a must-have item for high-end racers. Meanwhile, Aeroquip says it has several programs in the works to address this emerging market; expect to see some new hose designs later this year.

Depending on the specific exotic-outside-braid material used, ultralight, exotic-braid, PTFE hose may be anywhere from 3 to 15 times the cost of traditional CPE-based hose. But thanks to the big OE production volume, the cost of reasonably tight-bend-radius PTFE fuel hose with stainless braid is way down, often within 10 to 20 percent of CPE racing hose if you shop around. There are even some places selling the older, stiff, high-pressure/large-bend-radius PTFE hose for the same or lower price than CPE racing hose. And considering its unlimited life span, PTFE's actual life cycle cost is much cheaper in the long run.

Smooth OR Convoluted?

Today PTFE hose is available in a traditional smooth bore or with a convoluted (ribbed) bore. Depending on the specific manufacturer, the convoluted design may have a slightly tighter bend radius capability than a roughly equivalent smooth-bore hose. You may also soon see a radical new convoluted hose from Goodridge with an extreme bend radius beyond anything yet seen.

Available for both hose and rigid tubing, clamshell-style quick-disconnect couplings like this one from XRP are increasingly popular in the racing world. They snap together with no tools. Even when joining two lengths of rigid tubing, the clamshells offer excellent flexibility with up to 1/4 inch axial adjustment and ±4 degrees of angular misalignment.

Available for both hose and rigid tubing, clamshell-style quick-disconnect couplings like this one from XRP are increasingly popular in the racing world. They snap together with no tools. Even when joining two lengths of rigid tubing, the clamshells offer excellent flexibility with up to 1/4 inch axial adjustment and ±4 degrees of angular misalignment.

Smooth-bore adherents claim that fuel flow is slightly higher compared with convoluted hose, but Brown & Miller's Martin Clark counters that fuel flow in convoluted hoses does not encounter problems until fuel velocity exceeds about 70 gpm (gallons/minute)-that's Top Fuel territory.

Whether smooth or convoluted, PTFE hose intended for use in fuel or oil system applications should have a small amount of carbon impregnated into the tube bore. Low-conductivity liquid fuels such as oil, gasoline, and diesel have the potential to create an electrostatic discharge due to external environmental factors like high temperatures and humidity. Without the carbon to act as a grounding agent, there is the chance of a spark-inducing electrostatic discharge. Carbon-impregnated PTFE hose can be identified by its gray-black internal core instead of the usual pure white found in industrial-grade PTFE hose.

Reusable Fittings

One of the downsides of tight-radius, lightweight PTFE hose was that only swage- or crimp-on fittings were offered at first. That was no problem for OE automakers or high-end race teams, but it is a drawback for the home mechanic living far out of town. Brown & Miller, Goodridge, and others now offer aluminum fittings that you can install at home with simple handtools just like on traditional racing hose, however, for ultimate weight savings, the swage- or crimp-on style is still lighter and more compact. Moreover, most major hose companies and many of their authorized distributors such as Orme Brothers and Bonaco can make complete crimp-on assemblies to spec or per sample. Brown & Miller can also swage PTFE hose directly onto hard line, eliminating union fittings with their extra leak-point potential, or even come up with uniquely bent assemblies to order.

Sixty-percent lighter than stainless-braid/CPE-core hose, Earl's Ultra-Flex 650 hose combines a woven, ultralight, Kevlar braid with smooth-bore PTFE tubing. In -6, it has a 1,180-psi operating pressure, a 0.787-inch bend radius, and a -94-to-500-degree-F temperature range, but so far only crimp-on fittings are offered. HRM

Sixty-percent lighter than stainless-braid/CPE-core hose, Earl's Ultra-Flex 650 hose combines a woven, ultralight, Kevlar braid with smooth-bore PTFE tubing. In -6, it has a 1,180-psi operating pressure, a 0.787-inch bend radius, and a -94-to-500-degree-F temperature range, but so far only crimp-on fittings are offered. HRM

It is this writer's opinion that some PTFE-based hose variation will increasingly become the performance hose of choice for all hydraulic, fuel, and even oil systems. PTFE prices will continue to drop, fitting variations will proliferate as they did with traditional CPE hose, and eventually nearly all of us will use PTFE hose for just about every application from grocery-getters to race cars. Next time your rubber-core hose gives out, why not upgrade to PTFE? It'll be the last hose you ever install.

Hose Durability Test

SAE J30R9 or J30R12 hose may be the most compatible rubber-based hose formulations out there for today's street gas, but they still can't hold a candle to PTFE hose. TechAFX is a business partner with and performance outlet for StanPro/Cooper Standard's engineered PTFE hose assemblies; it asked StanPro to utilize its TS969 ISO-certified lab for comparing the hose compounds' performance using the industry-standard SAE J2260 aging/temperature-soak tests running industry-standard "Fuel C" (a nonexplosive fuel mixed with methanol that safely replicates today's gas).

Ten examples of both J30R9 hose and TechAFX Teflon hose were placed in separate thermal chambers: one set at 40 degrees C (104 degrees F); the other at 60 degrees C (140 degrees F). At specified time intervals, the hoses were removed and pressure-tested to their failure point to document any performance degradation.

As can be seen in the graph, the J30R9 rubber hose saw almost immediate deterioration. The failures occurred first at the hose and fitting mating point, with the failure point dropping almost 160 psi (a 25 percent capability decrease) as the hoses aged. The PTFE hose saw virtually no degradation or performance decrease. There was also about a 10 percent fuel boil-off through the J30R9 hose, and none from the Teflon.

Old Versus New

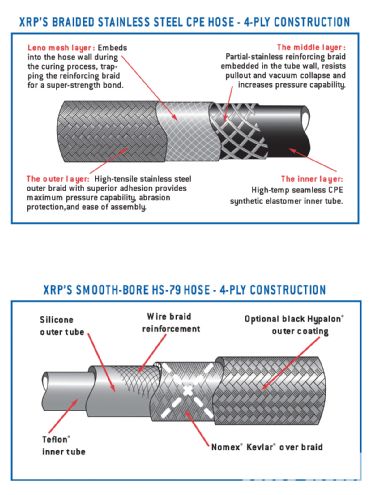

These cutaways show the material differences between CPE-core/stainless-braided racing hose; standard, high-pressure, stiff, stainless steel-braid PTFE hydraulic hose; and examples of new high-end PTFE-core fuel hoses: XRP's HS-79 PTFE-core fuel hose with extra layers of silicone, Nomex/Kevlar, and optional Hypalon outer coating. While the CPE and PTFE hydraulic hoses have higher pressure ratings, for pro fuel system use, the HS-79 outclasses them in every other respect. The figures below are for the -6 (3/8-inch) size.

STAINLESS CPE RACING HOSE

STAINLESS PTFE HYDRAULIC HOSE

HS-79 PTFE WITH OUT HYPALON

HS-79 PTFE WITH HYPALON

Operating temperature

-40° F to 300° F

-100° F to 450° F

-64° F to 400° F

-64° F to 400° F

Max operating pressure

1,500 psi

2,500 psi

600 psi

600 psi

Burst pressure

6,000 psi

12,000 psi

2,400 psi

2,400 psi

Weight/Ft

0.150 lb

0.090

0.074 lb

0.093 lb

Bend radius

2.5 in

4.0 in

0.75 in

0.75 in