Over the years there have been a variety of means used to increase the power produced by a Flathead Ford. It could be something simple, like adding additional carburetion or a better ignition—or more serious modifications, such as a bigger bore or a longer stroke. But of all the time-honored improvements made to a Flathead the most obvious was the addition of finned aluminum heads. Thanks again to the Herman’s at H&H Flatheads who made it possible to show intake manifolds in Flathead Fundamentals Part I. This time we’re looking at the contemporary crop of aluminum heads.

Aluminum heads not only look good, there are performance advantages as well. In most cases aluminum heads will raise compression, which helps throttle response. However bumping up the compression on a Flathead is often a case of diminishing returns as it directly impacts how well the engine breathes. With any head used on a Flathead there has to be enough room above the valves to allow them to open fully, and there has to be adequate clearance above the piston to avoid a collision if there is any carbon buildup, so the area between the valves and the cylinders is often made smaller to increase compression. Referred to as the transfer area the intake mixture and the exhaust gases have to flow through this restricted spot so breathing can be adversely impacted if it is made too small in an attempt to increase compression beyond a reasonable point. What it boils down to is this is too much compression results in a Flathead that has good power at low rpm but can’t breathe at higher engine speeds.

Any discussion on heads for a Flathead has to include the modifications that often accompany the installation of aluminum heads—porting, polishing, and relieving. Just like the heads on an OHV engine, porting a Flathead block involves modifying the intake and exhaust passages to improve airflow, meaning the intake runners have been blended, all the sharp corners have been rounded, and the valve pockets have been smoothed as well. On the exhaust side, the ports are smoothed as far up into the block as possible, and the edges of the end outlets are often rounded, or in some cases moved toward the ends of the block. While porting can provide a substantial increase in airflow, polishing the ports to the point they shine is an old-school modification that is not as effective as once thought.

Relieving a Flathead, which is the process of removing material from the block between the valves and the cylinder for better breathing, is a subject unto itself. Among Flathead builders there is considerable debate concerning the shape and depth of the relief and even if relieving should be done at all. As relieving does remove material from the combustion chamber, the compression ratio will be lowered. However, the amount of material removed is so slight the typical relief will lower compression less than half a point. Many head manufacturers offer compression ratio charts that take into consideration bore, stroke, and the depth of any relief.

In the opinion of some engine builders relieving a Flathead block is not necessary, then to further complicate things there were truck blocks that had a mild relief from the factory. The reasons commonly given for that include reduced compression, increased performance, and less likelihood of the block cracking, and while no one knows for sure why Ford did it we lean toward the reduced cracking theory.

Along with the other heads H&H offers for Flathead Fords is the Navarro High Dome design. By using a piston with a tall, Chrysler Hemi–style dome an adequate transfer area between the valves and the cylinders can be maintained at higher compression ratios.

When installing aluminum heads there are a number of considerations; certainly compression ratio is one, another is valve clearance (some manufactures will supply the amount of valve lift their heads will accommodate, but it’s always a good idea to verify clearances with clay). Due to their additional thickness aluminum heads will often require longer reach spark plugs (be aware plugs that extend too far may make contact with the exhaust valve at maximum lift). And finally, longer studs or cap screws will be needed, along with hardened washers.

Aluminum heads can enhance the performance of a Flathead Ford by increasing compression, they dissipate heat better than their cast-iron counterparts, and many aftermarket versions are designed to circulate coolant more effectively. And of course when it comes to cool let’s not forget how they look—nothing is cooler than a Flathead with a row of carburetors and aluminum heads. That’s just fundamental hot rodding.

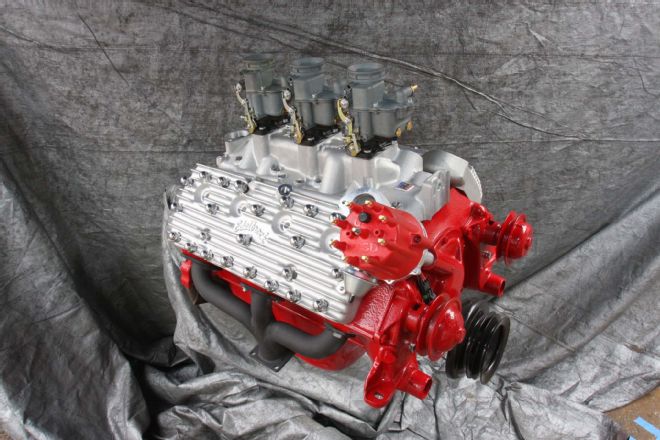

The classic 24-stud 59A Ford Flathead with a trio of Stromberg 97s and aluminum heads. In this case the manifold and heads are Sharp from H&H.

The classic 24-stud 59A Ford Flathead with a trio of Stromberg 97s and aluminum heads. In this case the manifold and heads are Sharp from H&H.

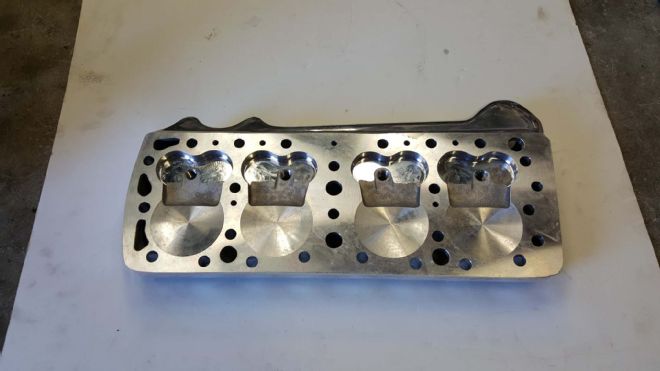

Although it’s hard to see in this photo, to improve breathing the Sharp head has stepped portions above the exhaust valve and around the area of the spark plug that extends further into the cylinder than on the intake side (from left to right valve layout is E-I-I-E-E-I-I-E).

Although it’s hard to see in this photo, to improve breathing the Sharp head has stepped portions above the exhaust valve and around the area of the spark plug that extends further into the cylinder than on the intake side (from left to right valve layout is E-I-I-E-E-I-I-E).

This 8BA has been equipped with Navarro heads. Note the heater hose/temp gauge boss have not been drilled and tapped.

This 8BA has been equipped with Navarro heads. Note the heater hose/temp gauge boss have not been drilled and tapped.

The heater/temperature bosses in the Offenhauser 8BA heads come drilled and tapped—harder to detect is these heads have one less row of fins than the Navarro.

The heater/temperature bosses in the Offenhauser 8BA heads come drilled and tapped—harder to detect is these heads have one less row of fins than the Navarro.

Here is the stock, unrelieved deck of a 59A Flathead.

Here is the stock, unrelieved deck of a 59A Flathead.

Here a head gasket is being used to mark the area to be ground.

Here a head gasket is being used to mark the area to be ground.

The completed relief will help breathing and has little effect on the final compression ratio.

The completed relief will help breathing and has little effect on the final compression ratio.

Porting is another worthwhile Flathead modification. It’s best not to get too carried away, as some areas of the casting are thin.

Porting is another worthwhile Flathead modification. It’s best not to get too carried away, as some areas of the casting are thin.

This 59A has been equipped with Navarro blower heads with 75cc combustion chambers.

This 59A has been equipped with Navarro blower heads with 75cc combustion chambers.

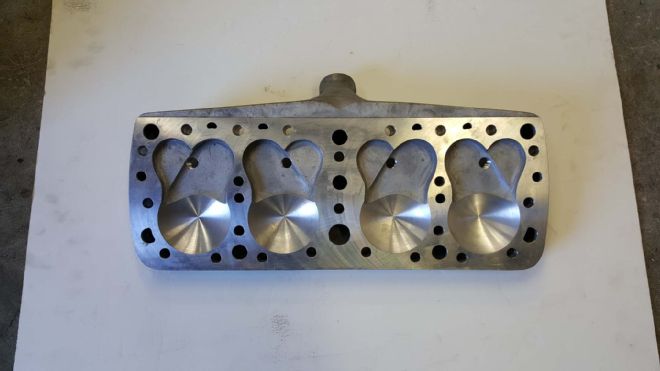

The Navarro heads 75cc head from the combustion chamber side.

The Navarro heads 75cc head from the combustion chamber side.

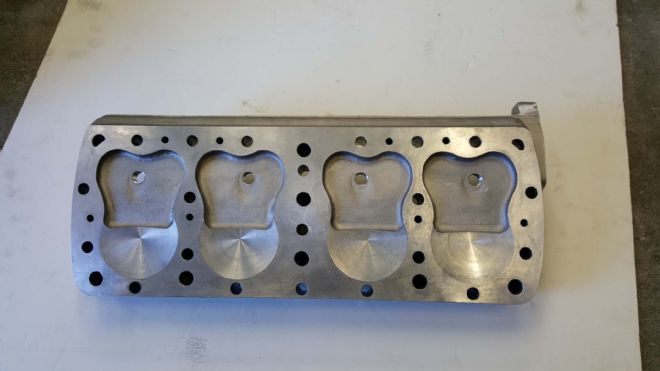

While the Sharp blower head looks similar to the Navarro, note the difference above the top row of head stud holes. It also has 75cc chambers.

While the Sharp blower head looks similar to the Navarro, note the difference above the top row of head stud holes. It also has 75cc chambers.

An 8BA with Edelbrock heads, intake, and carbs. Ignition is from MSD.

An 8BA with Edelbrock heads, intake, and carbs. Ignition is from MSD.

Note the depth of the valve pockets in this Edelbrock head to accommodate high lift cams.

Note the depth of the valve pockets in this Edelbrock head to accommodate high lift cams.

The early 21-stud crowd can use these Sharp heads for 1932-36 Flatheads.

The early 21-stud crowd can use these Sharp heads for 1932-36 Flatheads.

This is the combustion chamber side of the Sharp 1932-36 head. Note that most heads located the spark plug closer to the exhaust valve than the intake.

This is the combustion chamber side of the Sharp 1932-36 head. Note that most heads located the spark plug closer to the exhaust valve than the intake.

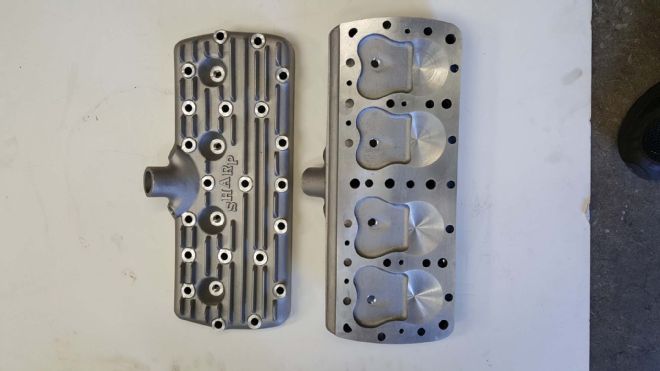

Shown here are both sides of Sharp’s 21-stud heads for 1937-38 engines. Note the center three holes in a 21-stud engine are in a vertical row.

Shown here are both sides of Sharp’s 21-stud heads for 1937-38 engines. Note the center three holes in a 21-stud engine are in a vertical row.

Compare the 59A (top) and an 8BA head. Note the differences in the water passages in the center and upper corners.

Compare the 59A (top) and an 8BA head. Note the differences in the water passages in the center and upper corners.

The unique Navarro High Dome heads has a pad over the exhaust valve to maintain compression, and a relief over the intake to allow for larger intake valves with lots of lift. The area over the piston accommodates a piston with a Chrysler Hemi–style dome.

The unique Navarro High Dome heads has a pad over the exhaust valve to maintain compression, and a relief over the intake to allow for larger intake valves with lots of lift. The area over the piston accommodates a piston with a Chrysler Hemi–style dome.

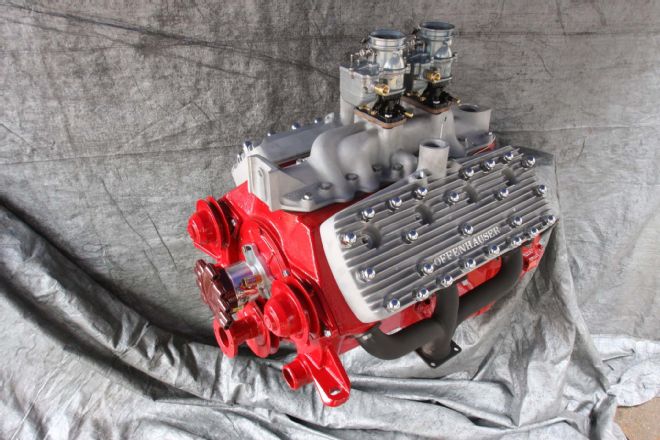

Offenhauser heads on a 59A engine. Note there are only two studs in vertical alignment in the center of a 24-stud head.

Offenhauser heads on a 59A engine. Note there are only two studs in vertical alignment in the center of a 24-stud head.

Fans of the V-12 haven’t been forgotten, H&H has aluminum heads for those too.

Fans of the V-12 haven’t been forgotten, H&H has aluminum heads for those too.

Mike Herman of H&H practices what he preaches; this 8BA is in his Model A. It uses a McCulloch supercharger, four-barrel intake, vintage Mallory distributor, and Navarro heads.

Mike Herman of H&H practices what he preaches; this 8BA is in his Model A. It uses a McCulloch supercharger, four-barrel intake, vintage Mallory distributor, and Navarro heads.