Ahh, this is way better. If you read our "Rehashed Hemi" story last month, you endured whining about how only 599 hp and 578 lb-ft from our Hemi just wasn't that great. Now our whimpering is vindicated. In this story we'll kick the torque curve in the shorts, gaining 200 lb-ft at 3,600 rpm compared with the original setup. OK, so it was really an improvement of 192 lb-ft, but it's so stupidly better that who's gonna argue? It's like tossing in more than an extra Toyota Matrix engine, but the resulting acceleration will be purely intentional.

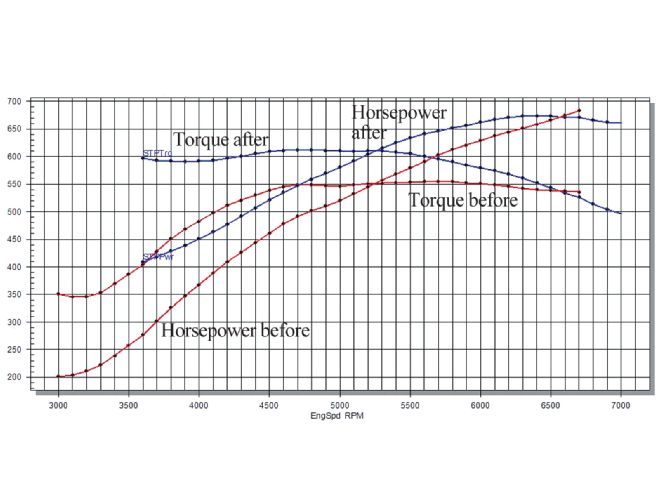

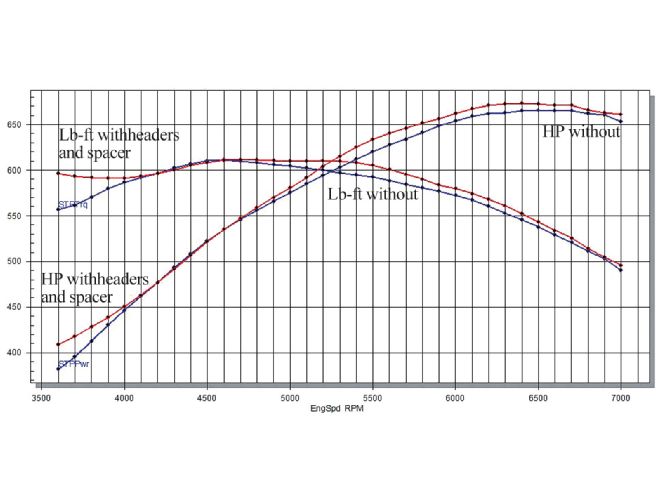

This you have to see! The red lines represent how the Hemi performed straight out of the car, and the far superior blue lines show the horsepower and torque after all our work this month with a new Comp cam, smaller headers, and a four-hole carb spacer on the dual-plane intake. We made massive improvements at every point below 6,600 rpm.

This you have to see! The red lines represent how the Hemi performed straight out of the car, and the far superior blue lines show the horsepower and torque after all our work this month with a new Comp cam, smaller headers, and a four-hole carb spacer on the dual-plane intake. We made massive improvements at every point below 6,600 rpm.

The Backgrounder

If you're late to the story, here's a recap. In 1996, HOT ROD covered the buildup of a 484ci, 10.25:1-compression, pump-gas Hemi at Dick Landy Industries, and that engine was stuffed into the Rumble Bee, a '70 Dodge Super Bee project car. The Hemi made 751 hp at 7,600 rpm and 573 lb-ft at 5,800 rpm on the dyno at DLI, and the car ran 10.60s at 128 mph. That was borderline impressive at the time, but it took 5.13 rear gears and a ludicrous-stall converter to get there. The car was useless on the street, and we abandoned the Super Bee outright, letting it rot for 11 years until we unearthed it for the July '10 cover story.

Then, in last month's issue, we strapped the old Hemi to the dyno at Westech Performance, verified the Landy power numbers (which were down a bit from what was reported in 1996), and proceeded to tame the engine for streetability. That involved an old Crane solid roller cam that we considered weak sauce. We also fiddled with intake manifolds and waffled about whether we should give up a little low end in order to use a Stage V Engineering dual-quad intake for appearance' sake or if we should stick with the engine's original Landy-modified Mopar M1 dual-plane.

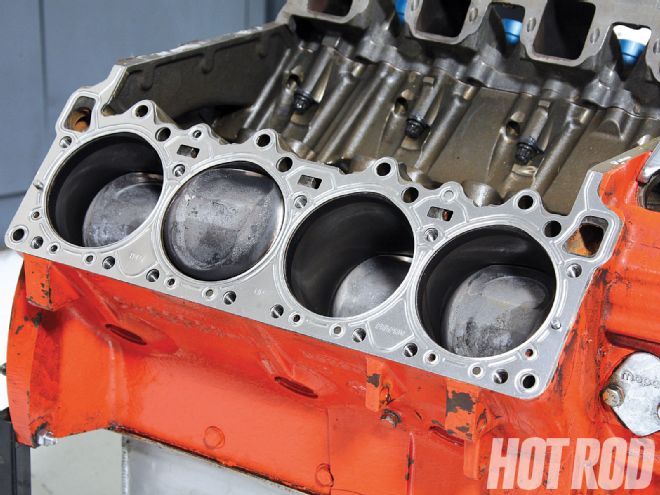

When the timing chain broke last month, six intake valves hit pistons. Actually, they just grazed them, knocking off the carbon and not even dinging aluminum. Dave Akard at Burbank Speed & Machine rescued our high-dollar titanium intake valves with just a touch-up, and he also lapped the exhaust valves.

When the timing chain broke last month, six intake valves hit pistons. Actually, they just grazed them, knocking off the carbon and not even dinging aluminum. Dave Akard at Burbank Speed & Machine rescued our high-dollar titanium intake valves with just a touch-up, and he also lapped the exhaust valves.

It was good fortune that the Hemi's timing chain broke near the end of our dyno session, forcing us to fix it and answer our own questions. Here in round two we'll make power we're not embarrassed about and walk away happy.

The Fix Is In

A cam swap led to instant gratification. This engine delivered the most dramatic example we've seen of cams too big, too small, and just right. The baseline for the tests below includes an M1 single-plane intake and cylinder heads hogged to absurd levels by Mike Landy, a Dominator carb, 2 1/4-inch headers, and MSD ignition with Champion C63YC plugs. We ran it on Rockett Brand 100-octane unleaded.

Too big: The original solid roller was a Crane custom grind with 262/274 at 0.050 tappet lift, 0.650/0.659-inch lift, 0.030/0.030 lash, and a lobe-separation angle of 112 degrees. It called for spring pressures of 620 pounds, which is a lifter killer. Not that you'd ever want to drive the thing with its 7,600-rpm power peak, anyway. The cam was ratty to 5,000 rpm and the torque curve was gutless. On Westech's dyno it made 558 lb-ft at 5,600 rpm. We never made it to peak horsepower due to valve float at 7,000 rpm, but we dead-reckoned it to 720-730 hp at 7,600.

We reassembled the Hemi using Fel-Pro PN Z1145 head gaskets, the same kind Landy used 15 years ago. They are steel shims with a compressed thickness of 0.021 inch and a bore diameter of 4.365 inches; they are available from SummitRacing.com for $31.95 each. Fel-Pro gaskets were also used for the remainder of the reassembly, as were ARP head studs and other fasteners. On a Hemi, the studs can't be threaded into the deck until the heads are set in place (thanks to the studs that extend down into the lifter valley at a

different angle).

We reassembled the Hemi using Fel-Pro PN Z1145 head gaskets, the same kind Landy used 15 years ago. They are steel shims with a compressed thickness of 0.021 inch and a bore diameter of 4.365 inches; they are available from SummitRacing.com for $31.95 each. Fel-Pro gaskets were also used for the remainder of the reassembly, as were ARP head studs and other fasteners. On a Hemi, the studs can't be threaded into the deck until the heads are set in place (thanks to the studs that extend down into the lifter valley at a

different angle).

Too small: In last month's story we installed another old Crane solid roller cam, this one 248/254 at 0.050 with 0.568/ 0.568 lift, 0.020/0.020 lash, and an LSA of 112 degrees. Performance was subaverage considering the rest of the hardware on the engine: 599 hp at 6,000 rpm and 578 lb-ft at 4,600. The streetability improved significantly.

Just right: We decided that our half-hearted torque curve could be improved with a modern camshaft with improved ramp rates and more lift, and we considered narrowing the lobe-separation angle a bit because we could stand a choppier idle. We also thought we could live with another 10 degrees of duration. Those statements, along with some engine specs, were fed to Comp Cams' head lobe designer Billy Godbold, who thought about the direction we were headed and selected specific lobe numbers that would survive on the street. He also suggested grinding the cam 4 degrees advanced, mostly because that would close the intake valve sooner for this low-compression engine. Here are the final numbers: 252/258 at 0.050, 0.664/ 0.626 lift, 0.016/0.018 lash, and an LSA of 108 degrees.

Our new valvesprings for use with the Comp 252/256-at-0.050 solid roller cam are Comp Cams PN 935-16. Installed at 1.900 inches, they have a seat pressure of 190 pounds and an open pressure of 480. That makes them fairly friendly to the Comp Elite race solid roller lifters, which feature pressurized oiling to the roller axles. These retainers are Comp's lightweight steel units-lighter than regular steel, and heavier but cheaper and more durable than titanium.

Our new valvesprings for use with the Comp 252/256-at-0.050 solid roller cam are Comp Cams PN 935-16. Installed at 1.900 inches, they have a seat pressure of 190 pounds and an open pressure of 480. That makes them fairly friendly to the Comp Elite race solid roller lifters, which feature pressurized oiling to the roller axles. These retainers are Comp's lightweight steel units-lighter than regular steel, and heavier but cheaper and more durable than titanium.

Billy nailed it. With no other changes to the engine, the modern Comp Cams unit delivered a stunning improvement, gaining torque and horsepower everywhere and making a more surprising improvement than we've ever seen in our years of cam testing. Compared with the smaller, 248/254 cam, the Comp 252/258 made 33 more lb-ft at both cams' peak of 4,600 rpm. The Comp made 66 more hp at a higher peak of 6,600 rpm-but even at the smaller cam's 6,000-rpm peak, the Comp grind was ahead by 55 numbers. The improvement was so ludicrous that you really can't grasp it without checking out the graphs above. They blew us away.

But how did Comp do it? Looking at the valve timing events at 0.050 tappet lift reveals that the Landy cam was just too nasty for a 10.25:1 engine, with the intake closing late at 59 degrees ABDC (with the piston on the way up during the compression stroke). Though the exhaust opening event is not as critical, it was at 72 degrees BBDC (with the piston moving down on the power stroke), which seems early, and it may explain why we've always commented that this engine was unusually loud.

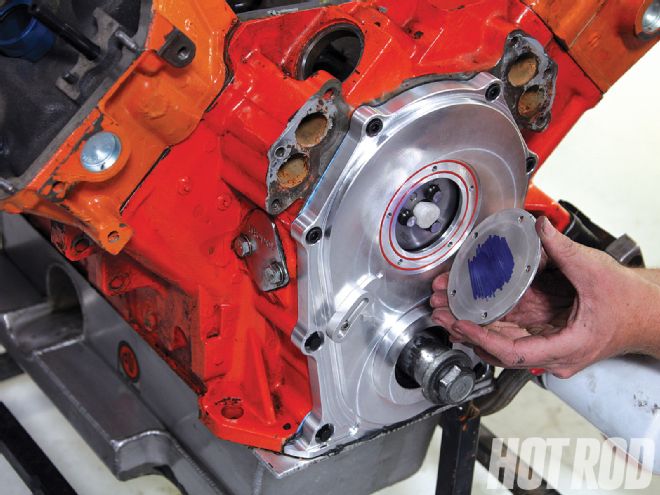

After breaking a timing chain last month, we didn't mess around, going straight to Comp's billet, nonadjustable timing set. It's hidden by a billet cover from Cleveland Speed and Machine, which sells these in black, clear, or natural on eBayMotors.com for $299.99. The removable cover helped us set the cam endplay quickly, though the ARP cam bolts had to be ground down to clear the cover. We liked the adjustable timing pointer.

After breaking a timing chain last month, we didn't mess around, going straight to Comp's billet, nonadjustable timing set. It's hidden by a billet cover from Cleveland Speed and Machine, which sells these in black, clear, or natural on eBayMotors.com for $299.99. The removable cover helped us set the cam endplay quickly, though the ARP cam bolts had to be ground down to clear the cover. We liked the adjustable timing pointer.

The small Crane and the new Comp cam opened the intake at the same time: 50 degrees ABDC. However, the Comp grind had the advantage of a faster ramp rate and an improvement of 0.096/ 0.060-inch effective lift. Typically, the extra 6 degrees of intake duration would shift the power peaks to a slightly higher rpm, hurting low end and gaining top-end rpm, but in this case, the overall design was so superior that it proved to be the just-right cam.

Proof of the efficiency came in a review of the Brake Specific Fuel Consumption (BSFC), a measurement of pounds of fuel used per horsepower per hour, an indicator of how effectively an engine processes gasoline into power. At peak torque, the Landy cam's BSFC was 0.502, the smaller Crane was 0.472, and the new Comp grind delivered the most efficient 0.464.

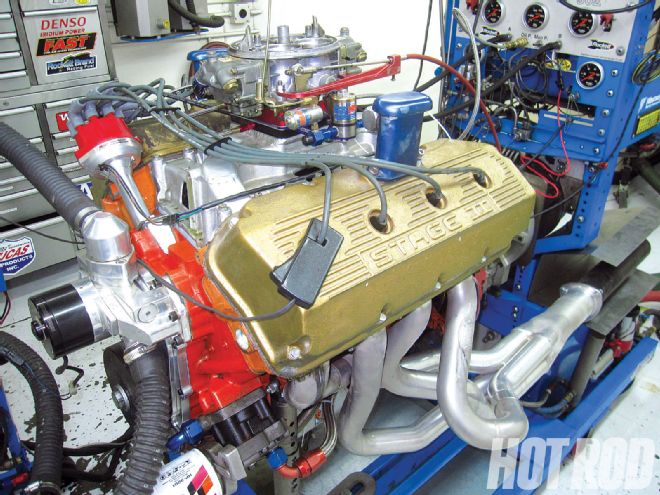

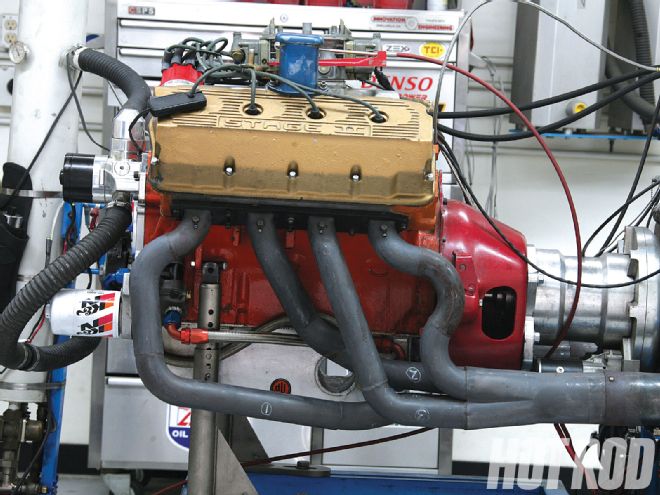

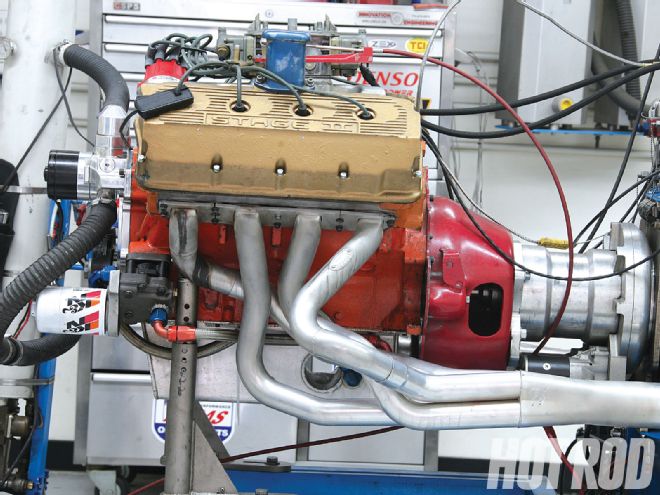

Yeah, our Hemi is wearing different valve covers than in last month's story. We left our chrome ones at home and borrowed these gems from Westech's Rick Stoner. We have some spiffing to do before this lump goes back in the car.

Yeah, our Hemi is wearing different valve covers than in last month's story. We left our chrome ones at home and borrowed these gems from Westech's Rick Stoner. We have some spiffing to do before this lump goes back in the car.

There's also Brake Mean Effective Pressure (BMEP), which is the average amount of pressure in psi that must be exerted on the piston to create the measured horsepower. This indicates how effective the engine is at packing in the air/fuel mixture, compressing it, and getting the most power out of it. The higher the number the better. At peak torque, the Landy cam had a BMEP of 169, the smaller Crane was better at 177, and the Comp was best at 188. Getting into the 180s makes a nice pump-gas engine.

Oh! We never told you the new peak power numbers. With the Comp cam, we had 611 lb-ft at 4,600 rpm and 665 hp at 6,500 rpm, and it didn't roll over until 7,000. If you want the same custom Comp solid roller, three-bolt Hemi cam that we used, order CRH 12526R/2978R-108+4.

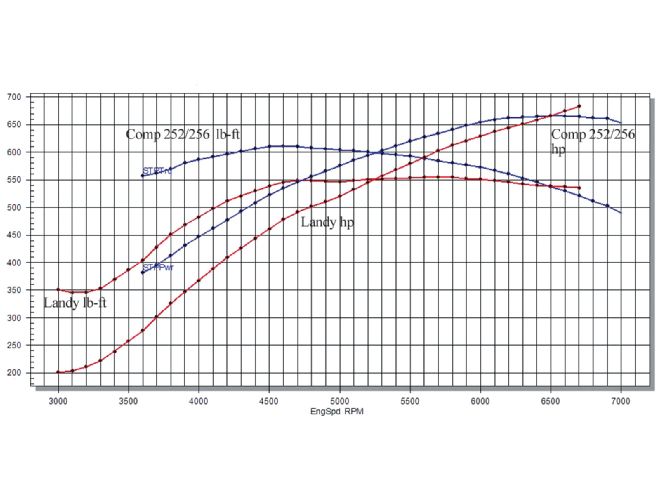

Here's the tale of the Dick Landy custom 262/276 cam (red lines) versus our new Comp Cams 252/256 'stick (blue lines). Yeah, that's a gain of more than 150 lb-ft at 3,600 rpm from a cam swap alone. The smaller, more modern Comp cam made more power all the way up to 6,500 rpm.

Here's the tale of the Dick Landy custom 262/276 cam (red lines) versus our new Comp Cams 252/256 'stick (blue lines). Yeah, that's a gain of more than 150 lb-ft at 3,600 rpm from a cam swap alone. The smaller, more modern Comp cam made more power all the way up to 6,500 rpm.

Headers We hoped to earn even more street power, and exchanged the Super Bee's custom 2 1/4-inch headers with 4-inch collectors for some Hooker 2 1/8-inch units with 3 1/2-inch collectors, and with tubes that are longer by 6 to 8 inches. Theory says those changes make more torque, and they did.

The smaller headers lost torque and horsepower by 3-4 numbers from 4,000 rpm on up, but it was worth the trade for the 30-plus lb-ft that we gained at points below 3,700 rpm. We won't use that low-speed power at the dragstrip, but it may show itself on the street. Plus the 21/8-inch tubes are easier to fit in the car.

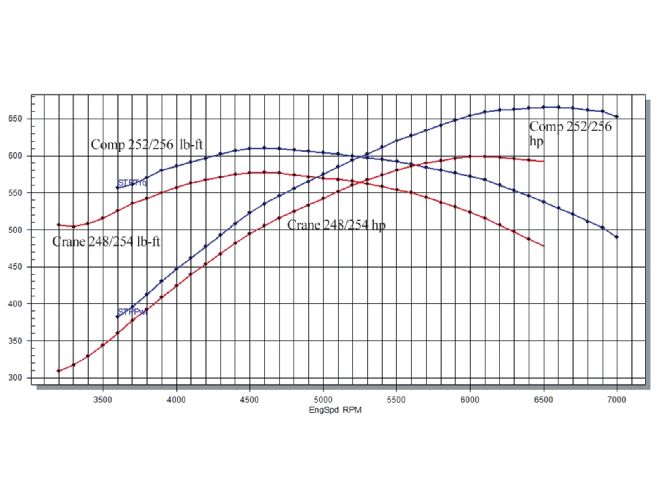

Another cam comparo, this time our new Comp 252/256 custom roller (blue lines) is flaunting its superiority over the old Crane 246/254 roller. The Comp unit showed an impressive spread of 1,900 rpm between peak torque (4,600 rpm) and peak power (6,500 rpm). The ported Hemi heads let the engine run a bit higher than it would with an average wedge and the same cam profile.

Another cam comparo, this time our new Comp 252/256 custom roller (blue lines) is flaunting its superiority over the old Crane 246/254 roller. The Comp unit showed an impressive spread of 1,900 rpm between peak torque (4,600 rpm) and peak power (6,500 rpm). The ported Hemi heads let the engine run a bit higher than it would with an average wedge and the same cam profile.

Carb Spacers

We quested to gain back the few power numbers we'd lost to the bigger headers, and tried a bunch of different carb spacers under the Dominator and atop the ported dual-plane. We tested 1-inch-tall open spacers and even a four-hole stacked on top of an open, but it was the four-hole on its own that delivered the goods. It slightly improved power everywhere in the curve. Looking at average numbers from 3,600 to 7,000 rpm, the Hemi made 575 hp and lb-ft without the spacer and 583 hp and lb-ft with it. (Note: it's only a coincidence that the average horsepower and lb-ft were the same number, especially on two different tests. That's very unusual.) The peak numbers were the best yet: 612 lb-ft at 4,700 rpm and 673 hp at 6,400 rpm.

Dual-Quad Intakes

Eight barrels are just correct; no production 426 ever came with less. That's why we tested two dual-quad intakes, both with a pair of Holley 1850- series, 600-cfm carbs modified with adjustable jet plates and quick-release vacuum pods loaded with the white (lightest) springs.

These shots compare the headers with 2 1/4-inch tubes to the...

These shots compare the headers with 2 1/4-inch tubes to the...

First up was the Stage V Engineering single-plane casting. In last month's test with the smaller Crane cam this intake made more peak horsepower than the Landy dual-plane, and we were trying to decide if we could live with its corresponding reduction in torque. This time the answer was clear: no. On average from 3,600 to 7,000 rpm, the Stage V lost 25 lb-ft and 22 hp compared with the dual-plane and four-hole spacer. The peak numbers with the Stage V were 589 lb-ft at 5,300 rpm and 667 hp at 6,300. That peak horsepower is essentially the same as the dual-plane without the carb spacer, but still down overall.

Next we ran the Mopar Performance PN P451063, which was $575.95 at Summit Racing.com. This intake is a dual-plane with the same height as the factory Street Hemi inline dual-quad, but the carb pads are spread to make room for Holley carbs (with side-hung float bowls) rather than the production Carters. It's a duplicate of the Chrysler Marine unit sold in the '60s and '70s. Too bad it didn't like to party with our Hemi, pulling the peak power numbers down to 584 lb-ft at 5,000 and 638 hp at 6,200.

...2 1/8-inchers that also have more average length and smaller collectors. Both were run with 18-inch collector extensions and no muffs. The smaller headers made notably more power below 4,000 rpm.

...2 1/8-inchers that also have more average length and smaller collectors. Both were run with 18-inch collector extensions and no muffs. The smaller headers made notably more power below 4,000 rpm.

As can be predicted with any dual-plane versus single-plane comparo, the MP two-plane liked the low end and the Stage V one-plane made more top-end. The breakover was 4,900 rpm. If you have a very tame Hemi-like with a power peak under 6,000 rpm, the MP dual-quad is probably a good pick. Anything more radical and the Stage V is the way to go.

Nitrous

When testing headers and carb spacers we sought small gains here and there. Now we'll blow away that subtlety with nitrous. We hosed the Hemi twice: once with the Landy dual-plane and again with the Stage V dual-quad, because we figure that many of you will pick the Stage V for your own project. We jetted the NOS nitrous systems for 175 hp, but both times we made 230-plus. Yeah, the Hemi screamed to 900-plus horsepower and nearly 750 lb-ft. The larger, 21/4-inch headers may have made more power on the spray, but oh well. We have a solution for that: It's called a bigger nitrous jet. Awesome.

Amazingly, this engine was so sensitive to carb spacers that the extra 1/2 inch from the NOS Big Shot plate and gaskets caused it to lose a bit of power compared with the 1-inch, four-hole spacer alone. But the 230hp of nitrous power pretty well covered that up.

Amazingly, this engine was so sensitive to carb spacers that the extra 1/2 inch from the NOS Big Shot plate and gaskets caused it to lose a bit of power compared with the 1-inch, four-hole spacer alone. But the 230hp of nitrous power pretty well covered that up.

Conclusions

We met our goal of taming the Hemi enough to drive it around while still making 673 hp and 612 lb-ft and clarified that the Landy-ported intake was the better pick than the dual-quads. We'll lose the visual appeal of twin carbs, but the hacked/welded/ported M1 is sort of a signature of this particular engine, and it ties into the Landy and Mopar Performance history, so that's pretty cool.

The extra 200ish lb-ft at 3,600 rpm is going to bring the Bee to a new level of mayhem on the street and will let us regear the car and pick a friendlier torque converter. There's a chance that the Super Bee will be as quick at the track as it was with the old combination. And 900 hp on nitrous? We've learned not to predict e.t. numbers before we're holding a timeslip...but do the bench racing yourself and send us a prediction (email hotrod@hotrod.com).

This chart shows the gains we made with the smaller headers and the four-hole carb spacer (red lines) versus the Comp cam alone (blue lines). The torque gain below 4,000 was from smaller headers, and the power pickup above 4,800 was from the carb spacer.

This chart shows the gains we made with the smaller headers and the four-hole carb spacer (red lines) versus the Comp cam alone (blue lines). The torque gain below 4,000 was from smaller headers, and the power pickup above 4,800 was from the carb spacer.

Now we're off to prep the car with new suspension and fuel system parts plus a fresh Strange 60 rearend and a revamped converter. We've got Power Tour(r) between then and now so we probably won't get that stuff done in time for the next issue, but we'll not forsake the Bee again. Watch for it a couple of issues down the road.