The turbocharger, or exhaust-driven centrifugal supercharger, is the world's most efficient power-adder, but it is also the most complex to install. It's been six years since HOT ROD examined turbocharger design, selection, and system setup (see HOT ROD, Dec. '03, Jan. '04, and Feb. '04). In that time the technology has continued to advance to the point that turbos in racing clearly dominate beltdriven superchargers or nitrous oxide. If anything, turbos used in competition have become victims of their own success: Rule makers have been forced to legislate against turbos, adding vehicle weight, reducing engine displacement, restricting the turbo's size or numbers per engine, relegating turbos to a separate class, or even banning them entirely.

Durable midsize Turbonetics Y2K-series turbos support up to 1,200 hp in single apps and more than 2,000 hp in dual configurations. They feature a streamlined ASME compressor inlet, HP high-pressure billet compressor wheels designed for max power over 30 psi, a compressor-side ceramic ball bearing, and a V-band discharge turbine housing.

Durable midsize Turbonetics Y2K-series turbos support up to 1,200 hp in single apps and more than 2,000 hp in dual configurations. They feature a streamlined ASME compressor inlet, HP high-pressure billet compressor wheels designed for max power over 30 psi, a compressor-side ceramic ball bearing, and a V-band discharge turbine housing.

Meanwhile much of the technology previously seen only on high-end racing units has trickled down to the street. New turbo materials and machining practices plus improved packaging are combining to make the turbos more street friendly on the one hand, and even more unbeatable on the racetrack on the other.

Compressors

The compressor, or air-into-engine side of the turbo, is where the most significant performance improvements have occurred. The major change has been the introduction of machined billet aluminum compressor wheels in place of the previous cast wheels. Historically OEMs have utilized billet wheels for selected extreme-duty applications due to their superior fatigue strength, but they've just been cloned versions of the weaker cast wheels they replaced.

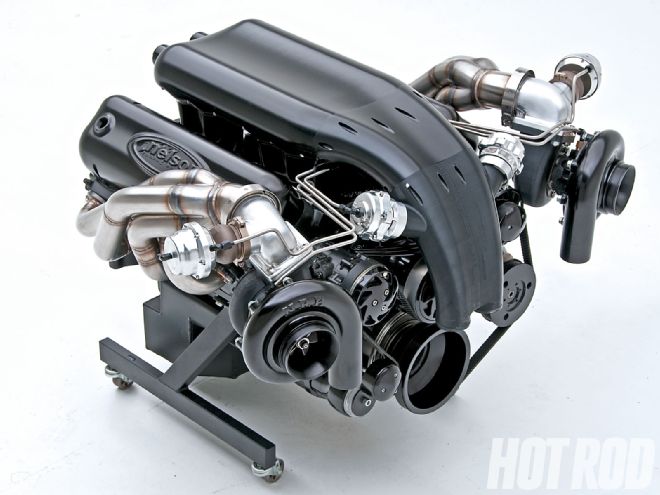

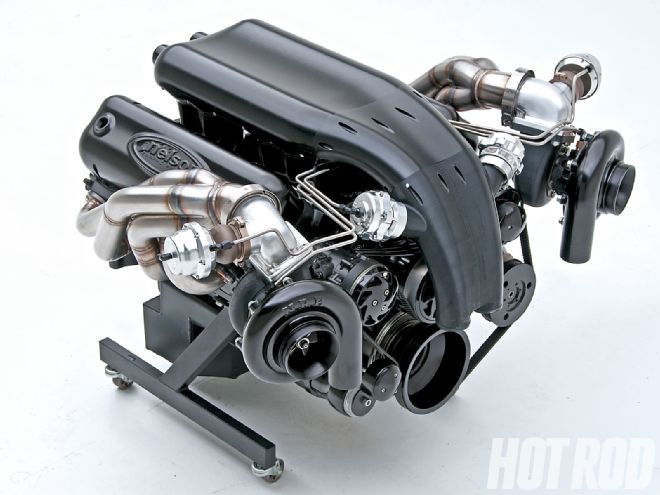

Not the latest Alien flick: Nelson Racing Engines' 572ci Hot Rod Series big-block Chevy makes 2,000 hp and 1, 972 lb-ft of torque with its patented dual mirror-image turbos, each of which rotates in the opposite direction. Not just for profiling, the symmetrical turbos allow equal-length intake and exhaust piping.

Not the latest Alien flick: Nelson Racing Engines' 572ci Hot Rod Series big-block Chevy makes 2,000 hp and 1, 972 lb-ft of torque with its patented dual mirror-image turbos, each of which rotates in the opposite direction. Not just for profiling, the symmetrical turbos allow equal-length intake and exhaust piping.

On newly designed aftermarket billet wheels, blade angles and curvature have been refined using the latest computer-aided design programs, then machined on sophisticated computer-directed tooling stations. Continuous and incremental improvements as dictated by advancing technology and real-world field experience can be implemented virtually overnight for racers merely by changing the machining program. Many of the new shapes can't be implemented in a weaker casting. And for the street guy, the lighter wheels spool up quicker, making for a more driveable combination. New series of compressors utilizing billet-wheel technology include Garrett's GTX-R series, Precision Turbo's Competition Engineered Aerodynamics (CEA) compressor wheels, and Exile Turbo's new offerings.

Previously, turbo builders could vary blade count, shape, and angle, but changing the wheel's diameter also required swapping out the entire one-piece inlet housing casting, which often mandated plumbing and mounting changes, and sometimes a different exhaust-turbine housing as well. Now Exile Turbo's new ET-R modular inlet housing makes it possible to utilize different-diameter wheels in the same basic housing. The unique, two-piece, bolt-together casting accepts separate, interchangeable compressor wheel shroud inserts. Changing to a different wheel diameter merely requires installing a corresponding shroud insert. Plus, it saves about 20 pounds over diesel-truck-derived one-piece units.

Bearing Housings

Exile has also lightened the bearing housing (the turbo's center-section), developing an aluminum unit that replaces traditional sluglike heavy iron housings. Exile uses a separate cast-iron shroud installed between the aluminum center-section and exhaust housing that protects the lightweight aluminum from excessive exhaust-side heat transfer. The housing also has water-cooling provisions.

Of course, the bearing housing is also the unit where the bearings that support the turbine's rotating assembly/driveshaft reside. The big change here has been the replacement of sintered brass inlet-side bearings with ceramic ball bearings that are stronger with less friction for quicker spool-up, as well as more heat resistant. For some apps, Precision and Garrett also use ball bearings on the exhaust side.

Turbines

Companies like TiAL, Precision Turbo, and Nelson Racing Engines have introduced lighter, stainless steel turbine housings in place of the industry-standard cast iron. So far, the turbine wheels inside haven't mutated as much as compressor wheels. Typically made from heat-resistant Inconel, they're expensive and hard to machine, so in the past, turbo companies were forced to work with the limited selection of available OEM wheels. Leading companies are just starting to develop new turbine wheel configurations as well as multiple configurations that fit the same size exhaust housing. For example, Turbonetics' F1 turbine wheels feature a new design with 10 blades and a tall tip-height configuration to maximize exhaust gas energy while keeping backpressures low.

Nelson Racing Engines is also making its own turbine wheels; each takes 13 hours to machine and wears out two tools per wheel. They're part of its symmetrical turbo program, where each turbo assembly in a twin setup is the mirror image of the other. The internal parts in each turbo rotate in opposite directions, requiring internal bearing alterations plus compressor and turbine blades angled in opposite directions. Originally developed for aesthetic reasons, it turns out there are performance benefits as well: Inlet ducting and exhaust headers are now the same length on each bank of a V-type engine, simplifying pulse tuning while minimizing cylinder bank-to-bank variations.

One Turbo or Two?

Single big performance turbos might be required to conform to specific sanctioning body rules limiting the number of turbos, or in narrow-bodied Bonneville Streamliners with clearance problems (which don't need to spool up quickly anyway). Fortunately, they're available: Turbonetics' large 115mm-inlet compressor can support 2,800 to 3,000 hp on gasoline; a 122mm prototype in the works can support more than 3,000 hp. Precision's HP118 turbo is rated to 2,800 hp on its own, while Pro Mod 108s can support more than 4,000 hp when used in a twin configuration. For the majority of nonconstrained applications, the crossover point from single to twins is still in the 700-to-900hp range, however.

Remote Mounting

Mainstream theory holds that turbos should be mounted as close to the engine's exhaust ports as possible to maximize the amount of exhaust heat entering the turbine; the expansion of the hot gases helps provide additional turbine rotational impetus. But the closely cowled, tight engine bays on many late models and street rods may lack clearance for near-motor mounting. Heat radiation can also be a problem, reducing the life span of critical parts. Mounting the turbos upstream from the catalytic converter can prolong light-off time, increasing emissions. On any model year, up-front mounting requires complex header configurations. And adding front-end weight is not optimum for traction-limited drag racers or Bonneville racers.

The alternative is remote-mounting the turbos toward the rear of the car. Squires Turbo Systems holds a bunch of patents that make this "break-the-rules" system work effectively. By properly configuring and sizing the remote-mount turbo's compressor trim, the exhaust turbine's A/R ratios, and its associated inlet and exhaust ducting and plumbing, Squires has been able to successfully engineer both street and record-holding race car systems. Many of its street kits for late models are fully California smog legal. Because there are no complex, up-front exhaust systems and turbo mounting issues, Squires is also able to offer fully universal kits applicable to earlier vehicles that simplify turboing your classic muscle car or street rod. Squires will walk you through selecting the proper turbo size and trim for your particular universal application.

Boost Management

Most turbo setups use a wastegate to bleed off excessive top-end boost. As turbos have increased in capacity and efficiency, so have wastegates. Companies like Turbonetics, Precision Turbo, TiAL, and Turbosmart have designed and maximized wastegate bowl size, valve diameter, and spring rates to control even the most powerful systems. Recent improvements include TiAL's new offerings that are more compact for a given flow capacity than their predecessors and also offer a unique water-cooling feature. "The compact size of the new wastegates is a major advantage. Packaging is often tight in new car engine bays," says Shearer.

Squires' unique wastegates operate in reverse from standard practice, using added pressure to actually increase boost level via its own electronic boost controller. "You get more stable boost control from the wastegate by adding pressure to the wastegate spring than by removing pressure from the system and only relying on the wastegate spring to regulate boost pressure," Squires maintains. Its adjustable boost controller can change between running on standard low-boost wastegate pressure and the regulated high-boost pressure by flipping a switch.

In fact, stand-alone electronic boost control devices have really come of age for high-end applications. NLR has developed a control that can regulate boost levels based on rpm, boost over time, transmission gear-ratio selection, and other inputs. Devices like these are very popular in traction-limited radial-tire and 10.5-inch-tire-width racing. Both Nelson and Shearer like NLR's AMS-1000 unit. "It's by far the most popular boost controller out there and is being used on anything from street cars to the fastest turbo cars and bikes," says Shearer.

On the inlet side, many turbo setups now use a blow-off or bypass valve. Modern-day turbo systems are mostly blow-through designs where the turbo mounts in front of the throttle-body or air meter. In this type of system, sudden throttle closure under boosted conditions can cause the turbo to surge or go over pressure. Not only does this condition slow response time when you get back on the throttle, it can also pound on the turbo's bearings and raise the inlet air temperature.

Intercoolers

Intercoolers are vital for cooling the compressor's charge-air after it's been heated up by proximity to hot exhaust gases. Outwardly intercoolers haven't changed much in appearance-but subtle internal changes have made the best designs more efficient. Higher efficiency means either greater temperature drop in the same-size unit or reducing the unit's size to save weight and fit in tighter spaces while still maintaining the same temperature drop as the larger, previous-generation unit.

"One of the biggest improvements is the switch toward more bar-and-plate-style construction," Precision says. "They can withstand higher boost pressures than traditional tube-and-fin designs and are much more resistant to damage from road hazards. They also tend to be higher density, acting as a heat sink, which is especially advantageous in stop-and-go traffic." Precision offers a whole lineup of high-tech air/air and air/coolant units; its new 3,000hp-capable PT3000 is 15 to 20 pounds lighter than the older, previously top-of-the-line, PT2400 unit. Spearco's WAVE (Wide Area Vane Effectiveness) intercoolers have cores that incorporate a complex network of highly effective vanes said to decrease temperatures by as much as 30 degrees F compared with conventional tube-and-fin units. New Garrett water cores have shown huge efficiency increases as well. "Back in the day, seeing intake temperature creep 150 degrees using an air-cooled core in a quarter-mile pass used to be common," Shearer points out. "Now we commonly get those increases down to 25 degrees or even less."

Compounding and the Future

Most twin turbo installations are mounted in parallel, but they can also be mounted in series. Called "compounding," this technique was generally reserved for 50 psi or higher boost pressures seen on tractor pullers, big diesels, and aircraft. If one turbo alone had to make 50 psi under extended operation, the result would be shaft overspeed and eventual unit failure. On traditional compounding, a larger unit mounts ahead of a smaller turbo. The larger unit's relatively low boost (typically around 15 psi) is multiplied three to four times as it passes through the smaller unit, generating high boost without causing the smaller unit to overspeed. Since the air is already compressed, the second, smaller unit is not a restriction.

Hellion says its unique compounding with twin turbos feeding a supercharger provides the low-end torque lacking on Ford 4.6L engines while boosting power even more on top.

Hellion says its unique compounding with twin turbos feeding a supercharger provides the low-end torque lacking on Ford 4.6L engines while boosting power even more on top.

Forms of compounding are now starting to make inroads into more mainstream applications. Hellion sells kits in which two turbos blow into an engine-mounted Roots or screw-type beltdriven supercharger. Initially they were for factory-supercharged Ford Mustangs-the '03 to '04 Cobra Terminator and the '07 to '11 Shelby GT500-but recently, Hellion has introduced kits for late normally aspirated Challengers and Camaros as well.

As emissions and mileage standards continue to tighten, expect to see more radical new compoundlike turbo configurations on OEM applications. Rather than using separate units, the new breed combines a form of compounding within a single unit. Garrett has an integral compound design with two compressors staged in series, but designed integrally within a common compressor cover driven by a common turbine. There is also a single sequential turbo configuration that uses two separate compressor wheels driven by a single turbine, so designed that the compressors flow in parallel. This is said to reduce overall rotor mass and inertia, increasing the turbo's acceleration rate. Variable geometry on the turbine side of some of these units improves efficiency, reduces emissions, and improves low-end torque, even eliminating the wastegate in some instances. It's only a matter of time before similar concepts migrate into the next generation of performance turbochargers. Who knows what performance turbos will look like in another five years?

On this Cobra Terminator, it yields 1,200 hp, good for 9.90s in the quarter.

On this Cobra Terminator, it yields 1,200 hp, good for 9.90s in the quarter.

Cheap Turbos

Turbo installations can be expensive, so in these hard economic times some rodders are seeking affordable alternatives. The traditional econo route was trying to make wrecking yard units work on a nonstock application. This approach has a low success rate. As Hellion puts it, "Finding a turbo in a junkyard most likely will lead to a missized unit that will spool too slow or too fast, and have durability issues." Adds Precision Turbo, "Simply modifying or changing one system will ultimately have an effect on many others. Adding a turbo to a car without considering the total package will not yield beneficial results."

Another money-saving possibility is rebuilding a used turbocharger. Turbo City is one source for refurbished turbos, as well as do-it-yourself rebuilder kits.

Commonly available OEM or junkyard turbos like this BMW unit generally don't adapt well to nonstock use and generally lack capacity to get the job done on healthy V-8s.

Commonly available OEM or junkyard turbos like this BMW unit generally don't adapt well to nonstock use and generally lack capacity to get the job done on healthy V-8s.

The latest alternative is new Chinese "clone" turbos that cost half the price of their domestic counterparts, but quality control and materials are sketchy. Some have had good luck with them; others claim they won't survive more than six months of hard use, at best. A turbo is a precision component using high-tech materials put together under tightly controlled standards. "Clone manufacturers left on their own to inexpensively copy a complete turbo that may rotate at speeds of over 3,000 rotations per second at 1,700 degrees F is a bit scary, especially without the engineering necessary to support the fundamental complexities of the product," maintains Precision. Eventually the quality is bound to improve (as have import rods and cranks), but right now it's still pretty much a crapshoot, particularly if you intend to make serious power in a combo that lives. Sources for inexpensive new turbos include eBay Motors and L&Y Honesty Turbocharger.