It seems as if nothing has escaped the effects of today's economy-and our hobby is certainly no exception. General Motors has filed bankruptcy, and the Division that lends to the existence of this very publication, is no more. Major aftermarket manufacturers haven't gained immunity, either. Some of the largest names in the business have filed for bankruptcy or closed their doors altogether. As bleak as it seems, it's simply a fact of the world we live in today.

The present State of the Union shouldn't prevent you from having fun with your Pontiac, however. While some hobbyists are satisfied with their ride's current performance level, there are many others who maintain the continuous hunt for added go, but not all have the available funds to create a large-cube, high-output Poncho at this time.

Sure, you might have to shelf the thought of more exotic aftermarket components like aluminum cylinder heads, roller camshafts, and high-voltage ignition systems for the time being, but there are other ways to produce a potent combination without breaking the bank.

While 500hp budget builds aren't totally unreasonable, a range of 375 to 450 is far more realistic when planning a street-friendly 400 or 455 build-up. Follow along as we share 14 ways to take an affordable approach toward performance. It's sure to provide you with plenty of fun on the cheap, while weathering the economic storm!

1. 400 For Fun

Not every Pontiac needs to be powered by a 455 to go fast. While added displacement can certainly improve street manners and increase low-speed performance, the Division's 400ci engine was its mainstay for more than a decade. Though most 400s were used in conventional applications, and not necessarily intended for maximum performance, there are, undoubtedly, a large number of unmolested cores available today.

Some will argue that the mid-to-late '70s 400 blocks are less rigid and questionable for use in performance applications, and while that may be true in extreme conditions, virtually any '67-'78 400ci will make a sound foundation for a moderate-performance street build like the ones we're discussing here.

If you don't already own a 400ci, it's quite likely that a small assortment of potential candidates is hiding in your locale, just waiting to be discovered. We suggest visiting local salvage yards and/or perusing the online classifieds of nearby towns. Spreading word of your search at local car shows or swap meets might also keep others on the lookout for you.

Maintaining a sharp eye and following all potential leads should easily net you a number of affordable 400s within driving distance, and, if you're lucky, the one you choose will be equipped with usable cylinder heads, intake manifold, distributor, and carburetor.

Don't expect to pay more than a few hundred bucks for a complete rebuilder 400, and less if said components are missing. We shelled out $100 for this particular '74 model year 400 as it sits. It ran great before the owner removed the heads.

2. Rod Shop

Pontiac's stock cast-iron connecting rod is quite reliable when it's operated within its original parameters, and if properly reconditioned, it most likely remains adequate for a modern moderate-rpm performance build. But after considering the fact that even the newest rods are now more than 30 years old, and that proper reconditioning includes finding eight useable cores, upgrading each with 7/16-inch ARP bolts, and then resizing the caps, it's no wonder aftermarket forged-steel connecting rods are such an attractive option.

A number of companies offer forged 4340-steel connecting rods, which are capable of enduring much higher output levels than the type of build discussed here, and that can be reflected in the price. However, Pacific Performance Racing (PPR) in San Pedro, California, and SD Performance in Chilliwack, British Columbia, sell the Tomahawk; Butler Performance in Leoma, Tennessee, sells the RPM; and Kauffman Racing Equipment, in Glenmont, Ohio, sells the Pro-Warrior. These are all affordable options designed for more moderate combinations.

These connecting rods are 5140-steel I-beam forgings that are considered a direct replacement for the stock cast-iron units, and a complete set costs around $250, or about as much as it would to recondition a set of stockers. They come fitted with 7/16-inch ARP bolts and are ready to handle at least 500 horsepower.

3. Stroke Me

I know, I know. You had your heart set on a 455, but you can't seem to find one locally. Well, you don't actually need a Pontiac 455 to attain that displacement.

Virtually all of the major Pontiac builders can supply you with an aftermarket long-stroke crankshaft kit that will turn a 400 into a 455, and possibly larger. Such kits also include forged 4340-steel H-beam connecting rods, specific forged-aluminum pistons, and all of the piston rings and bearings required for a complete rebuild. The near-$2,000 price tag may not be within your budget, however.

Butler Performance provides an affordable solution for the budget-minded build. Using a cast-steel long-stroke crankshaft, forged 5140-steel I-beam connecting rods, and Sealed Power forged-aluminum pistons, BP's kit (shown here) will take a typical 400ci to at least 455 for $1,350. The assembly is also computer-balanced for ease of installation. A forged 4340-steel H-beam rod option adds about $125 to the kit.

Kauffman Racing Equipment offers a similar budget-minded long-stroke crankshaft kit that includes a cast-steel crank, forged 4340-steel H-beam connecting rods, and Keith Black forged-aluminum pistons. It also includes all necessary rings and bearings, is balanced, and comes ready for installation for $1,410.

While a long-stroke kit can soak up a good portion of your available budget, don't forget that it includes everything shown here, which is virtually all you need for a complete short-block rebuild and can easily set you on course toward 400-plus horsepower with as-cast D-port cylinder heads.

4. Camshaft Query

Camshaft technology has come a long way over the years and roller valvetrain components are commonplace in modern vehicles. Only recently has a wide array of retrofit roller camshaft and lifter kits been made available for the Pontiac V-8, but the technology comes at a price. The possible performance gain a hydraulic roller camshaft might possess over a similar flat-tappet doesn't always outweigh the added cost in a budget-minded rebuild.

Hydraulic flat-tappet camshafts remain a popular hobbyist choice for a number of reasons. They not only provide strong performance at an affordable cost, they operate quietly and require little maintenance after initial break-in, and an upgrade to a more radical grind isn't an overly expensive proposition.

Some critical high-pressure additives have been removed from modern-spec oil and that can cause flat-tappet camshaft failure, but said failure can be averted by following the manufacturer's recommended break-in procedure and stated instructions for normal-operation, as well as using top-quality oil that contains the necessary level of additive.

Expect to pay around $200 for a high-quality camshaft and lifter set like that shown here, while hydraulic roller cams generally start at approximately $600.

5. Rhoads Lifter Lowdown

Rhoads lifters are a popular way of increasing the idle quality and low-speed street manners of an engine with an aggressive hydraulic flat-tappet camshaft. At low speed, the Rhoads lifter reacts to valvespring pressure and bleeds down at a greater rate than a conventional hydraulic lifter, which can make the camshaft appear as if it were about 10 degrees smaller than it actually is. As engine speed increases, the Rhoads lifter has less time to bleed down and it begins functioning like a normal lifter above about 3,500 rpm.

If the camshaft selected for your rebuild is a bit too radical for your liking, the entry-level offering from Rhoads sells for $110 and can make your Pontiac more pleasurable to drive without compromising full throttle performance and may save you the price of replacing your cam with a milder one.

6. CNC Connection

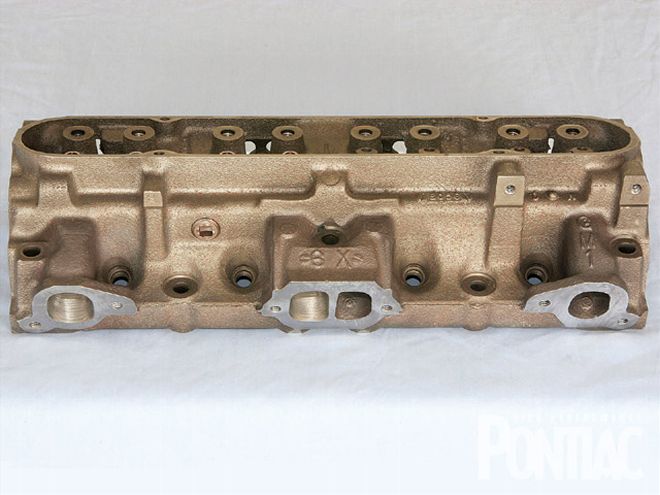

If your intended build requires a certain amount of cylinder head airflow, but your budget can't support a set of aftermarket-aluminum castings, all is not lost. SD Performance offers an affordable CNC-porting service that increases the available intake airflow of a typical D-port cylinder head toward 250-cfm using its in-house CNC mill.

Beginning with bare castings that you supply, SD Performance modifies the intake and exhaust ports, and then completely rebuilds the pair, using top-quality components for less than $1,300. The cylinder heads are returned to you in bolt-on condition and should feed around 450 horsepower on a typical street engine.

7. Small Valve Value

In an attempt to increase the output of its performance engines for the '67 model year, Pontiac engineers increased the intake and exhaust valve diameter of its D-port cylinder heads to 2.11/1.77-inches, respectively. It seems that castings from this '67 to '72 era are most desirable for the D-port performance crowd. Similar castings were used in low-performance applications, but valve sizes were limited to 1.96/1.66-inches, which reduced peak intake airflow from roughly 210 cfm at 28 inches of pressure to about 190. However, port volume remained the same as the big-valve heads.

Most hobbyists are quick to consider Pontiac's small-valve castings worthless from a performance standpoint, and blindly discard them in favor of a more valuable large-valve casting during a build-up, but few are aware that the small-valve castings contain enough material around the valve seats to install 2.11/1.77-inch diameter valves. Simply cutting the valve seats to the appropriate sizes, like that shown here, will produce a small-valve casting, which provides large-valve performance at a fraction of the cost.

Additionally, because Pontiac's low-performance applications were often built around lesser-displacement engines, most feature combustion chamber volumes of 80-90cc, which are ideal for producing a compression ratio between 9:1 and 10:1 when building a 400 or 455ci engine. Expect to pay no more than $100 for any pair of small-valve cylinder head castings, around $250 to install larger valve seats, and an additional $125 to convert from pressed to threaded rocker-arm studs.

Note: Additional port-work like that performed to this particular head will increase overall cost.

8. Multi-Angle Mojo

Increasing cylinder head airflow is the most efficient way to improve the peak performance of any engine, but, most often, the actual port work is aimed at maximizing airflow at moderate-to-high valve lift and the task can be quite labor intensive, which can be costly. When considering said points, we found that cylinder head porting may be impractical for certain builds and/or exceed the intended budget of others.

A simple, yet effective way to improve overall airflow is with multiple-angle valve seat cuts, as opposed to just one, when rebuilding a set of typical cylinder heads. The various angles can be depicted here as rings in different shades around the seat. As air begins flowing past the valve as it opens, the varying seat angles tend to smooth the transitional flow into or out of the port, and that can improve low-lift airflow by a few cfm over stock, generally slightly improving low-speed performance.

Additional blending into the bowl area with a grinder and modifications to the valves can yield further increases that can equate to as much as 10 to 15 cfm over stock at low-and-moderate lift values. The airflow gain from such work diminishes as the valve progresses toward peak lift, since the seat and its angles become less of a factor and the actual port shape comes into play.

In today's hobby, it seems that three is the minimum number of multiple-angle valve seat cuts used when preparing cast-iron Pontiac cylinder heads, and it's referred to within the industry as a "three-angle valve job." One should expect to pay around $225 to have such a valve job performed to a typical set of heads.

9. Rocker Arm Affordability

The stamped-steel rocker arm assembly found on every Pontiac V-8 from its introduction in 1955 was developed by Pontiac engineer Clayton Leach. The simple design proved very effective, and other manufacturers, in one form or another, adopted it within a few years.

Over time, the aftermarket developed a variation of it that included a roller tip and trunion, aimed at reducing overall friction, and today roller rocker arms are commonplace in virtually any performance rebuild. The added cost over a traditional stamped steel rocker isn't within every budget, however.

Performance Racing Warehouse in Placentia, California, offers its own entry-level rocker arm for budget-minded rebuilds. Its Sportsman Steel Roller Tip Rocker Arms use a main-body cast in 4340-steel and feature a roller tip to minimize side loading on the valve stem. Unlike most stamped, cast-steel, or aftermarket rockers, PRW's units include 7/16-inch positive-lock nuts for accurate valve setting.

Available in 1.52:1 or 1.65:1 ratios, PRWs are an excellent alternative when replacing worn, stock 1.5-ratio rocker arms or to gain some additional lift from an existing camshaft. A complete set retails for less than $100.

Note: Be sure to clearance the cylinder head's pushrod guide tubes if 1.65:1 units will be used now or at any time in the future.

10. Iron Intake Exclusive

Even today, one of the most common modifications hobbyists first make when attempting to improve the performance of a vintage vehicle is to replace its factory-installed intake manifold with an aftermarket replacement. While that might be wise for other brands, Pontiac's cast-iron four-barrel is a solid performer for street applications, and is many times a better choice than an aftermarket unit.

If the engine you're rebuilding isn't already equipped with a factory-cast unit, finding a '68-'72 iron four-barrel manifold (or '67 Q-jet) at a relatively affordable price shouldn't be overly difficult. Because of the addition of EGR on the '73-'74 manifolds and the overall restricted appearance of the '75-'78 units (shown), these iron intakes are often cast aside, but testing has shown that the effects on airflow are limited-especially for a moderate street build.

Expect to pay no more than $100 for any '68-'72 cast-iron four-barrel manifold and substantially less than $50 for any '73-'78 emissions-era casting.

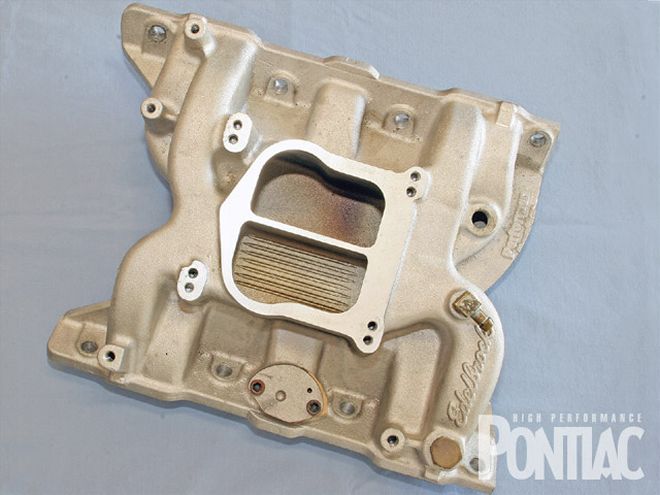

11. Aftermarket Answer

We've already established that the factory cast-iron intake manifold is a formidable performance piece, but the fact that it weighs at least 40 pounds can make it somewhat unattractive to some, while others simply prefer the appearance of a cast-aluminum intake manifold. If that's the case, an Edelbrock Performer is an excellent alternative that, essentially, performs identically to a factory iron unit in most street applications.

Careful hunting through online classified or auction sites can provide a used example like this for less than $100.

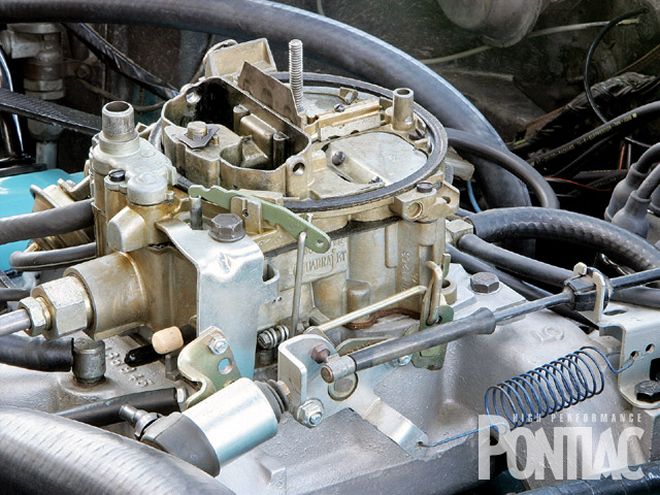

12. Quadrajet Quotient

If you've been a faithful HPP reader for any length of time, you've likely noticed that we've dedicated a great number of pages to the Rochester Quadrajet, over the years. This isn't just because it was the most-common carburetor Pontiac installed on its four-barrel applications, it's also due to the fact that it provides excellent performance when correctly modified.

Though the Quadrajet and its associated performance modifications have been extensively covered within recent issues, it's still worth noting that its small primary-barrels provide excellent throttle response and strong low-speed performance, which yields excellent street manners and good economy. Its large secondary barrels allow for strong full-throttle performance.

A Quadrajet installs easily and is compatible with the stock throttle linkage and its associated brackets. It also fits well under a factory Ram Air pan or Trans Am Shaker. Surprisingly, any Pontiac unit from the mid-to-late '70s is an excellent base for performance use-even those from the lowly 301ci are capable of flowing in excess of 800 cfm.

Swap meet or salvage yard finds should set you back no more than $25 for a typical unit. Expect to pay considerably more if you're searching for a specific casting number, however.

13. Spacing For Performance

Your budget might not allow for a high-flow aftermarket dual-plane intake manifold, such as an Edelbrock Performer RPM, but you're wondering if your combination might benefit from it. If so, you might consider installing a simple four-hole carburetor spacer onto the factory cast-iron intake, which serves to increase overall plenum volume and adjacent runner length. Examples like those from Summit Racing (though this particular one is for a square-bore carb) are available from most any local-area speed shop or popular mail-order supplier for less than $30.

If you're really looking to test one on the cheap, you can fashion your own from solid wood. Simply using a carburetor-base gasket as a template, spacers in varying thickness and configurations can be produced for a few bucks. It may sound crude, but it's an affordable and effective way to determine what your particular combination likes, while also isolating the carburetor from engine heat that migrates upward from the intake manifold.

14. Ignition System Simplicity

It's been proven time and again that Delco's original points-type or HEI ignition systems are more than adequate for dedicated street applications, but the HEI gets our vote for its simplicity and low-maintenance operation.

As opposed to purchasing a high-dollar aftermarket unit, scouring through local salvage yards, or swap meets should produce a usable Pontiac HEI (like this) that's in relatively good working order for less than $50. It'll likely only require a thorough cleaning and replacing any of its questionable components with high-quality, stock replacements to again operate as intended. And, after adjusting its centrifugal and vacuum advance curves to match your engine's needs, your low-buck ignition should provide strong performance that can rival anything from the aftermarket on the street.