In these tough economic times, we all have to compromise a little. Many folk's 401(k)s are now 201(k)s, and the cubic dollars that fed the automotive aftermarket have dwindled. Enthusiasts are stretching to make every small dollar buy more goodies. In a parallel line, many engine builders, like Brett Miller of BH Performance, are discovering the secrets that stretch the power from small cubic-inch engines into big-block territory.

Brett's been a Mopar guy since birth. You see, his pop drove him and his mom home from the hospital in their '67 Barracuda fastback just after he was born. Poor guy didn't stand a chance to be anything but. When he decided to enter the ring with some of the top engine builders in the country and compete in the Jegs Engine Masters Challenge, he didn't hesitate to make his entry a version of the legendary small-block 340. Taking the best of the 318 and 360 engines, the 340 has always been known as a big-bore, short-stroke, high-winding rev-turner. It would surely make good horsepower, but would the design lend itself to making the torque necessary in a contest where the dyno pull starts at 2,500 rpm and shuts of at 6,500? Read on. (Hint: the answer is "yes.")

A derivative of the 273ci LA engine, the 340 first showed up in late 1967 for the '68 model cars, and immediately began beating up on the big-blocks. It was especially effective in cars destined to actually make left and right turns instead of just a straight line down the strip. Unlike the 273 and 318 blocks, the 340 used a big bore. Actually, at a 4.040 standard bore, the 340 is a bit bigger than even the 360 engine's 4-inch bore.

The block that Brett used was a vintage piece that was in good shape and cleaned right up at 0.030-over with a torque-plate hone. A torque-plate bolts in place of the cylinder head when machining the block, and typically would distort the block a good amount as it simulates the stresses that the head bolts pass onto the block. The four head bolts on a small-block Mopar surrounding the cylinders, though, are actually spaced far away enough from the cylinder that the distortion seen is not quite as bad as on Chevy stuff. There is still pinching all around the top of the cylinder as the armor ring of the head gasket is compressed, making the use of a torque plate a requirement in any high-performance build.

Brett's crank for the engine was a 4340 forged steel piece he picked up from Eagle Specialty Products. Their forgings in small-block setups like this have been used in many applications well over 700 hp, so Mr. Miller was pretty confident he would have no problems. In addition to the big 0.125-inch radius fillet that makes the crank so strong, Eagle's optional ESP Armor finishing on Brett's crank helped reduce stress risers and created an ultra-smooth, oil-shedding finish on the shaft. He had never used the ESP Armor finish before, but was totally sold after checking it out. He even ordered the finish on the ESP H-beam rods used in the project. Brett told us: "I think it's amazing! That stuff really toughens the finish up. It's a lot nicer finish on everything after it's treated. The journals, everything, just a much nicer finish. Even on the rods, when you pick them up in your hands they just feel better. If that makes sense." For the claim that it was oil repellent, Brett was equally surprised. "On the counterweights, whenever it got oil on it, it just beaded up. It's definitely weird. It's very slippery and I don't know exactly what the process is, but it definitely made it harder. I'm a believer."

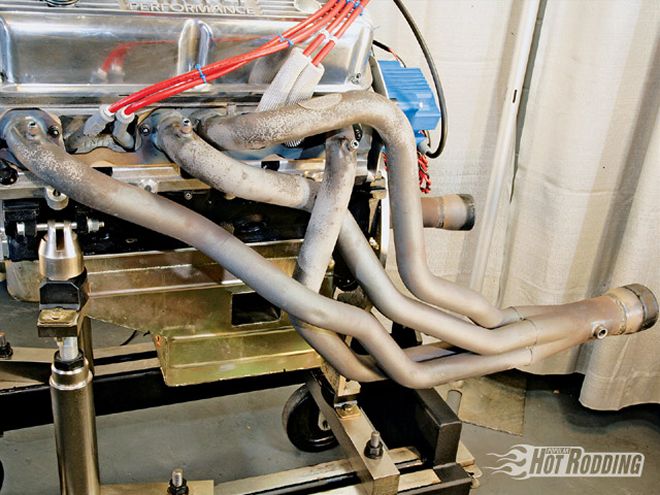

The Hooker Super Comp headers would make this engine a drop into any early Mopar A-body. Imagine how fun it would be to drive donuts around your big-block buddies with this little jewel!

The Hooker Super Comp headers would make this engine a drop into any early Mopar A-body. Imagine how fun it would be to drive donuts around your big-block buddies with this little jewel!

The ultra-smooth crank journal finish allowed Brett to use an out-of-the-box set of Clevite H bearings without any concern for wear. When asked about the oil pressure he ran to maintain those bearings, he says, "Man, I had way too much. It was like 85 psi. Chryslers are notoriously bad oilers, and I just wasn't comfortable running 40 psi. I know it can be done, but this is my first year [in the EMC] and I just wanted to keep it safe." The 5W-30 Royal Purple didn't let Miller down, and the bearings looked perfect after the dyno runs.

A source of pride and contention among the Chrysler fans is the whole camshaft area. Mo-Powers use a big 0.904-inch lifter that lets the cam grinder get super aggressive with lobe designs. Brett used lifter bushings installed with a BHJ Lifter-True fixture to make sure they were all correctly located, and then had COMP Cams whip up a custom solid flat-tappet cam with their "Mopar only" MM cam lobes for those honkin' lifters. One of the tricks of the trade that Miller keyed us in on was that you can build cylinder pressure and fake the engine into thinking it has more compression than it really does by closing the intake valve early in the camshaft cycle. He used an externally adjustable Weber belt drive to make quick changes on the dyno. Starting with a pretty tight 106-degree lobe separation to allow the exhaust to help pull in the intake charge, he set up the intake centerline at 102 degrees. "I remember this vividly. That's why we put the belt drive on, so it'd be easy to jack the cam around. It made pretty good power, so I said, 'hey, let's see if we can pick up the bottom end. I want to advance this cam.' I had it in at 102, then I advanced it to 100 and it killed it, which shocked me. I said, 'Let's go 2 more degrees and see what it does.' We started another pull and it did so bad we just aborted it." It turned out that the initial 102-degree intake centerline was the sweet spot. "I think the reason advancing it more didn't help me was because it just built too much cylinder pressure [for the pump gas]."

Factory blocks like Brett's used a cam tunnel that is significantly raised compared to the Brand X guys, letting cranks with mucho-mondo arms to swing around without running the connecting rods right into the cam. That is a good thing. The curse of that raised-cam tunnel design is the odd 59-degree angle that the lifters sit at. While most V-8 engines use a lifter angle around 45 degrees (makes sense right?), the engine designers must have been out watching the Ramchargers running down the strip the day they were supposed to design the lifter placement, leaving the chore to some intern. The problem here is that it sets up a compound angle with the pushrod creating a point of friction and wear, costing power and longevity. Thankfully, Brett's 345 survived the rigors of the Challenge without any issues.

In '68 through '70, the 340s were blessed with a 10.5:1 compression ratio, same as in the Challenge. JE provided the domed pistons that would support that compression ratio. Unlike the aluminum ashtrays of yesteryear, these technologically advanced pistons were built with the precision of a Swiss watch with tight ring grooves and a full round skirt to reduce piston rock and combustion pressure loss. JE also supplied the narrow, metric rings for Brett's endeavor. The low-tension rings, along with the ESP Armor crank treatment, allowed the fully assembled short-block to rotate with a mere 16 lb-ft of force. Basically, you can grab the crank snout with your bare hand and turn the engine over!

Sneaking in under the radar is this modified HVH super sucker carb spacer. Brett milled off the bottom of it and re-drilled the intake to bolt it directly on with just a thin layer of sealant.

Sneaking in under the radar is this modified HVH super sucker carb spacer. Brett milled off the bottom of it and re-drilled the intake to bolt it directly on with just a thin layer of sealant.

For the cylinder heads, Miller knew that he had to make the right choice or risk losing out on big torque and/or horsepower. All of his experience and research led him directly to Indy Cylinder Heads. Their line of big oval-port heads was where he started. Indy offers their castings in a few different configurations and Brett preferred the earlier style CNC-ported combustion chamber design along with their latest 230cc CNC runner design. Some numbers were keyed into the machine and a few hours later, Brett's heads were spit out of the CNC mill and ready for delivery. They would be perfect as-is for a higher-rpm engine, but as he was shooting for big average torque and horsepower numbers across a broad range, he wanted them just a little smaller. "It was a 360 CNC runner that started out at 230 cc, and we shrunk them down to 210." Compared to the stock 2.02-/1.60-inch valves in the original 340 heads, the massive 2.10/1.60 heads had no problem moving the air. To control the valves as they were pounded open and shut, a set of COMP Beehive valvesprings was set up right at 150 pounds on the seat and 420 pounds open. "I don't think I could have put enough spring force on it for as fast as I was trying to open those valves with that [T&D] 1.8 rocker and that [COMP] MM lobe. There's just a ton of weight in the valvetrain."

Edelbrock just about has the market cornered on intake manifolds, and that was what was on the 345. The Victor W2 Miller chose is actually such a nicely designed intake that many of the Chevy guys have adapted for use on their small-blocks. Brett massaged the big oval runners to match the heads for an easy transition and lots of velocity. The benefit of the oval design is the ability to get the maximum amount of air down the pipe without having dead spots like a conventional rectangle port would have. Eliminating the dead spots while keeping that air going gets the ports really working faster, increases the signal to the carb, and starts building torque sooner. Perfect for a fun street/strip engine destined to blow off the tires at will. More modifications converted the 4150-style intake to run a Dominator carb. As the Challenge rules only allowed use of a 1.5-inch carb spacer/adapter, Brett milled off the bottom of a taller HVH adapter and recessed it directly into the plenum. Pretty sneaky.

When it came to the fuel squirter sitting on top of the Victor intake, Brett had only one name in mind, Pro-Systems. Owner and racer, Patrick James, has been modifying Holley carbs for years, and his babies have won several Engine Masters Challenges along with tons of NHRA, ADRL, ORSCA, and SCCA events. Before calling Patrick, Brett was thinking something like a 650 hp. "...Cause I'm thinking small carburetor," says Brett. "But it seems like the bigger carburetors, even on a small motor, are the way to go." Patrick considered the specifications of the engine, and determined Holley's baddest-of-the-bad 1050 Dominator would actually be the best choice. He said: "I'm a records fanatic, and I've seen a lot of combinations and you keep records of them, so when someone pops up who has a similar combination, you can look back in your records and go, 'well with this guy we tried a 4150, and then we tried this, and then we tried that, and wow, the Dominator seemed to be the program.' So really it's just a matter of keeping records and looking at history. You might take that same guy and change to a different set of heads, and look through your records and see that it didn't like a Dominator." Patrick put together a beautiful piece that maintained a super-flat fuel curve and was amazingly responsive for such a big carb. When considering the huge carb for the engine, and considering how it would react in an actual car and not just on the dyno, he said, "Oddly enough, some of the dynos now are getting so good at simulating the proper loading that they are just darned close. They are usually within two main jets every time." Only a few final tuning adjustments would normally need to be made once the engine is under the hood of a car as full exhaust, underhood heat, and total ventilation would have an effect on street manners. Seeing how this is a "street"-oriented competition, a common Moroso 14x3 air cleaner topped off the carb without freaking out the air/fuel mixture a bit.

Rounding out the combination was a set of Brett's favorite Hooker headers. The Super Comp headers were designed to drop this bad boy into an A-body (Dart, Demon, early Barracuda) and the 13/4 primary tubes really let the exhaust ports breathe easy. Bolted to the hind end of the collectors were a pair of Magnaflow mufflers. "We ran the Magnaflow mufflers and obviously those things are great. I mean there's no difference running them or open. They are really amazing."

Lest you think this was some high-tech bucks-up ordeal, Brett assures us that he just builds engines on the side and holds down a regular day job to feed his family. He says, "I'm working out of my two-car garage. What I've done for years is port heads on the side." Instead of being a victim of the economy, Mr. Miller downsized his engine while upsizing its horsepower. His fruits paid off as the little engine pumped out more than 1.4 lb-ft of torque per cubic inch, and 1.55 horses per inch. Numbers like that don't normally show up in small stroke, low-rpm engines, much less with low compression and on pump gas. Hat's off to a working-man's engine that bucked the system.

BY THE NUMBERS 345CI SMALL-BLOCK MOPAR Bore: 4.070-inch Stroke: 3.310-inch Displacement: 345 ci Compression ratio: 10.48:1 Camshaft: COMP solid flat-tappet Cam duration: 239/242 degrees at 0.050-inch tappet rise Valve lift: 0.638-/0.585-inch Rocker ratio: T&D 1.8/1.65 Lobe separation: 106 degrees Top ring: 1.2mm, JE Second ring: 1.5mm, JE Oil ring: 3mm, JE Piston: JE dome top Block: OEM Crankshaft: {{{Eagle}}} 4340 w/ESP Armor Rods: Eagle 6.125 inch H-beam w/ESP Armor Main bearing clearance: 0.0025- to 0.0028-inch Rod bearing clearance: 0.0025-inch Cylinder head: Indy Cylinder Heads 360 CNC Intake valve diameter: 2.10-inch Exhaust valve diameter: 1.60-inch Intake manifold: Victor W2 Carburetor: Holley 1050 Dominator by Pro-Systems Header: Hooker Super Comp 1 7/8 A-body Ignition: MSD Water pump: Mezeire {{{DTS}}} DYNO DATA RPM TQ HP 2,500 382 182 2,{{{600}}} 390 193 2,700 397 204 2,800 404 216 2,{{{900}}} 409 226 3,000 411 235 3,{{{100}}} 409 241 3,{{{200}}} 403 246 3,{{{300}}} 397 249 3,400 390 252 3,500 385 256 3,600 379 260 3,700 376 265 3,800 380 275 3,900 389 289 4,000 402 306 4,100 419 327 4,200 433 347 4,300 447 366 4,400 456 382 4,500 463 397 4,600 470 411 4,700 474 424 4,800 477 436 4,900 481 449 5,000 484 460 5,100 485 471 5,200 485 481 5,300 485 489 5,400 483 497 5,500 481 504 5,600 480 512 5,700 479 520 5,800 475 525 5,900 471 529 6,000 466 532 6,100 459 533 6,200 455 537 6,300 439 527 6,400 408 497 6,500 378 467