The history of Buick is filled with dreams, inspirations, and innovations. David Dunbar Buick built the first Buick automobile in 1901, and the next year created the first overhead valve engine for use in an automobile. Though David would leave his namesake company by 1906, the Buick Motor Company would live on to become the founding cornerstone of the General Motors empire. An impressive list of names worked for Buick at one time or another. Chief investor William Durant, Louis Chevrolet, Charles Nash, and Walter P. Chrysler were all key players for Buick. With forward thinking, the Buick brand often found itself on the cutting edge of technology. How was it, then, that the engines powering these cars were relegated to playing second fiddle in the muscle car world? That may be a question for the marketing historians. One thing is for sure though, engine builders like Mike Phillips of Automotive Machine and Performance are doing their best to ensure that the Buick powerplants don't play second fiddle to anyone.

Since opening his shop 22 years ago, Mike has always focused on performing quality machine work and pushing the horsepower envelope. About 12 years ago, he started to refine his focus, centering on the under served world of Buick high-performance engines. Several customers brought him engines with ideas that the Buicks had to be built a certain way, but Mike treated them like any other engine; finding inherent flaws and fixing them, maximizing the architecture of the design, and using his solid machining background to build reliable power. This formula helped him build one of the highest horsepower engines in the '08 Popular Hot Rodding Engine Masters Challenge.

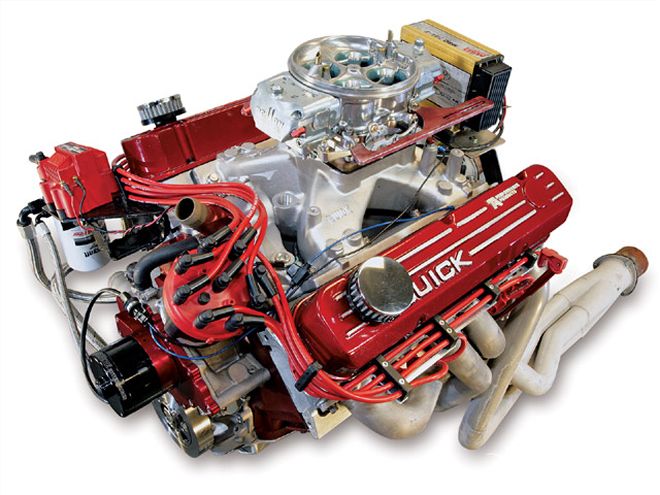

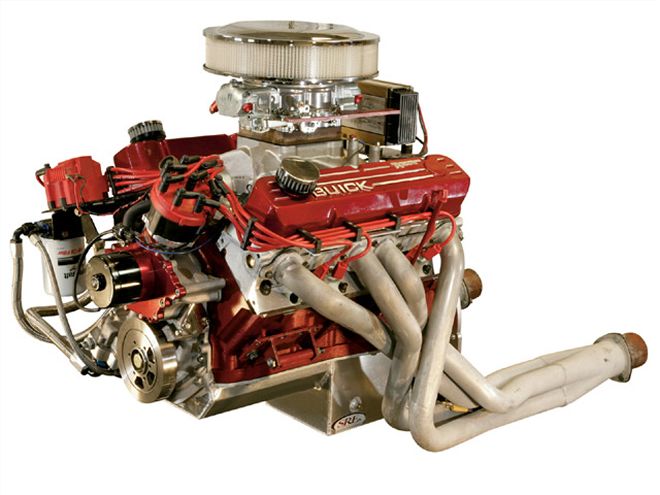

To create his 464ci monster, Mike started with a factory 455 block and gave it the full Automotive Machine treatment. Buick V-8 blocks have always used a lightweight design, and though that makes for less expensive manufacturing, it does leave a little strength on the table. To beef it up, Mike used a main girdle from TA Performance. The girdle is a stout cast-iron piece that ties all of the main caps together, also attaching them to the oil pan bolt holes. When making north of 600 lb-ft of torque, this is a necessary step to ensure the life of the main bearings. Another piece to strengthen the block was a lifter-bore girdle. Similar to Pontiac and Olds engines, the lifter bores in a Buick V-8 just hang out in space, unsupported in the lifter valley. If a solid roller cam is used, the increased spring pressure and loading from the roller cam can break off the lifter bores from the block. The lifter bore girdle ties the bores together and prevents failures like that from ruining the day.

The oiling system is an area that Mike spent a good deal of time modifying. To begin with, he used an external -16 oil line from the pan to feed the pump. He explained that this alone solved a good portion of the oil flow problems. "There's a lot of harsh 90-degree turns in the block. There's four before you get to the gears, and there's three once it leaves the gears. And just like a fuel system on a car, you wouldn't dare put a 90-degree fitting on a fuel system. That's basically how the block is designed." He used a pump called a "scavenger" that bolts in place of the factory block-mounted pump, but really works as an external pump with external feed and pressure lines. "Everything up through our street stuff that we do, we don't put this scavenger on, but we radius all those 90-degree turns in the block." Often, the oil holes in the main bearings don't line up with the holes in the block, so some minor grinding on the block and opening up of the holes in the bearings is the solution. These modifications allow the Royal Purple synthetic to maintain 55 psi of hot oil pressure with just a standard volume oil pump. Mike says: "that's the life of the whole motor--just working on the oil system." Since the factory oiling system feeds the lifters first and then the mains, all of these modifications ironically presented the problem of having too much oil fed to the top end. Mike has tried a few different approaches to restrict the oil to the top end, including small orifice lifters and custom pushrods with a restricted orifice. Ever the thinking man, he found that he was able to modify stock-type pushrods with some silver solder and a small drill bit to get the restriction he wanted. With that bit of technology under his belt, he was able to use standard Comp Cams lifters and save the expense of custom lifters or pushrods.

The block supports, and the oil system modifications made the engine strong enough and reliable enough that he was able to use a stock cast-iron 455 crank to handle to the 720-plus horses. With a 3.25-inch main journal, there is more than enough material to handle the stresses. The stock rods had to go though, in favor of a set of Eagle H-beams. Known for their strength, they would have no problem holding the JE pistons in place. Mike stuck with a tried-and-true set of Speed Pro piston rings to seal up the combustion process. Speed Pro was also the supplier for the engine bearings. As for clearances, Mike says: "I do it just like I do a Chevrolet. Just like anybody would tell you 0.003 inch is the best cooling on a bearing, and 0.002 inch is best for load. So with the mains as big as they are on that, we try to have 0.0025-plus, and I don't mind going over 0.003 inch. On the rods, I try to stay right on 0.0025 inch."

When it came time to pick a camshaft, Mike admits the Buick has a weak spot they have to work around. "The cam journal size restricts you to what you can do on everything. You can't put much of a lift on the camshaft." He entrusted the gurus at Comp Cams to grind the stick with as aggressive a lobe as possible. Trying to get even more lift to make the heads work their best, he used high-ratio rocker arms to make up the difference. "We have probably the only set of 1.75 rockers in existence for a 455 Buick, and T&D made those especially for me. They even took out the 7/16-inch adjusters and put in 5/16-inch adjusters to get the adjuster close enough to the shaft. Then we had to go in there and mill the heads out toward the shaft, where the pushrod hole is, to get clearance. Even with that, 0.650 is really pushing it on lift on these things." As for spring pressure, they had it cranked up pretty good at 180 pounds on the seat, and 400 open. He says they could have even stood a little more, as he heard a little valve float just as the engine was cresting 6,500 rpm on the dyno.

Above the deck, Mike needed a cylinder head that would fulfill the high torque needs of the engine, and still flow enough air to make big horsepower. Coincidentally, the early Nailhead Buicks with their small valves and tall runners provided lots of velocity in the ports that when combined with their long duration camshafts, made the original "torque" engine. Later designs evolved into large-port, large-valve heads as used on the legendary Stage 1 GS and their big brothers, the Stage 2 heads--perfect for making lots of horses in big-inch engines like Phillips' bad boy. Unfortunately, the supply of good Stage 2 heads for maximum effort engines is about dried up, so he would have to go a different route. Mike Tomaszewski, founder of TA Performance, saw this need for a replacement casting that would meet or exceed the performance of the quickly disappearing Stage 2 heads, and began casting his own several years ago. The raised-runner TA heads now offer the peak of performance in the Buick world. By raising the intake runner 0.400 inch, Mike Phillips claims the flow numbers aren't that much greater, but it gives the fuel a straighter shot at feeding the chamber. This raised design posed a small problem, as the EMC rules dictated the use of a standard-type intake manifold that wouldn't normally fit the heads. Using his gray matter, Mike saw the solution. He milled the block 0.130 inch, milled the heads 0.040 inch, used a thin Felpro head gasket, and with a little bit of slotting on the bolt holes, was able to use the TA Performance standard port intake. From there, he was able to calculate the piston dish volume they needed to meet a pump-gas-friendly 10.5:1 compression ratio. He said: "Now we have what I consider the best intake on the best heads."

They had tried installing a small "turtle" in the intake to remove some of the plenum volume, but in testing, it didn't seem to pick up any power, so they took it out to get the volume back. Stacked on top of the intake was a Jomar 1-inch dual-taper spacer that Mike fell in love with. "I've tested a lot of that stuff. For a Dominator, I've probably got six or seven different spacers to test with, and that dual-taper spacer from Jomar in a 1-inch configuration is the best thing we've ever tried."

For the carb, a Barry Grant King Demon with the 995-cfm sleeves was used. "I've got one carburetor that I've used since 2003 in the contests, and I've got sleeves everywhere from 995 to 1150. I started with the 1050 sleeves on this 464, and I actually made more power with the 995 stuff." The Demon carb managed to meter out the Shell V-Power 91-octane pump gas evenly, and responded well to changes on the dyno. The Automotive Machine Buick used an MSD Pro Billet distributor hooked to a 7AL2 box firing the Champion plugs. The 7AL2 provides more than enough juice to power the engine, and is commonly found on 1,000-plus horsepower dragsters, so there were no issues with misfiring. The final pieces were a set of 1 7/8 chassis headers to push the exhaust through the Borla mufflers.

Once Mike had the engine hooked up to the pump, he fired it up and the crowd of EMC competitors knew they were in for something good. I was fortunate enough to be right there when that 640-plus foot pounds shook the building as it bent the dyno needle. Hopefully, David Dunbar Buick felt the heavens shake just a little when Mike Phillips' engine roared. It is a tragedy that poor old Dave never was able to enjoy the successes of the company he gave his name and heart to, but his dreams and spirit of innovation were alive and well when Mike's Buick took its place as one of the most power-pump-gas engines in the country.

BY THE NUMBERS

BY THE NUMBERS