Last month, we featured Chuck Henley's spectacular '69 Ray Faro Pontiac Ram Air V GTO Judge and told the story of how he found it and researched its history for a top-notch restoration. It was a great project to report on, yet we didn't go into a large amount of detail on the engine build. Not to worry-this month we focus on the stock and aftermarket components that went into this incredible powerplant and provide an inside look at the rare pieces.

This buildup is unique in several ways, the first being cost. While the machine and assembly expenditures were no more or less than any other Pontiac V-8, the rarity of the required factory parts became an important factor, both in cost and the time needed to locate everything. How much of a factor? The bill for collecting the necessary parts in this eBay-driven market and the build itself topped $58,000. This is serious coin. "I kept telling myself that I got such a great deal on the car that I could afford to spend more on the engine," Chuck says. "At least, that's how I justified it."

Interestingly, this engine buildup represents the reuniting of several key pieces with the Judge. As mentioned, two engines were used back in the day-a '70½ 400 Ram Air V and another engine built with a Ram Air V top end on a service-replacement 400 Ram Air IV short-block. The top end used here was from that second engine.

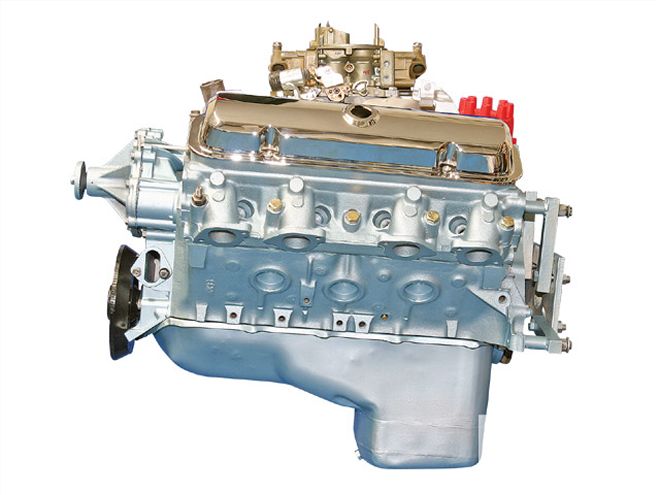

The mission that Chuck assigned to Don Johnston of DCI Motorsports in Mogadore, Ohio, was to build an engine that was externally correct down to the last detail, yet modified internally to enhance streetability while adding horsepower. It was a tall order to be sure, but Johnston's approach did achieve all of the goals of its owner. Best of all, Chuck graciously offered to share with HPP readers the inside scoop on this historic engine buildup.

Ram Air V Background

Pontiac's Ram Air V program is, without a doubt, one of the most mysterious and legendary projects in the division's history. Operating under the infamous GM Racing Ban of 1963, much of the development work was at least officially designated as a high-performance street engine. Anyone in the know, however, realized this program was intended to get competitive hardware to well-heeled, privateer racers.

Though Pontiac fired the opening salvo of the musclecar wars with the '64 GTO, by the end of the decade, the competition had more than caught up, and Pontiacs were taking a beating at the strip from rectangle-port, big-block Chevys and 426 Hemi Mopars, among others. Pontiac engineers knew what it would take to get back on top, and they were more than willing to put those engines in the hands of racers, even if the corporate bigwigs had other ideas.

Four versions of the Ram Air V were built, all using the Tunnel-Port head design: a short-deck 303 intended for the production '69 T/A. Its introduction would have homologated the engine for SCCA Trans Am competition. Also developed were a 366 intended for use in NASCAR, a 400 for use in production GTOs and Firebirds, and a 428ci version for all-out drag racing. A variety of single and dual four-barrel induction systems were designed for more specialized use.

All versions of the Ram Air V used extreme-duty block castings with four-bolt mains and lifter-bore reinforcements, forged rods and cranks, high-speed ignition systems, and Holley four-barrel carbs. As it turned out, only the 303 and 400 were intended for production, and those two engines had the highest production run. About 25 of the 303s and 80-200 of the 400s were built. After the program was canceled, the remaining engines went into the PMD parts system as crate engines.

The Quest For A Streetable Ram Air V

While most collectors would tremble at the thought, Chuck was actually interested in driving his Judge to cruise nights and occasionally around town. As a result, he was looking for a combination that was docile and user-friendly, yet offered plenty of power. If that meant some top-end performance would be sacrificed to achieve those goals, so be it.

Hearing good things about DCI Motorsports from other Ohio Pontiac fans, Chuck called upon proprietor Don Johnston to tackle this unusual engine and science out a streetable combination. "Chuck had an idea of what he wanted, but he left the details to me," Don says. "The engine had to look like it just came out of the crate, yet it had to be a true street performer. This was going to be a challenge with those gigantic intake ports."

Don's approach centered on two critical areas. With 324 cfm of intake airflow, it would be a monumental compromise to achieve the stated goals with just 400 cubes. The answer was to inject a large boost in displacement.

Don decided to substitute the stock crankshaft with a nodular-iron 455 unit with 4.21 inches of stroke. With a 4.13-inch bore, displacement would jump to 451 ci, a much better match for the intake airflow. As the 455 uses 3.25-inch mains and the 400 uses the smaller 3-inch size, the journals were cut to the appropriate size.

Rod journals were also cut from 2.25 to 2.20 inches to make use of readily available big-block Chevy-style aftermarket rods, a fairly common practice. "I would've gone with one of the new forged cranks that have come to the market," Don says. "At the time, though (spring 2007), they were not yet available. In my opinion, the factory crank is better than the current crop of aftermarket cast cranks."

The second part of the equation centered on the camshaft. With those huge ports, anything that could be done to increase mixture velocity would benefit streetability. Don wasn't about to divulge the exact specs of the profile he developed. He did, however, offer some clues. First off, it's a mechanical roller ground by Comp Cams on a custom blank for the unique R/A-V valve placement. "I'll tell you this much: It's a short-duration, high-lift grind," he says. "It has over 0.600-inch lift and 44 degrees of overlap-most cams at this lift usually run about 60 degrees of overlap, so there's a clue there."

The result is a very flexible engine that has a broad powerband. It will rev to 7,000 rpm if called upon to do so, and it has plenty of manifold vacuum to work with the automatic transmission. "The intake manifold and the cam are limiting total power; the intake design is not that good," Don says. "If we were going for maximum power, we'd build a new manifold and use a bigger cam, but that's not what this engine is about."

What is it about? For Chuck, it allows him to take out his historic race car and actually have some fun with it at the local shows and on the street. "I'll do a burnout with it every now and again, and it will hit seven grand," he says. "It also idles so smoothly, like no other Ram Air V I've ever heard. For me, it's the perfect balance."

Follow along as DCI Motorsports assembles a Ram Air V that lives up to the legend.