When John Walker builds an engine, he builds it in style. Cadillac style. John is one of those rare few who think outside the box and dare to go where few have tread. When asked how he got into the luxobarge powerplants, he chuckled and said it was by accident. Several years ago, he was in the middle of a trade deal and was supposed to get a 454 for his end of the bargain. When it came time to collect, the Chevy engine was a no-show. Instead, he was offered a pair of Cadillac engines. "Of course, I had to pull them," he says.

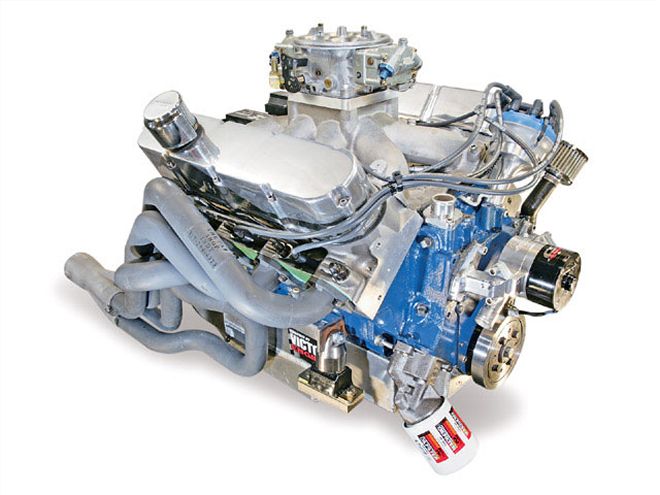

As he started building more power from the Caddys, he found the aftermarket lacking, so he started making his own parts. This 505ci monster that he built for the 2007 Jegs Engine Masters Challenge is not so much a tribute to GM's highest luxury line as it is a showcase of the parts that John (through his company Torque Inc. and a few other daring companies like MTS) have created for the engine family. Over the last several years, new heads, cams, intakes, rods, and pistons have found their way into the Cadillac engines that Torque offers. This 505 is a good mix of those parts.

When building an engine of this caliber, it takes a good plan to hold up to the abusive torque that the engine makes. The engineers at GM had a few of the bases covered on this point. John used a factory 500-inch block from a generic mid-'70s Caddy. He could have used either the 472 or 500 block built from 1968 to 1976, as they share the same dimensions other than stroke and piston compression height.

Prior to dropping the hammer at the Engine Masters Challenge, John Walker and Don Harrison of Torque Inc. double-check everything to make sure the valvetrain (the most vulnerable system for Challenge engines) is working perfectly.

Prior to dropping the hammer at the Engine Masters Challenge, John Walker and Don Harrison of Torque Inc. double-check everything to make sure the valvetrain (the most vulnerable system for Challenge engines) is working perfectly.

There are positives and negatives to the factory block. The small cam tunnel limits the cam dimensions. Choosing a cam with big lift means grinding the base circle smaller, instead of making the lobes bigger. This weakens the cam core, and in a contest where running a factory-style cast-iron core for a flat-tappet cam is mandatory, that can be bad news. On the positive side, John is a big fan of the on-center connecting rods. He explained that almost all V-8 engines use offset rods, meaning the small end of the rod is not directly in line with the big end. The Cadillac, like the newer LSx engines, uses a rod that's directly in line. "We had it right all along," John says, referring to the rod design. His argument was that running an on-center rod will keep the force from the combustion process firmly centered at the base of the rod instead of trying to tip it over and side load it. John often has Scat build several sets of rods at a time, so when it came time to order a set of seven-inchers for the engine, it was no problem for his normal supplier to comply. For many high-horsepower combinations, billet main caps and/or main girdles help keep the caps from walking. In this case, the factory caps-accompanied by a set of ARP main studs-were easily able to handle the forces in play.

Cadillacs, like their Pontiac cousins, have a lifter valley with a massive hole that sits wide open and allows oil to rain down onto the cam and crank. "It's got a great big section in the middle you can stick your hand in." Not bad if you want to make sure oil gets splashed all over creation, but bad news if you are trying to reduce windage. John made a metal block-off plate and welded it into place. After installing that, he installed some plastic plugs in the lifter holes, made some breather stands, and filled the lifter valley with epoxy. He says the red goo was "a high-temperature epoxy coating that they put on the inside of hot water pumps, like in a nuclear plant. Nothing sticks to it." As for prepping, John says after a good washing he "put Sikkens primer on the valley as soon as it dried, so it wouldn't rust up. That stuff is designed to have an epoxy coating put on top of it."

Like the block, the crank was a factory piece. All 472/500 engines used cast-iron cranks, but as usual, there are some good and bad castings. OK, Maybe not bad castings, but not as totally bombproof. The cream of the crop is the 094 nodular-iron crank from the '70-71 cars that weighs a good 9 pounds more than the more common ones. The unit John used here was one of the plain-Jane versions from the mid-'70s that he claims holds up fine. This must be the case, as his huge engine made over 600 hp and 600 lb-ft of torque! He had the specialists at Shaftech give the crank the full tune-up, including cutting down the counterweights and balancing before installation.

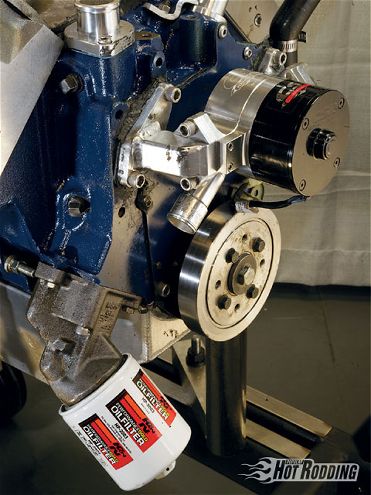

John showed off some of his creativity by adapting a CSR Chevy-style electric water pump to fit the Caddy engine. The MTS harmonic damper up front does a much better job of protecting the crank than any of the 30-year-old OEM dampers.

John showed off some of his creativity by adapting a CSR Chevy-style electric water pump to fit the Caddy engine. The MTS harmonic damper up front does a much better job of protecting the crank than any of the 30-year-old OEM dampers.

Torque Inc. is one of the few suppliers of forged pistons for GM's luxury engines. They keep a good supply on hand and have them made by either Diamond or Probe. In this case, Diamond whipped up a set of forgings with a fairly common .043/.043/3mm ring pack and an uncommon dish design. For lack of a better term, we'll refer to this as the "Altoids box" dish. There have been different schools of thought in piston dishes recently. Some use a traditional inverted dome, some use a spherical dish, and there are some using a "dual quench" design like the Torque Inc. engine. John told PHR: "Since the aluminum head is a little different than the iron head, there's actually quench on both sides of the combustion chamber. I saw what the Sprint Cup guys have been doing, and what some of the piston companies have been doing for pistons with heads similar to the Cadillac, and figured I might as well put all the dish in the middle to even the quench out on both sides. I don't know that it helps, but it certainly lightens that piston a bunch." Any time you can get a big-bore piston down to a measly 579 grams, it takes a tremendous load off the beam of the rod and frees up horsepower in the crank that isn't trying to throw a big weight around.

John had the piston skirts coated with a low-friction, oil-shedding coating, and the tops coated to keep the heat in the chambers. Normally, Cadillacs use a massive 1-inch wrist pin, but in this case, it was knocked down to a lighter big-block Chevy size. The rings were Speed Pro file fits, and as the bore size was fairly common to big-block Chevy numbers, they were easy to get a hold of. John says many of his engines are built this way to keep the cost down. Using a .020-inch oversize piston instead of a .030 oversize really opens up the availability of inexpensive rings.

The Torque Inc. engine used a set of uncoated Clevite main bearings. There is not a tremendous selection of undersize bearings available for the big Caddy, but Clevite has always managed to keep a good variety for rebuilders. In years past, John had become a fan of the legendary Vandevell bearings for connecting rods. Their lead-indium overlay allows them to absorb a good amount of debris and still be very forgiving on the journals. As far as hardness, they lie somewhere between a typical Clevite H-series and their super-malleable M-series microbabbit bearings. Clevite does offer their take on the Vandevell bearings, known as the V-series; however, when the Vandevell company went the way of the Dodo bird, Childs and Albert began to reproduce the bearings to the exact specifications as the originals. John picked up a set of those for use in this buildup, and was quite pleased with the results.

When it came time to work on the oil system, John acquired a Melling pump and immediately tore into it. Using 3M diamond files, he meticulously deburred any sharp edges on the case and gears, as well as sleeving and honing the pressure relief plunger cylinder. His diligent work showed as the oil pressure stayed steady during his dyno pulls, averaging 51-52psi. The only change in pressure was a slight rise and subsequent fall between 2,800-3,800rpm. This range is typically when detonation problems occur, so the extra pressure was not shunned. Whether this was by intelligent design or divine intervention is still unclear. John does feel there is an inherent design flaw in the OEM-style pump. "I think the design of that oil pump has a tendency to turn the oil into foam. The rotor design is identical to a Buick, and they have nothing but oiling problems, especially when you spin them over 4,800 or 5,000. All of a sudden everything just starts going haywire. We've designed a new oil pump; we just need to find a way to make them inexpensive." When asked whether he would prefer a gerotor pump, he expressed his dilemma: "The pump is in the front, and most of the pans are either a mid-rear or rear sump, so you've got that stupid, ungodly-long pick-up that's on a really bad angle. If I went to a gerotor, that's fine, as long as somebody wants to use some sort of a pre-oiler, because the one thing that's bad about a gerotor pump is they don't want to self-prime."

CSU has gained a reputation in the blow-through, turbo-, and supercharger community, but they also build a great naturally aspirated carb. For John's Cadillac, they felt that starting with a three-circuit Holley Dominator would make great power, and allow for extreme fine tuning of the fuel curve.

CSU has gained a reputation in the blow-through, turbo-, and supercharger community, but they also build a great naturally aspirated carb. For John's Cadillac, they felt that starting with a three-circuit Holley Dominator would make great power, and allow for extreme fine tuning of the fuel curve.

The fabricators at ProPan built the custom oil pan for John's engine out of aluminum, and were able to incorporate a full-length kick-out to absorb some of the oil that was whipped around in the crankcase. The final element of the oil system was the K&N oil filter that traps microscopic particles.

Besides the big camshaft companies, there are a few smaller shops that offer custom cams. One of these is Dougherty Racing Cams (DRC), a small company in Northern California that John has trusted for his customers, and his own engines. Besides the cams on the Torque Inc. website, John mentioned that he has at least 50 other cams that he has used successfully. For those wanting to build really big power, he said: "We do rollers; they're just ungodly expensive right now. We're making hydraulic roller camshaft cores to bring the motors into the 1980s." John Dougherty, the man behind the cam grinding machine, has been grinding cams for two decades, and has worked alongside some of the most respected names in the cam world before striking out on his own. DRC put together a solid flat-tappet cam for the Torque Inc. entry that took advantage of the high-flowing exhaust ports, ending up with the same duration and lift on intake and exhaust. Though the cam was not nitrided, the tool steel lifters and aggressive lobes managed to survive the abusive environment. Torque Inc. offers a modified Cloyes roller timing set to spin the big Caddy's cam, but was tight-lipped about what changes had to be made to adapt to this uncommon engine.

Anyone who's spent more than 10 minutes trying to hop up a Cadillac finds out quickly that if you want to use factory heads, you only have two choices: The early model pre-smog heads have relatively decent 76cc chambers yielding a little over 10:1 compression, and the '74-76 smog heads have lame 126cc chambers with an 8.5:1 compression ratio. Bulldog cylinder heads gained a reputation over the last few years as a company building heads for the black sheep of the American car manufacturers. Not too long ago, they began offering a head for the Cadillac engine that was the answer to John Walker's prayers. Cast in aluminum, these heads offer big valves, efficient combustion chambers, and, of course, high-flowing runners. As John was progressing in the build of his engine, his friends at Maximum Torque Specialties (MTS) were progressing in their bid to become the foremost manufacturer of aftermarket Cadillac performance parts. As such, they acquired the design rights to the Bulldog heads and intake manifolds for Caddy engines in the middle of 2007. With the desire to improve an already great product, Paul and Marty at MTS enlisted the help of Torque Inc. to aid in redesigning the old heads and intakes. John's personal touch is seen in the new MTS heads and intakes being cast now. They will be switching the aluminum to a better grade, downsizing the runners for better performance, and offering them bare or fully assembled with one-piece stainless valves.

The ICE ignition system almost looks too easy to use. In fact, the basic wiring system, matched component selection, and the easy-to-adjust rev limiters make the setup hard to beat. ICE claims that part of the key to putting out so much power is their voltage booster.

The ICE ignition system almost looks too easy to use. In fact, the basic wiring system, matched component selection, and the easy-to-adjust rev limiters make the setup hard to beat. ICE claims that part of the key to putting out so much power is their voltage booster.

The Bulldog/MTS heads on John's engine were given a good amount of attention. Lightweight hollow-stem valves reduced the tendency of the lifter to shoot off the nose of the cam at max lift, while allowing the valves to seat with minimal bounce. Using coated PSI valvesprings and titanium retainers certainly helped ensure the stability of the valvetrain. Cadillacs are blessed with a 12-degree valve angle that allows for an efficient combustion chamber. The steep angle also promotes excellent flow numbers when treated with an appropriate amount of port work. When asked about flow numbers, John says: "They went 345 at .650 on the intake, and 268 at .650 without a pipe on the exhaust." Those are definitely numbers that promote big horsepower. T&D shaft rockers are all designed for a specific head, and in this case, the 1.8 ratio pieces functioned perfectly. They included a set-up tool that allows the engine builder to discover the correct valvetrain geometry easily and set pushrod length correctly.

The Bulldog-branded intake manifold's design was purchased by MTS. John took the design even further by adding a significant amount of epoxy to the floor of the plenum, as well as reshaping the carb flange from an open box to a cloverleaf design. The clover design tends to increase signal strength to the carb, and really helps get the fuel flowing correctly at low rpm. This design is extremely close to what the new MTS intake casting will be, minus the inch of epoxy on the plenum floor. CSU prepared the big 1050 Holley Dominator that sits atop the intake.

Another of the showcase items John had on display was the electric water pump he offers. Starting with a CSR center section from a big- or small-block Chevy, he makes his own end pieces, as they just bolt onto the center section. Voil, an electric water pump for your early '70s El Dorado!

Using a Hall-effect trigger in the distributor instead of a typical magnetic pick-up has the advantage of creating a square-wave ignition signal instead of a sine-wave. The square wave creates a more accurate reading that newer digital ignition systems prefer.

Using a Hall-effect trigger in the distributor instead of a typical magnetic pick-up has the advantage of creating a square-wave ignition signal instead of a sine-wave. The square wave creates a more accurate reading that newer digital ignition systems prefer.

The only other item drawing electricity on this beast was the ignition system, and what a system it is. Ignition Components and Electronics (ICE) is an Australian-based company that's been taking the hot rodding and racing world by storm. They've created three levels of ignition systems (6, 7, and 10 amp) that put out significantly more joules of energy than other similar systems. The 6- and 7-amp systems are common for street, strip, or circle track applications, while the big 10-amp setup was designed for forced-induction and alcohol engines that are notoriously difficult to keep lit. Typically, a naturally aspirated pump-gas engine like the big dude that John Walker built doesn't call for a 10-amp ignition, but overkill be damned, he put it on there, and it worked perfectly. The system used a billet aluminum Hall-effect distributor that's proven to be more accurate than a magnetic trigger distributor. Extremely simple wiring connects a voltage booster pumping out 24 volts to the ignition box, again a simple design with a built-in adjustable rev limiter, and a two-step for drag racing. The coil and plug wires are equally high-quality pieces.

Once all the Shell 91 octane was ingested, it was spit out through a set of custom headers built by the Fab Shop in Indianapolis. John couldn't find enough good things to say about the quality of their work. Running a set of two-inch primaries, they dumped into a set of three-inch Howe Racing merge collectors. Once only found in the upper echelon of NASCAR and Pro Stock, merge collectors have found their way into the sportsman racing world with prices decreasing and availability increasing. Ten years ago, an engine like this 505 would probably have had 2.5-inch primaries dumping into four-inch collectors. The use of energy by the merge collectors and a rethinking of how exhaust works have brought a major decrease in the size of exhaust systems. John's efficient system was able to successfully scavenge the exhaust gasses without creating a restriction in the system.

When this creation finally came to life on the dyno, the remainder of the Engine Masters Challenge competitors expected to see some big power numbers from this seasoned competitor. They were not disappointed. Even with the restrictions imposed by the EMC, John and Torque Inc. created a bombproof, mega-power combination using common sense and a little bit of ingenuity. "I want people to know that this motor is basically the motor we build for everybody." Can you imagine the reality of dropping a 607 lb-ft monster in your Caddy? With the availability of Cadillac engines still fairly good, and now some nice parts hitting the market, it might be about time to rethink the old formula before you build your next project. When it's time for that first rolling burnout, you can do it in style. Cadillac style!

BY THE NUMBERS TORQUE INC. 505CI CADILLAC Bore: 4.320-inch Stroke: 4.304-inch Displacement: {{{505}}} cubic inches Compression ratio: 10.5:1 Camshaft: DRC solid flat-tappet Cam duration: 258/258 degreesOn The Dyno Dts Dyno Data Torque Inc. 505CI Cadillac

RPM TQ HP 2,500 488 232 2,{{{600}}} 493 244 2,700 493 254 2,800 490 261 2,{{{900}}} 484 267 3,000 478 273 3,{{{100}}} 474 280 3,{{{200}}} 474 289 3,{{{300}}} 476 299 3,400 477 309 3,500 484 322 3,600 502 344 3,700 526 370 3,800 552 399 3,900 569 422 4,000 578 440 4,100 585 457 4,200 594 475 4,300 598 490 4,400 601 503 4,500 602 516 4,600 604 529 4,700 607 543 4,800 607 555 4,900 605 564 5,000 601 572 5,100 595 578 5,200 590 584 5,300 583 588 5,400 577 594 5,500 575 602 5,600 575 613 5,700 572 621 5,800 568 628 5,900 558 627 6,000 547 625 6,100 536 623 6,200 526 620 6,300 516 619 6,400 508 619 6,500 500 618