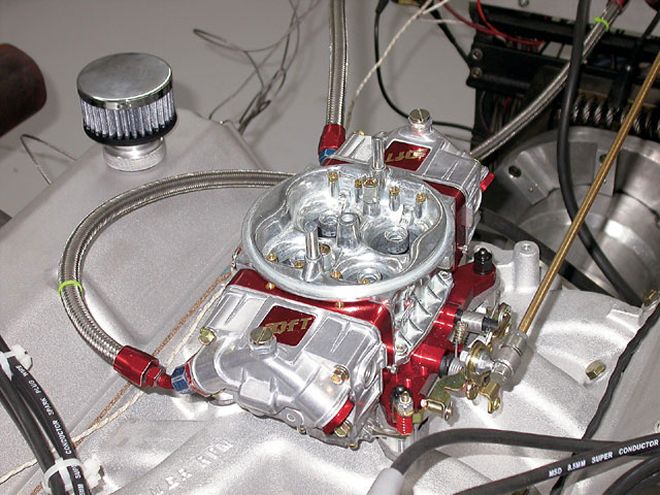

Dynatek Racing's new Classic Fuel Injection sure looks great atop an FE Ford big-block. Read on and find out how well it performed on an engine dyno.

Dynatek Racing's new Classic Fuel Injection sure looks great atop an FE Ford big-block. Read on and find out how well it performed on an engine dyno.

Back when Shelby was looking to make its little Cobras go faster, it turned to multiple carburetion in the form of a quartet of downdraft Weber carburetors. Not only did having eight individual throttle bores flow better than a conventional four-barrel carb, but the design of the IDA Webers all but eliminated the dreaded fuel starvation produced by high cornering loads. Thus the Weber-carbed small-blocks offered not only more power but also improved throttle response exiting the corners. Now throw in the fact that nothing looks better than four downdraft carbs perched on top of a Ford motor and you have the makings of a serious performer. While the Webers worked wonders on the racecars, they were unfortunately not ideal for daily street use. Complaints about hard starting, driveability, and poor fuel economy continue to this day and are all but accepted as the trade-off inherent in ownership of a multi-carb Cobra. What the world needed was something that offered the visual appeal of the original carburetors with the driveability of a modern EFI system-enter Classic Fuel Injection by Dynatek Racing.

Fuel-injected Fords are hardly something new. In fact, companies have been applying the benefits of fuel injection to fast Fords for some time now. They have even gone so far as to produce individual-runner systems a la the original Weber carburetion. The difference between those systems and this one from Dynatek Racing is that all the other systems available for the Ford applications look like fuel injection. The new Classic Fuel Injection (CFI) from Dynatek Racing looks like carburetion. Of course, the new CFI system is a far cry from the original carburetors, offering all the driveability, throttle response, and even fuel mileage associated with a modern electronic fuel injection system. By combining the retro-modern good looks with the performance and sophistication of an EFI system, Classic Fuel Injection has the potential to provide the best of both worlds. Now toss in the fact that the new system also offers significantly more flow than the original carburetors and you have the potential for looks, power, and driveability. According to Dynatek Racing, its CFI throttle bodies outflow a typical 48mm downdraft carburetor by almost 90 cfm per runner, for a total system improvement of nearly 720 cfm. That's a lot of extra airflow (the system total is near 3,000 cfm) and the reason the new CFI system will support motors exceeding 750 hp.

Dynatek's retro-modern Classic Fuel Injection combines the good looks of the original downdraft carbs with the sophistication and improved performance of modern fuel injection.

Dynatek's retro-modern Classic Fuel Injection combines the good looks of the original downdraft carbs with the sophistication and improved performance of modern fuel injection.

While the looks were certainly spot on, we had to take Dynatek up on its offer of some performance testing. In fact, we ran not one but three different Ford motors using its new CFI system. To illustrate the power offered by each system, we compared Classic Fuel Injection to a conventional four-barrel carburetor and intake. The first system to be tested was run on a 482ci FE stroker built by FE specialist Robert Pond. To illustrate the power potential of the new injection system, we needed a decent test motor. The 482 FE stroker was perfect for our needs. The all-aluminum (4.25 bore x 4.25 stroke) motor featured a compression ratio of 10.5:1, a custom hydraulic roller cam, and CNC-ported Edelbrock aluminum cylinder heads. The FE stroker motor was run with a set of 2-inch Fairlane headers, an offset distributor (though a small cap distributor will work with the CFI system), and an 8-quart Canton oil pan. The motor was first run with an Edelbrock Performer RPM intake that was port-matched to the Stage 2 CNC-ported heads. Using a trick (3-circuit) Quick Fuel 750-cfm carburetor, the 482 FE motor produced peak numbers of 606 hp at 5,900 rpm and 592 lb-ft of torque at 4,300 rpm. That's a far cry from the 425hp rating offered by the original 427 Sideoiler. The stroker motor was stout indeed, offering over 550 lb-ft of torque from 3,200 rpm to 5,800 rpm. Naturally, the carbureted combination was optimized with jetting and ignition timing and all runs were made at the same operating temperature.

After the baseline runs with the carburetor, it was time for Classic Fuel Injection. From a visual standpoint, what sets typical injection systems apart from Weber carburetors is that an external fuel rail must feed the fuel injectors. Weber carburetors are fed through a single feed hole located on the side of the carburetor. In order to facilitate the carburetion faade, Dynatek housed the fuel injectors inside the throttle bodies (between the two throttle bores) in an area usually occupied by the emulsion and jetting circuitry. This allowed the modern fuel injection to be fed through the same single fuel-feed orifice and eliminate any need for an external fuel rail. A hole located at the bottom of each throttle body provided access for the wiring harness to each pair of injectors. Pretty slick! Installation of the CFI system on the awaiting FE stroker required removal of the valve covers, rocker arms, and carbureted intake manifold. After bolting on the CFI FE intake, we installed the four throttle bodies. The 482 was run with a set of 65-lb/hr injectors installed in the throttle bodies. Additional sensors included those for coolant temp, air temp, and a manifold absolute pressure sensor. Also present was a throttle position sensor, cleverly concealed in the back of the rear throttle body.

After some tuning, the 482 stroker was run again in anger with the new Classic Fuel Injection. Equipped with the retro-modern injection, the peak power numbers jumped from 606 hp and 592 lb-ft of torque to 630 hp and 629 lb-ft of torque. Improving peak power numbers is always good, but what was really impressive was the fact that the new CFI system improved the power output of the 482 FE stroker throughout the rev range, from 3,000 rpm right through 6,000 rpm. Classic Fuel Injection improved the power output of the FE motor by as much as 42 hp and 48 lb-ft of torque, with significant gains offered from 3,500 rpm to 6,000 rpm. We shouldn't have to tell you how much cooler the FE motor looked with the four individual downdraft throttle bodies, as an IR induction system always ranks right at the top of the good-looking scale. That it also offers more peak power, more average power, and did so using less fuel than the carbureted combination is simply icing on the cake. As if 630 hp wasn't enough, Dynatek has plans to test its CFI system on a much more powerful FE combination to further illustrate the power potential. According to Dynatek, its Classic Fuel Injection system has enough airflow to support over 750 hp on a suitable engine configuration.

To properly test Dynatek's new fuel injection, we decided to compare it to a conventional carburetor. This stroker FE motor was first run with a ported Edelbrock Performer RPM intake topped off with a Quick Fuel 750-cfm carb.

To properly test Dynatek's new fuel injection, we decided to compare it to a conventional carburetor. This stroker FE motor was first run with a ported Edelbrock Performer RPM intake topped off with a Quick Fuel 750-cfm carb.

The next two tests were actually run for a couple of our sister publications, namely Muscle Mustangs & Fast Fords and Engine Masters Challenge. They are included here because being small-block Fords, they are natural choices to motivate any Cobra, Daytona Coupe, or GT40. Obviously, Dynatek Racing is serious about testing its components-in addition to the FE stroker, it also ran its systems on 408 and 331 Ford Windsor stroker motors. Its 48mm throttle bodies will bolt to any manifold that will accept 48mm carburetors, but it is important to point out that Dynatek has designed specific intake manifolds for the injection. These intakes offer both improved flow and a common plenum located below the intake to provide a constant and balanced signal to the map sensor. This common plenum is an important element in tuning the individual-runner intake. It should also be noted that the management system supplied with Classic Fuel Injection will run closed loop operation, meaning that it will self-adjust to a target air/fuel reading provided by the supplied oxygen sensor. This learning ability greatly reduces the time required to tune the all-important part-throttle and cruise conditions that make up the majority of daily driving. Combine this with offsets for air and coolant temperature and you have a system that will provide instant start-ups, throttle transition, and even fuel economy regardless of the ambient air or engine coolant temperature.

Test No. 2 was run on a 408 Windsor stroker combination equipped with AFR 185 heads, a streetable hydraulic roller cam, and MSD ignition. Like the FE, the small-block Ford intakes require use of a small-cap distributor. To establish a baseline, the 408 was first run with an Edelbrock Victor Jr. intake and Holley 750 HP carb. We were very impressed by the air/fuel curve provided by the HP Holley, while the timing curve remained at 34 degrees (where the carbureted and EFI combinations made the most power). Run with a ported Victor Jr. intake and Holley carb, the 408 produced 528 hp and 523 lb-ft of torque. After swapping on the Classic Fuel Injection, the peak numbers jumped to 541 hp and 545 lb-ft of torque. Like the FE test, the CFI system improved the power output throughout the tested rev range, from 3,000 rpm to 6,300 rpm. While the peak-to-peak power gains were impressive, the CFI system improved the power output of the 408 by as much as 31 hp and 36 lb-ft of torque. Everyone knows the Victor Jr. intake is tough to beat, and usually intake swaps result in more power at some rpm and less at others, but the CFI system produced more power everywhere.

The final test on Dynatek Racing's new Classic Fuel Injection was run on a 331-stroker crate motor from Ford Racing. The crate motor was equipped with CNC-ported Z304 heads, a wild solid flat-tappet cam, and a powerful single-pane intake that combined to push the peak power reading beyond 7,000 rpm. In truth, this is actually beyond the optimum operating range of the CFI system (at least with the standard-length air horns), but the test once again favored the injection system, at least from 4,000 rpm to 6,900 rpm. On this high-rpm small-block, the carbureted combination produced a higher peak power reading (527 hp vs. 513 hp), but a lower peak torque value (406 lb-ft vs. 418 lb-ft). From 6,900 rpm to 7,300 rpm, the single-plane Funnel Web intake produced more power than the injection. Below that point, the CFI system improved the power output by as much as 29 hp and 33 lb-ft of torque. It would have been nice to try the shorter air horns (stacks), but none were available for this early test. Just before the deadline for this article, the gang at Dynatek Racing tested its CFI system on LS2 and Dodge 5.7L Hemi applications with exceptional results. Like the Ford testing, the CFI system improved the power output of the LS2 and Hemi combinations throughout the rev range. Given the impressive dyno results, it looks like the new Classic Fuel Injection from Dynatek should find its way into the engine bay of many Cobras. After all, what Cobra owner isn't looking for retro-modern performance?