You can clearly see the problem with this camshaft.

You can clearly see the problem with this camshaft.

Flat-tappet camshafts are commonplace in the motorsports scene. From NASCAR Sprint Cup Series to IMCA Mods, guys across the nation are running this venerable design. About ten years ago, these cams started failing for no apparent reason. Through quite a bit of hard work, the cam companies eventually got to the root of the problem...oil. Since then, it has been fairly well publicized and one would think with all the media coverage of the subject racers would have caught on. However, people are still experiencing problems with their flat-tappet cams so we decided to take a look at the solution.

Of course before delving into the solution, let's take a look at the problem. All motor oils contain a variety of additives based on their intended use-high RPM, high mileage, low temperature, etc. Some have more, some have less. It all depends on the application. For years, one of those additives was Zinc Dialkyl Dithio Phosphate, or more commonly known as ZDDP. Originally developed in the '30s, ZDDP is an anti-wear/anti-oxidant additive. It also offers up excellent anti-scuffing properties as well, making it a perfect protectant for engines running flat-tappet cams. It was a standard ingredient in motor oil all the way through the '90s.

Unfortunately, the phosphorous in ZDDP plays havoc with catalytic convertors. The roller cam engines of today's production cars don't require the oil to have a big shot of ZDDP, so Detroit lobbied the oil companies to drop the ZDDP levels to preserve the cats and, subsequently, make it easier to achieve the government mandated 100,000 mile emissions warranty.

This cam has undergone a process called Pro Plasma Nitriding, which increases its hardness. Courtesy of Comp Cams

This cam has undergone a process called Pro Plasma Nitriding, which increases its hardness. Courtesy of Comp Cams

The problem was nobody in the oil companies said anything to the aftermarket. "I think from our standpoint they neglect to see an entire market that exists today," says Comp Cams' Scooter Brothers. "They saw it only through their eyes and figured everything has roller cams in it so it's no big deal. Let's just do it."

These formulation changes had a huge effect on the aftermarket that rippled through the racing community, and Brothers had firsthand experience with it. "Many years ago I had the problem with the engines from Roush. We couldn't even get an engine off the dyno without failing a cam," says Brothers. "We kept beating ourselves up thinking we didn't know how to make a cam anymore. We changed tapers, we changed lifters, we changed everything we knew how to change on the cam looking for the solution."

Brothers sort of laughs about the incident now, but it was a lot of work back then.

"We went through all kinds of things throughout this process of trying to find out what was wrong, scribing a little line on the lifter bores to squirt a little oil down there, drilling a hole in the bottom of the lifter, putting a spray bar in there to spray oil directly on the cam. Well, that was when Roush was sponsored by Valvoline, and we found out that somebody in the Valvoline labs changed something in the oil. As it turned out, as long as we had the correct oil it was fine. You know we just didn't have the right lubricant package in the oil." Once Brothers and Roush got the manufacturer to put the ZDDP back in the oil, the problem went away.

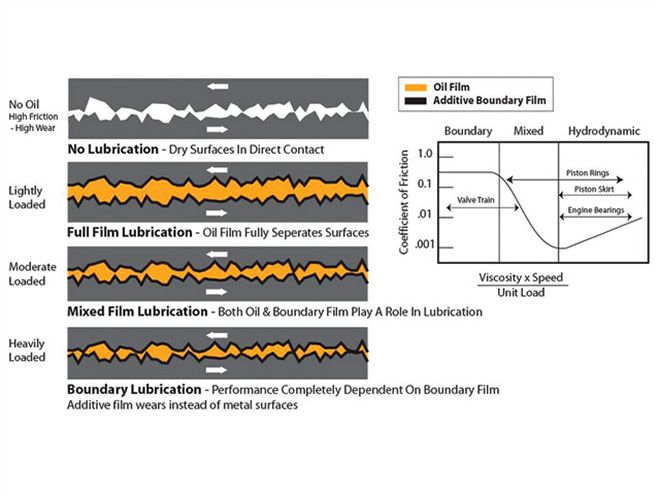

In heavily loaded applications such as a race motor, an oil wedge between metal parts such as camshaft, rockers, etc., cannot be sustained. As a result, metal-to-metal contact will occur unless a sacrificial coating is formed (see chart A, p.48). ZDDP is a polar molecule, so it's attracted to carbon steel surfaces where it reacts with heat, to create that sacrificial coating. The protective coating prevents metal-to-metal contact, which reduces friction and wear, and ultimately in a race motor prevents flat-tappet cam failure.

In heavily loaded applications such as a race motor, an oil wedge between metal parts such as camshaft, rockers, etc. cannot be sustained. As a result, metal-to-metal contact will occur unless a sacrificial coating is formed. ZDDP is that sacrificial coating. Courtesy of Joe Gibbs Racing

In heavily loaded applications such as a race motor, an oil wedge between metal parts such as camshaft, rockers, etc. cannot be sustained. As a result, metal-to-metal contact will occur unless a sacrificial coating is formed. ZDDP is that sacrificial coating. Courtesy of Joe Gibbs Racing

It's simple enough. If you run a motor with a flat-tappet camshaft then you need to use the proper assembly lube, break-in oil and racing oil all the time. These lubricants should have enough ZDDP or other zinc additive to provide a sufficient buffer against cam lobe failure. Today's race motors have higher engine speeds, higher spring loads, faster lifter acceleration and more. We're using crankcase evacuation systems where there is negative pressure in the crankcase which is pulling all the oil away from the camshaft. All of these things add up to a tremendously harsh environment. If you aren't using the right lubricant package you're asking for trouble.

But be warned, you may have a buddy who has run standard engine oil in his flat-tappet motor and never experienced a problem. "There's a chance that he'll put it in and never have a problem," says Brothers. "It'll perform just fine, it'll break in just fine and he'll never have a problem. However, that all depends on where that engine falls in the performance spectrum and how lucky the guy is that day."

The risk isn't worth it, and there is absolutely no risk to using the proper oils. So, unless you like replacing expensive engine components, you should not be buying the motor oil for your race engine at Wal-Mart. But how do you know which oil is the best for your application? Ask. There are a number of manufacturers out there who produce and market oils and lubricants specifically for racecar applications, such as Brad Penn, Royal Purple, and Joe Gibbs Racing Oil. All of which have sufficient levels of ZDDP to ensure flat-tappet cam operation.

"Late in the '90s we first began to see the problem," says Lake Speed Jr. of Joe Gibbs Racing Oil. "With the reduction in phosphorous and zinc levels, we began to experience engine failures with our Cup series engines. Of course this was magnified by the fact we were trying to turn 9,000 rpms." At the time the team had a sponsorship from an oil company making it relatively easy for them to find and solve the problem. Their sponsor custom blended an oil formula for them that solved their problem. "We needed a lube system that would allow us to assemble and break in the engine so that we knew what we had," says Speed. Eventually that formulation provided the foundation for a whole business for Gibbs and now that race team sells the oil they use in their cars.

Like many performance oil manufacturers, Joe Gibbs Racing Oil makes an assembly grease designed to work in concert with their break-in and racing oils. Photo by Joe Gibbs Racing

Like many performance oil manufacturers, Joe Gibbs Racing Oil makes an assembly grease designed to work in concert with their break-in and racing oils. Photo by Joe Gibbs Racing

Like Gibbs, American Refining Company offers a range of lubricants under the Brad Penn brand that offer high ZDDP concentrations for racing applications. American Refining Company is the oldest continuous running refinery in the United States. In addition, they are the only refinery in the United States that processes 100 percent pure Pennsylvania crude oil, which provides a unique cut off of the fractional tower. Now, refining crude oil into gasoline, butane, and motor oil is a complicated process, but suffice to say the fractional tower is a key machine in the whole system. The "cut" is oil industry speak that refers to the base oil taken from the refining process. Once a base oil is in hand, refineries can then begin to add other additives to develop a product that delivers optimum lubrication for a particular application.

American Refining's Dick Glady cautions that achieving the optimum lubrication for your race engine means balance. "The industry is attributing a lot of the problems with flat-tappet cams to the reduction of the zinc in the oil. That reduction upset the balance. Having a good balance of base oils and additives is the key in formulating a good race engine oil. For example, race engine oils need to have a range of 1,200 to 1,500 ppm (parts per million) of zinc. Our Brad Penn Grade 1 Racing Oils have 1,500 ppm zinc and 1,410 ppm phosphorus."

But having those levels of zinc and phosphorous are only half of the equation. You also need to consider the base oils. Pennsylvania crude oil, which is the base stock for Brad Penn Racing Oils, has a naturally occurring wetting agent that enables the oil to stay put and resist slinging for an extended period of time. That's important for critical areas such as flat-tappet cams and pistons/cylinder walls. After all, oil staying put means that it can better do its job of lubricating and protecting those internal engine components.

Brad Penn Racing Oil's full line of motorsports lubricants are refined from 100 percent Pennsylavnia crude oil. Courtesy of Brad Penn

Brad Penn Racing Oil's full line of motorsports lubricants are refined from 100 percent Pennsylavnia crude oil. Courtesy of Brad Penn

Regardless of the type of oil you choose to run, Speed and Glady agree that you should remain consistent with your brand choice. "The worst thing you can do to your motor is change your brand of oil regularly," says Speed.

"You shouldn't mix oil brands because each brand is typically formulated with a select balance of additive systems that are unique," adds Glady.

Different oils and lubricants have different additives that can, at the very least, compete with one another and in the worst case scenario cancel each other out. Remember when you drain the oil from your engine the internal components that were exposed to the additive package still have those additives on their surfaces.

Speed says, "Be consistent with a good quality brand, and change the filter regularly."

In addition to buying a race specific oil, you can also use a conventional oil and then buy a zinc additive to put into the oil, thereby boosting the zinc levels to the necessary 1,500 ppm that Glady spoke of. Richard Iskendarian of Isky Racing Cams says, "As far as oils go, we highly recommend the Brad Penn Racing Oil and Joe Gibbs Racing Oil. However, if customers prefer to use other oils without a high zinc content, we recommend a product called ZDDP Plus which replaces the EOS that GM discontinued about the middle of last year. The ZDDP Plus will take a sub-par oil and boost the zinc levels considerably. However, you should not add the ZDDP Plus to Brad Penn or Joe Gibbs as these already have generous amounts of zinc already." That would upset the balance Glady spoke of.

Pro Plasma Nitriding from Comp Cams provides an additional layer of protection to flat-tappet cams. Courtesy of Comp Cams

Pro Plasma Nitriding from Comp Cams provides an additional layer of protection to flat-tappet cams. Courtesy of Comp Cams

Comp Cams just introduced a new surface treatment available on all their products, Pro Plasma Nitriding. The process treats a narrow band of 1.5 to 2 thousanths deep on the surface, thereby increasing its hardness by about 15 pts on the Rockwell scale. In a nutshell, it eliminates any type of break-in problems.

The origin of Pro Plasma Nitriding is interesting to say the least. "Years ago we'd sell a lot of the 2300 Pinto cams," says Scooter Brothers. "Everybody here used to laugh about them and call them boomerang cams because they always came back with flattened lobes. Then somebody got this wild hair to try nitriding them. So we sent them to a place in Michigan. Once we started nitriding them, all of a sudden we didn't have any more problems."

With the rise of the sport compact movement, the Pinto cams and similar designs found a new home, and with the increased business the guys at Comp decided to buy their own machine and Pro Plasma Nitriding was born. "It's the closest thing that I've ever seen that enables me to say it absolutely stops the problem. I hate to say 100 percent assurance that it won't go flat, but knock on wood I haven't seen any probelms."

Synthetic oils are all the rage, but that doesn't necessarily mean they are good for racing applications. "The lubricity of synthetics is too much for a break in process," says Dick Glady, who recommends a break-in specific oil when firing up that new engine for the first time. And while they have their place in the industry, you don't need to run a full synthetic in your race motor. In fact, Brad Penn's synthetic blend oils have only 10 percent synthetic base stock. They've found that percentage is optimum in delivering better oxidation stability on the top end.

At the end of the day, if you're running a flat-tappet cam motor (and there are a lot of you out there) you owe it to your racing program to choose the right oil for your application. If you're building a motor, you need to use a good racing assembly lubricant, the proper break in oil and finally a good racing oil, like one of the brands mentioned here. Don't hesitate to contact the manufacturer of the oil or the cam as they will be more than happy to answer any of your questions. Remember using the proper oil may be the easiest thing you can do to prevent an unwanted cam failure.