Proclaiming that the annual Engine Masters Challenge is already a marquee hot-rodding event will have people shaking their heads by default. As savvy readers, you know that our inherent bias as organizers of the event severely compromises our objectivity. However, we're not the only ones who have reached this conclusion. Eagerly awaiting the announcement of the rules for the following year's competition-then vigorously scouring the fine print for loopholes-has become an annual tradition for participants. From that moment until just days before they hit the pump for qualifying, the country's top engine builders dedicate hundreds of hours throughout the year to engineering and testing their combinations. With pride, glory, and big stacks of cash at stake, the Engine Masters Challenge has become the UFC of internal combustion engines. This begs the question: Does a little guy stand a chance against the expertise and resources of professional engine builders? You bet.

One of those "little guys" is Len Caverly of Barrington, New Hampshire. He's an excavation contractor by trade, not an engine builder. He competes strictly out of passion for the hobby, not as a means of generating publicity for his business. Although the odds are stacked against privateers like Len when going head-to-head with big-name shops, his 655hp Pontiac gave them a run for their money. The 434ci Indian qualified Ninth overall, barely missing a spot in the finals. Along with his sons Arthur and Bob, Len relied on decades of grassroots racing experience in lieu of deep pockets to scheme a surprisingly simple, yet potent engine combo.

Stock Pontiac motors can need as much as 40 degrees of ignition advance.

Stock Pontiac motors can need as much as 40 degrees of ignition advance.

Poncho Power

For the professional engine builder looking to win at all costs, the engine make he chooses to field is often dictated by whichever platform gives him the biggest advantage based on how the rules are written. With the requirement to run production-style cylinder heads, this explains the overwhelming number of Cleveland-headed small-block Fords at last year's competition, and the peculiar shortage of small-block Chevys. On the other hand, for enthusiasts like Len, it's all about brand loyalty. He digs Pontiacs, has been racing them since the '60s, and has built more than 25 Poncho motors over the years. "After looking through the rules, I realized that a Pontiac motor could be very competitive, especially with the new aftermarket head castings that are on the market," Len explains.

Although the uninformed wouldn't consider a Pontiac a front-runner, Len's 434 proves that it's got the oats to run with the big boys. Once again, it comes down to the cylinder heads. Valve angle isn't everything, but in a naturally aspirated brawl like the Jeg's Engine Masters Challenge, it sure matters a lot. Len says that from 1967 on, all Pontiac motors came equipped with 14-degree cylinder heads from the factory. "In the world of small-block Chevys, 18-degree heads are pretty exotic, and 15-degree heads are full-race hardware, but Pontiacs came with 14-degree heads in regular production cars," he says, chuckling.

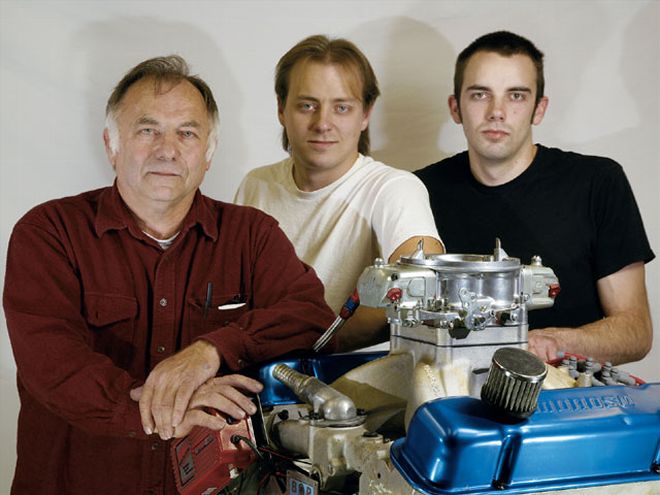

Len has passed his obsession with Pontiacs down to his sons, Arthur and Bob.

Len has passed his obsession with Pontiacs down to his sons, Arthur and Bob.

In addition to valve angles that are conducive to power, the generous bore spacing of Pontiacs allows a relatively short stroke to be used when targeting the rulebook's 434ci displacement limit. By combining a 4.155-inch bore with a 4.000-inch stroke, Len ended up with over-square dimensions favored by the bulk of the competitors. "From my experience, I really like over-square motors," he says. "A 4.155-inch bore gives you plenty of room to deshroud the valves and cut down on friction. Pontiacs had great bore and stroke dimensions from the factory."

Stupid Easy Short-Block

Len's 434 is so simple, it seems as if the rules were written specifically for Pontiacs. While many competitors opted for the largest bores their blocks could handle, then had a custom billet crank made to whatever length stroke yielded 434 ci, Len's motor is based entirely on affordable off-the-shelf hardware. By combining a 400 block's 4.121-inch bore (cleaned up .034 over) with a 428's 4.000-inch crank, the Poncho measured in right at 434 ci without the need for any custom components or tedious block prep. In fact, the crank is a cast-steel Eagle unit instead of a forging, and proved plenty stout for the task at hand. With 2.20-inch rod journals, it enabled the use of Scat 6.700-inch steel big-block Chevy connecting rods, resulting in an excellent 1.675:1 rod/stroke ratio. This is partly attributable to the Pontiac block's commodious 10.230-inch deck height. Likewise, considering Pontiac blocks can gobble up 4.500-inch cranks without much fuss, Len's 434 required zero internal clearancing. A set of CP 10.5:1 pistons completes the rotating assembly, and R&L Machine (Dover, NH) performed all of the machine work.

With one of the first sets of Kauffman Racing's new high-port castings to hit the market, Len had only two weeks to work on them.

With one of the first sets of Kauffman Racing's new high-port castings to hit the market, Len had only two weeks to work on them.

The lifter bores are the Achilles' heel of Pontiac blocks, but Len's not a fan of the reinforcement kits on the market. He's come up with his own method of beefing up the problem area by filling it with epoxy. "When you start getting cams with over .600-inch lift and 225 lbs of seat pressure, you want to reinforce the lifter bores," Len explains. "I prefer to pour epoxy into the entire valley surrounding the lifter bores, so the reinforcement ends up being one solid piece." Because sonic testing revealed very thick, uniform cylinder walls, Hard Blok wasn't necessary. The only other block modification is a set of Pro-Gram four-bolt main caps.

Cylinder Heads

The simplicity and effectiveness of the 434's bottom end is impressive, but short-blocks don't make horsepower. The key to this Poncho's stout power output is its Kauffman Racing high-port cylinder heads. They feature intake ports that are raised nearly an inch over stock, which straightens out the short-turn radius significantly. Consequently, they flowed 335 cfm out of the box, but that's before Len got to work on them. He's been porting heads in his garage for nearly two decades, and the local machine shop was so impressed by his work, they hired him to port heads for them in his spare time. In exchange for his services, the shop allows Len to use its flowbench, and after two weeks of work, he managed to squeak 385/273 cfm out of the heads at .800-inch lift.

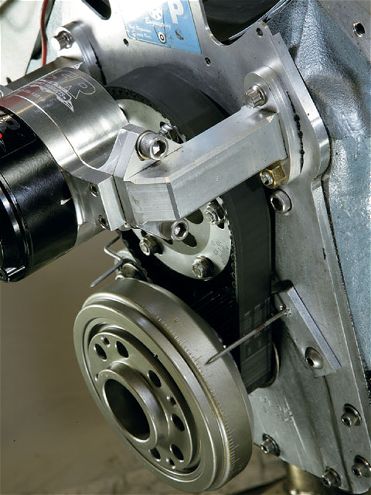

A BOP Engineering belt drive assembly makes short work of adjusting camshaft timing.

A BOP Engineering belt drive assembly makes short work of adjusting camshaft timing.

Len attributes the bulk of the airflow improvement to massaging the short-turn radius. "I ended up with about a 7/8-inch radius on the short-turn and widened it considerably," he explains. To give himself some more material to work with when opening the ports, he ordered the heads bare. "Because the pushrod holes weren't already drilled, that allowed me to relocate them, which gave me more room to open up the ports." Although he didn't measure the volume of the ports, they ended up measuring 2.50 inches tall and 1.310 inches wide. As any porter will attest, cross-sectional area more accurately reflects how a head will perform than its port volume in cc's.

The heads were so good out of the box that little else was required to get them to flow so well. "The CNC work they did to the chambers was excellent, so all I had to do was clean up the area around the valve seats a bit," Len says. "There's so much meat on the heads that you have a lot of room to spare before you hit water." The only epoxy added to the heads was used to reshape the port rather than to add material for porting. "Just to smooth out airflow, I added epoxy on both ends of the valveguides to act as fairings. That alone picked up 3 to 5 cfm."

The BG King Demon RS carb has been rubbed to 995 cfm, and features removable sleeves.

The BG King Demon RS carb has been rubbed to 995 cfm, and features removable sleeves.

Induction

Good heads are useless if they're choked by a restrictive intake manifold. To ensure the countless hours he invested in his heads didn't go to waste, Len matched them with an Edelbrock Victor intake. In addition to cleaning the runners, the bulk of the labor involved raising them in order to properly mate up with the relocated runners of the Kauffman Racing heads. "Just by raising the runners the necessary amount, it dramatically improved the entrance into the port from the runner," he explains. Likewise, he radiused the carb flange to improve flow and help direct air and fuel toward the ports. Mixing the air/fuel charge is a BG King Demon 995-cfm carb, which Len spec'd out on the conservative side. "It might have cost us some power on the top end, but it probably helped out in the low- and mid-range," he says. It was bolted to a 1-inch Edelbrock cloverleaf spacer to provide additional plenum volume.

The 1-inch Edelbrock cloverleaf spacer is a cross between a four-hole and an open design.

The 1-inch Edelbrock cloverleaf spacer is a cross between a four-hole and an open design.

One Block Fits All

A big-inch Pontiac isn't necessarily a big-block, and a small-inch Pontiac isn't necessarily a small-block. That's because in the walk of Poncho motors, one block fits all. Although they ranged in displacement from 326 to 455 ci from the factory, all Pontiac blocks share the same external dimensions and bore spacing. That makes it one of the most versatile engine platforms ever built, and besides a few exceptions, all components are interchangeable from one motor to another.

Perhaps the biggest distinguishing factor among Pontiac blocks is their main journal diameter. Pontiac's 326, 350, 389, and 400 blocks all share 3.00-inch mains, while 421, 428, and 455 blocks have larger 3.25-inch mains. Overall, the 400 block is the most prevalent. Considering the 455 featured a 4.152-inch bore and a 4.210-inch stroke, most stroker motors can be built with absolutely no clearancing at all. In fact, dropping a 4.500-inch crank into a Pontiac block requires less than five minutes of work with a die grinder. Furthermore, the Pontiac's tall 10.230-inch deck height allows retaining plenty of meat above the piston's wristpins, which yield excellent durability from the rigors of high cylinder pressure.

{{{DTS}}} DYNO RESULTs 434CI PONTIAC RPM TQ HP RPM TQ HP 2,500 458 218 4,{{{600}}} 569 499 2,600 472 234 4,700 574 514 2,700 480 247 4,800 580 530 2,800 480 256 4,{{{900}}} 586 547 2,900 483 267 5,000 591 562 3,000 494 282 5,{{{100}}} 593 576 3,100 504 298 5,{{{200}}} 597 591 3,200 513 313 5,{{{300}}} 599 605 3,300 518 325 5,400 598 615 3,400 518 336 5,500 595 623 3,500 516 344 5,600 592 631 3,600 512 351 5,700 588 639 3,700 507 357 5,800 585 646 3,800 504 364 5,900 580 651 3,900 503 374 6,000 573 655 4,000 508 387 6,100 563 654 4,100 517 404 6,200 551 651 4,200 529 423 6,300 542 650 4,300 544 445 6,400 533 650 4,400 555 465 6,500 523 647 4,500 563 482 ENGINE SPECIFICATIONS Bore: 4.155 inches Stroke: 4.000 inches Displacement: 434 ci Compression ratio: 10.5:1 Camshaft: COMP, solid roller Cam duration: 249/257 degrees at 0.050 Valve lift: .804-inch Rocker ratio: 1.73:1 Lobe separation: 108 degrees Installed centerline: 105 degrees Top ring: .043 inch Top ring gap: .022 inch Second ring: .043 inch Second ring gap: .022 inch Oil ring: 3 mm Piston: CP Block: stock 400 {{{Pontiac}}} Crankshaft: {{{Eagle}}} cast steel Rods: Scat 6.700 inches Main journal: 3.00 inches Main bearing clearance: .002 inch Rod journal: 2.20 inches Rod bearing clearance: .0015 inch Bearings: Mahle Clevite Cylinder heads: Kauffman Racing Intake valve dia.: 2.230 inches Exhaust valve dia.: 1.750 inch Intake manifold: Edelbrock Victor Carburetor: BG King Demon 995 cfm Ignition: MSD