So you've done the heads and cam swap and added all the bolt-ons your late-model LS-powered Trans Am or GTO can stand, but 11-second time slips are just not scratching the itch anymore, and you're ready to step up the excitement level. Perhaps it's even time to retire your Pontiac from daily transportation duties and snuggle up to around 500 cubic inches and a big dose of power adder. Until recently, this would have required tossing your modern LS-series engine and converting to a Pontiac IA II based engine, or commiting the sacrilege of swapping in a big-block Chevy, but no more. The impressive efficiency of the 15-degree LSX series heads can now be used on a block that can deliver serious inches, rock-like stability, and 6-bolt head clamping-all for about $2,000!

The Current Choices

The LS family of engines has already come to be regarded as great street performers, and the number of companies offering speed parts and power-increasing services for them has grown tremendously. Unfortunately, the lightweight aluminum block that helps them to be so potent on the street eventually becomes an Achilles heel when we talk about serious drag racing, and single-digit e.t. cars with LS OEM blocks are viewed by some as hand grenades with the pin pulled.

Some racers go with sleeved LS2 blocks, but apart from the '05-'06 GTO, no Pontiacs have come with LS2s. You must figure in the purchase price of the OEM block with the cost of sleeving it, which increases the cash outlay to more than buying the LSX block outright.

Another option is the C5-R block. CAD designed for prototype road racing as part of the chassis, it was never intended for public sale, let alone drag racing, so it is very expensive and simply does not allow the overbore size and stability of the LSX iron block.

World Products has announced its Warhawk block, a 356-T6 aluminum piece with iron liners. It appears to be sturdy and has many features in common with the LSX block, such as 6-bolt heads, priority oiling and provisions for a dry sump system, but it will have a smaller bore capacity and is over twice the cost of an LSX block.

The General Motors 6.0 liter iron truck block is the value leader. Although overbore capacity is limited, it is reasonably sturdy, cheap and can be stroked to about 410 ci. However, it was never designed as a performance block and was replaced in the GM trucks with an aluminum one in '07.

What is needed is a block that can be safely bored to 4.250 without getting major cylinder wall deflection, and it must have a rigid, thick deck with extra head bolts to hold the cylinder pressures required to reach over 2,000 hp. The real dream is to be able to do this at an affordable price. GM Performance Parts has now stepped up to the plate with a big bat, but will it be a home run?

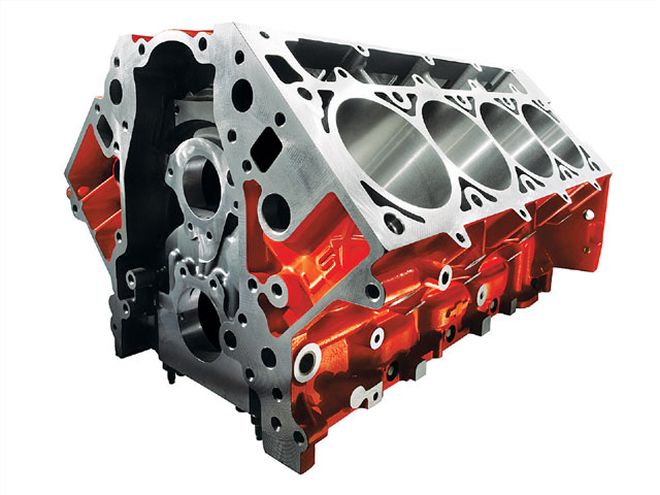

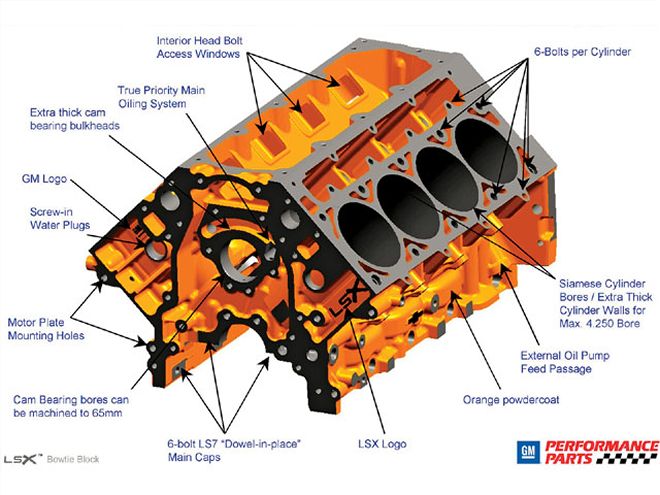

Inside The Lsx Block

The new GMPP LSX block is not simply a thicker version of a production block. Instead, it was designed from a clean sheet of paper with the help of famed Pro Stock racer Warren "The Professor" Johnson specifically to withstand racing stresses. GMPP reps estimate that it will handle 2,000 horsepower. Essential to achieving this goal was a very rigid structure for minimum cylinder deflection, increased crankcase web strength and head sealing, yet it still had to allow the largest possible bore-up to a 4.250-inch-while retaining 0.200-inch wall thickness. This required the inherent strength of a Siamesed bore iron block.

Although the LSX block pays a weight penalty because of the beefy construction and material choice, it is simply because "The Professor" kept nudging GMPP to design this block with no compromises in strength or limits regarding the ability to fit true racing components. This makes it perfect for use in high-boost/large displacement racing and extreme street car applications.

GM chose an extra-tough 280 kPa tensile strength block material (stock iron castings are 220-240, anything above 280 makes machining difficult), which not only helps rigidity but will also aid in bore durability. Features include 1045 billet steel 6-bolt main caps, two extra head bolts per cylinder (now six per hole), much thicker Siamesed cylinder walls and other beefy areas throughout to allow maximum head clamping integrity as well as distortion and twist resistance.

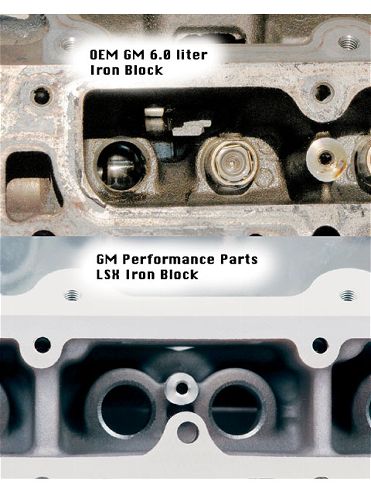

Another benefit of this sturdy construction is that the significantly thicker areas around the cam bearings and lifter bosses were designed to allow machining for oversized lifters and larger cam bearings to support the huge race cams that a serious racer will need to be competitive.

Other design characteristics of interest are extra bay-to-bay breathing pockets, which GM engineers found critical to high rpm power on big engines, and drilled and tapped bosses on the block for mounting motor plates. The oiling system on this block is a true priority system. Oil from the pump exits the filter, goes directly to the main bearings, then is routed to the cam bearings and valvetrain. This is beneficial because it puts the freshest, coolest oil at the main bearings with minimum startup time, minimizes pressure fluctuations at the mains, and tends to reduce windage by requiring less oil to be returned from the top end to the sump. If you're going to go racing with an LS-family engine, this is the block for you

Because the new LSX block was designed to use as many components as is practical in going back to the LS1, all LS-engine-equipped cars will find it easy to convert to a big displacement or high-boost racing class simply by adding the LSX block to their engine build recipe.

Only two caveats prevent transferring all of your existing hardware from another LS-family engine-the first being the need for special lifter retainers to get to the sixth head bolt access windows in the block valley. GMPP includes the required lifter retainers with every block, even though they are only needed if the engine builder decides to use stock-type hydraulic roller lifters. GMPP designed the extra head bolts to use studs that thread into the bottom of the cylinder heads, as running bolts in from the top would require compromising the head and intake port areas with holes to allow bolt access from the top. With the stud design, nuts can be easily put on the extra top head bolts from the intake valley windows and on the bottom bolts from outside the block. If your engine doesn't see very high cylinder pressures, feel free to use the standard pattern to bolt up whatever LS-type heads you want with the standard 4-bolts per cylinder.

A comparison of the 6.0 iron block and the LSX block shows the additional material around the lifter boss, which allows oversized lifters for a very large cam on the LSX version.

A comparison of the 6.0 iron block and the LSX block shows the additional material around the lifter boss, which allows oversized lifters for a very large cam on the LSX version.

The other requirement is the use of a Gen IV front timing cover for the ignition pickup mount, as the rear-mounted Gen III system would have interfered with the optional larger diameter cam and cam bearing journals. LS1 owners fear not. Thom Bates, GMPP marketing specialist, reports that for about $100 retail, an LS2-style front cover comes complete with the ignition sensor and seals.

Everything else on this block can use all components from any LS-series engine, including the LS7 internal-mount dry sump oiling system. The block even has provisions for an aftermarket external dry sump pump.

Since iron was chosen to create the ultimate big-bore racing block, the price of the block is significantly lower than the factory LS7 block. GMPP reps realized that more of these blocks will probably find their way into big-bore street vehicles, so they took great pains to cast in and machine all accessory and street-necessary lugs and bolt holes to run it in a street car, and to ensure that it would run cool and collected under all predictable street conditions. Bates told HPP, "We worked very closely with the GM Powertrain engineering team, which has thousands of hours of testing on coolant flow models for the LS engine series, and we have no problem recommending this block for street use at maximum (4.250-inch) bore with no cooling problems." Hmmm, how about a 500 ci LSX blown nitrous street car that puts out 1,000 hp? I immediately envision a glove box full of speeding tickets

GM engineers discovered that power flattened out on the 427ci LS7 at the top end without the bay-to-bay breathing pockets that go around the mains. Being capable of significantly larger displacement than the LS7, the LSX would suffer even greater power loss, so generous bay-to-bay breathing pockets were designed into the casting.

GM engineers discovered that power flattened out on the 427ci LS7 at the top end without the bay-to-bay breathing pockets that go around the mains. Being capable of significantly larger displacement than the LS7, the LSX would suffer even greater power loss, so generous bay-to-bay breathing pockets were designed into the casting.

Since this block is over-engineered for almost any reasonable engine build, or even for most racing classes, Bates also stated that there is plenty of extra material that can be "profiled" (machined out) to lighten up the block significantly. Guesstimates are that simply boring the as-delivered 3.99 inch bores out to the 4.250 maximum would drop approximately 20 pounds from the block, and if you don't need the block to survive 2,000 hp, there are plenty of other places that material can be safely removed.

Another point made by Judson Massingill of SAM racing, a well-known racer of LS-powered cars, is, "I have to meet minimum weight requirements per class rules and have to add weight to the car anyway, so the weight of the block is not a problem. Ring seal at high rpm with the old blocks is more of a problem."

Conclusion

It would appear that GMPP has put a large displacement race-ready engine block within easy reach of the performance-minded LS-engine community at a price that most can afford. If you're considering a major engine build on an LS-series engine, it is probably something that you should look into. But perhaps the greatest testament to the durability of this engine block is that it could be the last one you ever need to buy, no matter what you intend to do with it now or in the future-and the future looks very promising for the LS-powered cars.