Many teams choose to run without an alternator. The power needed to run these units is in the range of 1-3 hp. It makes sense to capture all of the available power we can, but does the loss of voltage in the battery make a difference in ignition efficiency? We decided to find out.

Many teams choose to run without an alternator. The power needed to run these units is in the range of 1-3 hp. It makes sense to capture all of the available power we can, but does the loss of voltage in the battery make a difference in ignition efficiency? We decided to find out.

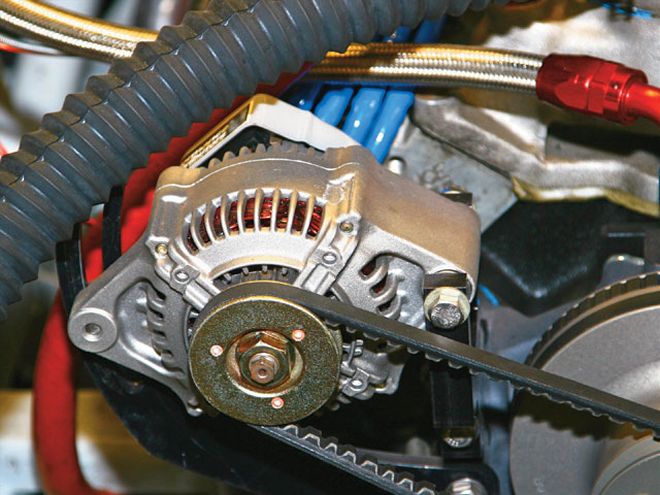

Over the past few years, we have run across some teams who, for the goal of attaining maximum power, chose to run without an alternator. We started thinking about that and decided to see if there were any detrimental effects associated with varying levels of input voltage to the ignition system.

There are basically two types of ignition systems in use in stock car racing. There is the inductive ignition in which the current goes directly to the coil and then directly to the distributor. In this system, the magnitude of the output spark is directly proportional to the input voltage. So as the voltage becomes lower, the ignition spark becomes less, reducing the efficiency of the combustion process.

The other system is the CD, or capacitive discharge, ignition in which a capacitor stores electrical energy and releases it to the coil. In these systems, more or less voltage does not affect the magnitude of the ignition spark in a positive or negative way within a certain range.

Our primary focus is on the more popular CD system and how it is affected as the battery voltage becomes low. We thought we might see a negative effect, mainly with the longer races and over the course of an event through practice, heat races, and the main event, if the battery voltage became too low.

The inductive ignition systems should always run an alternator because they are directly affected by the level of input voltage. That means that the output ignition spark at the spark plug is only as intense as the input voltage. A lower voltage input means a less efficient combustion process. Having a topped-off battery means having the most horsepower.

To gain a better understanding of this subject, we consulted with industry experts and even ran an impromptu test at Jay Dickens' facility, where we tried different voltage levels while dynoing a motor. We asked several knowledgeable persons if they knew of anyone who had ever evaluated the relationship between input voltage and ignition efficiency. The recurrent answer was no. That surprised us somewhat. What if there was an effect? Wouldn't that be important to someone who was trying to decide whether or not to run an alternator?

This high-energy ignition system from MSD is a very popular unit for some applications. The inherent design of these types of ignition systems causes them to be more dependent on the correct voltage input. So the output charge is directly affected by the input voltage. For these units, we recommend always running an alternator.

This high-energy ignition system from MSD is a very popular unit for some applications. The inherent design of these types of ignition systems causes them to be more dependent on the correct voltage input. So the output charge is directly affected by the input voltage. For these units, we recommend always running an alternator.

WHAT THE EXPERTS SAY

Our first call was to Todd Ryden with MSD Ignition. We discussed the various types of ignition systems and how they might be affected by varying voltages associated with the absence of an alternator to replenish the battery power.

He told us that MSD had not run any tests of its own, but believed that the ignition output for the CD ignition, such as the MSD HVC-L unit, would be consistent over a wide range of voltages. "If we ran a 16-volt battery, we would see no increase in combustion efficiency and horsepower output over using a 12-volt battery," Ryden explained. In other words, the units keep the output consistent even though the input is not.

What does happen with a CD ignition system is that once the battery output goes below a certain voltage, the ability to release a substantial charge is affected and the system may not operate correctly.

We also spoke with Paul Lundquist, who runs MG Industries, a manufacturer of racing starters and high-output alternators. His take is that running without an alternator "is the wrong way to go." He brings up the matter of additional battery drain from using electric fans and fuel pumps, but his references are mostly concerning the inductive ignition systems.

On those systems, horsepower drops of 3 to 30 hp are not uncommon due to low voltage levels. The direct-induction ignitions are typi-cally designed to be used with 14.0 to 14.8 volts of input for maximum efficiency.

We installed a new MSD HVC-L ignition box in our NASCAR Late Model stock car. A rev limiter is included in this variation of the popular HVC unit. The rpm limit is adjustable with plug-in modules.

We installed a new MSD HVC-L ignition box in our NASCAR Late Model stock car. A rev limiter is included in this variation of the popular HVC unit. The rpm limit is adjustable with plug-in modules.

TESTING ON THE DYNO

Jay Dickens, an engine builder and contributor to Circle Track, ran a test at our request in which he dyno'd a high-horsepower dirt Late Model motor in phases. He was asked to try to find differences in horsepower as the battery that ran the ignition system was discharged.

The initial base run was done, as is customary in his shop, with a fully charged battery and a charging system attached to the battery. This ensured a full and consistent voltage output to the MSD 6ALN ignition system that was in use.

Once the horsepower curve was established, a battery was attached just to power the ignition system and not start the motor. This battery was not aided by a charging system, either. That battery was slowly drained after each run and the engine horsepower levels were noted. The first run was at 13.6 volts, and then backup runs were at 12.8 and 12.1 volts.

We used a digital voltage meter to accurately record the battery voltage for each run during our dyno test. A fully charged battery carries around 13.5 volts. A discharged battery that won't crank a motor is usually down to around 11.0 volts or less.

We used a digital voltage meter to accurately record the battery voltage for each run during our dyno test. A fully charged battery carries around 13.5 volts. A discharged battery that won't crank a motor is usually down to around 11.0 volts or less.

When the next dyno pull was run at 11.4 volts, the motor started running rough. A further drop in voltage to 11.1 volts caused even more disruption in the firing of the motor, and the run was stopped to avoid hurting the motor. It would seem, according to this test, that when the battery reaches a level of less than 11.5 volts, the motor will not only begin to lose power and run erratically, but also may cause damage to engine components.

This correlated somewhat with what Todd had told us. He predicted a drop to 9 to 10 volts would cause problems, but the threshold appears to be a bit higher. The CD ignition works the same through different levels of voltage unless it drops to a certain level-then the system will not function properly. This is understandable. At least we have a consistent output through a wide range of voltage levels with the CD system.

The following recommendations are based on our research and the information we received:

* Don't run without an alternator if you're using an inductive ignition system such as an HEI or something similar.

* If you're planning on running without an alternator, you need to install an accurate voltage meter so you can monitor the voltage levels in your battery.

* It might be a good idea to run two batteries. With the modern, small, light battery packages (such as the Dyna-Batt we run in our Late Model stock car), running two batteries is not a weight disadvantage. The battery box in our car is built for a standard-sized battery and will easily hold two of these smaller batteries. Then you can install a battery switch similar to the ones used on boats and, if need be, switch bat-teries when the voltage gets low.

* Another idea would be to run the accessories off a separate battery from the engine/ignition system's main battery. Things such as the electric radiator fans, electric fuel pumps (if you use one), as well as the starter all draw lots of amps to deplete your battery.

* Always charge your battery whether you run an alternator or not. When the car is in the pits between practice sessions and while waiting for the start of the race, charge that battery. There are cheap charging systems available that could be installed in place of some of the ballast weight (so you're not adding weight to the car). These units trickle-charge the battery and have an automatic shutoff when the battery is fully charged. Along with a recessed male 120-volt plug, you could run an extension cord to the car and easily plug it in when the car is not on the track and even when it's in the shop.

The new-generation racing batteries are much smaller and lighter than those of past years. This Dyna-Batt from Performance Distributors was installed in our NASCAR Late Model stock car.

The new-generation racing batteries are much smaller and lighter than those of past years. This Dyna-Batt from Performance Distributors was installed in our NASCAR Late Model stock car.

CONCLUSION

This was a fun exercise and one which we think broke ground somewhat. We don't like unknowns for any system on the race car, and when we were trying to decide whether or not to run an alternator on our own Late Model stock car, we decided to investigate a little further.

The last thing you or I need when we get in the position to win is for our ignition system to break down. So we think it's a fair trade-off to give up the 2 or 3 horsepower and gain a lot of reliability. That's our decision and we're sticking to it.