There's nothing quite as exciting or nerve racking as building a new engine. It's exciting because more power is fun, but it's hard on the nerves because it's an expensive investment. Our '70 Fairlane 500, named project Fastlane 500, has been coming along nicely, and we're at the stage where the big Ford needs some big power. When we purchased the Ford, we ran it at the track and knocked down a leisurely 17.64 at 77 mph in the quarter-mile. With a crappy time like that, making it go faster should be easy. Actually, we want the car to be a lot faster, and for that we needed more than what the old 302 could muster.

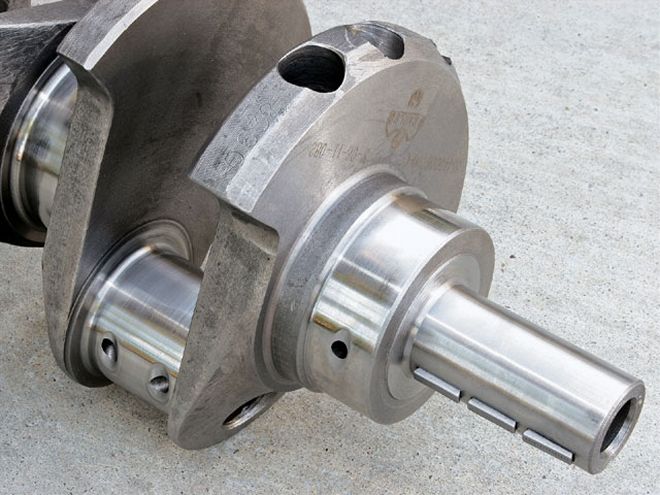

This kit from Eagle Specialty Products makes a 351W-based 408 stroker a breeze. You get the whole rotating assembly (PN 16123030) in one package for $1,279.95.

This kit from Eagle Specialty Products makes a 351W-based 408 stroker a breeze. You get the whole rotating assembly (PN 16123030) in one package for $1,279.95.

We had a lot of choices for a new mill. We could stroke the 302 to a 347, but the larger Fairlane needed torque-generating displacement. We considered going with a 460 big-block, but the swap wouldn't have been easy. We finally decided to stroke a 351W. The question was how big. We called Scott Johnston of Reincarnation High Performance to get his take on our build. He placed third in last year's Engine Masters Challenge with a Ford, so he obviously knows his stuff. He helped us develop our build, and made several suggestions about what would work.

It's All About Cubes

The maximum size that can be made from a 351W is 429 ci, but living near the limit doesn't bode well for longevity. We decided that going with a more conservative displacement would still make great power, and be rock-solid reliable. The choice to go with a 408 over something like a 392 was based on wanting just a few more cubic inches of small-block goodness. Also, the guys on Fordmuscle.com and Stangnet.com have had great luck with 408s, and offered good advice. The Fastlane Fairlane tips the scale at 3,460 lbs without the driver, and the 408 should provide enough torque to overcome that pesky first law of motion.

Also included in Eagle's 408 stroker kit are rod and main bearings, a moly ring set (4.030 bore), and appropriate pins for the pistons. This beats hunting around for all these parts separately.

Also included in Eagle's 408 stroker kit are rod and main bearings, a moly ring set (4.030 bore), and appropriate pins for the pistons. This beats hunting around for all these parts separately.

The Cost

When planning the build, we had to consider cost. We wanted quality, but not at a crazy price. Still, it's amazing how fast this stuff adds up. At first, we were going to run hypereutectic pistons and stock rods with our cast crank, but the cost difference was only about $170 for forged pistons and rods, so we splurged to gain extra durability. We were tempted to upgrade to a forged crank for another $335, but decided to draw the line somewhere, and the Eagle cast crank should hold up to our projected power level easily. We'll have a complete parts list and price breakdown next month when we assemble the 408. Here are the main power players in our 408 engine build.

Stroker CrankThe key player in any stroker build is the crank. A normal 351W has a 3.50-inch stroke, but our crank has a torque-building 4-inch stroke. According to Eagle, its ESP cast-steel cranks have a higher ductility than OE units, and feature .092-inch radii on all journals for extra strength. They also can use OE-style bearings. Brian Taube of Eagle Specialty Products told us that this package is rated for 500 hp at 6,500 rpm. Our mill should make peak power around 6,000 rpm, so we're good to go. "Cast crankshafts are fine for most street/strip applications," Brian says. "Things like heavy pistons and rods, and extreme rpm usage are what cast crankshafts cannot handle. The lighter the piston and rod combo, the better, and extreme rpm can cause a level of harmonics that no casting can handle. For this reason, Eagle builds lightweight connecting rods and uses quality aftermarket pistons to form an assembly for years of reliability."

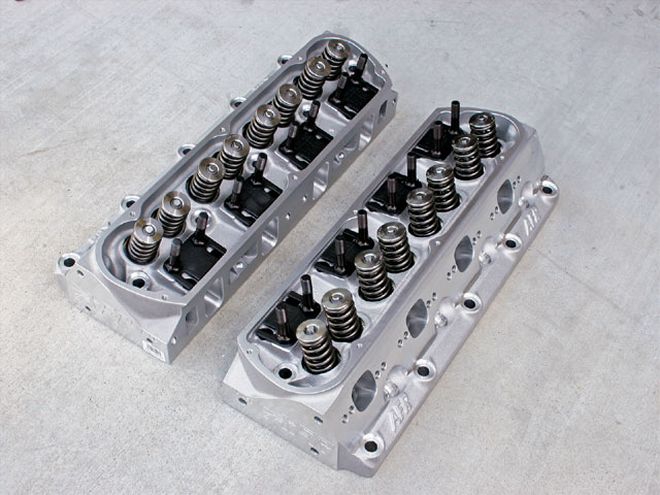

AFR Cylinder HeadsIf clothes make the man, then the heads make the engine. These AFR 205cc heads are based on their popular 165cc and 185cc heads, the only difference is that the intake ports are larger and the exhaust ports are raised .125 inch. They also use premium bronze-manganese valve guides for low friction, tighter fit, and durability. On the other end are ductile-iron seats, so any type of fuel can be used. The rocker bosses are extra thick and feature steel thread inserts. The valve spacing and angles are stock, so any popular valvetrain will bolt on, with the exception of rail-type rockers.

AFR 205CC FLOW NUMBERS Lift: Intake: Exhaust: .{{{200}}} 154 122 .{{{300}}} 224 173 .400 273 208 .500 296 231 .{{{600}}} 308 243 .700 311 249

The Bumpstick

When choosing a camshaft, it's important for it to work well with the cylinder head as a combo. Stiff springs with a mild lobe profile will wipe the cam lobe, but springs that are not stiff enough will cause valve float. When we ordered our AFR heads, we gave them our cam specs so they could install suitable springs. We ordered the rest of our gear from COMP to ensure it would work together. Choosing the cam profile was the hardest part. It was tempting to go with a radical stick to nail a big peak number, but we wanted to ensure that the car still had good low- and mid-range power, and that it was fun to drive on the street. After asking for advice around the Internet, and from Scott at Reincarnation, we came up with a 236/240 duration at .050, .555-/.576-inch lift, 110 LSA hydraulic roller camshaft from COMP (PN 35-426-8, $255.95). This should make good power at the track and be a blast to drive around town.

The AFR's 60cc combustion chamber has been milled to 56cc for our application. A .024-inch thick 4cc cut (to 56cc) is all the straight milling that's allowed. A 46cc chamber is possible if you want to go the angle-milling route. You can also see the stainless 2.080-inch intake and 1.600-inch exhaust valves. With our 56cc chamber and a negative 19cc dish piston, we should end up with a 10.9:1 compression ratio (assuming a .040-inch thick head gasket). The heads also have AFR's nitrous port. "The nitrous exhaust is simply a stronger flowing exhaust port," Tony explains. "Its benefits can be realized on any application, especially if properly cammed to take advantage of it. It allows the end user to run a single-pattern cam (or slight forward split) with an N/A engine without sacrificing any peak or after peak power. The fact the customer can run a tighter spread allows the engine to make more torque and horsepower across the lower and middle part of the curve. A smaller spread on the valve events also helps smooth idle and increase the streetability of the package due to less overlap."