I don't know about you, but I've never been able to pass by a street rod, or any performance vehicle for that matter, that sports a gaggle of injector stacks poking up from the intake valley of a V-8. There's just something inherently exciting about the sight of an engine equipped with an old school-style Hilborn injection system. You'll note I said old-school "style" because in this day and age we now have the opportunity to enjoy the performance and killer looks of early-style Hilborn injection that is really and truly streetable. You got it-the street-friendly, head-turning looks of mechanical injection with electronic performance you can enjoy without the constant tuning and tinkering!

My lifelong love affair with the looks of Hilborn injection was rekindled at a recent event when I spied from quite a distance a set of radical stacks poking skyward. Of course, I immediately headed over to take a closer look at what I assumed was a vintage drag car of one sort or another that someone had trailered to the event. The closer I got, though, the more I realized that this car was a street-driven vehicle rather than the race car I'd assumed it to be. Boy, I thought to myself, mechanical injection on a street car? How cool is that? Unfortunately it must really suck around town and in traffic. But, hey, that's the price you pay for a heavy dose of wow factor-full-throttle performance and little else. And though I may be a day late and a dollar short when it comes to modern injection technology, was I in for a pleasant surprise (one that has me seriously thinking about fulfilling my dreams of owning a Hilborn-injected hot rod). After corralling the car's owner and getting the lowdown on both the system and his enthusiasm for it, I realized the full-throttle-only barrier that for years had precluded said dream had been toppled by the availability of EFI in wolf's clothing-Hilborn EFI, right from the source, not via a third-party conversion!

With this newly kindled enthusiasm foremost in my mind, I decided to check out this exciting possibility as soon as I got back home from the event. For me, checking things out would entail a heck of a lot more than shaking the piggy bank and deciding what style of ram tubes would look the most evil; to be totally honest, I know next to nothing about EFI. I am, and always have been, much more at home with a pile of steel and a MIG welder than with laptops and power curves. Heck, I'm so technologically challenged that my wife has to reset the clock in my truck for daylight saving time for me every year. So it was with this in mind that I surfed on over to the Hilborn Web site to start my education. Of course I loved what I saw, but I really needed to get some type of guidance before I made the decision to proceed. Luckily I was pointed in the direction of Hilborn's EFI specialist, Andrew Star, who did his absolute best to shed some light on the subject for me. The following (much of the technical info supplied verbatim from Star) will hopefully be of interest to those out there who share both my love for the look of Hilborn fuel injection and my lack of full understanding of the subject. So read on; you may just end up sporting a gaggle of stacks sticking out of your hood and holding court with the throngs of admirers you find congregating around your engine bay from that point on.

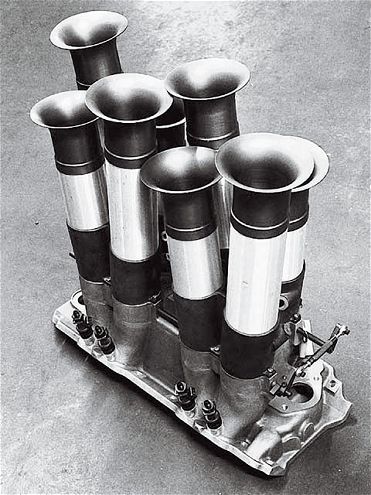

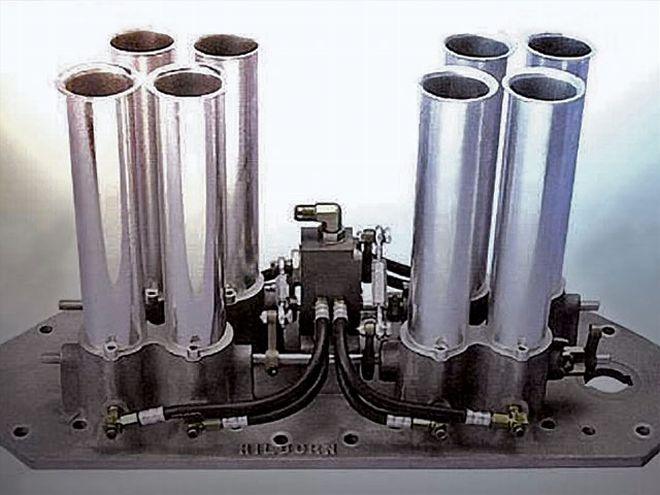

Hilborn EFI kits include an ECU that allows you to tune your engine simply and accurately without a laptop computer. The fuel-injector manifold features a split-throttle shaft design for smooth performance with gasoline setups, and offers a cool-looking, great-performing alternative to standard carburetion.

Hilborn EFI kits include an ECU that allows you to tune your engine simply and accurately without a laptop computer. The fuel-injector manifold features a split-throttle shaft design for smooth performance with gasoline setups, and offers a cool-looking, great-performing alternative to standard carburetion.

In The BeginningPerformance fuel injection owes its success and popularity to a gent by the name of Stuart Hilborn. Hilborn was first exposed to racing in the late 1930s when a friend took him to Muroc Dry Lake to take in some racing action. Needless to say, he was hooked right off the bat. Not long after, he built and raced an A-V8 Ford and also began constructing a streamliner that was unfortunately sidelined by the onset of WWII; Hilborn took a break from racing and joined the Air Force. It was during his stint in the service that he began to draw up plans for his first mechanical fuel injector. His construction began in earnest after the war ended, when he developed a completely new and unknown principle now known as "constant flow" fuel injection. Despite skepticism from many so-called experts regarding its success, Hilborn began racing with his fuel injector in 1947, and the success of his technological breakthrough earned him the reputation as the "father of fuel injection."

A lot of rodders were skeptical, yet the next year Howie Wilson piloted the then-completed Hilborn streamliner beyond the 150-mph barrier, thus effectively silencing his critics. While the car broke all records, the streamliner's design was appreciated as a piece of art as well. In April of that year, it appeared on the cover of Hot Rod magazine and continued to campaign at the lake. Unfortunately, the car flipped several times while on another speed run not long after, putting both Hilborn in the hospital and the streamliner out of action. After Hilborn healed up, he took his injectors to Indy where they became an instant success. Bill Vokovich drove the Fuel Injection Special, and, though he crashed while leading after the 190th lap, Hilborn injection still got a First Place with a Troy Ruttman win. During the 1950s, 1960s, and 1970s, there were more than 34 wins at the Indy 500 using Hilborn's fuel injector. Today it is used on many types of engines and all types of racers, including Sprint Cars, dragsters, Super Modifieds, off-road vehicles, and motorcycles.

Hilborn mechanical fuel injection has been a boon to racing over the years. Unfortunately, not so for street-driven vehicles that must operate throughout the rpm range for extended periods rather than full-throttle blasts. That is until recently with the advent of modern computer controls and EFI, or electronic fuel injection. The idea behind EFI goes kinda like this: When you step on the gas pedal, the throttle valve opens up more, letting in more air. The electronic control unit (ECU) senses that the throttle valve has opened and increases the fuel rate in anticipation of more air entering the engine. Sensors monitor the mass of air entering the engine, as well as the amount of oxygen in the exhaust. The ECU uses this information to fine-tune the fuel delivery so the air/fuel ratio is just right.

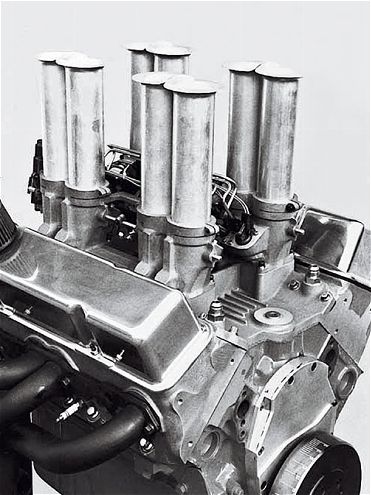

You've got to admit-Hilborn setups like this have to be one of the most impressive-and aggressive-looking induction systems there are, and great street performance and drivability is a given with Hilborn's EFI technology.

You've got to admit-Hilborn setups like this have to be one of the most impressive-and aggressive-looking induction systems there are, and great street performance and drivability is a given with Hilborn's EFI technology.

A fuel injector itself is really nothing more than an electronically controlled valve. It is supplied with pressurized fuel by the fuel pump in your car, and it is capable of opening and closing numerous times per second. When the injector is energized, an electromagnet moves a plunger that opens the valve, allowing the pressurized fuel to squirt out through a tiny nozzle. The nozzle is designed to atomize the fuel to make as fine a mist as possible so it can burn easily and completely.

The amount of fuel supplied to the engine is determined by the amount of time the fuel injector stays open (this is called the pulse width, and it is also controlled by the ECU). Electronic injectors are mounted in the intake manifold so they spray fuel directly at the intake valves. A pipe called a fuel rail supplies pressurized fuel to all of the injectors.

Operational benefits of a street-driven, fuel-injected engine include smoother and more dependable engine response, easier and more dependable engine starting, better operation at extremely high- or low-ambient temperatures, reduced maintenance, and increased fuel efficiency.

This Hemi-powered Mopar was spotted amongst the ranks of rods present at the recent Cruisin' Ocean City event back in Maryland and the crowd was drooling over the evil looks of its Hilborn injection.

This Hemi-powered Mopar was spotted amongst the ranks of rods present at the recent Cruisin' Ocean City event back in Maryland and the crowd was drooling over the evil looks of its Hilborn injection.

An engine's air/fuel ratio must be accurately controlled under all operating conditions to achieve the desired engine performance, emissions, driveability, and fuel economy. Modern Hilborn electronic fuel-injection systems meter fuel accurately and precisely, and let fuel-injected engines run considerably cleaner than comparable carbureted engines. Properly designed fuel-injection systems can react faster and more precisely to rapidly changing inputs, such as rapid throttle movements, and can tailor fuel distribution to closely match the engine's needs across a wider range of operating conditions, such as load, ambient temperature, operating temperature, fuel quality, and altitude (i.e., barometric pressure). You got that?

Carburetors Vs. Eight-Stack InjectionHilborn EFI specialist Andrew Star has written extensively on electronic fuel injection and he's given me permission to quote a bit of technical info that will hopefully be of interest-especially to those with a more technologically adept psyche than I.

"The carburetor can best be described as an air/fuel mixer that uses a differential in pressure to provide fuel at an established metered amount. Although easy to define, the actual workings of a carburetor are complicated, enough so that very few people are able to maximize its potential.

"With air movement toward the intake valve in the intake manifold, a result of piston movement and valve timing, the main venturi of the carburetor has air flowing past the booster, creating a pressure drop. This pressure drop causes fuel to be pushed into the booster supplied by the fuel bowl via the main well of the carburetor. The shearing of the fuel as it enters the air stream out of the booster causes the fuel to separate into smaller particles, where it is picked up by the air and carried into the intake manifold.

"The legendary Smokey Yunick states, 'The carburetor is a big restriction in the intake system. This is because in a round column of airflow, flow speed is fastest toward the center of the column. The design of the carburetor places the booster toward the center of that column in order to receive the strongest signal, or pressure drop at the booster, for maximum booster performance. Since airflow is impeded, the direction of part of that flow is diverted into eddies of spinning air that will disrupt the rest of the airflow around it.'

This is an example of an early mechanical setup for the Ford Flathead V-8. These days Hilborn offers street-friendly electronic setups that are every bit as impressive to look at as they are dependable and streetable.

This is an example of an early mechanical setup for the Ford Flathead V-8. These days Hilborn offers street-friendly electronic setups that are every bit as impressive to look at as they are dependable and streetable.

"Float bowl volume is essential for correct air/fuel ratio. With a needle and seat size a nominal .110-inch for gas, coupled with fuel pressure of 6 to 8 lbs psi at the needle and seat, it is difficult to keep the bowl filled. Carburetors use atmospheric pressure to provide lift of the fuel, therefore as the bowl empties, an increase in pressure drop is required to lift the fuel up the main well into the booster, compromising consistent air/fuel ratio. Fuel bowl problems also manifest themselves in applications that incur aggressive changes in direction, as in road-race and autocross applications.

"Cfm ratings for carburetors were introduced as a way to identify correct carburetor sizing for specific applications. In actuality, only the throttle blade size is needed to identify size, since a venturi will only flow so much air at a certain depression. Any published cfm ratings, regardless of product, should also include their depression in inches of water. Unlike the cylinder-head aftermarket where the standard for cfm ratings is 28 inches of mercury for pressure drop, there is nothing published for the carburetor aftermarket. As an example, all of Holley's 750-cfm carburetors use a 1.375 primary and secondary throttle blade, yet there are many companies who will claim up to 950 cfm with the same throttle blade size. These types of exaggerated specifications only lead to confusion for the end user on what size carburetor will fit his needs. Qualified carburetor shops will sell a carburetor by throttle blade size and not by exaggerated cfm ratings.

"At idle when air speed is low, the fuel droplet pulled from the booster is much larger than the one pulled when air speed is greatest or wide-open throttle. This has a profound effect on mixture distribution. If a carburetor's venturi is sized for low- to mid-range torque and strong acceleration, it will be too small to produce top-end power. Conversely, if the venturi is sized for top-end power, low- to mid-range torque and throttle response will suffer. The correctly sized carburetor for some applications will be a compromise of low- to mid-range torque and top-end horsepower."

With an abundance of ram tube and air filter designs, a Hilborn injection system can be tailored to the user's styling preferences-whether that's contemporary or traditional, they've got you covered.

With an abundance of ram tube and air filter designs, a Hilborn injection system can be tailored to the user's styling preferences-whether that's contemporary or traditional, they've got you covered.

The Eight-Stack Manifold"In a test conducted with a common plenum intake against the same engine with a Hilborn eight-stack manifold, with both adjusted to provide the same air/fuel ratio, the eight-stack manifold made more power. There are numerous reasons why.

"Without a carburetor's booster in the way, the eight-stack manifold will flow more air than a comparably sized carburetor venturi. Without the need for a pressure drop to supply fuel for the engine, the bore size of the eight-stack can be increased to supply the required air for top-end horsepower, yet have increased throttle response along with increased low- to mid-range power. The mild turning radius of the eight-stack intake helps promote line of sight for the air/fuel into the cylinder head. Since there is no common plentinum, the cylinders no longer need to digest an air/fuel mixture that is contaminated with pulses from companion cylinders. Since each cylinder is separate, there is no dilution to companion cylinders from reversion, eddy currents, fuel puddles, and the tight bends for the air/fuel to follow causing mixture distribution concerns.

"The eight-stack manifold employs a converging tract design, meaning the larger ram tube top is reduced in size as it enters the lower portion of the manifold before entering the opening of the cylinder head runner. With this design, air/fuel speed is increased when going from the larger opening to the smaller opening, ensuring that the air/fuel stays in suspension, unlike the tract of the common plenum manifold, which allows the air to slow when going from the small venturi of the carburetor to the larger opening of the plenum.

"Around the point that the intake tract is constricted, fuel is injected under pressure, allowing it to take maximum advantage of the air speed. In the converging tract manifold, most of the fuel that falls out of suspension as the wall is constricted is picked back up and put into suspension instead of being pushed along the walls.

"Fuel supplied into the nozzle of an EFI Hilborn injector can be as high as 60 lbs psi, allowing the injector to spray the fuel in a fan pattern. It also allows a consistently smaller-sized droplet, which is much more consistent than that of a booster. Therefore, the airspeed will not dictate the size of the droplet, which in turn allows the fuel to mix in better proportion with the air, providing improved engine efficiency and therefore making more power.

The Hilborn injection systems utilize a Carabine ECU that doesn't require a laptop to tune. It doesn't require a MAP, MAF, or O2 sensor either, and it is quite easy to install. The fuel curve is pre-programmed at the factory and simple tuning requires only a screwdriver. The Carabine ECU uses wide-open throttle, part throttle, and light throttle inputs for fuel management; there are also inputs for idle quality, cold start, and accelerator pump. A rev limiter is provided for those who require one, and optional altitude and air charge temperature sensors are available. It's the perfect answer for those unsure about a laptop system.

The Hilborn injection systems utilize a Carabine ECU that doesn't require a laptop to tune. It doesn't require a MAP, MAF, or O2 sensor either, and it is quite easy to install. The fuel curve is pre-programmed at the factory and simple tuning requires only a screwdriver. The Carabine ECU uses wide-open throttle, part throttle, and light throttle inputs for fuel management; there are also inputs for idle quality, cold start, and accelerator pump. A rev limiter is provided for those who require one, and optional altitude and air charge temperature sensors are available. It's the perfect answer for those unsure about a laptop system.

"Since a Hilborn injector does not require a bowl for fuel storage, it is an ideal system for any application that will create excessive fuel slosh, as in road race and autocross applications.

"Separation caused by the fuel crashing into the plenum floor is eliminated due to the individual throat design of the Hilborn injector. Also important is the reversion in which one cylinder has no effect on the other cylinders. This allows each cylinder to act on its own, greatly improving the engine's ability to produce equal power from the fresh intake charge each cylinder receives on the intake stroke. Since each cylinder has its own throat, the line of sight to the intake valve is improved, resulting in a straighter shot for the air/fuel mixture. The fewer turns the mixture has to make, the more the fuel stays in suspension, providing enhanced distribution into each cylinder.

"The Hilborn injector has numerous advantages over carbureted systems. A carburetor requires a correctly sized venturi for its application in order to pull fuel out of the booster. However, the Hilborn, with its injected fuel, can maximize airflow potential by removing the restriction associated with the booster while enlarging the throat diameter, allowing maximum breathing for the engine.

"This increase in throat size does not impede low-speed engine performance but enhances throttle response and engine acceleration. This allows for maximum engine rpm output without sacrificing low speed performance."

For maximum power, razor sharp throttle response, street-friendly drivability, and respectable fuel mileage, it's quite apparent that the Hilborn fuel injector is the right choice-and besides that, it looks awesome.