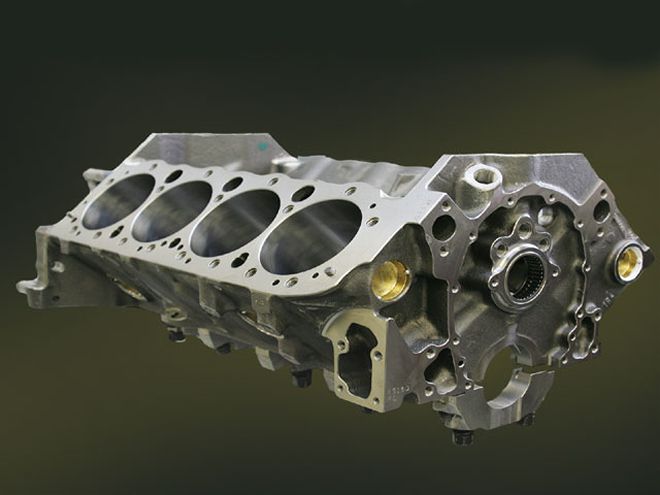

To many, it's little more than the case that holds the important stuff. But a properly prepared block is the foundation of a durable race engine that makes good, consistent power.

To many, it's little more than the case that holds the important stuff. But a properly prepared block is the foundation of a durable race engine that makes good, consistent power.

Have you ever broken down the costs associated with getting a new race engine built? Or even getting an old engine rebuilt? If you have and were surprised by how much it cost just to prepare the block for the build, you certainly aren't alone. New racers especially are often surprised by how much goes into preparing a new engine block to make it race ready. "After all," they say, "it's a new block-or it was running fine before we took it out for the rebuild-is all that stuff really necessary?"

This month, we are going to take a look at all the "stuff" that goes into preparing a block before the first part gets bolted to it. From cleaning, to boring the cylinders, to freeze plugs: What's critical, what can be done without (not much, really), and what can you do yourself?

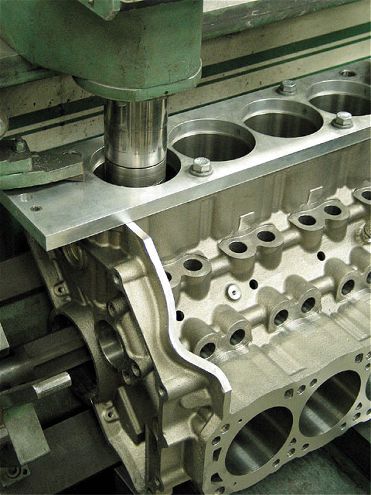

Believe it or not, the cylinder bores may not be correctly located from the foundry. This is because production-line tolerances aren't nearly what racers require. Using a B-H-J fixture when boring the cylinders helps center them over the crankshaft journals.

Believe it or not, the cylinder bores may not be correctly located from the foundry. This is because production-line tolerances aren't nearly what racers require. Using a B-H-J fixture when boring the cylinders helps center them over the crankshaft journals.

When it comes to engine block prep, most tasks can be split into two categories. Call them what you will, but they are easily summed up by calling them "The Basics" and "The Extra Mile." The Basics are those machining processes that really must be done just to have a properly operating engine. These processes include boring and honing the cylinders, align-honing the mains, and decking the block. The Extra Mile involves doing things that make sure you are squeezing every last bit of available power out of your engine. These tasks also increase durability. These include properly indexing the lifter bores, locating the height of the cam tunnel based off of the crank's centerline, and even polishing the oil galleries. Whether you spring the cash to go with The Extra Mile procedures is up to you, but if you are racing in the lower classes you can usually get by without them. If you are racing a stock block, there often isn't enough extra material to go about correcting errors with extra machining, so you simply must do the best with what you have. As we go through the procedures, we'll assume we are dealing with a new block. Whenever the criteria changes for a rebuilt block, we'll mention it specifically. Also, thanks to KT Engine Development in Concord, North Carolina, for sharing much of its price list with us for this article.

Don't let the name fool you. We call it The Basics, but that doesn't mean the procedures are necessarily simple. You may be able to assemble the engine yourself, but almost all of us must depend on a machinist to take care of the cutting on the block. Find someone you trust to hold the tightest tolerances with your block. It will pay off in the long run.

Cleaning Yes, this is a necessary step even if you are using a brand-new block. New blocks can often have casting slag hanging around in the cracks and crevices, and it becomes a big, gritty problem if not removed before assembly. This is a step you can definitely do yourself. If the block is new, all you need is a water hose and a variety of brushes to make sure you scrub everything. If you are cleaning a rebuild, however, the work gets tougher. You need to use hot water and a cleaner capable of cutting through the grease and grime that builds up just about everywhere. When you are finished, make sure to hit all the surfaces with a light coat of WD-40 or some other type of light oil as soon as the surface has been dried to prevent rust.

Line-honing the mains is the first step in the block prep process because everything else must be located off of the crankshaft's centerline.

Line-honing the mains is the first step in the block prep process because everything else must be located off of the crankshaft's centerline.

Engine builders usually charge around $120 to clean a block, and most racers consider it money well spent to avoid the hassle. The engine builders usually use a mild acid or caustic wash, either in a hot tank or a jet sprayer. Whether you choose to do it yourself or have your engine shop handle the duties, make sure the freeze and gallery plugs are removed beforehand so that anything hidden behind them can get out. After all the machining processes are complete, the block needs to be cleaned again to get rid of any accumulated machining oils and metal slivers left over from cutting.

Sonic and Pressure Testing It doesn't make sense to do machine work on a block that may not even be usable. That's why it's wise to sonic test the block before much effort is put into it. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. Even on a new block, this is important because core shift can cause one side of a cylinder wall to be too thin. Engine builder Peter Guild of PME Engines says he likes to see the cylinder wall thickness at least 0.275 inch. A sonic tester is also capable of catching a block that's just too far gone to be rebuilt again.

Decking the block is the process of removing material from the face to which the cylinder head bolts. You deck the block to get the appropriate piston height (at TDC) so that you have the best compression ratio and quench for your race package.

Decking the block is the process of removing material from the face to which the cylinder head bolts. You deck the block to get the appropriate piston height (at TDC) so that you have the best compression ratio and quench for your race package.

If you have your freeze plugs in place, it's also a good idea to pressure test the block before beginning the big projects. Pressure testing is done by filling the water jackets and then adding air pressure to see if there are any cracks or leaks. Both of these processes should be repeated after all the machine work is done to make sure you didn't cut too much away. Many machinists say they have seen situations in which a chunk of casting slag that was knocked away during one of the cutting procedures opens a pinhole through to a water jacket. The only way to catch this is with a final pressure check before engine assembly begins.

Align-Hone the Main Bores Align-honing the main bores for the crank journals should be the first machining operation performed because every other machining operation should ideally be referenced off of the crank centerline. Since the crank isn't in the block, this point is determined by the housing bore. When this is done, the caps must be properly fitted to the block and torqued into place. It is also a good idea to have an old oil pump housing bolted into place to simulate the distortion created.

The process of align-honing the main bores ensures that the bore housing inside diameters are correct and that all the holes are perfectly aligned to eliminate excessive bearing wear on any high or low spots. A good machinist spins the block 180 degrees during the process and runs the hone through the bores in the opposite direction for a few passes. This ensures that all the bores are identical and there is no droop caused by the boring bar. Usually, this procedure costs $225.

When honing the cylinders, a torque plate mimics the stresses a cylinder head bolted to the engine will place on the cylinder bores. The bolts holding the head in place can actually distort the cylinder walls, but as long as the cylinders are honed with this distortion present, it can be corrected.

When honing the cylinders, a torque plate mimics the stresses a cylinder head bolted to the engine will place on the cylinder bores. The bolts holding the head in place can actually distort the cylinder walls, but as long as the cylinders are honed with this distortion present, it can be corrected.

Boring and Honing Boring is the process of cutting away metal with a carbide cutting tool. Honing is much the same except a stone is used and you deal with much smaller increments.

Boring and honing isn't just about punching out the cylinder bores to a larger size. You have to make sure each cylinder is perfectly round and straight (perpendicular to the centerline of the crank). When boring the block, the machinist should use a fixture that locates the block on the crank saddles and another that locates the proper place for each cylinder (commonly a B-H-J Bor-Tru plate). This can help fix cylinder bore misalignment from the factory. Typically, the bores will be bored within approximately 0.005 or 0.006 inch of the final diameter.

The last bit of material is left on purpose to be removed by the honing process. Honing a bore, when properly done, leaves a fine crosshatch of valleys in which oil collects. A perfectly smooth cylinder wall wears rings very quickly. For racing, make sure your machinist attaches a torque plate before honing. A torque plate simulates the stretch caused by torquing a cylinder head in place. Also, you must use a head gasket between the block and torque plate to properly simulate the stress caused by a cylinder head. The head gasket should be the same type used on the final build. Guild says he has seen variances caused by honing with a standard composition head gasket and then building the engine with an MLS (multilayer steel) gasket. Usually, honing is done with a series of progressively finer stones (usually three) and takes some time. That's why the boring and honing process on the cylinders can cost $300 or more.

On a rebuild, if the engine has not been damaged, you can often get by with a light re-hone that removes as little as 0.0005 inch. This is enough to etch the cylinder walls, but removes so little that you don't have to go up a piston size.

Sonic testing is an easy way to ensure that the cylinder bores are thick enough in all areas to withstand the rigors of high-rpm racing.

Sonic testing is an easy way to ensure that the cylinder bores are thick enough in all areas to withstand the rigors of high-rpm racing.

Decking the Block Decking is the process of cutting down the portion of the block to which the cylinder heads mate. This is important for several reasons. First, it is often necessary to remove some material from this part of the block just to "square up" the cylinder heads. The deck of the block must be perpendicular to the crankshaft centerline. In a V-8, the decks on both sides of the block are at 90-degree angles to each other. A block should also be decked to ensure a good, flat surface so that you can achieve a good gasket seal.

Finally, a block must often be decked to achieve the proper deck height. Deck height is the distance from the crank centerline to the deck surface. Normally, the deck height is established just a few thousandths above the piston top when it is at TDC. Manipulating the block's deck height helps dial-in compression and also ensures the proper quench area. Quench is when the piston comes within around 0.060 to 0.045 inch of the deck of the head (this includes the thickness of the gasket). Proper quench area promotes good mixture motion of the air/fuel charge and more efficient combustion. Whenever you make a change in deck height, you must also make sure that there is still sufficient piston-to-valve clearance. Ken Troutman of KT Engine Development says decking a new block usually costs around $175.

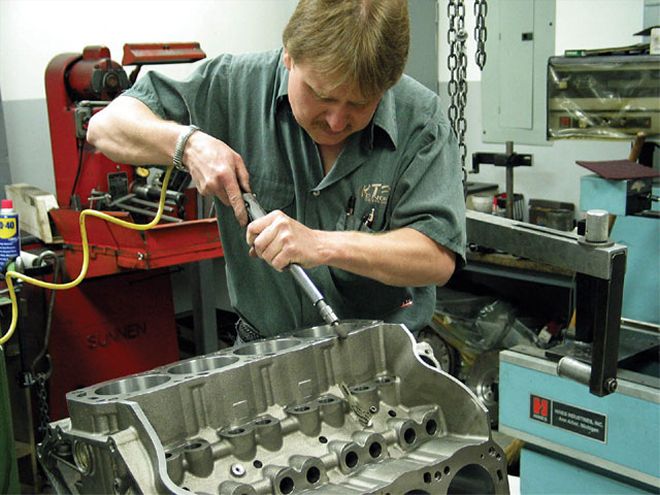

It may seem minor, but an important step involves breaking all the sharp edges created during the machining steps, especially at the top of the cylinder bores and around the edges of the deck. This ensures a good head gasket seal.

It may seem minor, but an important step involves breaking all the sharp edges created during the machining steps, especially at the top of the cylinder bores and around the edges of the deck. This ensures a good head gasket seal.

Align-Bore/Hone the Cam Tunnel The cam tunnel should be align-bored or at least honed on a new block for the same reasons that the main caps/saddles should be. Once it is correct, however, this process doesn't normally need to be done again. Unlike the main journals, where detonation can cause distortion, the cam bores don't see too much stress. On a rebuild, the cam tunnel should be honed if there is a spun cam bearing.

Many engine builders are using oversized camshafts whenever possible to reduce the chances of camshaft flex. This requires enlarging the cam bores even more than usual. The same holds true if you intend to install roller cam bearings. Honing the cam bores usually costs around $40 or so, but if you require the machinist to increase the diameter of the bore 0.010 or more, expect that price to jump closer to $75.

As stated earlier, steps in The Extra Mile category won't keep your engine from running, but will help give you an edge in some manner. It may be power, improved durability, or a small handling difference for your car. These processes are not cheap, so if you are racing in a lower level class, you'll probably find more efficient ways to spend your money. If, however, you are racing in a touring series, where the competition is cut-throat, these processes may be necessary to keep up with the top cars.

This is an extreme example of block lightening performed on a CNC machine. But you can safely remove a few unnecessary pounds from your race block just by removing any unnecessary bosses (engine mount bosses, for example, if you are using a front mount plate) with a hand grinder.

This is an extreme example of block lightening performed on a CNC machine. But you can safely remove a few unnecessary pounds from your race block just by removing any unnecessary bosses (engine mount bosses, for example, if you are using a front mount plate) with a hand grinder.

Valvetrain Alignment This actually involves two steps-properly locating the cam bores and the lifter bores-but they work hand-in-hand. Earlier, we mentioned boring and honing the cam tunnel, which is done to ensure the bores are the correct size and in alignment with each other. Valvetrain alignment takes it a step further by ensuring that the camshaft centerline is the correct distance from the crank centerline. This can be off slightly on mass-produced blocks and can affect cam timing.

The correct lifter bore alignment is normally found with a B-H-J fixture, which works in much the same manner as the one that centers the cylinder bores. If a lifter bore is out of alignment, many engine builders can ream it out, insert a bushing, and then re-cut the lifter bore in the correct location. This can help in a couple of areas. First, an improved alignment between the lifter and the cam lobes helps ensure that both wear properly, which is a concern with the high spring rates being used today. Second, when a cam is designed, it is assumed that the lifters are in the correct locations. If they are off by a degree or two, they will contact the camshaft at a different point from where the designer intended and make the valve opening and closing events happen either earlier or later than intended. This, of course, is going to cost you power.

Deburr Oil Galleries The oil galleries should already be inspected and clear of any obstructions during the cleaning procedure. Examples of obstructions include metal shavings from the machining processes, casting slag, pieces of shot (if the block has been bead-blasted), and just general unidentified trash. Deburring or polishing the galleries takes things a step further. To ensure vital engine oil flows easily to the places it needs to be with a minimum of pumping effort, many engine builders buff the galleries. The easiest way to do this is with a piece of emery cloth or fine sandpaper attached to a long, thin rod. Chuck the rod up an electric drill and spin the emery cloth as you move it along the length of the gallery. If this procedure is performed, it should be done before the final block cleaning.

Lightening Lightening the block adds neither power nor durability, but it can make you faster on the track. Peter Guild says that you can easily remove 5 to 6 pounds from a standard block without sacrificing durability. This includes profiling the main gaps and grinding off unnecessary bosses. You can do some of this with a grinder, but just be aware that it's hard work for little results. Removing weight from the engine allows you to move more of it to the framerails, where you can adjust its location to improve handling, but most of what you are removing is already pretty low. It may, however, be helpful if you have trouble getting enough of your weight percentage over the rear tires.

This article assumes that you are using an unfinished block that requires machining before it is ready for assembly. Some manufacturers, such as Dart, Brodix, and World Products, offer engine blocks that are already machined. In most cases, they are machined to standard specs. Some manufacturers allow you to choose from an options list. This is a good choice if you prefer to do most of the work yourself or don't have an engine machine shop nearby. Some leave the final honing to be done in order to match your final piston size, but others prepare the engine so all you have to do is wash it and begin pre-assembly. If you choose this option, make sure you are confident in your ability to check all the critical clearances so that the parts you assemble in your block meet the correct tolerances.