In last month’s issue we outlined the series of events that resulted in a complete rebuild of the 455 H.O. in our ‘72 Trans Am. What started out as a simple frost plug repair quickly escalated to a full blown rebuild, as we found several additional issues at the time of disassembly that could have certainly ended much worse. There are no two ways about it—we dodged a major bullet.

With only 1,286 Trans Ams built during the ’72 model year, and the fact that ours retains its numbers-matching drivetrain, we were set on reusing as many original components as possible during the 455 H.O. rebuild. Looking to improve reliability, we made a few concessions that would remain undetectable from any external view. This would also give us a chance to inject some modern technology, which could boost performance slightly, too.

Knowing a new crankshaft and pistons were required, it made sense to purchase a complete rotating assembly that would include everything needed to assemble the short-block. We opted for a forged 4340-steel crankshaft as it offered increased durability for only a few hundred over the cost of a cast replacement. It also made the jump to a stroker assembly a sensible choice—it didn’t add to the cost, would increase total displacement by a few more cubic inches, and could possibly add a few extra lb-ft of torque.

1 With a main journal diameter of 3.25-inches, the forged 4340-steel crankshaft from Eagle is a direct replacement for the stock nodular-iron unit. It boasts 0.040-inch more stroke length than stock. Eagle’s ESP Armor finishing process provides the brilliant appearance. Designed to shed oil and remove surface imperfections, ESP Armor doesn’t increase journal sizing but can be removed with polishing or machining, so be sure your machinist is familiar with it. Eagle is so confident that the finish improves crankshaft durability, the company warrants any such 4340-forging against failure for one full year regardless of application or usage. "> <strong>1</strong> With a main journal diameter of 3.25-inches, the forged 4340-steel crankshaft from Eagle is a direct replacement for the stock nodular-iron unit. It boasts 0.040-inch more stroke length than stock. Eagle’s ESP Armor finishing process provides the brilliant appearance. Designed to shed oil and remove surface imperfections, ESP Armor doesn’t increase journal sizing but can be removed with polishing or machining, so be sure your machinist is familiar with it. Eagle is so confident that the finish improves crankshaft durability, the company warrants any such 4340-forging against failure for one full year regardless of application or usage.

5 A few areas too close for comfort were gently massaged with a large ballpein hammer.">

<strong>1</strong> With a main journal diameter of 3.25-inches, the forged 4340-steel crankshaft from Eagle is a direct replacement for the stock nodular-iron unit. It boasts 0.040-inch more stroke length than stock. Eagle’s ESP Armor finishing process provides the brilliant appearance. Designed to shed oil and remove surface imperfections, ESP Armor doesn’t increase journal sizing but can be removed with polishing or machining, so be sure your machinist is familiar with it. Eagle is so confident that the finish improves crankshaft durability, the company warrants any such 4340-forging against failure for one full year regardless of application or usage.

5 A few areas too close for comfort were gently massaged with a large ballpein hammer.">

<strong>5</strong> A few areas too close for comfort were gently massaged with a large ballpein hammer.

<strong>5</strong> A few areas too close for comfort were gently massaged with a large ballpein hammer.

Flat-tappet camshafts remain an excellent performance value, but roller technology provides several advantages. When compared to a similar flat-tappet, a roller-grind can open the valves quicker, which allows for more seat time. The result is improved idle quality with no degradation to full-throttle performance. The friction loss associated with the roller lifter may also free up a few more horsepower, too, and because hardened components are used, they’re unaffected by modern spec oil and aren’t susceptible to lobe and/or lifter failure like flat-tappet cams.

A quick call to Butler Performance netted most everything we needed for our rebuild, including a high-quality rotating assembly. It and the other pieces we ordered were delivered to our doorstep in a matter of days.

We searched through Comp Cams catalog and considered a few of its off-the-shelf hydraulic roller grinds. We couldn’t find the exact specs we wanted so we simply ordered a custom-ground unit, which arrived along with everything else we needed for the valvetrain in little more than a week.

Willard Auto Machine (WAM) in Omaha, Nebraska, was enlisted to machine the 455 H.O.’s existing components to accept the kit we’d purchased, perform the complete engine assembly, and then measure the freshly rebuilt 455 H.O.’s performance on its in-house engine dyno. Follow along as the rebuild progresses and the 455 H.O. proves its worth as a formidable street engine, generating impressive numbers from a relatively simple combination. And to think we were satisfied with its performance before the rebuild!

HPP Engine Buildup Worksheet

Block

Oiling System

Heads

Before Rebuild

*Lift Int/Exh

After Rebuild

*Lift Int/Exh

Camshaft

Induction System

Ignition

Exhaust

Gaskets

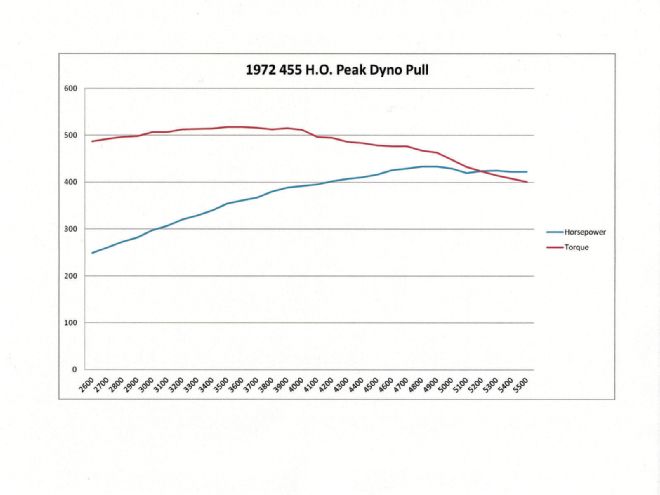

<strong>18</strong> One look at this dyno graph and it’s easy to see that Pontiac engineers knew exactly what they wanted to accomplish when designing the 455 H.O., and we simply expanded on that during our rebuild. The torque curve is remarkably flat and consistent, producing at least 500 lb-ft for more than 1,000 rpm, and the horsepower curve is smooth throughout the entire rev range. This excellent combination of horsepower and torque will reward us with a Firebird that’s smooth and docile at any speed on the street.

19 With the 455 H.O. cleaned and stripped to bare metal, it proved the perfect opportunity to repaint it in the correct shade of blue Pontiac used during the ’71-’72 model years. Mike Cole of D&R Auto Paint & Supply in Council Bluffs, Iowa, expertly mixed us a custom color that replicates the hue exactly. Local friend Mike Buzzello used his equipment and safety gear to first apply an epoxy-primer base, which was then followed by two light coats of color. The 455 H.O. looks factory fresh. ">

<strong>18</strong> One look at this dyno graph and it’s easy to see that Pontiac engineers knew exactly what they wanted to accomplish when designing the 455 H.O., and we simply expanded on that during our rebuild. The torque curve is remarkably flat and consistent, producing at least 500 lb-ft for more than 1,000 rpm, and the horsepower curve is smooth throughout the entire rev range. This excellent combination of horsepower and torque will reward us with a Firebird that’s smooth and docile at any speed on the street.

19 With the 455 H.O. cleaned and stripped to bare metal, it proved the perfect opportunity to repaint it in the correct shade of blue Pontiac used during the ’71-’72 model years. Mike Cole of D&R Auto Paint & Supply in Council Bluffs, Iowa, expertly mixed us a custom color that replicates the hue exactly. Local friend Mike Buzzello used his equipment and safety gear to first apply an epoxy-primer base, which was then followed by two light coats of color. The 455 H.O. looks factory fresh. ">

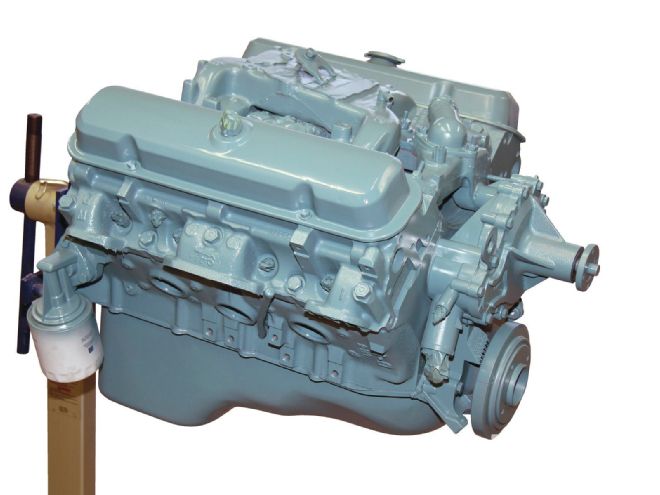

<strong>19</strong> With the 455 H.O. cleaned and stripped to bare metal, it proved the perfect opportunity to repaint it in the correct shade of blue Pontiac used during the ’71-’72 model years. Mike Cole of D&R Auto Paint & Supply in Council Bluffs, Iowa, expertly mixed us a custom color that replicates the hue exactly. Local friend Mike Buzzello used his equipment and safety gear to first apply an epoxy-primer base, which was then followed by two light coats of color. The 455 H.O. looks factory fresh.

<strong>19</strong> With the 455 H.O. cleaned and stripped to bare metal, it proved the perfect opportunity to repaint it in the correct shade of blue Pontiac used during the ’71-’72 model years. Mike Cole of D&R Auto Paint & Supply in Council Bluffs, Iowa, expertly mixed us a custom color that replicates the hue exactly. Local friend Mike Buzzello used his equipment and safety gear to first apply an epoxy-primer base, which was then followed by two light coats of color. The 455 H.O. looks factory fresh.