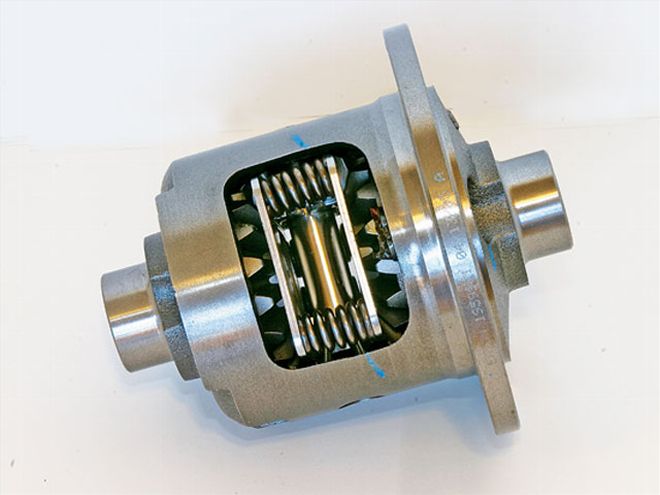

After determining the proper pinion depth, installing the pinion, and setting the preload to factory specifications, the replacement differential is pulled out of the box and examined. The Eaton limited-slip differential features a cast-iron case and utilizes carbon-disc clutch packs preloaded by a central-spring assembly located between each differential side gear. The preload from the spring assembly keeps the clutch packs engaged. However, when making a turn, the clutch packs are disengaged to allow one wheel to turn faster or slower than the other.

After determining the proper pinion depth, installing the pinion, and setting the preload to factory specifications, the replacement differential is pulled out of the box and examined. The Eaton limited-slip differential features a cast-iron case and utilizes carbon-disc clutch packs preloaded by a central-spring assembly located between each differential side gear. The preload from the spring assembly keeps the clutch packs engaged. However, when making a turn, the clutch packs are disengaged to allow one wheel to turn faster or slower than the other.

"Though this be madness, yet there is method in't." Had William Shakespeare been born in the modern age, surely his famous quote from Hamlet, Act 2, Scene 2, would have been used to aptly describe "Maximum-Effort Fourth-Gen 10-Bolt." According to the experts on all the late-model GM Performance boards, only the severely mentally challenged would waste their hard-earned dollars to build up a 10-bolt for their late-model F-body.

But wait just one second: The average Firebird hobbyist isn't putting down over 450 rwhp, hitting the dragstrip on "High School Night," or getting their nitrous bottles refilled on a weekly basis. Most fall somewhere between stock and moderately modified and are quite satisfied with lesser horsepower patinas. Is an expensive aftermarket GM 12-bolt or Ford 9-inch necessary for the majority of these hobbyists? The answer is probably not.

According to Jason Bailey, owner of Texas Drivetrain Performance, "10-bolts can be fortified to handle up to and beyond 425 rwhp. Before recommending what course of action a customer should take as it pertains to upgrading a 10-bolt or purchasing an aftermarket rearend, you must determine the use of the car. Since the 10-bolt has been bashed so much over the years, many owners will step up to an aftermarket rearend to avoid being thought of as either crazy or stupid by their peers. The goal of any rearend build is to know that when the customer leaves, the unit will handle whatever is thrown at it. If I can fortify a 10-bolt to get the job done for a quarter of the cost, everyone wins. By using aftermarket axles and a TA differential cover along with welding the axle tubes, the 10-bolt can be strengthened by 20-25 percent over stock. Owners who modify their Firebirds with the basic bolt-ons, such as headers and a cam, need the extra strength but don't necessarily need to spend thousands of dollars on an aftermarket rearend."

In the first installment, a used housing was purchased and completely disassembled by Texas Drivetrain Performance of Fort Worth, Texas. After detailing the major disassembly steps, the axle housing was taken to Peyton Automotive Performance so the axle tubes could be welded and the rearend straightened. After a quick trip to Enduro Powder Coating for an attractive semigloss-black finish, the housing rebuild began. New parts from Randy's Ring & Pinion of Everett, Washington, were used, and at the article's end, the pinion was reinstalled.

Hang in there as the rearend will soon be outfitted with a new limited-slip differential, and once complete, fitted with Yukon axles and a TA differential cover.

A side-by-side comparison of the Eaton limited-slip differential (left) and the Torsen unit shows the beefier casting of the Eaton. The Eaton unit utilizes two side gears and two spider gears as opposed to the eight worm gears and two side gears on the Torsen. For spirited driving and the dragstrip, the Eaton unit is hard to beat, while a Torsen T2R high-bias differential is the favorite of the road-racing and autocross crowds. A set of additional preload springs (T2 does not contain preload springs) in the T2R differential allows the unit to lock under low-torque settings. This is particularly helpful in start and stop conditions and in cornering.

The factory rearend is removed from under the Formula, and the disc-brake backing plates are relocated to the new rearend. Before inserting the Yukon axles into the housing, they are compared side by side with the factory offerings. The Yukon alloy axles are made of 1541H steel and are approximately 20-25 percent stronger than the factory offerings. Added strength comes from the increased levels of manganese in the 1541H configuration (versus the factory 1040 or 1050 steel), while computer-controlled hardening ensures a consistent metal grain structure, free of the imperfections that can lead to stress-induced failures. Note that the Yukon axle splines are cut longer and the diameter of the axle shaft is consistent, unlike the factory axles.

RECOMMENDED TOOLS AND RESOURCES

. Standard socket set

. Allen wrench set

. GM Kent-Moore differential service tool

. OTC race driver

. Prybar or large screwdriver

. GM service manual for 7.625-inch rearend

CRASH, BANG, BOOM-FIVE STEPS TO BLOW UP YOUR REAR

As the corollary to last issue's "Five Steps to a Stronger Rearend," here are some sure-fire methods guaranteed to shorten the life of your rearend, along with time-proven solutions:

Clutch-dumping-A manual transmission introduces significantly more driveline shock than an automatic transmission. Rev the engine up and dump the clutch and see how long the 10-bolt lasts (assuming your clutch holds).

Solution: If you must rev your LS1 to get it into the sweet spot to launch, go straight to a 12-bolt or Ford 9-inch.

Drag slicks or sticky drag radials-Enhanced traction from sticky rear tires transfers the power to the pavement, thereby placing additional pressure on the rearend to hold together.

Solution: Weld axle tubes, aftermarket axles, and TA differential cover.

Wheelhop-Six-speed-equipped Birds are especially susceptible to wheelhop, which causes the housing to distort and the ring to start creeping up the pinion.

Solution: Aftermarket torque arm, TA differential cover.

Addiction to deep gears-Although the 3.23 or 3.42 gears are nice, you can't live without 3.73 or 4.11 gears in order to accelerate even faster. The lower gear ratios put additional pressure on the housing, ring, and pinion, stressing the components.

Solution: Weld axle tubes, aftermarket axles, TA differential, and Eaton posi (drag racing only).

Poor service-The rearend fluid is designed to be replaced per the factory service intervals. If a rearend is starting to make noise or a gear change is in your plans, stay away from the corner service station or other service professionals that don't have extensive experience or the proper tools to set up your 10-bolt correctly.

Solution: Use a professional drivetrain specialist to set up and service your rearend.

RECOMMENDED PARTS AND SUPPLIES

. (1) Yukon rearend installation kit (YK GM7.5-B, retail $138.21)

. (2) Yukon axle bearings (PN AK1563, retail $15.20 each)

. (2) Yukon axle seals (PN 8660S, retail $2.68 each)

. (2) Yukon axles (PN YAG 26059962, retail $175)

. (1) Yukon 3.42-ratio ring-and-pinion set (PN GM 7.5-342, retail $196.35)

. (1) Eaton limited-slip differential (PN EAT19599, retail $541.04)

. (1) TA differential cover (PN YPT3-GM7.5, retail $148.11)

. (1) TA stud kit for differential cover (PN 1815, retail $24.99)

. (2) Qts. 80W90 gear oil (GM PN 88900329, retail $6.47 each)

. (1) Bottle GM limited-slip additive (GM PN 1052358, retail $7.65)

. (10) GM wheel studs (PN 955595178, retail $4.13 each)

COST COMPARISONS

A comparison of the 7.625-inch 10-bolt ring and pinion (top-center and right) versus an 8.875-inch 12-bolt car application (bottom-center and left) shows how the 12-bolt components dwarf that of the 10-bolt. Below are charts to help you wade through the choices when it comes to Fourth-Gen rearends.

10-BOLT BUILD: COMPLETEPart/ServicePart NumberPriceVendorParts, variousSee parts list$1,280.05Randy's Ring & Pinion10-Bolt (used)N/A$300.00Texas Drivetrain Perf.Powdercoat housingN/A$100.00Enduro PowderStraighten/weld axle tubesN/A$85.00Peyton AutomotiveRebuild labor and installationN/A$325.00Texas Drivetrain Perf.Total$2,090.05 + ShippingTotal minus housing/powdercoating$1,690.05 10-BOLT BUILD: PARTIAL Part/ServicePart NumberPriceVendor Yukon axlesYAG 26059962$ 175.00Randy's Ring & Pinion TA differential coverYPT3-GM7.5$ 148.11Randy's Ring & Pinion TA stud kit1815$24.99Randy's Ring & Pinion Fluid/gasketVarious$25.00GM/Auto Store Straighten/weld axle tubesN/A$85.00Peyton Automotive LaborN/A$100.00Texas Drivetrain Perf. Total$558.10 12-BOLT BUILD: COMPLETEPart/ServicePart NumberPriceVendor Moser 12-bolt 96-12B$2,148.00Thunder Racing ABS setup96-ABS-3CH$100.00Thunder Racing Fluid/gasketVarious$25.00GM/Auto Store Rearend installationN/A$200.00Texas Drivetrain Perf. Total$2,473.00 + ShippingAccording to Thunder Racing, "The Moser 12-bolt comes stock with 30-spline axles and a posi-traction unit. It can be used on three and four-channel ABS applications. The most popular options are 33-spline axles and an Eaton posi. For an extra $125 over the price listed above, you get stronger axles and a heavy-duty differential." FORD 9-INCH BUILD: COMPLETEPart/ServicePart NumberPriceVendor Moser 9-inchSpecial order$2,390.00Thunder Racing ABS setup (four-channel only)Special order$100.00Thunder Racing Fluid/gasketVarious$25.00Ford/Auto Store Rearend installationN/A$200.00Texas Drivetrain Perf. Total$2,715.00 + Shipping According to Thunder Racing, "The Moser Ford 9 comes stock with 31-spline axles and either a Ford Traction-Lok or Truetrac differential. The most popular configuration is a full-out racing rearend with 40-spline axles, spool, and Pro-Street gears that retails for $2,900. Three-channel-equipped Ford 9-inch rearends are not available, but a four-channel setup can be utilized."

REAREND FACTSThe largest contributors to how much horsepower and torque a rearend can hold are the size of the ring gear and the axle-spline count. As the size of the ring gear increases, so too does the weight of the housing and the amount of drivetrain power loss. A typical 12-bolt weighs approximately 190 pounds, or over 15 pounds more than the 7.625-inch 10-bolt. A Ford 9-inch clocks in at approximately 200 pounds unless optioned with an aluminum centersection, while the burly Dana 60 is almost 215 pounds. RearendApplicationsRing GearAxle Splines 10-boltF-body ('82-89), G-body ('81-88)7.500-in2610-boltF-body ('90-02)7.625-in2810-boltA-body ('64-72)8.125-in2810-boltA-body ('73-'81), F-body ('71-81)8.500-in2812-boltA-body (F-body 1970)8.875-in309-inchFord9.000-in30Dana 60Chrysler9.750-in31

Conclusion

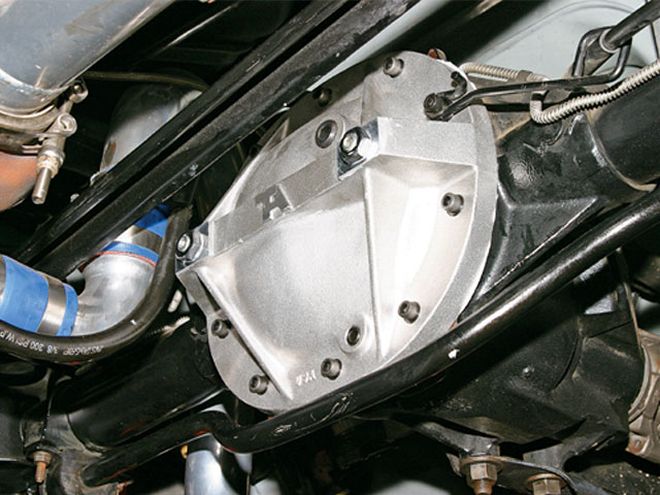

Before installing the cover, the optional TA stud kit is installed. The studs effectively replace the main cap bolts, allowing additional clamping force. A 51/48-inch socket is used to break the four cap bolts loose, but only one bolt at a time is removed. Loctite is applied to the replacement TA stud, and a 31/416-inch Allen wrench is used to tighten the stud to approximately 10 ft-lbs. This procedure is repeated until all of the TA studs are in place. The bearing caps are reinstalled and torqued to 55 ft-lbs using the supplied TA Performance washers and nuts.

Before installing the cover, the optional TA stud kit is installed. The studs effectively replace the main cap bolts, allowing additional clamping force. A 51/48-inch socket is used to break the four cap bolts loose, but only one bolt at a time is removed. Loctite is applied to the replacement TA stud, and a 31/416-inch Allen wrench is used to tighten the stud to approximately 10 ft-lbs. This procedure is repeated until all of the TA studs are in place. The bearing caps are reinstalled and torqued to 55 ft-lbs using the supplied TA Performance washers and nuts.

The 7.625-inch 10-bolt in your Firebird remains an enigma to the enthusiast as well as the aftermarket community. According to Jason Bailey, owner of Texas Drivetrain Performance, "Two identically equipped cars on a stock rearend can have shockingly different results. Some stock rears live long and happy lives with only routine maintenance and constant dragstrip action, while others snap axles or tear up differentials the first time a set of drag radials are bolted on. The common denominator seems to be the inconsistent quality of the metal in the factory axles and the setup of the backlash from the factory.

"Since you can't control the quality of the metal used in the stock axles, don't tempt fate. Replace them with a set of aftermarket axles. Rearends that are set at the upper end of the backlash specifications (0.008 and 0.009) or lower than 0.005 seem to experience greater parts breakage. With very tight specs, the gears can get too hot, gall, and fail. Conversely, if there is too much backlash, the pinion has added momentum when it smacks up against the ring gear. Set the backlash right in the middle of the specification at 0.006 or 0.007, and only use a qualified professional to service the rearend."

Decide what you want to do with your Pontiac, and then make an informed decision on whether the 10-bolt can survive with your driving interests and style. For drag racing applications pushing up to 425 rwhp with an automatic transmission, the 10-bolt might perform great, whereas an identically equipped six-speed might not fare as well. If you intend to drag race on a regular basis, seriously consider a 12-bolt. For Birds looking to run 8s and 9s, a Ford 9-inch or even a Dana 60 will serve you well.

Road racers shouldn't even consider a 12-bolt or Ford 9-inch unless competing in a "tube chassis" type race series. Instead, road racers should invest in a Torsen T2R differential and build a maximum-effort 10-bolt. Since a 12-bolt and Ford 9-inch are both heavier and require more power to turn, slight gas mileage and rear-wheel power losses should be expected. For the street cars and occasional drag and/or road racers, a properly prepared 10-bolt will likely serve you well. Invest $500 to weld the axle tubes, install aftermarket axles, put on a TA differential cover, and avoid a costly repair bill.