If you race a wet-sump oiling system, establishing proper oil control inside your engine block can help you put more power to the rear wheels

If you race a wet-sump oiling system, establishing proper oil control inside your engine block can help you put more power to the rear wheels

It's a funny thing that motor oil is a double-edged sword when it comesto racing. Yes, it lubricates moving metal parts that otherwise wouldbecome so much scrap metal without it in a matter of seconds. And yes,oil helps pull heat out of those same metal parts for which you paid somuch money. Those are definitely the good things.

But pumping that life-saving oil throughout the engine also requirespower that could otherwise be sent out the end of the crankshaft. If youthink you could use a little more power (and who doesn't?), then youknow this is a bad thing.

Unfortunately, there is no way to completely remove pumping lossesassociated with moving oil through the system. You've got to pump theoil where it needs to go, and that's going to require some of the powercreated by the combustion process in order to spin the oil pump.Fortunately, you can reduce it dramatically without harming theengine--if you are smart about it. Reducing horsepower losses from theoiling system is all about limiting the amount of oil you have to pump,the pressure at which it must be pumped, and the viscosity of the oilthat must be used. The result of minimizing these factors is moreavailable power to the rear wheels.

Main bearing installation is relatively easy and, if the tangs fitproperly, it's hard to mis-align the oil holes. It is, however, slightlymore difficult with the cam bearings. These are one-piece cam bearings,and they are held in place by a slight crush fit between the mainbearing and the housing bore. If you have the right tools, installing aset of cam bearings isn't difficult. You just have to be aware that oncethey are in place, the oiling hole cut in the bearing lines up with theoil gallery from the main bearing.

Main bearing installation is relatively easy and, if the tangs fitproperly, it's hard to mis-align the oil holes. It is, however, slightlymore difficult with the cam bearings. These are one-piece cam bearings,and they are held in place by a slight crush fit between the mainbearing and the housing bore. If you have the right tools, installing aset of cam bearings isn't difficult. You just have to be aware that oncethey are in place, the oiling hole cut in the bearing lines up with theoil gallery from the main bearing.

The key to minimizing your engine's need for oil is tightening thebearing tolerances. When it comes to main and rod journals, a commonrule of thumb used by top race engine builders is that you need 0.001inch of bearing clearance for every inch of journal diameter. If the rodjournals on your crank are 2.00 inches in diameter, you should have only0.002 inch of clearance between the journal and the bearing surface.However, when you push your clearances this tight, your margin for errorhas just shrunk to nothing. The machinist working on your block--not tomention the manufacturer of your crank and rods--needs to be dead-on withhis work, or else you will be burning up bearings faster than you cansay, "Where's my credit card?"

But if you can hold the tolerances necessary to keep such tight bearingclearances, you can get by with a lot less pressure and volume and stillkeep proper separation between the moving parts. In this area, at least,you can also get by with lighter viscosity oils, which are easier topump. This means that the old standard of 10 pounds of oil pressure forevery 1,000 engine rpm goes out the window. Many engine builders arefinding that by using tight bearing clearances and high-qualitysynthetic racing oils, they can get by with 50 pounds of pressure orless and still push their engines to 8,000 rpm and beyond. If you areracing a wet-sump engine, this means you can get by with a standard pumpinstead of a high-volume pump, which is a bigger horsepower drain on theengine.

Restrictors

Don't try to install the cam bearing without a cam installation tool. Acam installation tool (sold by Goodson and other engine specialtysuppliers) uses a chuck that holds the bearing securely without damagingit. You can drive the bearing into the housing bore with even pressureusing a hammer on the other end of the tool.

Don't try to install the cam bearing without a cam installation tool. Acam installation tool (sold by Goodson and other engine specialtysuppliers) uses a chuck that holds the bearing securely without damagingit. You can drive the bearing into the housing bore with even pressureusing a hammer on the other end of the tool.

A big part of engine oil control is making sure the places that needplenty of oil at good pressure get it by restricting oil flow to theareas that don't need as much. You can do this by strategically placingflow restrictions inside the oil galleries. Oil galleries are thepassageways inside the block (and sometimes the heads, too) throughwhich the oil is pumped.

After the block is cast at the foundry, the oil galleries are drilledthrough the block. That means every gallery has at least one opening tothe outside of the block because of the tooling required to drill thepassageway. In many cases, galleries are open on both ends to make iteasier to thoroughly wash the block and clean out any debris. To sealoff the galleries, the openings are tapped and sealed with pipe plugs.By understanding the direction of oil flow through the block and wherethe access points are, you can strategically place restrictors tocontrol the amount of oil and where it goes.

Although the overall philosophy of gallery design is the same in allengines, the exact location, size, and number of galleries can varybetween Ford, Chevy, and Dodge blocks. Likewise, aftermarket blocks frommanufacturers such as World or Dart that are based on designs from theBig Three can also vary somewhat. For the purpose of this article, weare only speaking specifically about oil control in Ford's Windsor V-8block, but the general lessons learned here can be used anywhere.

In some cases--especially if the block displays signs of core shift--theoil hole in the camshaft bearing won't line up with the feeding gallery,even though both sides of the bearing are flush with both sides of thehousing bore. If this happens, you must either open up the oiling holein the bearing or offset the bearing in the housing bore to center thehole over the gallery. Don't take a chance of ruining a cam by denyingit enough oil.

In some cases--especially if the block displays signs of core shift--theoil hole in the camshaft bearing won't line up with the feeding gallery,even though both sides of the bearing are flush with both sides of thehousing bore. If this happens, you must either open up the oiling holein the bearing or offset the bearing in the housing bore to center thehole over the gallery. Don't take a chance of ruining a cam by denyingit enough oil.

In a Windsor block, the oil pump is in the front, so the oil in the maingallery it feeds moves from the front of the block to the back. Thatgallery feeds the main bearings. Off the main bearings, the oil isrouted to the rod journals through oiling holes cut in the crank. Thereis also access to a second gallery that allows oil to flow from the mainbearing straight up to the corresponding camshaft journal bearing. Thisis the first area where engine builder Ken Troutman of KT EngineDevelopment restricts oil flow. By tapping the gallery that connects thecrank to the camshaft, Troutman inserts a 5/16 -18 pipe plug with a0.030-inch oil hole in all but the first journal gallery (because that'spart of the route that feeds the main gallery).

At the end of the main gallery at the back of the block, the oil isre-routed to two separate galleries that cross the lifter bores. Thepressurized oil in these galleries not only lubricates the lifter bores,it also enters the lifter and travels up the pushrods to lubricate therocker arms. Because of the way the galleries branch off from the mainline, it is possible to use a single restrictor for both liftergalleries, but Troutman recommends against it. In this scenario, theleft bank of lifters (looking at the block from the front) will receivemore oil pressure than the right bank. Instead, Troutman uses separaterestrictors, usually with 0.060-inch holes, for each gallery.

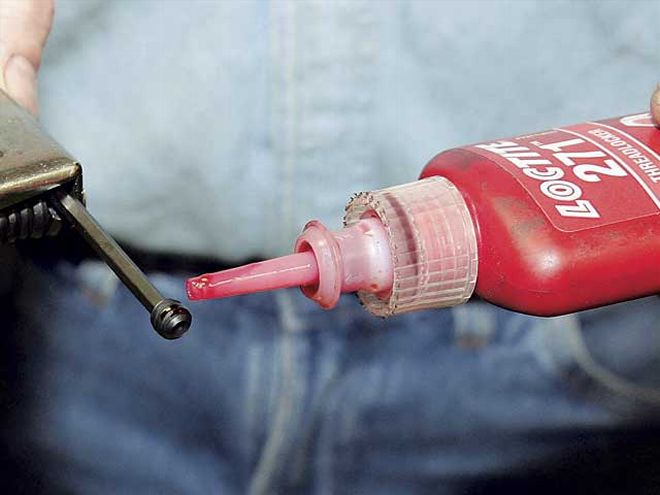

Oil restrictors are simply pipe plugs with holes of specific sizes cut through the center. You don't want to take a chance with one of these coming loose inside the engine, so apply a drop of Loctite before installing any restrictors

Oil restrictors are simply pipe plugs with holes of specific sizes cut through the center. You don't want to take a chance with one of these coming loose inside the engine, so apply a drop of Loctite before installing any restrictors

The amount of restriction that goes to the heads may vary depending onyour engine package. For example, when running flat- tappet lifters withEDM oiling holes in the face that feeds the cam lobe, Troutman opens therestrictor hole to 0.120 inch. The extra oil routed to the face of thecam lobes can bleed-off pressure, so the larger restrictor hole ensuresenough oil still gets to the rockers.

Finally, when it comes to determining how much oil pressure is enough,Troutman recommends taking into account exactly where your oil pressuresensor is located. In older Windsor blocks, the sensor is connected tothe main gallery at the front of the block--an area that will have thehighest oil pressure in the entire engine. Newer blocks, however, havethe sensor located off the main gallery at the back of the block. By thetime the oil reaches the sensor, it has already branched off tolubricate the crank and cam journals. This location will providepressure readings closer to the average pressure throughout the block.One location isn't necessarily better than the other, as long as you areaware of how this affects your readings.