Heat kills power. Heat damages parts. Oh, and heat robs the driver ofhis stamina, reflexes, and concentration. Bad stuff all around, andthat's why we've compiled this list of ways to beat the heat when itcomes to racing--everything from making sure your radiator is workingefficiently, to keeping the air/fuel charge cool, to keeping your drivercomfortable. To do this, we've contacted many of the industry leaders intheir respective categories for hints and tips on keeping excess heat atbay, and they responded with some pretty interesting stuff. Of course,this is still racing, so there is no way we can turn the inside of yourSuper Late Model on an Alabama track in August into a cool dip in amountain stream, but many of these tips can help you keep heat losses toa manageable level.

Fluids

Engine coolant "boosters," such as Royal Purple's Purple Ice, work bylowering the water's surface tension. This allows more efficient heattransfer from the metal in the engine to the coolant. When the hotcoolant reaches the radiator, it also means it can more easily transferits heat to the radiator.

Engine coolant "boosters," such as Royal Purple's Purple Ice, work bylowering the water's surface tension. This allows more efficient heattransfer from the metal in the engine to the coolant. When the hotcoolant reaches the radiator, it also means it can more easily transferits heat to the radiator.

We're talking about the car's fluids, not yours--lubricants andcoolants, specifically.

It's a well-known fact that when it comes to lubricants and oils,synthetics are less susceptible to thermal breakdown than mineral-basedlubricants. But that isn't the only way you can use your race car'slubricants to lower heat. The primary purpose of oil is to reducefriction. Reducing friction increases horsepower and torque, as youalready know, but it also reduces the heat that is a by-product of thefriction. This is also true in the transmission and rear end, where moreefficient oils can reduce the heat produced from driving the gears.

Royal Purple's engineers also tell us that the motor oil you use canalso aid the combustion chamber seal at the rings. By providing a betterseal between the cylinder wall and the piston rings, Royal Purple saysits oils can lead to a 12 percent reduction in coolant temperature. Asproof, the company says that it performed used thermal imagery testingon a V-twin motorcycle engine to find that the oil temperature can bereduced 25 to 44 degrees F with just an oil change.

When it comes to the coolant in your engine and radiator, additives arealso a popular way to knock the temperatures down. A good example isRoyal Purple's Purple Ice coolant additive. These "coolant boosters"work by reducing the surface tension of the coolant (plain old waterseems to work best), which allows better heat transfer from the metal inthe engine into the coolant, and then from the coolant to the radiator.A secondary benefit from coolant additives like Purple Ice is that theyalso inhibit corrosion and scaling inside the engine, which is importantbecause excessive scale buildup inhibits the flow of coolant through theengine and can lead to hot spots.

The Hard Facts on Coolant Boosters

As part of its testing, Royal Purple performed dyno runs checking enginetemperatures to see how different mixtures of coolant performed. Hereare the numbers they provided us:

50/50 mix of water and antifreeze 228 degrees F

50/50 mix of water and antifreeze with Purple Ice added 222 degrees F

Water only 220 degrees F

Water with Purple Ice added 200 degrees F

Radiator

Chris Paulsen of C&R Radiator says that choosing the proper fin count isimportant for determining the right performance for your car. Slower,tighter tracks mean less airflow and require more spacing between thefins.

Chris Paulsen of C&R Radiator says that choosing the proper fin count isimportant for determining the right performance for your car. Slower,tighter tracks mean less airflow and require more spacing between thefins.

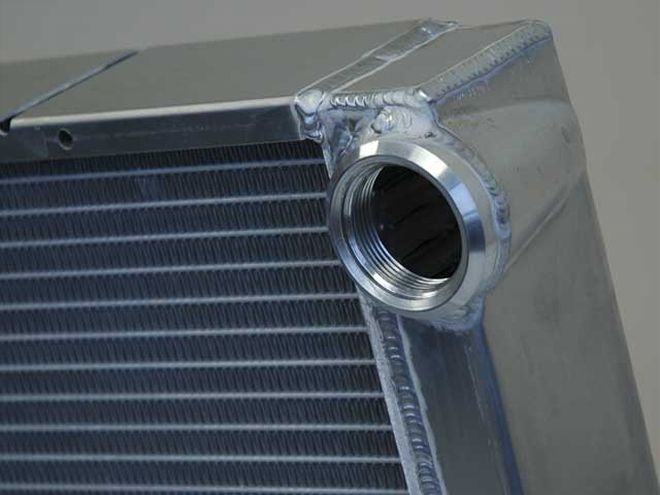

The used Nextel Cup parts market is a great thing for Saturday-nightracers trying to find more performance on a budget. But many racers havemade a big mistake purchasing a used radiator out of a Nextel Cup carand installing it into their short-track machine. When racing a slowercar on a more confined racetrack, the airflow to the radiator is goingto be significantly less. Because of this, most radiators built forshort-track racing use fewer fins to promote better flow through theradiator. "For a 1/4- to 3/8-mile track, I would recommend a radiatorwith a fin count in the range of 14 to 15 per inch with a two-row core,"says C&R Radiators' Chris Paulsen. "As you get faster, you can increasethe fin count, but on the lower speed tracks you will get better coolingby making sure you get plenty of flow through the radiator. More finsgives you a chance at better heat dissipation, but if you aren't gettingthe air moving through the radiator it doesn't do you any good."

Paulsen also recommends a regular cleaning regimen to ensure yourradiator remains at peak working efficiency. If you race asphalt, rubberbuildup can be a problem. Soaking your radiator in a solvent bath canhelp loosen up the tiny pieces of rubber that gets wedged between thefins. Just make sure, Paulsen cautions to always cap off the ends of theradiator so that the solvent doesn't get inside the coolant tubes. "Mostdouble-pass radiators use a baffle that uses a high-temp silicone seal,"he explains. "If you allow solvent to get inside the radiator it canattack that seal."

If you are racing dirt, rubber buildup isn't as large a problem, andsolvent doesn't have much effect on dirt. Instead, soaking your radiatorin a soapy water solution will help. After soaking your radiator (eitherasphalt or dirt), rinse it with low-pressure water from a garden hosefrom the back to push any debris out of the radiator in the directionfrom which it came. Never use a high-pressure water hose (the kind youwill find at a car wash) on your radiator because it can easily bend thecooling fins and do more harm than good.

Finally, Paulsen says that radiator stop leak products are a racer'sworst enemy. "That stuff uses a ceramic that coagulates when it makescontact with air to plug any leaks. But racers are always draining theirradiators to either pull it or the engine. As soon as that happens andyou get air in the system, all the stop leak inside the radiator hardensand creates a ceramic insulator inside all the cooling tubes."

Coatings

In many cases, when it comes to stock car racing, coating a set ofexhaust headers is preferable to wrapping them. But there are times whenyou require more insulation in specific areas--such as when the headerruns right beside the starter. For those occasions, header sleeves workwell.

In many cases, when it comes to stock car racing, coating a set ofexhaust headers is preferable to wrapping them. But there are times whenyou require more insulation in specific areas--such as when the headerruns right beside the starter. For those occasions, header sleeves workwell.

In just a few years, coatings have gone from something many racersconsidered to be little better than snake oil, into a tool that's usedjust about everywhere on a race car. Coatings are widely thought of as away to reduce friction, but other blends are great at controlling heat.The trick, according to Tech Line Coatings' Leonard Warren, is tounderstand what you want to do with the heat your race car produces.Coatings, known as thermal dispersants, can be used to help hot parts onthe car radiate heat more efficiently. Tech Line sells coatings designedto be applied to radiators, oil pans, brake calipers, and just aboutanything else you can think of to help them stay cooler. "We have seenthermal dispersants improve the thermal transfer efficiency of aradiator by 20 percent," he says. "I've applied it to an alternator andwatched it drop 30 degrees of operating temperature the next time it wasinstalled on the same engine."

Thermal barriers are an insulator and do the opposite. They can beapplied to headers to keep the heat inside the tube and keep the enginecompartment cooler. You can also mix and match the two. On an intakemanifold, for example, Warren recommends applying a thermal barrier tothe base and cylinder head flange to keep heat from radiating from theengine into the manifold. Then, apply a thermal dispersant to the topand under the runners, if you are racing an air-gap manifold, to helpradiate any heat that the manifold does absorb. This can help keep theincoming air/fuel charge significantly cooler.

Coatings have also become incredibly durable. Warren says one of theareas to apply an engine coating can be inside the combustion chamber. Athermal barrier on the chamber roof and piston floor traps heat insidethe negative space of the combustion chamber. "Many people think acoating inside the combustion chamber will make the metal hotter, but itdoes the opposite," he explains. "It keeps the metal from absorbing theheat from combustion and instead makes the cylinder firing moreefficient. Instead of being absorbed into the cylinder head or engineblock, the heat is used to produce more force pushing the piston downand then goes out the exhaust port."

Thermal Barriers

Design Engineering produces these sleeves designed specifically toprotect the spark plug boots from heat damage, which can cause misfires.

Design Engineering produces these sleeves designed specifically toprotect the spark plug boots from heat damage, which can cause misfires.

Like coatings, thermal barriers are used just about anywhere andeverywhere on a car. Thermal barriers come in many forms, but all arefor the same purpose: keeping heat from traveling through that area.Sometimes, it is to contain heat within a small area (header tubes).Sometimes, it is to protect a cooler area from being warmed by a radiantheat source (the driver's compartment).

Design Engineering produces several products designed to keep the heatproduced by your race car where you want it and away from the places youdon't. One of the most interesting products is what Design Engineeringcalls its Protect-A-Boot. These are insulated sleeves designed toprotect the spark plugs' connectors. These are extremely close to theexhaust headers, and if the rubber boots melt or burn in spots, it cancause engine misfires.

The company also produces insulating mats that work well at keepingradiant engine heat from invading the driver's compartment. DesignEngineering's Floor and Tunnel Shield is lightweight and just 3/16-inchthick but can withstand 1,170 degrees of direct, continuous heat whilereflecting almost 90 percent of that heat. When applied to the firewalland floorboard where necessary, this can make a big difference in termsof driver comfort--and safety. After all, air blowing on your driverfrom a NACA duct can only do so much good when the bottom of hisaluminum seat is cooking his backside like a frying pan.

Radiator Fans

Electric fans are normally more efficient than mechanical radiator fansbecause they use their own motor and don't pull power from the engine.

Electric fans are normally more efficient than mechanical radiator fansbecause they use their own motor and don't pull power from the engine.

Flex-a-lite is one of the leading manufacturers of automotive coolingfans of all types. When it comes to radiator fans to assist cooling, thecompany produces electric fans, clutch fans, and fans designed to bemounted solidly to the water pump, so we asked Lisa Chissus what worksbest for racing.

Whether you are using a mechanical fan or electric, a shroud willgreatly increase its efficiency in terms of how much air it actuallypulls through the radiator core. This Flex-a-lite electric fan comeswith a built-in shroud--just make sure it covers at least 70 percent ofthe radiator's surface area.

Whether you are using a mechanical fan or electric, a shroud willgreatly increase its efficiency in terms of how much air it actuallypulls through the radiator core. This Flex-a-lite electric fan comeswith a built-in shroud--just make sure it covers at least 70 percent ofthe radiator's surface area.

The answer, as you might expect, is to go with the electric fan wheneverpossible. Electric fans are powered by their own motor so they don't robpower from the engine, and dyno testing has proven that an electric fancan save you 25 hp versus an OE clutch fan. Fan clutches should never beused in racing because they only eat horsepower. If you find that youneed the extra pulling power of a mechanical fan mounted to the waterpump, Flex-a-lite produces flexible fans that essentially "flatten" outat high rpm and pull less power. They also pull less air, but if youhave correctly built your radiator box, the incoming air should bestrong enough to provide adequate cooling by itself.

Whether you decide to use an electric or mechanical fan, Chissusstrongly recommends using a fan shroud of some type. Air always followsthe path of least resistance, she says, so if you do not use a shroud,the fan will simply pull air from inside the engine compartment andlargely bypass the radiator. A shroud seals off the area between the fanand the radiator, forcing the air pulled by the fan to come through theradiator. Shrouds should be designed to cover at least 70 percent of theradiator's surface area.

Stainless Steel = Cool?

Leonard Warren gave us a neat tip when it comes to heat control and theair/fuel charge. It doesn't have anything to do with coatings, but itwas simply too good not to pass along.

"One thing many racers don't think about is to use stainless steelfasteners and insulated washers to connect everything between thecarburetor and cylinder head," he says. "Stainless steel doesn'ttransfer heat very well, but carbon steel does. You can insulateeverything, but if you use regular carbon steel bolts, the heat willjust travel down those like a wick. I know one company that did a testwith all different types of carburetor spacers. They found that nothingprovided much insulation until they switched out the bolts holding downthe carburetor and spacer with stainless steel bolts. If you are using aphenolic spacer but not getting the improvement you expected, it'sprobably because the heat from the engine is just traveling right up thebolts, past that phenolic spacer and heating up the fuel right in thecarburetor. Switching to stainless fasteners will make your phenolicspacer a lot more effective."

Oil Coolers

B&M Racing Performance produces stacked plate oil coolers (left) thatare designed to be both lightweight and virtuallyindestructible--perfect for racing. In applications where getting enoughairflow is a problem, it also produces cooler air with integrated fans.

B&M Racing Performance produces stacked plate oil coolers (left) thatare designed to be both lightweight and virtuallyindestructible--perfect for racing. In applications where getting enoughairflow is a problem, it also produces cooler air with integrated fans.

Since most Saturday-night races are less than 100 laps on tracks thatare 5/8-mile or less, many racers believe they don't need transmissionand rear-end oil coolers. Granted, it is critical to run a rear-end oilcooler if you are running a Nextel Cup race at Atlanta, but your LateModel may be helped by one too.

The friction created by gears meshing in the rear end produces extremelocalized heating. This heat is right between the gear teeth, soshooting an infrared temperature gun on the housing can be misleading. Asimple, belt-driven oil pump and a small oil cooler can make a world ofdifference. Keeping the temperature under control keeps the frictioncreated between the ring and pinion gears from robbing as much power andalso improves the reliability of the locker springs. By pumping the oil,you can also direct the cooled oil directly onto the ring gear as itre-enters the rear-end housing. This provides much better cooling andlubrication than relying on the ring gear to splash into a pool of oilat the bottom of the housing.

Simpson is producing apparel that uses a material called CarbonX toprovide better protection and wick sweat away from the driver's skin toimprove comfort over the course of a race.

Simpson is producing apparel that uses a material called CarbonX toprovide better protection and wick sweat away from the driver's skin toimprove comfort over the course of a race.

Manufacturers such as B&M Racing Performance produce high-performanceoil coolers that not only provide good heat transfer from the oil to airwith minimum size and weight, they are also very resilient in order tostand up to the abuses of racing. B&M produces a stacked-plate cooler,which you can literally stand on without damaging, and a cooler with anintegral fan for providing extra cooling power when needed.

Cool Suits

In longer, endurance-type racing events, it becomes critically importantto keep the driver cool and comfortable. For those situations, whereinsulating the driver from engine heat and providing a continuous flowof outside air simply isn't enough, driver "cool suits" are available.

This high-end cool suit from Cool Shirt cools the driver with bothchilled water against his skin and cool air to the helmet. It featuresregulators that the driver can control to adjust the level of coolingand a filter that cleans the air the driver breathes.

This high-end cool suit from Cool Shirt cools the driver with bothchilled water against his skin and cool air to the helmet. It featuresregulators that the driver can control to adjust the level of coolingand a filter that cleans the air the driver breathes.

Cool suits designed for racing typically employ a shirt with severalfeet of surgical tubing sewn in place. A small electric pump continuallymoves chilled water from a cooler through the tubing to keep the drivercool. By keeping the driver's trunk cool, the blood flow cools the restof the body. Other systems provide chilled air, which is blown insidethe driver's helmet. The cool air cools the lungs and, in turn, coolsthe rest of the body. The benefit of this system is that it can keep thedriver's face shield from fogging up, but if the driver is wearingcontacts, the air can also dry out his eyes.

Cool Shirt produces both types of driver cooling systems and even sellsa combination system that provides the driver with both chilled water toa cool shirt and cooled air inside his helmet. When shopping for asystem, Tom Engebretson, Cool Shirt's general manager, recommends makingsure it has a temperature or speed regulator that the driver cancontrol. If not, the driver can become chilled, which can be just asmuch a detriment to concentration. Also, many cool air systems offeroptions to filter the air before it reaches the driver, which is anexcellent idea.

Personal Protection Equipment

Simpson is producing apparel that uses a material called CarbonX toprovide better protection and wick sweat away from the driver's skin toimprove comfort over the course of a race.

Simpson is producing apparel that uses a material called CarbonX toprovide better protection and wick sweat away from the driver's skin toimprove comfort over the course of a race.

Personal protection equipment is just a fancy way to say the driver'sfiresuit, gloves, shoes, helmet, and anything else on his body. Thebiggest complaint about personal protection equipment, in general, isthat in order to protect you from a fire, the stuff makes you awfullyhot and sweaty.

Fortunately, many companies are working on ways to make the stuff moreprotective with less bulk. One of the latest developments is a materialcalled CarbonX that Simpson and other manufacturers of protectiveequipment are including in their products. When used in clothing,CarbonX is capable of withstanding 2,000 degrees F without damage andwon't shrink or char when exposed to direct flame. It's alsocomfortable. CarbonX can be worn next to the skin and possesses goodwicking properties. That means it keeps you more comfortable when yousweat.

The old adage still holds true that more layers in your firesuit willmean better protection, but with the new advancements in technology, theprotection is better than ever before.