It's difficult to argue with the old adage, "There's no substitute for cubic inches." But, it's always fun to build an engine that performs like it has a larger displacement than it actually does. There are also practical benefits to upgrading the power-producing capabilities of a smaller engine. In the case of small-block Mopars, 340 and 360 engine cores are increasingly harder to find, and when one is located, it tends to be expensive.

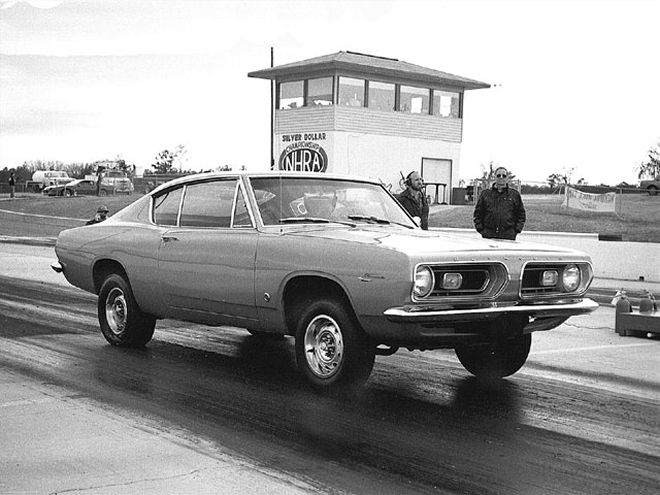

That was the dilemma Mickey Hamilton faced when he began building a '67 Barracuda for street/strip use. "I started out intending to build a 360," Mickey says, "but I couldn't find one at a decent price. But, every time I went looking for one, I tripped over a 318. Finally, the light came on, and I figured since I was working with Andy Giles, who is a great engine builder, I could give up 42 cubic inches and still get an engine that would put the car into the 12s at the strip."

Andy is one of those engine builders who never attended a trick-of-the-week training class. He takes a straightforward approach and concentrates on refining proven techniques and components. He also has a knack for wringing amazing amounts of horsepower from engines built almost entirely from stock or stock-replacement-type components. As the dyno test figures demonstrate, his approach delivers high-dollar horsepower figures at low-dollar expense.

Since this engine was to be suitable for street driving as well as dragstrip use, Andy didn't set out to build a full-tilt race engine. Realizing many Mopar lovers would like to boost the output of the engines in their exclusively street-driven cars and pickups, he started with a stock rebuild to establish a baseline. Then, he developed a number of combinations, each of which raised the horsepower bar a bit higher. At the conclusion of the test series, maximum power had risen from 187 to 357 hp, and torque jumped from 305 to 388 lb-ft. The best part about the power increase is it was achieved with nothing more exotic than ported cast-iron heads and a custom-ground hydraulic-lifter camshaft.

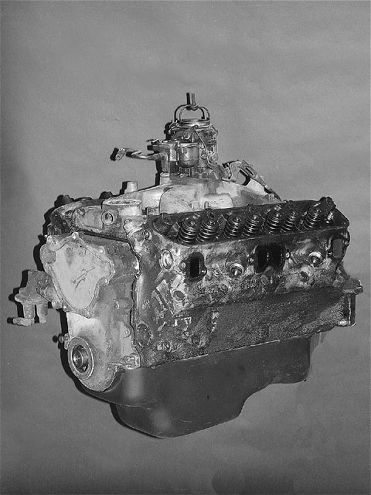

Does this engine look like it can propel a '67 Barracuda to 12-second quarter-mile e.t.'s?

Does this engine look like it can propel a '67 Barracuda to 12-second quarter-mile e.t.'s?

Before the rebuild, Mickey's engine spent its life as the motorvational source for a '73 Dodge Dart. Despite its age, it had relatively low mileage and was in excellent running condition. Equipped with its original two-barrel carburetor, 151/48-inch Hedman A-Body headers, and 3-inch exhaust system with Random Technology PowerMax mufflers, the 318 displayed its plebeian ancestry, cranking out a maximum of 187 hp at a mere 3,750 rpm.

Andy's rebuild involved all the normal machining, including a .060-inch overbore and torque-plate hone. He also align-honed the main-bearing bores and deburred the block. After the machine work was completed and the block thoroughly cleaned, the short-block was assembled using reconditioned stock connecting rods, hypereutectic pistons (9.8:1 compression ratio), Hastings rings, Clevite bearings, Fel-Pro gaskets, and a Comp Cams hydraulic-lifter camshaft.

To start the testing, a Comp 270H cam with .224/.224 at .050 duration and .470/.470-inch lift was chosen. With intake and exhaust duration of .224 degrees at .050 lift, the camshaft was definitely on the aggressive side for a 318 (now 328 ci by virtue of the overbore). But, specific timing points and a lobe-separation angle of 110 degrees provided a relatively smooth idle and good low-speed torque.

The short-block was topped off with the original heads that were pocket-ported prior to installing Mopar Performance 1.78- and 1.50-inch valves. Andy also performed a multi-angle valve job and gasket-matched the port openings. Of course, the stock two-barrel carb and manifold were consigned to doorstop duty. In their place, he installed a 340 cast-iron manifold and topped it off with a 625-cfm AVS carburetor.

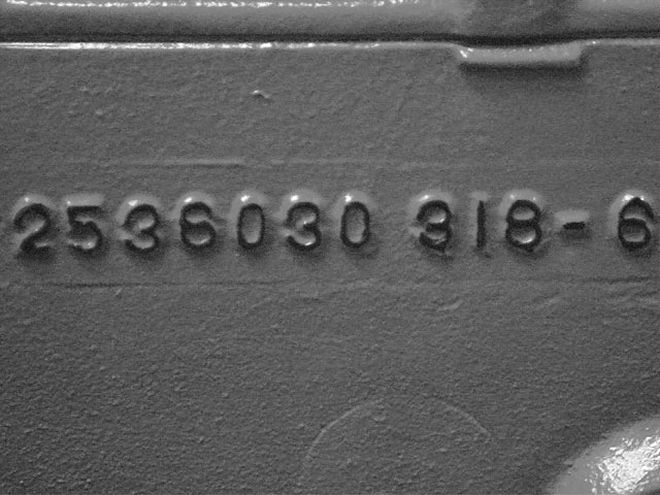

Small-block Mopar engines are easily identified by numbers cast into the side of the block. In this case, the last three digits indicate a displacement of 318 ci.

Small-block Mopar engines are easily identified by numbers cast into the side of the block. In this case, the last three digits indicate a displacement of 318 ci.

When the engine was reinstalled on the dyno, it underwent a dramatic personality transformation. Peak torque rose from 305 lb-ft at 2,500 rpm to 343 lb-ft at 4,000, and horsepower jumped from 187 lb-ft at 3,750 rpm to 301 at 5,000. Of equal significance was the broadening of the torque curve. Whereas the stock engine's torque curve dropped below 300 lb-ft at 3,000 rpm, the rebuilt 318 produced over 325 lb-ft from 2,500 to 4,750 rpm. A torque curve like that is just what's required for strong street performance or hauling heavy loads.

Next, Andy installed a camshaft with .234 degrees of exhaust duration at .050 lift and two degrees wider lobe separation (112 versus 110). His intention was to broaden the torque curve and increase top-end power without seriously degrading low- speed performance. As fate and the dyno would have it, that's exactly what happened. In fact, the cam change produced results that were better than anticipated. At 2,500 rpm, torque increased by 21 lb-ft, and peak torque rose to 370 lb-ft. Horsepower now peaked at 324-an increase of 23. Horsepower remained above 310 all the way to 6,000 rpm.

The most impressive aspect of this combination is, aside from the camshaft and valve gear, all the parts were of the stock or stock-replacement persuasion.

In the first test, we used a Comp Cams 270H grind with .224/.224 at .050 duration and .470/.470-inch lift. Lobe separation of 110 degrees provided a relatively smooth idle and good low-speed torque. The cam swap saw a dual-pattern camshaft, spec'd out with a .222/.230 at .050 duration and .470/.480-inch lift. This cam, with a 112-degree lobe separation, gave the engine a broader, flatter torque curve and also increased top-end power. Plus, it's mild enough to support a docile 750-rpm idle speed.

In the first test, we used a Comp Cams 270H grind with .224/.224 at .050 duration and .470/.470-inch lift. Lobe separation of 110 degrees provided a relatively smooth idle and good low-speed torque. The cam swap saw a dual-pattern camshaft, spec'd out with a .222/.230 at .050 duration and .470/.480-inch lift. This cam, with a 112-degree lobe separation, gave the engine a broader, flatter torque curve and also increased top-end power. Plus, it's mild enough to support a docile 750-rpm idle speed.

As is usually the case when changing components that affect the amount of air an engine can process, when an alteration eliminates one flow restriction, another becomes the factor that controls horsepower. With the second camshaft in place, the cylinder heads became the "cork" in the system. Andy's corkscrew was a pair of ported 360 heads with Mopar Performance 2.02- and 1.60-inch valves. These castings are similar to Mopar Performance's PN P5249574, an alternative if suitable used heads are not available.

With the 360 heads bolted onto the short-block, horsepower and torque ratcheted up another notch; this time, the peak readings were 381 lb-ft at 4,250 rpm and 346 hp at 5,250. Again, torque was up at all test points, with the engine now making at least 360 lb-ft, from 2,500 to 5,000 rpm.

For the final test, Andy installed a modified 750-cfm Thermo-Quad on a matching cast-iron intake manifold (which had a bit of clean-up work done on the inside). This paid off with a slight increase in low-end torque and 11 hp at the peak. The engine now produced 388 lb-ft of torque and 357 hp. Compared to the stock engine, the overall improvement was 83 lb-ft and 165 hp.

The dyno numbers only tell part of the story. After Mickey installed the engine in his '67 Barracuda, he took it to Silver Dollar Raceway in Reynolds, Georgia, for some real-world testing. Using the same Hedman headers used on the dyno, a 3.55:1 ring-and-pinion set, and a 3,000-stall torque converter, the 'Cuda cranked out a 12.76-second e.t. with a trap speed of 103.02 mph. On the street, the engine is deceptively docile and idles well at 750 rpm.

RPMTest 1Test 2Test 3Test 4Test 5CBTCHpCBTCHpCBTCHpCBTCHpCBTCHp250030514532615534716536017136417327503031583361763571873691933711943000297170338193364208373213377215325028617733820936622637523237923435002771842332223652432732493782523750262187337241363259371265377269{{{4000}}}246187343261369281378288385293425023018634327827029938130938831445002141843402923653133803263883334750197179331299356322372336380344{{{5000}}}180171376301341324362345371353525016316329829832432434634635735755001461532792933063213303453393555750290317312341321352{{{6000}}}271310295337302345CBT= Corrected brake torque

CHp= Corrected horsepower

Horsepower and torque corrected to 29.92 inches/Hg barometer, 60 degrees, with dry air.

Test 1-Stock 318 with two-barrel carburetor, 1 5/8-inch Hedman headers, and 3-inch exhaust system with mufflers.

Test 2-Rebuilt 318 with 9.8:1 compression ratio, pocket-ported 318 heads, 340 cast-iron intake manifold, 625-cfm AVS carburetor, and Giles Performance single-pattern camshaft.

Test 3-Same as test 2, but with Giles Performance dual-pattern camshaft.

Test 4-Same as test 3, with ported 360 heads.

Test 5-Same as test 4, but with 360 cast-iron intake manifold and 750-cfm Thermo- Quad carb.