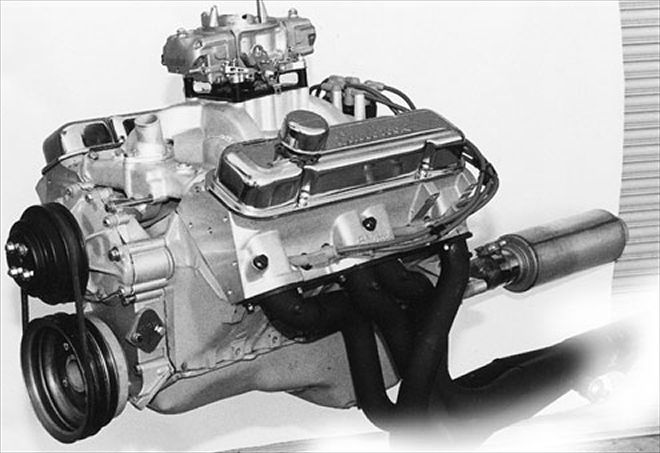

GM once sold three different 455 engines--a Buick, an Olds, and a Pontiac. All were stump-pulling torque monsters, but which has the potential to make the most power? Car Craft, in conjunction with Westech Performance, decided to find out by building up an example of each using commonly available speed parts: modern high-flow aluminum heads, a Comp Cams Xtreme Energy XE274H hydraulic flat-tappet cam and valvetrain parts, Fel-Pro gaskets, and Federal Mogul/Speed-Pro forged pistons, bearings, and piston rings. The 455 Olds was first up ("455 Buildup: New Life for an Olds Engine," Oct. 2000). Now it's the Pontiac's turn, and the result was a tough warrior ready to burn up the warpath and take scalps. Stay tuned to see if we'd really rather have a Buick.

Test Results

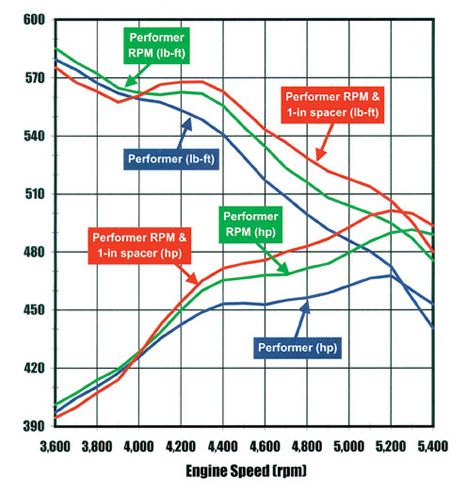

It's been said you can't kill the bottom-end torque on a Pontiac 455. We don't know just where this engine's true torque peak lies because Westech's SuperFlow dyno couldn't hold the motor below 3,600 rpm! But at that point--with the torque curve already on the downslope--the engine was still making 579.4 lb-ft with an Edelbrock Performer dual-plane intake and Speed Demon 750-cfm carb. In terms of max power, that intake and carb developed 467.7 hp at 5,200 rpm. Car Craft readers will recall the Olds 455 also used a Performer intake and 750-cfm Demon to make 565.3 lb-ft at 3,500 rpm and 469.4 hp at 5,200 and 5,300 rpm--so, overall, output was about a wash at this performance level. Unlike the Olds, Edelbrock also offers a taller Pontiac Performer RPM dual-plane, which we found was worth 5.8 lb-ft of torque and 23.7 hp at the peaks, where it developed 585.2 lb-ft and 491.4 hp, respectively. Overall numbers were also improved throughout the test range.

But we weren't done yet. Westech pulled out a Wilson Manifolds 1-inch open spacer and power jumped all the way to 501.3 hp, at the expense of a slight loss of power and torque below 4,100 rpm. But with "only" 575.3 lb-ft at 3,600, why quibble? Average numbers were still up by 5 hp and 5 lb-ft overall compared to the no-spacer configuration. The engine churned out over 500 lb-ft from 3,600 through 5,200 rpm, and over 400 hp from 3,800 on up! And yet its 12.5 inches of vacuum at 850 rpm and 180 psi cranking compression is OK for power accessories and 92-octane pump gas.

Cylinder Heads

Forget about iron Pontiac heads--unless you're building a 100-point resto, big E's Performer RPM Pontiac aluminum heads are the only way to go. We used the large 87cc combustion chamber versions (PN 6057, assembly) to keep compression under control on the big-inch engine. A 72cc version is also available.

Cam and Valvetrain

Comp's Extreme Energy cam is more aggressive than other cams with equivalent 0.050-inch tappet-lift durations, yet still makes decent idle vacuum. The cam comes as part of Comp's SK kit, which also includes lifters and a three-keyway Magnum double-roller chain. Edelbrock heads use an adjustable valvetrain. We went with Comp 1.65:1 aluminum full-roller rockers (the same ratio as used on Ram Air IV heads) and one-piece Hi-Tech 5/16-inch-od hardened pushrods.

Induction, Ignition, Exhaust

An Edelbrock Performer RPM intake with a 1-inch spacer was the overall best induction setup. MSD components ignited the air/fuel mixture. Scavenging is handled by '70-'74 Firebird Hooker Super Competition round-port headers (PN 4202; 2x27-inch primaries, 31/2x10-inch collectors) that dump into 3-inch dual pipes and straight-through Walker DynoMax race mufflers.

Bottom End

Our 455 engine core had seen better days. Years of running without antifreeze had trashed the aluminum front cover, timing cover sleeves, and water pump divider plate, requiring they be replaced. We had to go 0.060-over on the cylinders; Speed-Pro offers premium, file-fit plasma-moly rings for the weird Pontiac 5/64-1/16-3/16 ring-groove combo only in a 0.035-oversize, so a standard-gap Sealed Power moly ring was used. No 0.030-under Federal Mogul Competition Series bearings are available either, so we defaulted to Federal Mogul OE-replacement copper-lead rod bearings and aluminum main bearings. The regular rings and bearings don't affect power, but if available, premium components could enhance durability if you beat on the motor.

Maintaining the buildsheet clearances is critical for keeping the big Pontiac crank journals alive. Bearing-shell thickness varies per manufacturer and we've also seen different published crank-journal machining dimensions. Before machining the crank, line-hone the block and recondition the rods, install the corresponding bearing shells, and use an inside micrometer to measure the actual dimension--then your machinist can finish the crank to achieve the desired final bearing clearance. Dougan's decked the block, bored and honed the cylinders with a torque plate, turned the crank, align-honed the block, rebuilt the rods, and hung the pistons.