When choosing a clutch it is best to take everything into consideration. How much engine power are you producing? How much does the truck weigh? These can play a major factor in clutch choice. But what a lot of people don’t look at is what kind of driving they do.

Let’s just say you have a 450hp engine that produces the same amount of torque and you want to drive it on the street mainly. Then a clutch that is rated for 500 hp would work just fine 99 percent of the time. Add different driving conditions like drag racing or autocross and kiss the 500hp rating goodbye. The point I’m trying to make is that the clutch can only do so much until it starts getting overworked. Toss in improper break-in time and some abuse and you better be really good at pulling the transmission.

Sticky Tires and Better Suspension

Today’s tires are also made with better tread pattern design and stickier compounds that help the vehicle stick to the road. What that means is that the clutch now works harder to not slip under normal driving conditions and especially while goofing around with the truck. Add an adjustable four-bar or something of that nature and grip to the tires can be greatly increased.

01 Think of a clutch like a brake pad. That means the clutch grips and wears just like brakes. Instead of clamping force from a brake caliper, the clutch uses a pressure plate. The pressure plate moves away from the clutch disc and flywheel as the pedal is pressed in and pressure is applied when the pedal is at rest or foot off the pedal.

01 Think of a clutch like a brake pad. That means the clutch grips and wears just like brakes. Instead of clamping force from a brake caliper, the clutch uses a pressure plate. The pressure plate moves away from the clutch disc and flywheel as the pedal is pressed in and pressure is applied when the pedal is at rest or foot off the pedal.

02 The pressure plate sandwiches the clutch disc in between the flywheel that is attached to the engine. The engine then turns said flywheel, clutch disc, and pressure plate, and waits for you to press the clutch pedal and put the vehicle in gear. By easing off the clutch pedal you are now applying pressure to the clutch disc surface on the pressure plate side and the flywheel side, this allows the engine’s power to be transferred to the transmission, thus moving the vehicle. Shown is a Centerforce One clutch disc made for a slightly better than OE replacement clutch disc with better performance.

02 The pressure plate sandwiches the clutch disc in between the flywheel that is attached to the engine. The engine then turns said flywheel, clutch disc, and pressure plate, and waits for you to press the clutch pedal and put the vehicle in gear. By easing off the clutch pedal you are now applying pressure to the clutch disc surface on the pressure plate side and the flywheel side, this allows the engine’s power to be transferred to the transmission, thus moving the vehicle. Shown is a Centerforce One clutch disc made for a slightly better than OE replacement clutch disc with better performance.

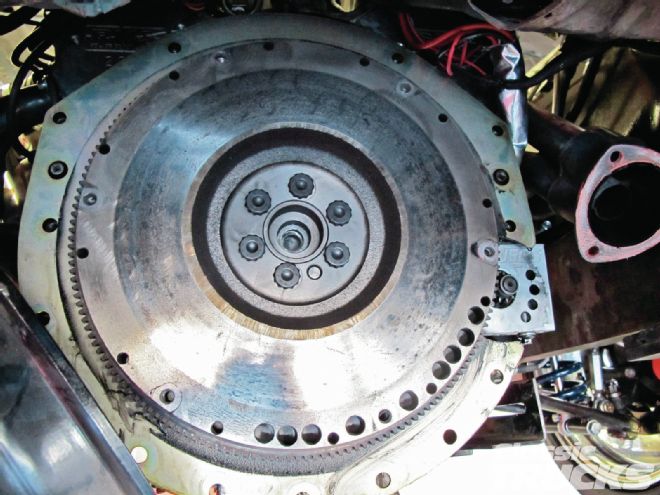

03 The flywheel’s job is not just to transfer engine motion to the clutch and transmission. What the flywheel also does is act as a balancing mechanism for non-internally balanced engines in combination with an off-balanced engine dampener. Now, here is where you have to be careful; some engines are semi balanced and others are internally balanced. Semi-balanced engines means the flywheel is off balance, but the crank dampener is neutral. Internally balanced engines require a neutral balance flywheel and crank dampener. I’ve experienced cases where the balance of the engine was off and engine parts start wanting to shake their way out.

03 The flywheel’s job is not just to transfer engine motion to the clutch and transmission. What the flywheel also does is act as a balancing mechanism for non-internally balanced engines in combination with an off-balanced engine dampener. Now, here is where you have to be careful; some engines are semi balanced and others are internally balanced. Semi-balanced engines means the flywheel is off balance, but the crank dampener is neutral. Internally balanced engines require a neutral balance flywheel and crank dampener. I’ve experienced cases where the balance of the engine was off and engine parts start wanting to shake their way out.

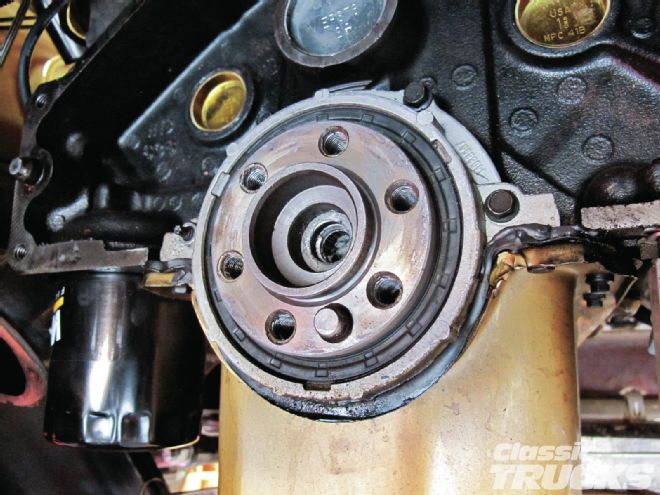

04 Pilot bearings don’t fly anything, but they do keep the input shaft of the transmission from floating around. Pilot bearings come in many shapes and sizes as well as materials. Before installing your new pilot bearing make sure it slides over the input shaft of your transmission.

04 Pilot bearings don’t fly anything, but they do keep the input shaft of the transmission from floating around. Pilot bearings come in many shapes and sizes as well as materials. Before installing your new pilot bearing make sure it slides over the input shaft of your transmission.

05 Throwout bearings are the link between the pressure plate and the clutch pedal. This particular throwout bearing is a non-hydraulic style bearing that requires a clutch fork and slave cylinder to work.

05 Throwout bearings are the link between the pressure plate and the clutch pedal. This particular throwout bearing is a non-hydraulic style bearing that requires a clutch fork and slave cylinder to work.

06 The hydraulic throwout bearing is used when space is limited under the hood and pedal area. The hydraulic throwout bearing replaces the clutch fork and mechanical style linkage common in older trucks. The bearing needs to be used with a single master cylinder similar to a brake master cylinder, but usually smaller.

06 The hydraulic throwout bearing is used when space is limited under the hood and pedal area. The hydraulic throwout bearing replaces the clutch fork and mechanical style linkage common in older trucks. The bearing needs to be used with a single master cylinder similar to a brake master cylinder, but usually smaller.

07 Let’s talk about disc shapes and materials. As the demands for a better clutch get higher, the friction material and methods to deliver pressure get better.

07 Let’s talk about disc shapes and materials. As the demands for a better clutch get higher, the friction material and methods to deliver pressure get better.

08 The Centerforce One and this clutch is an OE-style replacement with slight performance improvements. Great for a stock small-block or inline-six.

08 The Centerforce One and this clutch is an OE-style replacement with slight performance improvements. Great for a stock small-block or inline-six.

09 Centerforce Two is for the heavier vehicles like a truck that is 4,000 pounds, but still has no major power add-ons. The clutch can handle the added weight of the heavier vehicle from a standstill or long treks uphill.

09 Centerforce Two is for the heavier vehicles like a truck that is 4,000 pounds, but still has no major power add-ons. The clutch can handle the added weight of the heavier vehicle from a standstill or long treks uphill.

10 The dual-friction clutch is more for the enthusiast who has engine work done like heads, cam, exhaust, and or dyno tuning. These style clutches will also work in some applications with turbos, blowers, and nitrous. Remember adding more power to the engine means the clutch needs to clamp harder to the flywheel during acceleration.

10 The dual-friction clutch is more for the enthusiast who has engine work done like heads, cam, exhaust, and or dyno tuning. These style clutches will also work in some applications with turbos, blowers, and nitrous. Remember adding more power to the engine means the clutch needs to clamp harder to the flywheel during acceleration.

11 Centerforce pressure plates use a weighted style system that adds pressure to the clutch disc when rpm increases. This means that the more rpm the engine has, the more pressure or clamping force the pressure plate can apply to the clutch disc, thus less chances of slipping.

11 Centerforce pressure plates use a weighted style system that adds pressure to the clutch disc when rpm increases. This means that the more rpm the engine has, the more pressure or clamping force the pressure plate can apply to the clutch disc, thus less chances of slipping.

12 Think of flywheels like brake rotors and that they do wear over time or during heavy abuse. The flywheel material will have an effect on performance because of the weight to move the flywheel.

12 Think of flywheels like brake rotors and that they do wear over time or during heavy abuse. The flywheel material will have an effect on performance because of the weight to move the flywheel.

13 The difference between an iron or steel flywheel and an aluminum flywheel can make the vehicle feel like it will rev up faster with the lighter material.

13 The difference between an iron or steel flywheel and an aluminum flywheel can make the vehicle feel like it will rev up faster with the lighter material.

14 Now we’ll discuss pressure plate pivot points.

14 Now we’ll discuss pressure plate pivot points.

15 Something unique to Centerforce is their ball bearing technology. The ball bearing style pressure plate reduces the amount of pressure required at your foot to press the clutch pedal in. In other words it is easier to press the pedal in and out while still maintaining the same or more clamping load on the clutch.

15 Something unique to Centerforce is their ball bearing technology. The ball bearing style pressure plate reduces the amount of pressure required at your foot to press the clutch pedal in. In other words it is easier to press the pedal in and out while still maintaining the same or more clamping load on the clutch.

16 Look for leaks in the rear main seal. If you have a leak, or a potential leak, now is the time to take care of it. Leaks can cause not only a loss in oil, but can also cause clutch slippage.

16 Look for leaks in the rear main seal. If you have a leak, or a potential leak, now is the time to take care of it. Leaks can cause not only a loss in oil, but can also cause clutch slippage.

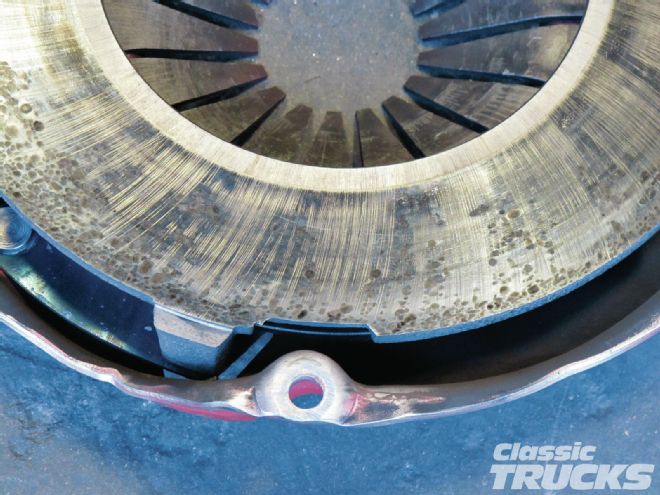

17 Flywheels need to be resurfaced or tossed out for fresh ones. The clutch travel will increase, as the flywheel material is lost. Machining too much surface depth off the flywheel will cause a bad pedal feel and or poor clutch travel.

17 Flywheels need to be resurfaced or tossed out for fresh ones. The clutch travel will increase, as the flywheel material is lost. Machining too much surface depth off the flywheel will cause a bad pedal feel and or poor clutch travel.

18 Setting up a hydraulic throwout bearing is easy if you look at it like this. The clutch and bellhousing need to be bolted up to the engine. A flat ruler is then placed across the surface of the bellhousing and measured the depth of the pressure plate fingers. Mark this number down, for us it was 27⁄8 or 2.875

18 Setting up a hydraulic throwout bearing is easy if you look at it like this. The clutch and bellhousing need to be bolted up to the engine. A flat ruler is then placed across the surface of the bellhousing and measured the depth of the pressure plate fingers. Mark this number down, for us it was 27⁄8 or 2.875

19 Kory from K&M equipment in Vista, California, was kind enough to lend us his shop and time. Kory removed the bellhousing from the engine and bolted it to the transmission. A ruler was placed on the bellhousing and a tape measure used to find the depth of the hydraulic throwout bearing. We measured 25⁄8 gap or 2.625.

19 Kory from K&M equipment in Vista, California, was kind enough to lend us his shop and time. Kory removed the bellhousing from the engine and bolted it to the transmission. A ruler was placed on the bellhousing and a tape measure used to find the depth of the hydraulic throwout bearing. We measured 25⁄8 gap or 2.625.

20 Depending on what bearing you use, the shims or spacers may or may not be needed. All we are doing is taking up the space so that the hydraulic throwout bearing does not over-travel and break. With our measurements, 2.875 – 2.625 = 0.25 gap. The manufacturer recommended a 0.150-200 gap between the bearing and pressure plate. We added .075 of shims to get an ideal gap of 0.175.

20 Depending on what bearing you use, the shims or spacers may or may not be needed. All we are doing is taking up the space so that the hydraulic throwout bearing does not over-travel and break. With our measurements, 2.875 – 2.625 = 0.25 gap. The manufacturer recommended a 0.150-200 gap between the bearing and pressure plate. We added .075 of shims to get an ideal gap of 0.175.

21 The centering tool is ideal when trying to align the clutch with the flywheel. This tool helps the transmissions input shaft to have a straight shot into the clutch and to the pilot bearing. Don’t forget to remove it before you try to put the transmission on.

21 The centering tool is ideal when trying to align the clutch with the flywheel. This tool helps the transmissions input shaft to have a straight shot into the clutch and to the pilot bearing. Don’t forget to remove it before you try to put the transmission on.

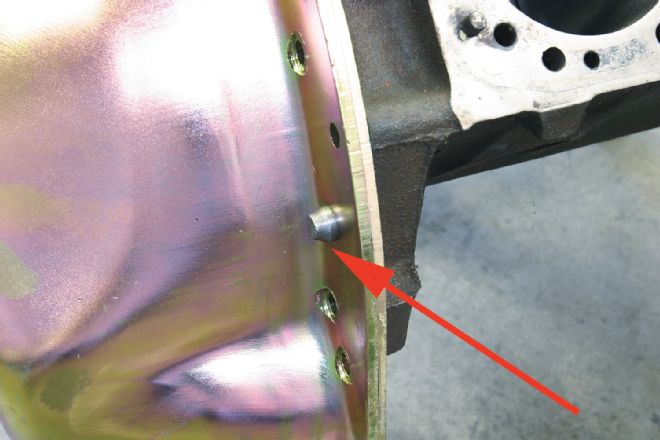

22 Bellhousing alignment can throw off the transmission’s input shaft and flex the transmission causing all kinds of weird stuff to happen. Most common is the trans will not shift well and or cause premature bearing failure in the transmission. Make sure to align the bellhousing to the engine.

22 Bellhousing alignment can throw off the transmission’s input shaft and flex the transmission causing all kinds of weird stuff to happen. Most common is the trans will not shift well and or cause premature bearing failure in the transmission. Make sure to align the bellhousing to the engine.

23 Alignment pins are sold to help offset the bellhousing to the center of the flywheel.

23 Alignment pins are sold to help offset the bellhousing to the center of the flywheel.

24 Clutches need a proper break-in period to work right. Take it easy on the clutch for about 500 miles. I know it’s hard to do sometimes, but being patient with the break-in period will make the clutch perform and last longer.

24 Clutches need a proper break-in period to work right. Take it easy on the clutch for about 500 miles. I know it’s hard to do sometimes, but being patient with the break-in period will make the clutch perform and last longer.

25 I almost forgot to add the DYAD clutch for those guys running mid/-high-horsepower engines. This clutch is a multi-drive system that can handle 1,300 lb-ft and still be driven with minimal pedal effort. It’s great for street and heavily abused clutches

25 I almost forgot to add the DYAD clutch for those guys running mid/-high-horsepower engines. This clutch is a multi-drive system that can handle 1,300 lb-ft and still be driven with minimal pedal effort. It’s great for street and heavily abused clutches

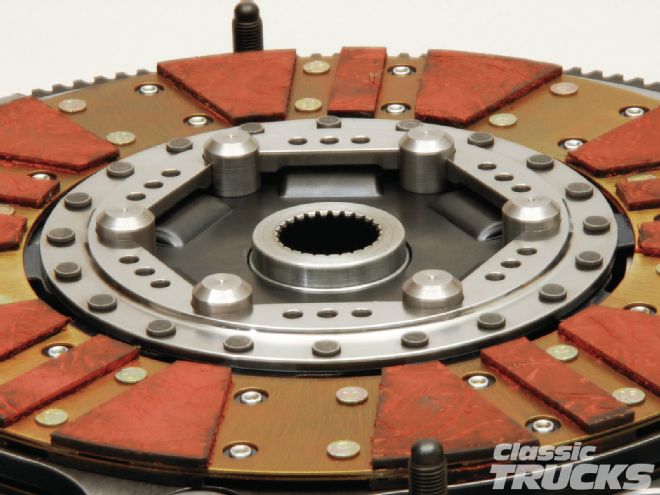

26 The multi disc has a smoother pedal engagement along with high-end holding capacity. This means the pedal is easy to press while having extra clamping pressure with a smoother transition on and off.

26 The multi disc has a smoother pedal engagement along with high-end holding capacity. This means the pedal is easy to press while having extra clamping pressure with a smoother transition on and off.

27 Check out the flywheel on the DYAD, it’s a work of art in itself. Makes you want to hang it on the wall and not hide it inside the bellhousing. The reduced weight of the flywheel also helps the rpms rev up faster.

27 Check out the flywheel on the DYAD, it’s a work of art in itself. Makes you want to hang it on the wall and not hide it inside the bellhousing. The reduced weight of the flywheel also helps the rpms rev up faster.

28 The center section is machined to have a floating drive plate that connects the two-clutch disc together. The floating drive plate is designed in a way that it is quiet in operation when moving/floating inside the clutch.

28 The center section is machined to have a floating drive plate that connects the two-clutch disc together. The floating drive plate is designed in a way that it is quiet in operation when moving/floating inside the clutch.

29 The clutch discs are similar to traditional clutches, but are not directly transferring power to the input shaft of the transmission. Notice where the input shaft slides into the floating drive plate and the clutch disc. As the pressure plate adds pressure to the clutch disc, the friction transfers the spinning motion to the floating metal disc, thus spinning the transmission.

29 The clutch discs are similar to traditional clutches, but are not directly transferring power to the input shaft of the transmission. Notice where the input shaft slides into the floating drive plate and the clutch disc. As the pressure plate adds pressure to the clutch disc, the friction transfers the spinning motion to the floating metal disc, thus spinning the transmission.