As the technology in Pontiac’s engines progressed over the years, so did its transmissions. Back in the glory days, manual boxes featured linkage-actuated clutches and three or four forward gears. The internals were simple and rugged, and the shifting a bit notchy, but they got the job done and provided a grin that can only be derived from manually slamming the shifter into the next gear.

Over the course of the next 30 years, three- and four-speeds gave way to the five-speed and six-speed transmissions with internal rail shifters and built-in reverse lockouts. The T56 six-speed was standard in Fourth-Gen Trans Ams and Formulas and late-model GTOs. It’s not uncommon to hear about a six-speed late-model LS car getting upper 20s in fuel economy or holding lots of rwhp with stock guts from Tremec, while still being a smooth shifter.

“How is this possible?” you ask. Let’s take a look inside a Tremec T56, more specifically an M12 out of an ’05 GTO.

This variant was shared by the other GM powerhouses of the day—the Corvette Z06 and Cadillac CTS-V—and has some upgrades inside straight from the Tremec factory that make it better than previous T56 transmissions. Out of the box, the synchronizer sleeves feature stepped teeth to make engagement feel lighter and more positive. The synchronizers also utilize high-density-carbon blocker rings and reverse synchronizers. Additionally, the M12 uses a one-piece countershaft, which is stronger than a two-piece.

Still, with all these upgrades, our intense downshifting and track duty combined with a few shifts during wheelspin resulted in the loss of Second gear. In our case, it was worn fork pads that prevented us from smoothly selecting Second gear and eventually caused the synchronizer to fail. We called Gray Fredrick from American Powertrain and explained our situation. We were soon provided with the correct package for our Goat.

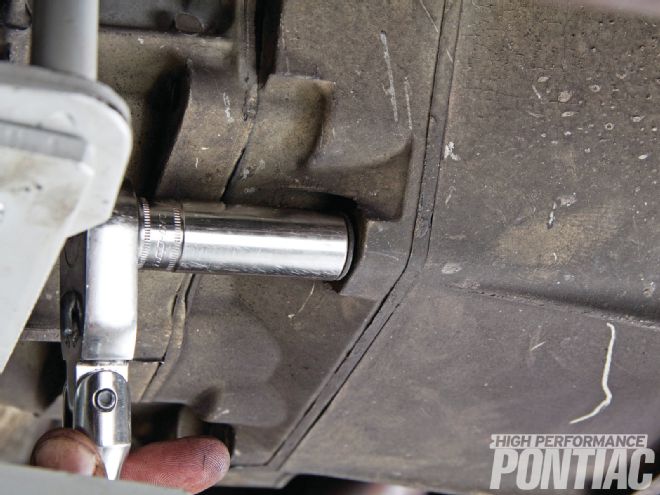

1 Because of the easy access to the adapter-to-bellhousing bolts, we decided to remove our transmission here. We also noticed a crack in our bellhousing, so we took extra precautions with the removal using our transmission jack.

1 Because of the easy access to the adapter-to-bellhousing bolts, we decided to remove our transmission here. We also noticed a crack in our bellhousing, so we took extra precautions with the removal using our transmission jack.

With our heads and cam GTO used primarily for road-course racing and on the street, there was no need to go crazy with upgrades and break the bank. According to Gray, there are affordable solutions for each power hike you make with your Pontiac.

2 With the transmission case removed, we discovered that the crack was actually a clean break (upper left), as the piece around the alignment dowel went along for the ride as we backed the transmission out and lowered it away from the car.

2 With the transmission case removed, we discovered that the crack was actually a clean break (upper left), as the piece around the alignment dowel went along for the ride as we backed the transmission out and lowered it away from the car.

“Unlike most packages out there, we include a vehicle-weight rating with ours because we can confidently say they can hold the claimed power level at the listed vehicle weight,” he says. “It’s easy to say a transmission can hold 500 hp, but is that 500-horse transmission going to hold the power in a car weighing 4,000 or more pounds? In our experience, it won’t.”

3 The fluid was drained prior to disassembly.

3 The fluid was drained prior to disassembly.

Because of these established power ratings, it was easy for Gray to suggest the Level 2 package, which is rated for a 495 lb-ft constant-torque load.

“This package is going to be the solution for 80-percent or more of enthusiasts out there. While peak loads and shock loads can climb well above this on the dyno, not many engines run these kinds of numbers on a sustained basis.

“The ratings are based on a 3,600-pound curb weight and street-legal radials. It covers the typical upgrades you would want, such as bronze fork pads and shims, but takes it a step further with cryo and REM treatments.” Those last two upgrades Gray mentioned add a new level of strength to the internal components.

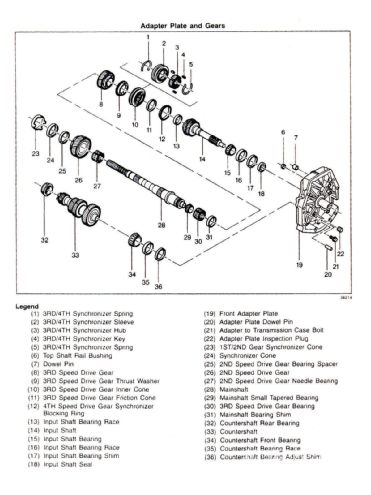

7 This diagram illustrates how the mainshaft and the input shaft and gear assemblies attach to the front adapter plate.

7 This diagram illustrates how the mainshaft and the input shaft and gear assemblies attach to the front adapter plate.

You may have already heard the word cryogenic or cryo thrown around the hot rod industry for some time. It can increase strength up to 30 percent without affecting tolerances.

American Powertrain’s cryogenic treatment consists of slowly reducing the temperature of the parts to -300 degrees F using liquid nitrogen, and then holding that temperature for 12 hours. This process relieves stresses and minute fissures in the part by refining the structure of the metal, resulting in a more uniform material. Strength and wear resistance are improved.

14 With the front adapter elevated, the cryo- and REM-treated input shaft with its pressed-in tapered bearing is lowered into place.

14 With the front adapter elevated, the cryo- and REM-treated input shaft with its pressed-in tapered bearing is lowered into place.

The rate at which the temperature of the part returns to normal also contributes to its attributes. According to American Powertrain, the quicker the part is returned to normal temperature after the process is completed, the better.

REM treatment follows cryo and is a process that fills the minute imperfections that occur naturally in the gear’s surface. By filling and polishing these minuscule valleys and inconsistencies, fluid pressure requirement and friction are reduced across the gear face, and durability and corrosion resistance are enhanced. According to Gray, this translates into reduced temperatures, noise, and parasitic loss—which is good.

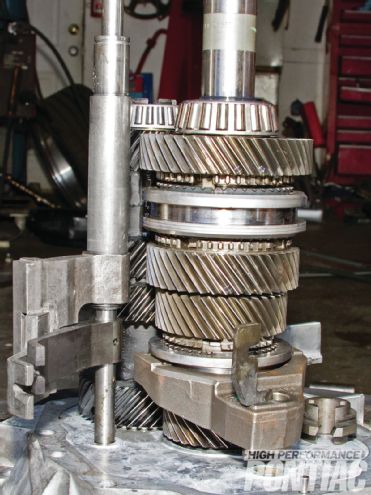

15 After Greg taps the bearing onto the front of the mainshaft using a properly sized traditional socket, the mainshaft is mated to the backside of the input shaft on the adapter.

15 After Greg taps the bearing onto the front of the mainshaft using a properly sized traditional socket, the mainshaft is mated to the backside of the input shaft on the adapter.

With the package chosen, we disassembled our broken transmission and sent the parts to American Powertrain to have them treated and put back together with parts included in the Level 2 package. Greg Lovell at Anti Venom handled the disassembly and reassembly.

16 Next the countershaft was installed after its tapered bearing was pressed on (shown behind the bottle). Maintaining optimal lubrication of the parts—especially the bearings—during the assembly process is crucial. Greg uses Pennzoil ATF.

16 Next the countershaft was installed after its tapered bearing was pressed on (shown behind the bottle). Maintaining optimal lubrication of the parts—especially the bearings—during the assembly process is crucial. Greg uses Pennzoil ATF.

While Anti Venom is mostly known for its high-end builds and performance installs, Greg has been rebuilding transmissions since he was a teenager and most of those high-horse cars that roll off out of his garage feature a trans he rebuilt. Even with the great “how-to’s” out there, it’s always best to seek out professional expertise when dealing with an expensive manual transmission.

17 The shift rails were installed next. These will house the shift forks that we sent out to American Powertain for the treatment process. This is where a professional installer comes in handy to line things up correctly. Everything will be installed in neutral to keep the Third/Fourth shift rail from engaging.

17 The shift rails were installed next. These will house the shift forks that we sent out to American Powertain for the treatment process. This is where a professional installer comes in handy to line things up correctly. Everything will be installed in neutral to keep the Third/Fourth shift rail from engaging.

Please keep in mind that this is not a step-by-step trans teardown and rebuild story, as space would simply not allow it. Instead, we cover most of the highlights of the process and discuss the upgrades.

The Transmission Package

Level 2 M12 T56 transmission

495 lb-ft constant-load torque rating

Price: $995

The Level 2 kit includes:

Bronze fork pads for 1st, 2nd, 3rd, 4th, 5th, 6th, and Reverse

Billet synchronizer keys and spring kit for 3rd/4th synchronizer assembly

Cryo treatment of 1st-4th gears, shift forks, and sliders

Call tag to pickup parts from customer (within continental U.S.) to have cryo-treatment performed

The following parts will need to be removed and boxed for American Powertrain to Call Tag for this upgrade:

1st/2nd/3rd/4th gears and their input shaft

Countershaft (lower gear in gearbox, also known as cluster)

Sliders, not hubs, for 1st-2nd and 3rd-4th

Shift forks (no rails) for 1st-2nd and 3rd-4th