For decades the ’55-57 Chevrolet rear axle housing was the choice for many hot rods. After all, they were plentiful and since they were all parallel leaf spring applications there were only two small brackets to trim off before installing the rearend in the hot rod of your choice.

We raised the Nomad on the chassis lift, note the support stands under the front bumper. When the rear axle is removed, the weight bias will shift forward, potentially allowing the car to fall.

We raised the Nomad on the chassis lift, note the support stands under the front bumper. When the rear axle is removed, the weight bias will shift forward, potentially allowing the car to fall.

Measuring about 60 inches from flange to flange, they were a bit wide for early hot rods, which may explain the number of hot rods with some sidewall showing outside the fender in the ’60s and ’70s. However that measurement was spot-on for many postwar cars so these rearends were among hot rodders’ favorite rear axle swaps. At the time you got modern drum brakes, easy-to-find gear sets, and best of all, a price that was approaching free.

Of course that was 55 years ago, and today things have changed dramatically. The supply of original ’55-56 rearends has dried up and those who are found are, well, 55 years old. Pitted housings, non-limited slip, small axles, bearings, and drum brakes that are no longer modern, are all features you can find on a ’55-57 Chevrolet rear. As a matter of fact, not only have these rear axles fallen out of favor with early street rods, even the Tri-Five bunch is removing them in favor of a more modern unit.

Using a transmission jack and a fabricated fixture that supports both axle tubes and the front of the centersection, the rearend was lifted taking the weight off the springs.

Using a transmission jack and a fabricated fixture that supports both axle tubes and the front of the centersection, the rearend was lifted taking the weight off the springs.

Longtime STREET RODDER reader Don Prieto (all-around hot rodder back to the days when his Cacklefest digger was really a race car!) owns a prime example with his ’56 Nomad. It’s a neat car with ample power and a great look but he wanted to improve the old Chevrolet’s street manners. It was time for improved suspension and brakes along with a limited-slip differential to handle the horsepower under the hood and provide better handling through better traction.

While the subject of our conversion is a ’56 Chevrolet, it should be noted this swap would be very similar on all Chevrolets from 1934-57 and virtually any other car or truck with parallel leaf springs. And if you are wondering, yes, Strange Engineering also has bolt-in rear axles for later coil spring cars.

From the rear you can see the stout 2-inch box tubing fixture supports both axle tubes for safe removal of the original rear axle housing.

From the rear you can see the stout 2-inch box tubing fixture supports both axle tubes for safe removal of the original rear axle housing.

To that end, a bulletproof Strange Engineering S60 bolt-in rear axle was ordered, along with performance shock absorbers from Performance Online. The original 1956 parallel leaf springs are still the main components of the rear suspension, but we will have superior brakes and shocks improve driveability, along with a gear set that will handle all the horsepower we can throw at it.

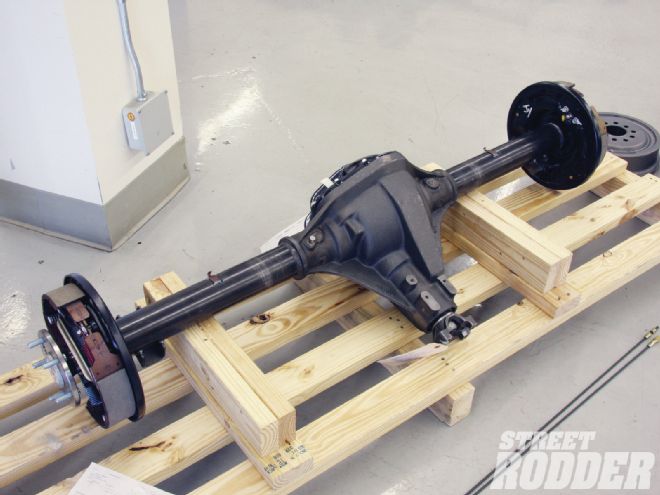

The S60 rear was developed by Strange Engineering for extreme street performance, particularly street/strip cars. Back in the day, the 12-bolt rear was king for the GM crowd, but today’s modern motors can easily overpower the old 12-bolt. The S60 incorporates Dana 60 components. The 9.750 ring gear will endure tremendous abuse, equal or better than the 9-inch Ford. The S60 is equipped with strong 35-spline axles so there is no need to upgrade axles and these rearends are available as complete units with no brackets, ready for your fabrication or there is also a long list of bolt-in housing for most popular cars. The very cool aluminum rear cover is the crowning touch to a true performance housing. We ordered the bolt-in variety of the Strange S60 with a 3:54 gear set, this way all the brackets were in place for our ’56 Chevrolet installation. Inside we selected the Trac-lock limited-slip option and on each end of those big 3-inch tubes we have drum brakes but several disc brake options are available too.

It’s always fun to uncrate new parts, and it was love at first sight for our Strange Engineering S60 rearend. With the spring’s pads already in place this will be a true bolt-in swap.

It’s always fun to uncrate new parts, and it was love at first sight for our Strange Engineering S60 rearend. With the spring’s pads already in place this will be a true bolt-in swap.

The installation was really very straight forward, being a true bolt-in swap. The only fabrication consisted of making new hard brake lines for the housing; the rest of the project was done with wrenches. The process is simple enough that just following the photos will show you how easy the swap really is, but always remember the safety side of things when you are working under a car. Axle housings are heavy so if you are working on a lift remember to put safety supports under the front bumper, and if you are working on jackstands be certain the vehicle cannot move after removing that rear weight. Use proper jacks and supports to raise and lower the housing and be certain the springs are completely unloaded before removing the shackles.

While there are several different disc brake options available from Strange Engineering we opted for the standard big drum brakes; they will be ample for our Nomad.

While there are several different disc brake options available from Strange Engineering we opted for the standard big drum brakes; they will be ample for our Nomad.

Since removing the rear housing involves dropping both leaf springs now would be the perfect time to replace both the front spring-eye bushing and the rear shackle bushings. We used a set of urethane bushings, U-bolts, and lowering blocks sourced from Performance Online. Our new adjustable gas shocks are also from Performance Online and will go a long way to controlling those springs. These changes along with the additional grip offered by the limited-slip differential helped us reap substantial performance gains.

We began by removing the driveshaft U-bolts; after removal, a couple of wraps of tape will prevent the endcaps from falling off the universal. You can tie the driveshaft up and leave it in the transmission to prevent fluid from leaking.

We began by removing the driveshaft U-bolts; after removal, a couple of wraps of tape will prevent the endcaps from falling off the universal. You can tie the driveshaft up and leave it in the transmission to prevent fluid from leaking.

A quick test-run through our slalom course bears that out. Our times dropped dramatically. On our 420-foot, seven-cone slalom our times dropped from 7.53 seconds to 6.51 and our average speed increased from 38.3 to 44.2 mph. Pretty impressive results when you consider there was no fabrication involved, just simple bolt-on goodies.

And so, as it may be time for you to consider a similar third member swap, follow along and you can see this is a simple and rewarding weekend job. We’ll give you time to get that done, then next issue we’ll show you a very cool front suspension upgrade.

Next we removed the hard line from the flex line where they meet on the frame. Always use line wrenches on brake lines. Remove the clip holding the flex line to the bracket.

Next we removed the hard line from the flex line where they meet on the frame. Always use line wrenches on brake lines. Remove the clip holding the flex line to the bracket.