| Head Games & Valve Jobs

| Head Games & Valve Jobs

An internal combustion engine is like a big air pump, and the more air you can get it to pump, the more torque and horsepower it will make. Things like bigger camshafts, aftermarket intakes and exhausts can help increase airflow to a certain point, but ultimately, to get the most out of your high-tech air pump, you've got to make the cylinder head more efficient.

The goal of modding any cylinder head is to increase its volumetric efficiency (VE). The VE is a measurement of how efficiently an engine can pump air relative to how much it displaces. For example, if an engine has a displacement of 1000cc and moves 700cc of air with every stroke, it has a VE of 70 percent. If it moved 1000cc with each stroke, the VE would be 100 percent.

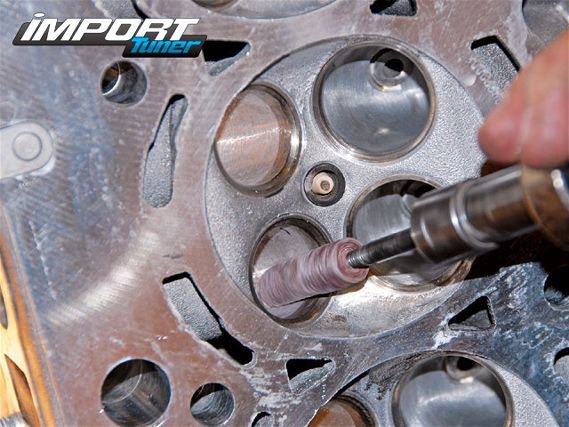

| 1.Cleaning up any imperfections where the valve meets the head, as shown here, will help the intake charge flow into the head with the least amount of resistance possible.

| 1.Cleaning up any imperfections where the valve meets the head, as shown here, will help the intake charge flow into the head with the least amount of resistance possible.

Most modern multi-valve engines have a peak volumetric efficiency of around 80 percent; which leaves plenty of room for improvement. All things equal, bringing the VE up by 10 percent should yield an additional 10 percent increase in power and torque-in theory at least. There are different ways to increase the VE of a 4-stroke cylinder head, and the key to getting the highest VE is to make sure all the methods and parts used are compatible.

Aftermarket cams can increase airflow by keeping the valves open for a longer period of time (more duration), or by just pushing the valve farther into the combustion chamber (more lift). Be warned, if you just install bigger cams without making any changes to the head, you're not getting all the power the cams can offer. Because OEM heads often have many manufacturing imperfections in the ports and combustion chamber that inhibit flow, often times opening the valves up more or longer won't increase airflow much over stock.

Even without changing the camshafts, mild headwork can increase an engine's VE substantially, and gains of around 10 percent or more are common if the job was done well. If that's not enough and you decide to toss some cams on too, consider this: Camshafts and heads are designed to work as a single unit. In order to get the best results, have the same shop that does the headwork grind you a set of custom camshafts to match the head.

In this article, we'll show you what you need to know if you deicide to take your air pump to the next level, as well as showing you a few tricks you can do at home to get the most out of your head.

| 2.This strange-looking machine is used to force an abrasive putty-like substance through things like intake manifolds and cylinder head ports to remove casting imperfections and increase airflow.

| 2.This strange-looking machine is used to force an abrasive putty-like substance through things like intake manifolds and cylinder head ports to remove casting imperfections and increase airflow.

Valve JobsBelieve it or not, all the cylinder head gurus we spoke with agreed that 50 percent of the gains of a full port and polish could be had by simply performing a quality valve job. This is good news for budget racers, considering the cost of a quality port and polish.

The reason behind this phenomenon is a simple one. All of the air that flows into the engine must flow directly past the valve, making the aerodynamic profile of the valve very important. If the valve has sharp angles and casting imperfections, it will create turbulence and decrease the amount of air that can move past it. Making the valve as aerodynamic as possible can pay in dividends.

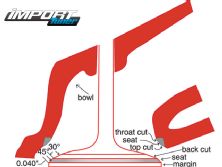

Multi-angle valve jobs are the most common way to make a valve more aerodynamic and make the head more efficient. A multi-angle valve job puts extra cuts on the valve near where it mates with the cylinder head, streamlining it and helping to move air past its surfaces with the minimum resistance and turbulence possible. OEM valve jobs are usually one or two-angle valve jobs. This is done to keep costs low, and even if they want more airflow, OEMs will often just switch to a larger valve instead of using multi-angle valve jobs because it's cheaper than performing the extra machining of a multi-angle job. However, for the average enthusiast, the opposite typically holds true because oversized valves can be very costly.

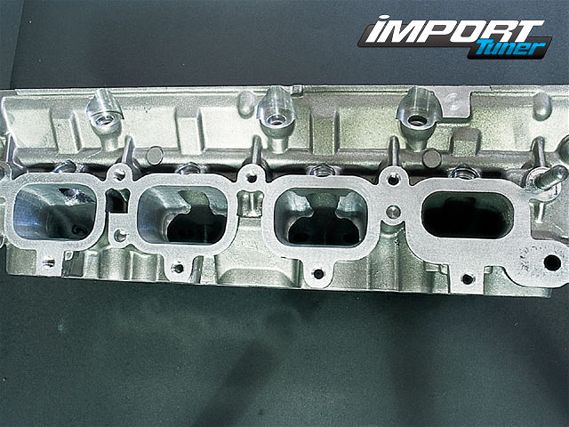

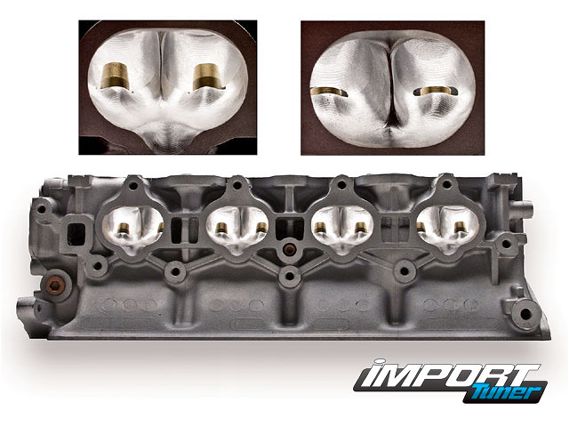

| 3.Here's a head that's received some mild work. As you can see, the ports are smooth and the combustion chamber has no imperfections. This is how it should look.

| 3.Here's a head that's received some mild work. As you can see, the ports are smooth and the combustion chamber has no imperfections. This is how it should look.

The more angles a valve job employs, the better it will generally flow. The most common multi-angle valve jobs are 3-angle, 5-angle and radius valve jobs. A radius valve job is basically a 5-angle job where the transitions between the 5 angles are smoothed out. The downside is that the more cuts, the higher the cost. For this reason, 3-angle jobs are the most common and offer a good balance between cost and performance. Don't underestimate the importance of a quality valve job.

Porting And PolishingWe've all heard the term "ported and polished," and it's likely we've all got idea what it means. To the average enthusiast, this means enlarging, and possibly reshaping the intake and exhaust ports and polishing the combustion chamber. Sounds simple enough, right?

| 4.Here's a head that's received some mild work. As you can see, the ports are smooth and the combustion chamber has no imperfections. This is how it should look.

| 4.Here's a head that's received some mild work. As you can see, the ports are smooth and the combustion chamber has no imperfections. This is how it should look.

Wrong. Cylinder head porting is an art. While we can explain some of the common methods and techniques, because of the advanced physics involved, porting is something best left to the professionals. In fact, without expensive and complex equipment, there is no way to even measure any changes.

Contrary to popular belief, a good port job doesn't simply include making all the ports as big as possible, as this will often result in a soggy engine that has lousy throttle response. Things like air velocity must be taken into consideration, which sometimes requires making the ports smaller than stock to increase the velocity. That's the thing about porting-sometimes the results are counter-intuitive; which means unless you are willing to destroy a few heads through trial and error, make sure your head shop knows what they are doing. The only real way to test if the changes that were made helped is with the use of a flow bench or a dyno... and do you have either of those?

What the car will be used for will generally dictate how much porting will actually be done. Proper porting takes into consideration things like engine size, RPM range, horsepower, etc and must be done to match the other mods. For a street car, this usually means only cleaning up casting imperfections, a mild un-shrouding of the valves and smoothing everything out. For a full-race motor, a port job might include enlarging the intake and exhaust ports as well as reshaping and polishing the combustion chamber. It all depends on the goals. Any reputable head builder should be able to tell you what is best for your application.

| 5.Gasket matching is a cheap and easy way to get more airflow. The scribed circle in the picture was made by placing the gasket on the head and tracing it. All that's left to do is grind away till we hit the lines.

| 5.Gasket matching is a cheap and easy way to get more airflow. The scribed circle in the picture was made by placing the gasket on the head and tracing it. All that's left to do is grind away till we hit the lines.

Important TermsCCing:The volume of the combustion chamber of the head has a direct effect on compression ratios. A smaller-than-stock CC volume will increase the compression ratio (CR), while a larger combustion chamber will decrease the CR. Because of this, it is important that all the combustion chambers are the same size, or each cylinder will have a different compression ratio and cause tuning problems later. CCing is performed by filling each combustion chamber with water or another liquid. The amount of liquid it takes to fill up each combustion chamber tells us the volume of each chamber. Material is then removed or added from individual chambers until they are all equal.

Intake Manifold Gasket Matching:As they come from the factory, the ports on most intake manifolds don't line up perfectly with the ports on the head. This is because of loose manufacturing tolerances to keep machining and tooling costs low. As a result, there is often a lip or bump where the head and manifold meet, causing a significant restriction and reduction in airflow. Gasket matching removes this restriction and can increase power-all for free! All you have to do is place the gasket on the head, then bust out the Dremel and hog out the ports until they perfectly match the gasket. Repeat on the intake manifold and, viola, you're done!

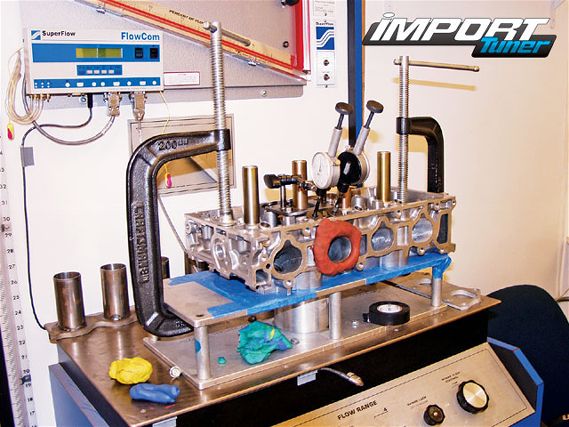

| 6.A must-have for any serious cylinder head shop, the trusty flow bench measures how much air (cfm) actually flows through the head-before and after the headwork.

| 6.A must-have for any serious cylinder head shop, the trusty flow bench measures how much air (cfm) actually flows through the head-before and after the headwork.

Flow Bench:Without this device, porting would be a strictly hit-and-miss deal. A flow bench measures airflow though cylinder heads. The bench lets head porters see if the changes they made to the head actually improved airflow before they actually bolt it to an engine. In addition, it gives quantifiable numbers that can be compared to the numbers from other heads on other flow benches. This is a must-have for any serious head shop.

Aftermarket Valves:While multi-angle valve jobs can improve airflow, if you want even more airflow, it's probably time to look at bigger and better valves. Obviously, bigger valves can flow more, but that's not the only benefit. High performance and particularly turbocharged engines can see very high exhaust gas temperatures (EGT). Valves made of stainless steel and those that are filled with sodium can withstand higher temps that OEM valves, making them a wise investment that can not only increase power, it can help with engine longevity too.

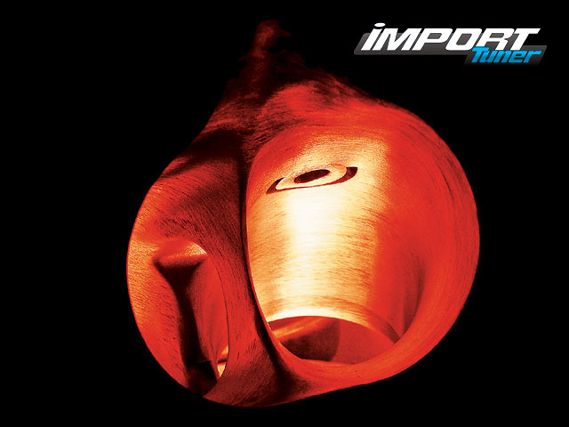

| 7.A beautifully sculpted intake port. This porting was done by a computerized CNC mill.

| 7.A beautifully sculpted intake port. This porting was done by a computerized CNC mill.

Unshrouding:Unshrouding is the removal of the excess material on the head immediately around the valves. Ideally, there should be at least 1/3-inch around the valve and the cylinder head at full lift. If there isn't, airflow will be impeded as it flows past the valve and hits the wall of the head, impeding flow. By clearing a space for the air to transition smoothly past the valve in a tulip-shape funnel into the engine without running into a restriction, more power can be made. Unshrouding clears the path for this tulip-shaped funnel.

Hand Porting:The old-school way of cylinder head porting is also the most common. With "hand-porting" all the grinding and shaping is done by hand with a Dremel-type tool. The porter relies on their eyes and experience to get everything just right.

CNC portingCNC uses a computerized machine to re-shape and smooth the cylinder head. Because a computer controls it, the chances of getting each port and combustion chamber matched perfectly are higher. CNC mills are extremely expensive, which is why most people still do it by hand.

| 8.Here the valve guide has been ground down to further increase airflow. In picture number 7, the guide was not ground down.

| 8.Here the valve guide has been ground down to further increase airflow. In picture number 7, the guide was not ground down.

Extrude Honing:A method of porting where material is removed from the head by forcing putty mixed with sand through the ports. This only slightly enlarges the ports while keeping the basic shape and contours the same. The real benefit comes from the cleaning up and smoothing of all the walls in the ports. Things like intake manifolds can also benefit from extrude honing. Good for street and race engines alike.

PolishingPolishing of the combustion chambers and exhaust ports is standard fare for a good porting job. Polishing the combustion chamber can prevent the buildup of carbon and help ward off detonation. Polishing the exhaust ports can also increase airflow. Intake ports are typically not polished. This is because leaving a slightly rough surface on the intake ports can help prevent fuel from sticking to the walls of the head and causing drivability problems. So if your head shop wants to polish your intake side too, you'll have good reason to question their expertise.

| 9.Here's a view of a head that's received some work. The port on the left is an intake and the one on the left is an exhaust port.

| 9.Here's a view of a head that's received some work. The port on the left is an intake and the one on the left is an exhaust port.

Valve springs/retainers/keepersIf you plan on spinning your engine to higher RPMs than it did from the factory or using bigger camshafts, it's a good idea to upgrade your valvesprings, keepers and retainers if you want it to live a long and fruitful life. Soft OEM valvesprings are oftentimes not up to the chore of holding the valve closed at high RPM and can physically bind if used with a cam that has additional lift (this is extremely bad). Stiffer and specially designed valvesprings can prevent this from happening. This is also a good time to look into things like titanium retainers, which in addition to being stronger, are lighter and can reduce wear on other valvetrain parts (good for performance and longevity). Many people are unaware that every time a valve closes on, it bounces on its seat. As the valve bounces up and down, the valve leaks. So even engines with mild camshafts can often gain power with slightly stiffer valvesprings and lighter retainers.

Intake Manifold SpacerThere are several different types of spacers on the market that sit between the head and the intake manifold. These spacers are made of materials that are supposed to isolate the manifold from the head and reduce the temp of the intake manifold. We've tested these in the past and found intake temp reductions of about 15 percent, on average. In theory, a 15 percent reduction in intake temps should yield a 1.5 percent increase in power.

| 10.Aftermarket dual valvesprings are often overlooked when doing headwork. Custom valve springs are a good thing to look into if you've got your head apart.

| 10.Aftermarket dual valvesprings are often overlooked when doing headwork. Custom valve springs are a good thing to look into if you've got your head apart.

QuenchQuench is one of the least understood cylinder head dynamics. Basically, a quench zone in an internal combustion engine is an area where the piston and the head come extremely close (0.05 inch) to each other at top dead center (TDC). The area where the piston and head almost touch is called the quench zone. Quench zones are usually around the perimeter of the head and are designed to force the air/fuel mixture towards the spark plug. Quench zones help reduce preignition and detonation, so it's important not to screw them up. For what it's worth, using oversized head gaskets can make the gap between the piston and head so large that it can negate the benefits of having a quench zone at all-which can bring on detonation despite the overall lowering of the compression ratio that the thicker head gasket would cause. You've been warned.