Adding 200 Horsepower To A Potent LMM Duramax Diesel

In the diesel performance realm, it’s not uncommon for general repair items to morph into high-horsepower builds. Case in point, when this ’09 GMC Sierra came into Flynn’s Shop in Alexander, Illinois, with a blown head gasket, the owner had two questions: 1) How can we make it never happen again? and 2) How much more power can we add? With the truck already sporting a BorgWarner S475 over a stock compound-turbo kit from Screamin’ Diesel Performance, EFILive tuning, a built Allison 1000 transmission, and an AirDog fuel system, it was obvious the owner had grown bored with driving a 550hp, 6.6L Duramax-powered rig.

| Shown here are the key ingredients used to turn this 44,000-mile ’09 6.6L LMM Duramax powerplant into a real animal: 60-percent-over injectors from Exergy Performance, a 10mm “stroker” CP3 injection pump (also from Exergy Performance), and ARP Custom Age 625+ head studs. Select parts from Mahle (head gaskets), Diesel Technology Source (double spring valvesprings), and Merchant Automotive (TIG-welded water pump) also make it into the build.

Knowing the owner didn’t want to dig into the bottom end of his engine just yet, the guys at Flynn’s devised a plan to add a couple hundred more ponies to the equation. The aforementioned compound-turbo arrangement would be retained, but 60-percent-over stock injectors, a 10mm “stroker” CP3, and ARP head studs would be installed. In order to keep the stock short-block happy (namely the pistons), EFILive tuning from DuramaxTuner.com would be employed. The spot-on ECM tuning should ensure the factory bottom end survives the added horsepower and torque. Here is how it all came together.

With the head stud washers installed and the nuts hand-tightened, Chad begins torquing the studs. Following GM’s head bolt torque sequence (center out) and ARP’s torque specs, Chad makes three different pulls on each stud. The first calls for 50 ft-lb, 100 ft-lb for the second, and 150 ft-lb on the final pass.

Next, the factory fuel return lines are hooked back up, and the return harness is placed back on the engine.

| Shown here are the key ingredients used to turn this 44,000-mile ’09 6.6L LMM Duramax powerplant into a real animal: 60-percent-over injectors from Exergy Performance, a 10mm “stroker” CP3 injection pump (also from Exergy Performance), and ARP Custom Age 625+ head studs. Select parts from Mahle (head gaskets), Diesel Technology Source (double spring valvesprings), and Merchant Automotive (TIG-welded water pump) also make it into the build.

Knowing the owner didn’t want to dig into the bottom end of his engine just yet, the guys at Flynn’s devised a plan to add a couple hundred more ponies to the equation. The aforementioned compound-turbo arrangement would be retained, but 60-percent-over stock injectors, a 10mm “stroker” CP3, and ARP head studs would be installed. In order to keep the stock short-block happy (namely the pistons), EFILive tuning from DuramaxTuner.com would be employed. The spot-on ECM tuning should ensure the factory bottom end survives the added horsepower and torque. Here is how it all came together.

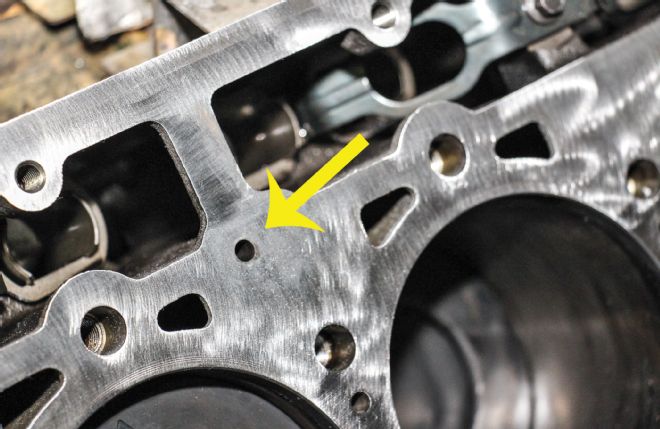

With the head stud washers installed and the nuts hand-tightened, Chad begins torquing the studs. Following GM’s head bolt torque sequence (center out) and ARP’s torque specs, Chad makes three different pulls on each stud. The first calls for 50 ft-lb, 100 ft-lb for the second, and 150 ft-lb on the final pass.

Next, the factory fuel return lines are hooked back up, and the return harness is placed back on the engine.

| Shown here are the key ingredients used to turn this 44,000-mile ’09 6.6L LMM Duramax powerplant into a real animal: 60-percent-over injectors from Exergy Performance, a 10mm “stroker” CP3 injection pump (also from Exergy Performance), and ARP Custom Age 625+ head studs. Select parts from Mahle (head gaskets), Diesel Technology Source (double spring valvesprings), and Merchant Automotive (TIG-welded water pump) also make it into the build.

Knowing the owner didn’t want to dig into the bottom end of his engine just yet, the guys at Flynn’s devised a plan to add a couple hundred more ponies to the equation. The aforementioned compound-turbo arrangement would be retained, but 60-percent-over stock injectors, a 10mm “stroker” CP3, and ARP head studs would be installed. In order to keep the stock short-block happy (namely the pistons), EFILive tuning from DuramaxTuner.com would be employed. The spot-on ECM tuning should ensure the factory bottom end survives the added horsepower and torque. Here is how it all came together.

With the head stud washers installed and the nuts hand-tightened, Chad begins torquing the studs. Following GM’s head bolt torque sequence (center out) and ARP’s torque specs, Chad makes three different pulls on each stud. The first calls for 50 ft-lb, 100 ft-lb for the second, and 150 ft-lb on the final pass.

Next, the factory fuel return lines are hooked back up, and the return harness is placed back on the engine.