When the 1997 C5 Corvette hit the road it was our first look at GM’s new LS1 powerplant. The all-aluminum EFI-fed mill was leaps and bounds better than the LT1 it replaced and there wasn’t an Opti-Spark to be found. Life was good. The power output was good as well with an advertised 345 horsepower and 350 lb-ft of twist (at the crank). And although that was great power in 1999, by today’s standards it falls a bit short, especially if you want to go hit the local open track day with newer C6s and C7s.

Thankfully, making more power with an LS engine is amazingly simple. Thanks to some GM engineer, who deserves a free beer, the exterior dimensions, as well as the mounting bosses, have been kept the same throughout the LS family of engines. This means that an LS1, LS2, LS3, LS7 and even the supercharged variants, can all accept engine mounts, pulley systems, and sensors, from any of the other variants. In short, upgrading the LS1 in a C5 to any other LS engine is pretty straightforward.

Our C5 project still wields its original LS1. Yeah, it has 80,000 miles on the odometer, but it still runs great. Our plan is to do some track days and if we want to keep up with newer Corvettes we need more power. So rather than tweak more ponies out of the LS1 we decided to see what’s involved with installing the C6’s LS3.

With that part of the plan gelled we had two ways to go. The first was to buy a Chevrolet Performance LS3 crate engine. This is the fast way from point A to point B. The crate engine is the same animal that comes in a new C6, so it’s a rock solid choice. But, in typical gearhead fashion, we wanted more. So that brought us to our second option; to build an engine. It’s a lot more work, but if done right the process yields a much better engine that puts out a ton more power.

Of course, when starting out with a bare block it’s barely more expensive to stroke it for even more displacement. To save on machine shop costs we didn’t hone the new block out to 4.070-inches as is typically seen on LS3 strokers. Instead, we worked with Eagle Specialty Products to source a kit that worked with the block Chevrolet sold us. That meant moving to a 4.00-inch stroker crank would yield 415 glorious cubic inches. For the build we headed over to Custom Built Motors (CBM) since crafting together LS engines is something they do every day. Once built we’ll detail how to install it into a C5 and inject a lot more power into one of GM’s best Corvette bargains out there.

01. The starting point for our 415 build was this 6.2L block from Chevrolet Performance (PN 12621769). Since the block was new we decided to not mess with it and source pistons for the stock 4.165-inch bore.

02. The biggest pain about starting off with a new block is that it’s missing all the “stuff” needed to build an engine. This block plug kit from Comp (PN 251) made life a bit easier and sealed up all the water and oil ports.

03. This is a stroker, so a small notch was needed in each cylinder sleeve edge to allow the rod to swing through. Doing this by hand is tedious, but Custom Built Motors (CBM) has a CNC program that knocks it out in a heartbeat. The time saved was well worth what they charged to cut the notches.

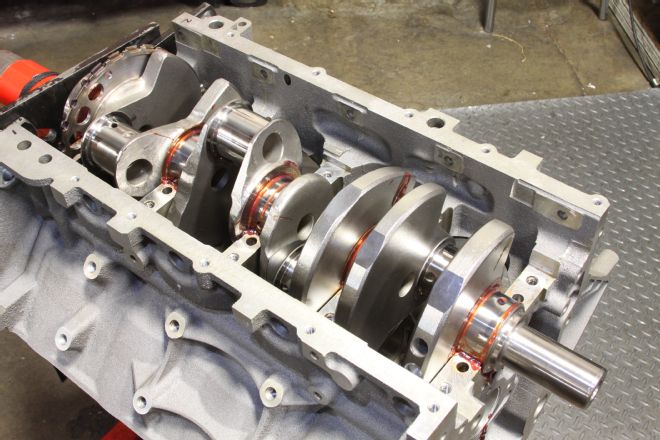

04. The key player in any stroker build is the crank. For our Vette transplant LS3 we chose an Eagle 4349 forged steel crank (PN Z434640006100). The non-twist forgings are heat treated, X-rayed, sonic tested and magnafluxed to ensure they are perfect. Later they are shot-peened and stress relieved for enhanced durability. The journals are nitrated and precision ground followed by micro-polishing. Cross-drilled and chamfered oiling holes are just icing on the cake. The crank was installed with a set of Clevite main bearings.

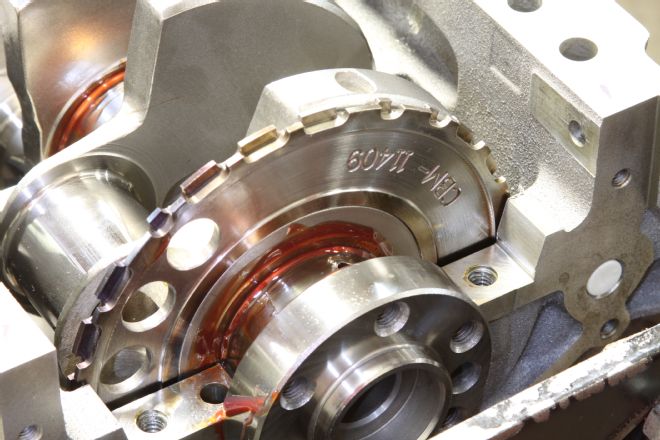

05. Our crank came with a GM 24x reluctor wheel so it would play happy with our 1999 PCM and not need any additional electronics. CBM isn’t a fan of the stamped two-piece GM reluctor, so they came out with this sweet one-piece billet reluctor wheel (PN 11409).

06. For slugs, we grabbed eight fully coated Mahle Motorsports forged pistons (PN 930223265). The 4.065-inch bore meant we didn’t need to pay a shop to hone the cylinders on our brand-new Chevrolet Performance block and they were built to dance with our 4.000-inch stroke crank and 6.125-inch rods. The -4cc volume should yield us a premium gas friendly 11.0:1 compression ratio.

07. Rods take a lot of abuse, so we paired up a set of Eagle H-beam connecting rods (PN 6125O3D2000) with our Eagle stroker crank. These 4340-certified rods are stronger than stock, yet lighter in weight. Like the crank, they are fully tested, shot-peened, and stress relieved. They came fitted with 230,000 psi rated ARP 2000 rod bolts. Like the crank, the rods received Eagle’s proprietary ESP Armor surface finishing process, which you can find out more about on their website.

08. With the crank installed we then slid the piston/rod assemblies into the cylinder bores.

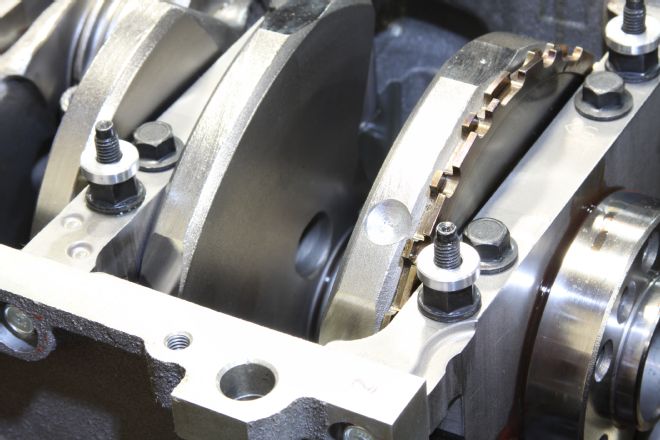

09. Once in place the ARP 2000 rod bolts were torqued to 70 lb-ft using the provided ARP lube.

10. Let’s be honest, if we tossed too much power into the C5 we would just break a lot of parts. We also plan on driving to the track (and hopefully home again), so we wanted a cam with great street manners. Given all of this, we opted for a cam a bit on the smaller side. This custom-ground Lunati stick spec’d out at 227/243 duration (at 0.50-inch) and lift of 0.619/0.632 with a 113 LSA.

11. One item we forgot was a cam plate (PN 12589016), luckily CBM had one in stock. It’s a $20 part, but if you don’t have one it can grind your engine build to a halt. The plate was secured with an ARP cam bolt kit (PN 134-1002).

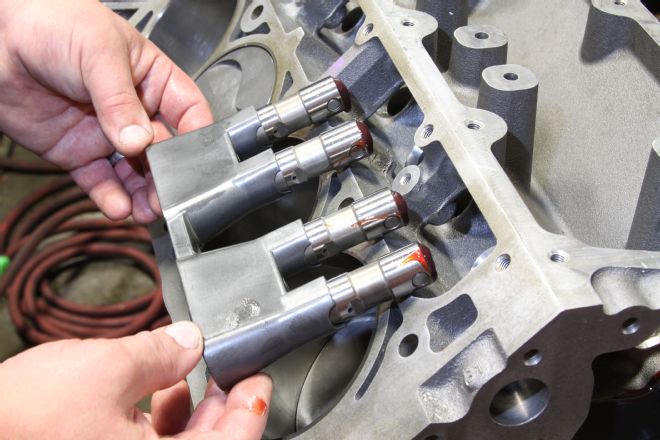

12. Because we needed lifters, we decided to buy a set of Lunati pieces (PN 72910-16) since they didn’t cost much more than the stock stuff and we felt they were a better product. We also needed four of the plastic GM lifter trays (PN 12595365), which cost less than $10 each.

13. We’re dealing with a 1999 Corvette ECU, so in addition to the older 24x reluctor ring we also needed a single-pulse cam sprocket. To keep the timing right, CBM installed a Rollmaster timing set (PN CS1180) and GM chain silencer (PN 12588670). To move oil, a Melling oil pump (PN 10296) was ordered from Summit Racing. The silencer came in a cool “completer kit” offered by GM (PN 19299099), which also included a timing cover, cam sensor, head dowels, crank sensor, and a valley cover. It was $200 well spent.

14. With the short-block essentially done, we started prepping to install the new heads. First up was a full set of ARP head studs (PN 234-4317) followed by a pair of Fel-Pro MLS head gaskets (PN 1161R053). We prefer the ARP stuff over the factory head fasteners since they are reusable in addition to being much stronger.

15. To make strong power you need a killer set of heads. For this build, we went with a set of Trick Flow GenX 255 LS3 cylinder heads (PN TFS-32610002-C01). The big 255cc intake ports should easily feed our stroked LS3, and these square-port heads work on engines with 4.00-inch bores and larger. The heads have 69cc combustion chambers and are completely CNC detailed. This equates to more airflow and better combustion.

16. Trick Flow also altered the valve angles from 15- to 12-degrees to increase piston-to-valve clearance and allow the use of larger camshafts. They came assembled with 2.165-inch intake and 1.600-inch exhaust valves, Viton seals, chromoly-steel retainers, and ductile iron valve seats. The coolant holes through the head deck were redesigned to work with all LS head gasket and engine block combinations. The dual valvesprings were rated for up to 0.650-inch lift.

17. The Trick Flow heads won’t accept OEM rocker arm rails, so Trick Flow included new billet LS3 1.7 ratio rocker arm rails.

18. If your lift isn’t too high it’s really hard to beat a set of GM LS3 rocker arms (PN 85428-16). Lunati did find a way to make them a bit more reliable by punching out the stock cageless, and sometimes sloppy, OEM needle bearings and replacing them with precision caged bearings and upgraded mounting hardware. After all, having a rocker come apart and blow needle bearings through your engine can really ruin your day. A set of Lunati 7.700-inch hardened pushrods completed our valvetrain.

19. For a little extra stroker clearance, CBM used these sweet aluminum standoff spacers. It sure beat stacking washers.

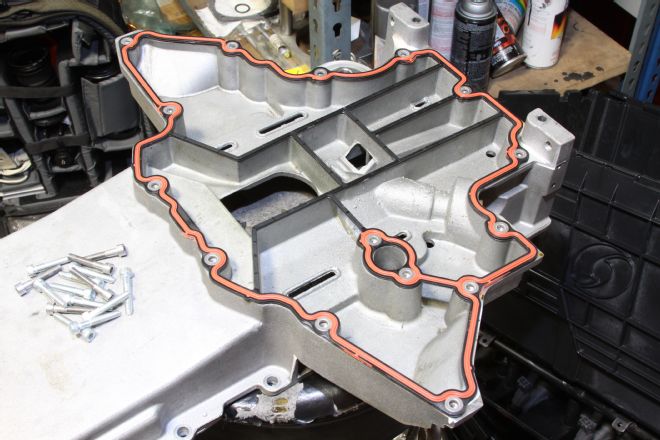

20. We considered different oil pan ideas, but Corvette guru Danny Popp convinced us to stick with the Corvette’s batwing oil pan. To save hassle on the engine swap, CBM loaned us one from its stock if we promised to return the one off the car. Here you can see some of the complicated internal baffling that makes this one of the best oil pans GM has ever offered.

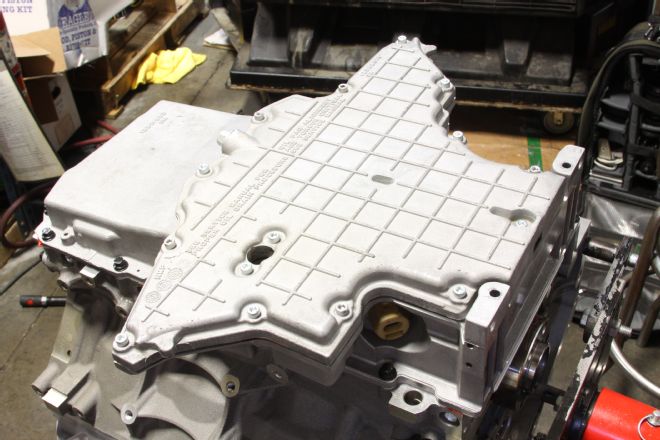

21. And here it is fully assembled and bolted to our LS3 with fasteners from our ARP accessory bolt kit (PN 534-9805).

22. We’re trying to go a bit stealthy, so we opted to run a factory LS3 intake we had left over from another build. The GM LS3 intake is one of the best ones they’ve ever turned out and really doesn’t leave much on the table. To finish off the top we added a GM LS3 fuel rail (PN 12633511) and a set of 39-pound FAST LS3 fuel injectors.

23. And here’s our stroker LS3 completely assembled and ready to head over to the Superflow 902 dyno at Westech Performance.

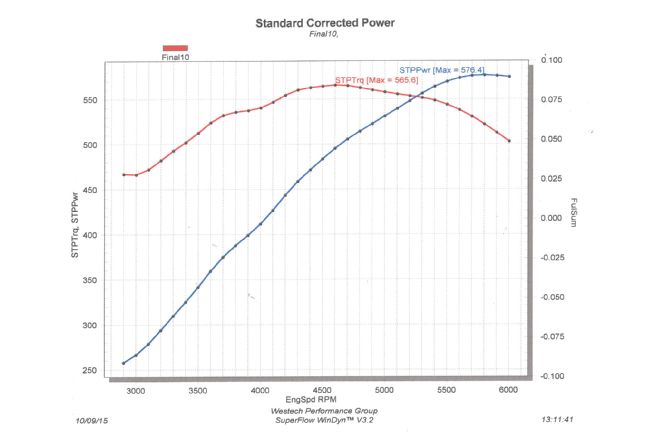

24. Fitted with a C5 damper, a Meziere electric water pump, and long-tube dyno headers (with mufflers), the stroker LS3 was ready to get broken in on a pan full of Lucas break-in oil. For ease on the dyno we swapped the 90mm electronic throttle body with a cable actuated FAST 102mm piece.

25. The worked over LS3 made 576 horsepower at 5,800 rpm and an impressive 566 lb-ft of torque at 4,500. In fact, it made excellent torque all across the pull with well over 450 lb-ft when we rolled into the throttle at 3,000 rpm. If you’re keeping track of the math you’ll note that’s over 220 more horsepower and 225 more lb-ft than the car came with from GM, which is more than enough power to breathe some new life into our 1999 FRC Vette.