When it comes to aftermarket performance enhancements and tuning, the C7 Corvette’s LT1 has proved itself a tough nut to crack. Although it is based on the familiar LS architecture, the combustion system is completely different and is designed to support the direct injection fuel system, while technologies including GM’s Active Fuel Management (cylinder deactivation) and camshaft phasing (variable valve timing) throw additional curves. Finally, the E92 engine controller is completely different than the ones used with LS engines.

“Taken all together, there is a lot to wrap your arms around with the new LT engines,” says Mike Copeland, Lingenfelter Performance Engineering’s vice president of operations. “It’s still a familiar cam-in-block V-8, but the technologies employed to optimize performance and efficiency in production form mean the traditional methods of increasing horsepower require different approaches to generate a result that doesn’t sacrifice drivability or overall performance for a comparatively minor maximum power gain.”

Take the combustion system for example, rooted in the cylinder heads. The combustion chambers are shaped very carefully to work with the unique topography of the pistons, which are designed to direct the fuel’s spray pattern throughout the chamber for an optimal, more complete burn. That’s because the fuel itself is introduced in the combustion chamber, rather than being sprayed into the intake manifold and delivered with the air charge as a homogenous mixture. It’s the essence of direct injection and it means conventional head-porting tricks aren’t necessarily beneficial.

“Because you’re mixing fuel with air for the first time in the combustion chamber, you don’t necessarily want to simply hog out the heads’ intake ports,” says Copeland. “That doesn’t give you the benefit you want and, in fact, it will likely cost you horsepower.”

The same goes for the camshaft, thanks to the cam phasing system. Because it alters valve actuation across the rpm band, applying traditional increases in lift and duration can easily wind up sacrificing low-end power to achieve an overall power gain that comes only at high rpm.

“It’s all too easy to go backward with LT power,” says Copeland. “It’s clear the GM engineers did their homework. The factory LT1 heads and camshaft work very well and taking them to the next level requires an extremely balanced approach.”

Lingenfelter has apparently found the sweet spot, as its heads-and-cam-based performance package takes output from the stock 455 horses to 550 horsepower – all while retaining excellent drivability and features such as the factory cylinder deactivation system and camshaft phasing. They’ve even got more radical cam packages that are rated at 600 and 630 horsepower, respectively, but they eliminate the cylinder deactivation and variable valve timing systems.

We were intrigued with the 550hp package mostly because it offered a maximum power rating that approaches the previous generation bolt-on supercharger system, but with natural aspiration and the retention of the factory technologies. Believe us, we love blowers – and so does Lingenfelter, which offers Edelbrock and Magnuson-based systems – but for those of us who like to run their Stingray on a road course for track days, there are a couple of big advantages to running without forced induction. For one thing, there’s no heat soak to contend with after a couple of laps. Secondly, blowers and their related plumbing and heat exchangers, add weight, perhaps 90 pounds overall, and most of it is located smack-dab over the front wheels.

Where the supercharger offers an advantage is more-immediate power delivery lower in the rpm range, so if you’re looking for that instant hit on the street or dragstrip, the blower may be the answer you’re seeking. But if you enjoy the satisfying sound and feel of high-winding horsepower, natural aspiration is your brand of yoga.

At Lingenfelter’s Decatur, Indiana, facility, we watched the upgrade of a stock Stingray to the head-and-cam package. It’s technically feasible to do it with the engine in the car, but with the space and tools, it’s ultimately easier to pull the engine out and that’s just what the technicians did. The bottom line for the upgrades, which included the removal of the engine, the installation of the new heads and cam, reassembly of the engine, installation back in the car and, finally, dyno tuning, was $9,395.

No, that’s not chump change, but it’s less expensive than having a supercharger system purchased, installed, and professionally tuned, while delivering a solid 95 horsepower increase over the stock power rating. Value, it is said, is in the eye of the beholder.

Our experience with the Lingenfelter-ized Stingray proved fun and rewarding. There’s nothing like the tingle in the spine generated by the sound of a 7,000+rpm Chevy V-8 as it screams up the tachometer. In this instance, you can forget the forced induction.

1. With its standard 455 horsepower and 460 lb-ft of torque, the Gen V LT1 is the most powerful standard Corvette engine ever. Its performance is due largely to a direct injection-based combustion system that upends many of the traditional methods of increasing performance. At least, it makes them more difficult.

2. The first step in Lingenfelter’s LT1 upgrades is removal of the engine. It’s possible to swap the cam and heads with the engine in the car, but by the time the engine has been torn down this far, it doesn’t take much more to pull it out, making the following engine work easier – and besides, leaving it in requires removal of some chassis parts to loosen and lower the front of the oil pan. As such, Lingenfelter recommends sending your car in for the work. The alternative is tearing it down yourself, adding the parts individually and sending in the car’s controller for calibration.

3. With the engine out of the Corvette and on a stand, the front-end accessories, timing chain cover, fuel system and finally the heads are removed. It’s a time-consuming process, but with its architecture rooted in the previous LS family, tearing down the LT1 is comparatively easy and straightforward.

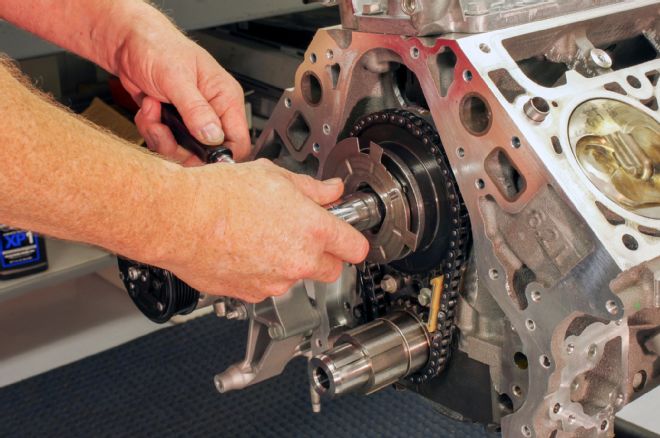

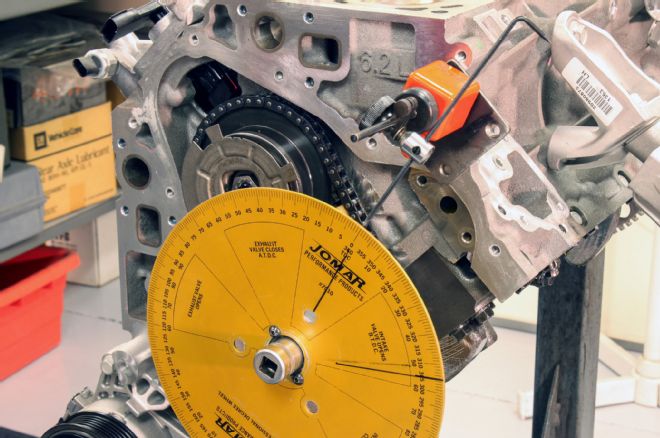

4. Next, the camshaft is slated for removal, which first requires the cam phaser to be removed. That involves rotating the engine so the crankshaft gear’s timing marker is pointing at the 12 o’clock position and the camshaft phaser gear timing marker is pointing at 6 o’clock – the dot-to-dot lineup. A 24mm socket is required to loosen the cam phaser bolt and extreme care must be used with the delicate phaser reluctor wheel on the front, which can be easily damaged. The phaser bolt is a one-time-use fastener and a new one is used during assembly.

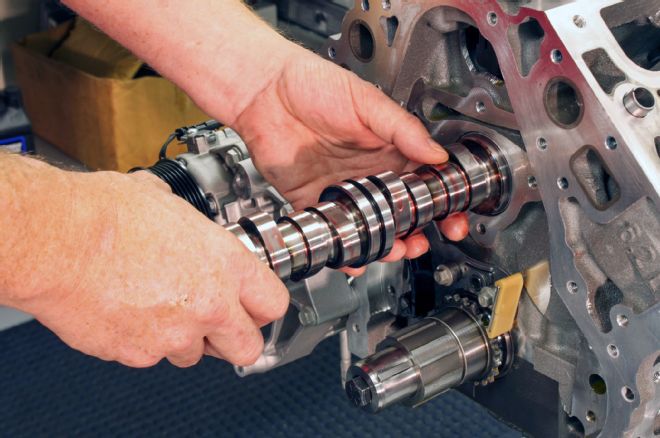

5. After the phaser mechanism is removed, the original camshaft slides out easily. The lifters were removed when the heads were, so there was no concern about supporting them as the camshaft was pulled out of the block. It’s immediately clear the LT1 cam’s lobes have larger base circles than the LS camshafts, along with wider ramps, to support the cylinder deactivation feature. The larger lobes also facilitate quicker valve actuation on the high-revving engine.

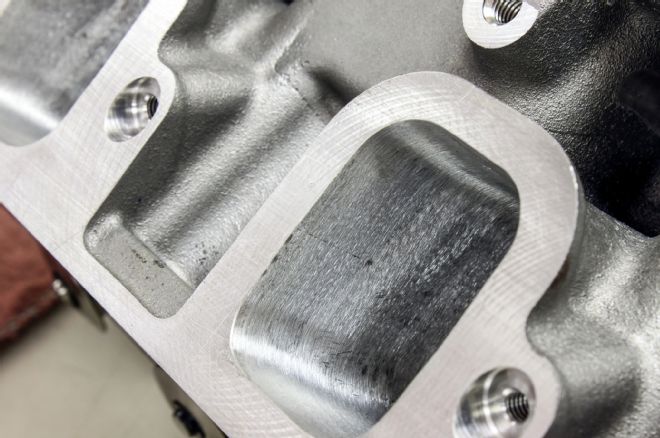

6. Lingenfelter’s CNC-ported cylinder heads are modified versions of GM’s castings. Out of the box – or off the production engine – they offer airflow capability comparable to the LS3 head, but with a greater emphasis on high-rpm performance.

7. The intake runners on Lingenfelter’s CNC heads are taken to 308cc – about 4 percent larger than the stock 297cc size. The exhaust runners are enlarged about 3 percent, from 107cc to 110cc.

8. The stock 2.13-inch hollow-stem intake and 1.59-inch exhaust valves are retained, but a three-angle valve job is performed to enhance airflow in and out of the uniquely shaped, 59cc combustion chamber. Note the hole at the bottom of the chamber. It’s where the fuel injector protrudes, rather than in the intake manifold of a conventional port-injected engine. With the stock pistons, this setup delivers a 12:1 compression ratio.

9. Designed by Lingenfelter and manufactured by COMP Cams, the camshaft in this 550hp package is designed for a moderate idle quality and the retention of the factory cylinder deactivation system. The lift specs are 0.576-inch on both sides, but the duration specs differ between the lobes working the “regular” lifters and the collapsible lifters for the cylinders that shut down on the highway. For the regular lifters, the duration at 0.050-inch valve lift is 217/229 degrees. On the deactivating lifters, the duration is 219/231 degrees. The lobe separation angle for both sets of lobes is 116 degrees.

10. Installation is basically the reverse of the removal procedure, with a new bolt used to install the phaser to the camshaft. Not surprisingly, the variable valve timing system is dependent on dead-nuts accuracy when it comes to the cam’s installation, which is carefully degreed. It’s another reason the engine work is easier with the LT1 removed from the vehicle.

11. With the camshaft installed, the heads are installed next. The head bolts are designed to stretch for more accurate and secure location, so new bolts should be used with the installation. Note the multilayer steel head gaskets being used, too.

12. Complementing valvetrain components include the stock lifters and pushrods, but new dual-coil valvesprings replace the stock beehive-type springs to support the higher-rpm capability the new camshaft enables. They are used with titanium retainers and 10-degree locks.

13. The stock 1.8-ratio rocker arms are retained and that’s not a bad thing. Although they don’t have roller tips, they have roller fulcrums, which is actually more important for reduced friction. The design has been proven over the years with other high-winding LS engines.

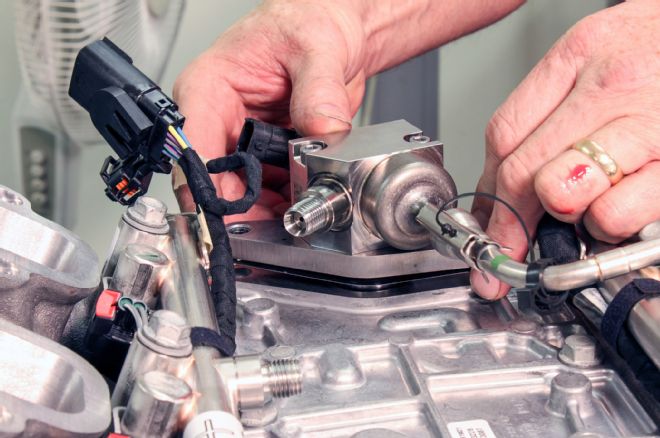

14. Here’s a look at the business end of one of the direct injection fuel injectors, as the fuel system is up next in the engine’s assembly. It works very much like the piezo injectors in a diesel engine to deliver a very finely atomized, almost mist-like fuel spray. Lingenfelter says the stock injectors have no trouble supporting the nearly 100hp increase this package offers.

15. The fuel system comes together further with the installation of the fuel rails in the heads and the unique, engine-mounted ultra-high-pressure fuel pump for the direct injection system. Driven by the camshaft via a unique “tri-lobe,” it generates about 2,175 psi. No kidding. The pressure is even greater in the Corvette Z06’s supercharged LT4 engine.

16. Next, the front of the engine is reassembled. Here, the LT1’s unique, space-saving offset water pump is bolted in place. That will just about do it before the engine is reintroduced to the chassis.

17. Finally, the enhanced LT1 slips back into its berth between the Stingray’s front fenders. There are a number of items that are more difficult to work on with the C7 cars, including exhaust removal and more, but once the engine is disconnected from the torque tube, it’s surprisingly easy to remove and re-install it.

18. Tuning is the next step. Not surprisingly, Lingenfelter was mum about the specifics of their calibration. If it’s not feasible for a customer to ship his or her car to the company’s Decatur, Indiana, facility for the entire procedure, the alternative is ordering the parts separately and sending in the ECM to be calibrated by Lingenfelter.

19. On the Dynojet chassis dyno in Decatur, the upgraded Stingray project vehicle delivered as advertised, putting down 461 rear-wheel horsepower, which is pretty much spot-on for the 550hp flywheel promise – a couple more horses, even. Torque registered 422 lb-ft at the wheels, or about 506 at the flywheel. It’s an engine that definitely likes to breathe and the greatest seat-of-the-pants performance gain came in the upper ranges of the rpm band. It may not have the low-end punch of a Roots-style supercharger, but there’s no heat soak to worry about, either. Less weight over the nose than a blower car, too.