The driveshaft is an often overlooked, yet critically important component of a vehicle's drivetrain. Not only must it be strong enough to contend with the engine's output but it must also operate properly during a constantly changing array of driveline angles. Moreover, being that it is rotating incredibly fast, the driveshaft must be in proper alignment with proper balance to avoid harsh vibration during operation.

When ordering a new driveshaft, there are numerous items to take into consideration, including (but not limited to): correct length, proper amount of yoke engagement with the transmission output shaft, driveshaft phasing, U-joint size and style, critical speed of the driveshaft, and overall strength. Follow along as we highlight the basics of the measurements required to be able to build a proper driveshaft for your vehicle.

In addition, there is a lot of misinformation regarding the operation of and determining the proper specs for a driveshaft. Thus, to address this concern, we spoke one-on-one with Denny Bringhurst of Denny's Driveshafts to get the straight scoop regarding many driveshaft myths.

Q&A With Denny's Driveshafts

Car Craft: My car is making much more horsepower than stock. Will I need a stronger driveshaft to prevent breakage?

Denny's Driveshafts: If your engine is making more than 500 hp, you should strongly consider upgrading the driveshaft and universal joints to a larger and stronger size or series. The stock-size U-joint is likely a 1310-series, so upgrading to 1330-series would be the first step, with a 1350-series being the best choice for anything with substantially increased power.

CC: Does a driveshaft need to be balanced?

DD: Yes. Driveshaft balancing is very important and often overlooked. Everyone knows that tires need to be balanced, but they don't think it is as important for the driveshaft. Unfortunately, too many driveshafts are sent to us to be balanced that already have been to one or two driveline shops only to find out it is worse after they are done with it. In high-performance applications, the customer really needs to shop carefully for a driveline shop capable of spinning the driveshaft to an rpm that is equal or higher than the customer will spin it in the vehicle. Low-speed balancers are very common and are not capable of producing the same results in high-rpm applications. Balancing a driveshaft to 1,500 rpm is certainly not the same as balancing a driveshaft to 7,000 rpm. Unfortunately, many people think that a low-speed balancing machine will work fine for all applications, regardless of power or rpm, and that is simply not true. Most everyone reading this knows of a friend who has had a driveshaft built, modified, or rebalanced and has had to take it back numerous times because it never ends up right. This may be because of the parts, the workmanship, or it may be as simple as the equipment that was used to balance the driveshaft is out of calibration or incapable of detecting problems that will act up at an rpm that is higher than they can spin it to. That is why a high-speed, high-rpm balancer is the only way to do it right.

CC: With regards to a driveshaft, what does "critical speed" mean?

DD: Critical speed is the maximum rpm a driveshaft operates at without exhibiting any distortion, causing vibration that can result in failure or breakage.

CC: Does a carbon-fiber driveshaft transfer less vibration than a steel or aluminum driveshaft?

DD: Yes. Carbon fiber is a type of material that will not transmit vibrations as readily as steel.

CC: How much should the front yoke of a driveshaft engage the output shaft of the transmission?

DD: The slip yoke should be able to go into the tailshaft of the transmission so the barrel is fully inside the seal. Then, pull out the yoke 1 inch. This is the correct amount of spline contact for the slip yoke.

Denny's Driveshafts is a leader in building heavy-duty driveshafts for high-powered street cars as well as for all-out, drag-racing vehicles. We recently upgraded to a new 1310-series driveshaft that Denny's says is good for well over 500 hp.

The stock 2.75-inch-diameter driveshaft on our 1965 Mustang was generating a lot of vibration during highway cruising, which was aggravating. In addition, we had just installed a new 400-plus-horsepower small-block, so it was time to upgrade to a new, heavy-duty, 3-inch-diameter driveshaft.

With the old driveshaft removed, measure the distance between the end of the transmission tailshaft housing and the leading edge of the rearend housing yoke. Contrary to myth, do not measure the driveshaft length with the rearend at full drop. Rather, have the vehicle sitting on a level surface and resting on its own weight when taking measurements.

Measure the width of the U-joint cup on the rearend housing yoke.

Measure the U-joint width on the rearend housing yoke. If your rearend yoke has small retaining tabs, be sure to measure the width between tabs—not between the outer edges.

CC: How does the amount of rear suspension travel affect the amount of slip travel needed for the front yoke?

DD: On most cars, the slip yoke total travel will be less than ¼-inch when the vehicle is driven, regardless of road conditions. The 1 inch of travel that we build into the driveshaft is for installation purposes. You do not need one full inch to drive the car but you need at least ¾ inch to get the rear universal joint to clear the pinion yoke when installing the driveshaft. A vehicle with a flat-style pinion flange will need much less travel for installation purposes.

CC: Short of using a larger U-joint for added strength, what other key items should you consider when choosing a U-joint for performance use?

DD: For performance applications, you really do not want a universal joint with a grease fitting because the joint body will be weaker than a solid body U-joint. We only use the solid-body, non-greaseable Dana/Spicer brand on all of our driveshafts because you cannot find a stronger or better made U-joint in any other brand.

CC: Why does a rear U-joint wear out so often?

DD: This usually only occurs when a U-bolt-style pinion yoke is used. The pinion yoke is not the problem; however, the over-tightening of the U-bolt is usually the cause of the failure. You may find that when you change the damaged U-joint, that one (or both) of the caps held by the U-bolts are distorted. In general, tighten the U-bolts to about 17 lb-ft for 1310- and 1330-series U-joints while 1350-series U-joints should be tightened to 20 lb-ft.

CC: Are U-joint girdles much stronger than traditional U-bolts?

DD: Yes and no. There is absolutely nothing wrong with U-bolts. Aftermarket girdles were originally designed to replace the strap and bolt setup on some GM and Dodge pinion yokes. Some had very small bolts no larger than valve-cover bolts, and they broke easily. The girdles were helpful on those applications but are unnecessary for U-bolt yokes.

CC: Most original driveshafts were a "seam tube" design, meaning that the steel was rolled into a tube and then welded. Is this a weak link?

DD: Seam tube is very strong, but when a thin wall stock driveshaft is overpowered it will break. DOM (drawn over mandrel) tubing is a better choice for strength and DOM also provides improved balancing.

CC: Because chromoly steel is stronger than mild steel, can the wall thickness of a chromoly driveshaft be thinner to reduce weight?

DD: If you have a 3-inch OD mild steel tube driveshaft that has a 0.083-inch wall thickness, it will be the same weight as a chrome-moly tube driveshaft of the same dimension and thickness. If the chromoly driveshaft was built in a 0.065-inch wall thickness, then it will be lighter. However, the weight savings would be very small by comparison.

CC: How much lighter is an aluminum driveshaft versus a steel driveshaft?

DD: While aluminum is lighter, it has to be thicker to offer the proper amount of strength. All said, there is usually an 8- to 10-pound difference between an aluminum and steel driveshaft depending on the original driveshaft construction.

CC: On a driveshaft, how critical is U-joint phasing?

DD: Phasing is very important, and that is why we take great care to have the two U-joint phased exactly the same. The U-joints must angle at exactly the same time to reduce unwanted vibration or surging as it rotates through an angle.

CC: If a driveshaft is slightly too short, can you simply use a longer slip yoke?

DD: While it seems like an inexpensive way to lengthen a driveshaft, this type of fix should be avoided. Some transmission slip yokes are available with a longer barrel, but they were designed for a specific application and not for the purpose of extending a driveshaft. Using a longer yoke on a driveshaft that is too short can lead to vibration and output shaft bushing failure. In extreme cases, the internal spline can twist, which will bind up the slip movement of the yoke.

CC: When putting an automatic transmission in Reverse, sometimes a loud clang sounds like its coming from the driveshaft. Does this indicate that the U-joints are about to fail?

DD: The noise is transmitted by the driveshaft, but the driveshaft likely isn't the cause of the noise. If the U-joint is truly bad, it will make this noise, but if it is in good shape, the noise is likely a result of improper rearend backlash, worn differential side gears, or loose rearend bearings.

Measure the diameter of the output shaft on the transmission. In addition, count the number of splines on the output shaft.

Measure the distance that the transmission output shaft extends past the end of the tailshaft housing.

Measure the outer diameter of the driveshaft yoke.

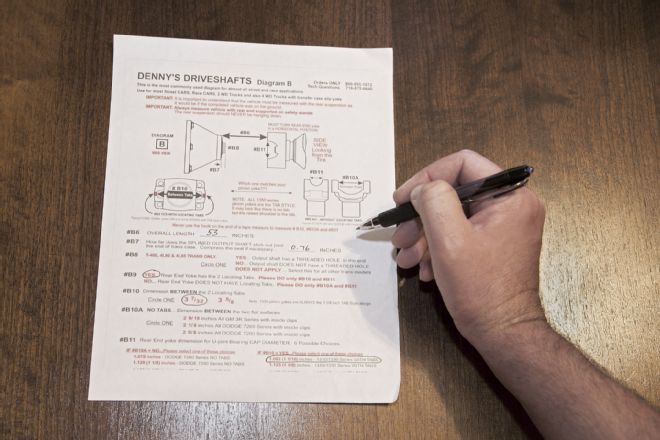

On a form available for download from Denny's Driveshaft, note all the measurements taken. Then, send Denny the form and he will build a heavy-duty driveshaft specifically tailored for your vehicle.

In goes the new heavy-duty driveshaft from Denny's Driveshaft. The driveshaft installed without issue, and once on the road we were thrilled to learn that the previous vibration issues were gone.