Like a lot of race shops located in industrial sections of Southern California, Don Ferguson’s place is nondescript to the point of camouflage. No signage, not even a number on the front door. Heck, not even a front door, really. Just a tall gray wall with a rolling bay door that blends so perfectly you may not even know it is a door until Don sticks his head out.

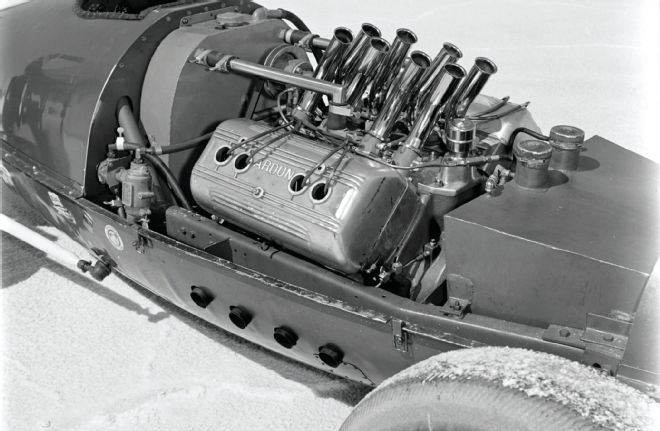

Behind that door are bays, shelves, and rafters chock-full of streamliners and other cars under construction, customer engines on stands, the Ferguson’s lakester under a car cover, bare engine blocks wrapped in plastic, a Superflow engine dyno waiting for its next tune session. Standing out among the parts and projects is a flathead engine on a rolling cradle, fitted with Ardun cylinder heads and a S.Co.T. supercharger. Turns out that’s the third of three such engine combos owned by Scott Gillen, whose gray Deuce is this issue’s cover car.

There was a time when Ardun overhead-valve cylinder heads were incredibly rare. The originals still are. But thanks to the efforts of several hot rodders and land speed racers, especially Don, the coveted conversion kits are readily available and much improved over those first heads built in the ’40s and ’50s.

Before we get to the tech, some history: Ardun is a contraction of Arkus-Duntov, a name well known among the Chevy faithful, especially Corvette owners. Before he joined General Motors, Zora Arkus-Duntov, with his brother Yura, operated Ardun Mechanical Corporation in New York. In 1947, they were commissioned by Ford to improve the output of its truck engines. The brothers, working with designer George Kudasch, greatly enhanced the breathing and combustion efficiency of the flathead by developing an overhead-valve cylinder head with hemispherical combustion chambers.

Not many of the heads were made—best guesstimates put the number at 200 to 250 sets, with another dozen or so made for the smaller V-8/60 engines—and a few more were built in England during a short association Duntov had with Sydney Allard and his J2 sports car. But it didn’t take long for the hot rodding community to learn about these conversion kits and how well they hopped up the flattie. Those few Ardun heads that did trickle down were found at the lakes, on the salt, and at dragstrips, running on various types of fuel, setting records, and winning races.

Don Clark and Clem Tebow of C&T Automotive put an Ardun flathead in their ’32 roadster and averaged more than 162 mph on the salt in 1951. They, in fact, did more than just convert their flathead; they got into the heads themselves, fixing several problems with the original design and making the Ardun an even more potent performer.

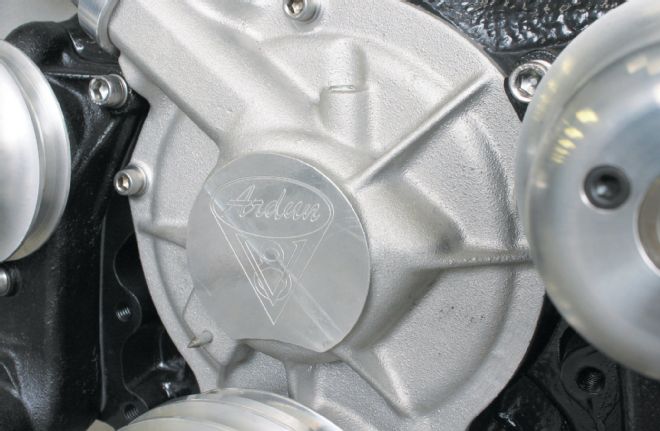

Other accessories Ardun Enterprises offers to complement the heads include this fluted breather tube and a cover/mount for the magneto.

Other accessories Ardun Enterprises offers to complement the heads include this fluted breather tube and a cover/mount for the magneto.

Timing, as they say, is everything. The C&T Ardun was really coming into its own right about the time that the flatheads were being overtaken by the growing number of overhead-valve engines coming from the OEs. The flathead faithful were still out there, as were the Ardun heads, but the heads became even scarcer.

Fast-forward nearly half a decade. Don Orosco is a hot rodder and vintage racer whose restoration business (now known as Monterey Speed and Sport) was responsible for the rebirth of several significant and historic hot rods, including the Dick Flint roadster and the So-Cal “Triple Threat” coupe. In the mid ’90s, Orosco took on the task of reproducing the Ardun heads, improving on their design yet making sure they were visually exact duplicates of the originals. Orosco had 30 sets made, sold all but two (one set is on the So-Cal coupe), and realized the undertaking was more than he wanted to continue.

Enter the Ferguson family. Don Jr. was the man showing us around the shop; his father was a longtime land-speed racer in whose arsenal were Ardun-equipped motors. Those streamliners we mentioned earlier in the story are among the Ferguson’s current stable of salt-assault vehicles. (The Fergusons represent three generations of speed. Don Sr. has passed away, but at the shop with us was Don Jr.’s son Don III.)

Orosco approached the Fergusons about taking on the Ardun reproductions. Don was interested, but his approach would be different from Orosco’s. While Orosco wanted the heads to be as exact a replica as possible—“He would be at the foundry getting the shade of the aluminum in the valve covers just right,” Don says—Ferguson was less interested in the cosmetics and more concerned with re-engineering the heads for maximum performance. He wasn’t about to change the iconic Ardun look, and he wanted to ensure his parts would fit the old flat motors, but he saw an opportunity to revamp the workings inside those bulbous covers.

Pull off the iconic valve covers and here’s what you see: beefy aluminum rocker arms on polished shafts, lubricated by an internal oiling system. Arms (and pushrods) are adjustable to accommodate a variety of lift specs.

Pull off the iconic valve covers and here’s what you see: beefy aluminum rocker arms on polished shafts, lubricated by an internal oiling system. Arms (and pushrods) are adjustable to accommodate a variety of lift specs.

Pull off said cover and the biggest difference you see is the change in the rocker arms. Arms in a gennie Ardun head look downright delicate compared to the beefy 2024 aluminum arms in Don’s Ardun. Ratios are 1.375 on the intake side, 1.2 on the exhaust. “You can grind the cam to get the lift and duration you want,” Don says. He works with a couple different cam grinders and will help spec the stick to deliver the power—or the lope—desired.

The arms have an internal oiling system that Don has set up with stainless lines, a compact banjo fitting on the edge of the head, and a drainback plug plumbed to a finned oil pan of Don’s design. All tidier and more efficient than original.

Valves are 1.875 inches in diameter on the intake side, 1.5 on the exhaust. All have 11⁄32-inch valve stems and get a three-angle cut to improve flow. Don has also raised the floor of the intake and exhaust ports to better move the air.

Joining the blower with the heads is an Ardun Enterprises reproduction of the S.Co.T. intake manifold.

Joining the blower with the heads is an Ardun Enterprises reproduction of the S.Co.T. intake manifold.

No detail has escaped Don’s attention. Lifters look nearly identical to the originals, except his are made from solid chilled iron. He offers spark plug tubes in two diameters: a reproduction of the originals, which will fit the original plugs, and a new style, narrower tube that accepts contemporary plugs and offers a little more room to clear the rockers, should you want to get more radical with the lift. The heads and valve covers are made from 356 T6 aluminum, far superior to the alloy used back in the day. And Don has rimmed the valve cover with an O-ring for leak-free sealing.

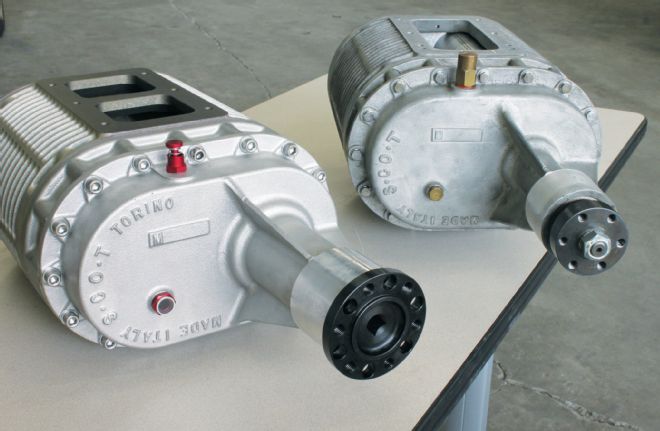

Since taking on the cylinder heads, Don’s fabrication business has grown to encompass much more than just the Ardun conversions. He is now replicating S.Co.T. superchargers, which, like the heads, look period-correct but are filled with contemporary tech, in this case 4-71 helical-cut rotors. He has even made some aluminum flathead blocks, with massive main caps and deep, sturdy skirts, for those interested in making ultimate flathead power.

Compare the reproduction S.Co.T. supercharger on the left with the original on the right. As with the heads, Don retained the look of the component while improving its guts, here filling the case with helical-cut 4-71 rotors.

Compare the reproduction S.Co.T. supercharger on the left with the original on the right. As with the heads, Don retained the look of the component while improving its guts, here filling the case with helical-cut 4-71 rotors.

But, he says, most of his Ardun-related business is for hot rodders, not racers. “These engines look cool, run cool, and are reliable,” he says. The conversion kits are not inexpensive; pricing starts at just below $14,000. For that, you’re getting cylinder heads with a ton of development work and premium-quality pieces. “Look, if you’re going to spend upwards of $30,000 on a motor, why wouldn’t you get the best components?” Don asks.

What kind of power are these Arduns putting out? Well, what kind of motor do you want? He showed us dyno sheets of full-race engines making north of 800 hp on alcohol. The street motors, on the other hand, typically put out “about 1 horsepower per cubic inch, unblown,” he says. The blown motors make another 50 hp at an easy-to-live-with 5 pounds of boost. “I can make whatever you want, but 350 horsepower in a hot rod will smoke the tires all day long.”

“Flat-Heads Battle Rocker-Arms for All-Out Supremacy” blared the Nov. ’53 HOT ROD. The times they were a-changin’, and change was happening fast. “This year’s Nationals saw the mass use of overhead valves,” said the magazine. “Of 17 new records established at this meet, 12 of them were set with overhead valve engines.” Bridging the gap was a couple of Ardun conversions of note.

The Chrisman brothers competition coupe—so handsome it warranted its own “Fantastic Coupe” feature in the magazine as well as a Rex Burnett cutaway drawing—used an innovative rear engine-mount cradle that could be uncoupled from the chassis to speed repairs or swaps. The Chrisman coupe ran three engines at Bonneville that year, but only one, Harry Duncan’s 258-inch Ardun-Mercury, held together with any success. With that motor, the Chrismans won the B Comp Coupe class and set a new class record of 160.178 mph.

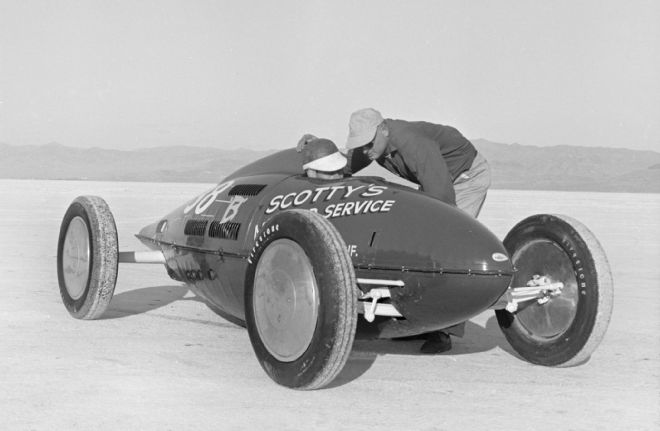

The Scotty’s Muffler Service tanker: 201.015 mph powered by an injected Ardun flathead.

The Scotty’s Muffler Service tanker: 201.015 mph powered by an injected Ardun flathead.

The Chrisman competition coupe: 160.178 mph using Ardun heads on a Merc flathead.

The Chrisman competition coupe: 160.178 mph using Ardun heads on a Merc flathead.

Charles Scott was also running an Ardun at the meet, a Hilborn-injected flathead nestled in the back of his Scotty’s Muffler Service belly tanker. Scott’s car, too, won its class and set a new B Lakester record of 201.015 mph with LeRoy Holmes at the wheel, becoming the first open-wheeled car to reach 200 mph.