When it comes to big power in a compact and lightweight package, there is nothing more tempting than building an engine starting with a top-shelf aluminum block. If there is any drawback, the cost factor can put such ambitions on the sidelines. For Ford Windsor fans, the Z351 block from Ford Racing has dramatically improved the situation, with fresh aluminum blocks at the mid-$3,000 price bracket. While not exactly budget in comparison to yanking a 9.5-deck iron Windsor from an old pickup truck, this puts building an all-aluminum Windsor within the realm of serious consideration for many enthusiasts. Now, you can bet we are not going to fool around with a fat aluminum block Windsor to build a 400hp street cruiser. No, step up to this level of the game and you will want to fill the block with parts for big power.

The target for this engine is to crest the 700hp mark, and to get there we will need serious displacement, rpm, and power parts. Most of all, those internal components are going to have to be pieces that are proven in the areas of strength and durability. You simply do not cut corners when talking about a high-rpm stroker engine and looking to make big power reliably.

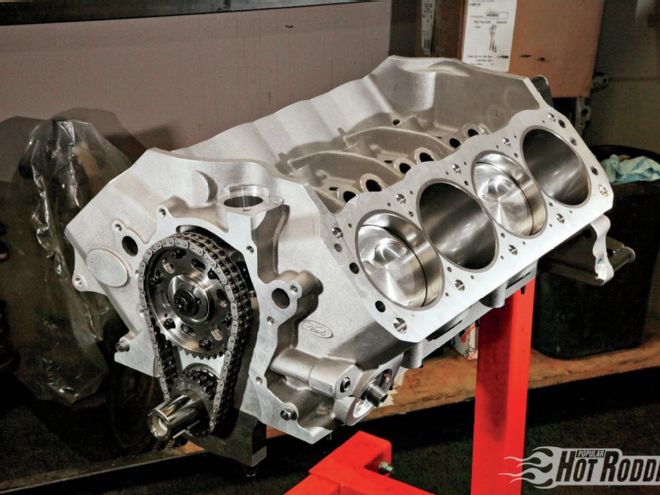

The foundation for our build is the Ford Racing Z351 block, detailed in the Oct. ’13 issue of PHR, and prepared to a final bore size of 4.125-inch. Featuring light weight and strength, it is ideal when cornering ability is as important as all-out power. The Ford Cleveland-sized 2.75-inch mains receive Clevite MS1010HX bearings in preparation for the crank installation.

The foundation for our build is the Ford Racing Z351 block, detailed in the Oct. ’13 issue of PHR, and prepared to a final bore size of 4.125-inch. Featuring light weight and strength, it is ideal when cornering ability is as important as all-out power. The Ford Cleveland-sized 2.75-inch mains receive Clevite MS1010HX bearings in preparation for the crank installation.

Our block was finish machined to a bore size of 4.125 inches, and delivered to Outlaw Motorsports in Riverside, California, for assembly by Ron Aschtgen. To take the displacement to the upper limits we turned to Eagle for an ESP Armor treated forged steel crankshaft with 4.250 inches of stroke. This bore and stroke combination conspires to deliver a displacement of 454 ci. The big Eagle crank really makes use of the real estate provided by the Ford Racing block. (See "Revenge of the Windsor! Part 1," Oct. 2013.) Such a long arm will greatly increase the high-rpm stresses on the bottom end, but the bulletproof main structure of the Z351 block is designed to take the punishment.

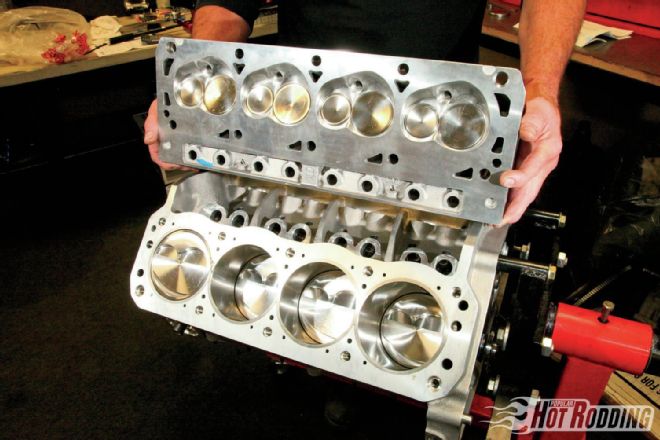

Filling the cylinders in such an application will also require the good stuff. We turned to JE for a set of custom pistons designed for the task. These forged slugs are designed for a shorter piston pin, which are made of tapered tool steel for reduced reciprocating weight. The pistons include custom skirt lightening to reduce a few more precious grams, and a friction-reducing dry film coating where they meet the bore. To hit a targeted compression ratio of 11:1, a very short dome was added, matching the chamber shape of the TFS high-port 240 CNC cylinder heads. The moderate compression ratio was a requirement to ensure the big Ford’s appetite will be satisfied with a diet of straight pump gas. JE also supplied the rings in a low-friction .043/.043/3mm arrangement, adding to the power potential. Linking the pistons to the crank are Eagle 6.300-inch H-beam rods, fortified with premium L19 fasteners, and like the crankshaft, feature Eagle’s ESP Armor surface treatment.

With the rotating assembly components handled, the next major part of this puzzle was the camshaft. For advice here we turned to Judson Massingill of the School of Automotive Machinists, one of the top competitors at the annual AMSOIL Engine Masters Challenge. We knew we wanted the high-rpm capabilities of a solid roller, and Massingill worked with the technical crew at COMP Cams to come up with the profile. With specifications of 268/280 degrees duration (at .050-inch lift) on a 112-degree lobe separation, and .768/.748-inch lift through 1.7:1 rockers, this is no small ’shaft!

Our internally balanced, forged 4340 crankshaft from Eagle (PN Z435242506300) features Eagle’s proprietary ESP Armor surface treatment, while the stroke of 4.25 inches adds a giant boost to displacement. Combined with the 4.125-inch bore block, our Windsor carries big-block displacement at 454 ci contained in a light and compact small-block package.

Our internally balanced, forged 4340 crankshaft from Eagle (PN Z435242506300) features Eagle’s proprietary ESP Armor surface treatment, while the stroke of 4.25 inches adds a giant boost to displacement. Combined with the 4.125-inch bore block, our Windsor carries big-block displacement at 454 ci contained in a light and compact small-block package.

Massingill explained: "We knew that with the large displacement the cylinder head, even at a 240cc intake port volume, would seem small, especially at the top end. Given the long stroke and high piston speed, the power was going to be very good through the midrange, even with relatively long duration. The intake lobe in the high 260-degree range was not going to hurt the lower end of the curve, but will add to the top. With more compression, the combination could handle even more intake lobe. The long exhaust timing and relatively wide lobe separation, likewise, will help the engine make power and carry longer past peak torque. We did not go with super-aggressive lobe profiles, looking to enhance valvetrain stability and reliability for this application."

Given that the short-block is comprised entirely of aftermarket parts, we were pleasantly surprised to find the assembly to be free of any unforeseen hang-ups. We followed along as Aschtgen pulled out the wrenches and had the bottom end for this Windsor warrior assembled in time to pack up and call it an early day. With the potential built into our big-inch Ford, we expect it will deliver the power to send our competition packing when it hits the track.

More Video Online!

Watch the step-by-step buildup of our 454ci Windsor at Outlaw Motorsports in a 22-minute video on our YouTube channel! Log on to www.YouTube.com/PopularHotRodding, and check out the video "454ci Windsor Short-Block Buildup." Want a sneak peek of next month’s top end assembly and dyno test? Check out the video "454 Windsor Induction Assembly and Dyno Test."

When preparing the internals for a short-block assembly, it is important to have a clear, clean, and well organized work area. First, the rods are assembled to the pistons, noting the orientation of the rod to the crank, and the pistons to the valve position of each bore. The JE rings were already file-fit to specifications of .024-inch top and .026-inch second using a ProForm ring filer.

When preparing the internals for a short-block assembly, it is important to have a clear, clean, and well organized work area. First, the rods are assembled to the pistons, noting the orientation of the rod to the crank, and the pistons to the valve position of each bore. The JE rings were already file-fit to specifications of .024-inch top and .026-inch second using a ProForm ring filer.

The JE pistons are custom units with a small .020-inch domed crown specifically matched to the engine’s Trick Flow cylinder heads. The assembly here features a lightweight tapered tool steel pin, Eagle’s premium 6.300-inch H-beam rods with ESP Armor (PN CRS6300B3DL19), premium L19 fasteners, and Clevite CB663 HN-series bearings.

The JE pistons are custom units with a small .020-inch domed crown specifically matched to the engine’s Trick Flow cylinder heads. The assembly here features a lightweight tapered tool steel pin, Eagle’s premium 6.300-inch H-beam rods with ESP Armor (PN CRS6300B3DL19), premium L19 fasteners, and Clevite CB663 HN-series bearings.

Torque specification will vary depending upon the lubricant used. These high-strength L19 bolts from ARP are torqued to 79 ft-lb using ARP’s moly fastener lube. Aschtgen inserts a feeler gauge between each pair of rods to eliminate the side play during the torquing process.

Torque specification will vary depending upon the lubricant used. These high-strength L19 bolts from ARP are torqued to 79 ft-lb using ARP’s moly fastener lube. Aschtgen inserts a feeler gauge between each pair of rods to eliminate the side play during the torquing process.

A tapered ring compressor specific to the bore size is the best way to install a piston, minimizing the potential to hang and damage a ring in the process. Aschtgen lightly oils the skirt, rings, and bore, and pushes each piston in its assigned hole.

A tapered ring compressor specific to the bore size is the best way to install a piston, minimizing the potential to hang and damage a ring in the process. Aschtgen lightly oils the skirt, rings, and bore, and pushes each piston in its assigned hole.

A racy COMP solid-roller cam was selected to make good on the high-lift flow of the TFS cylinder heads, as well as the high-rpm capabilities of the bottom-end components. Duration measures a healthy 268/280 degrees at .050 inch, while .768/.748 inch of lift is generated with 1.7:1 ratio rockers. The cam is ground on a lobe separation angle of 112 degrees.

A racy COMP solid-roller cam was selected to make good on the high-lift flow of the TFS cylinder heads, as well as the high-rpm capabilities of the bottom-end components. Duration measures a healthy 268/280 degrees at .050 inch, while .768/.748 inch of lift is generated with 1.7:1 ratio rockers. The cam is ground on a lobe separation angle of 112 degrees.

COMP Cams’ number 8138 adjustable timing set features an inner hub that bolts to the cam, and a separate drive gear. This allows infinite cam timing adjustment over a range of 20 degrees, and the ability to alter the cam timing without removing the gears.

COMP Cams’ number 8138 adjustable timing set features an inner hub that bolts to the cam, and a separate drive gear. This allows infinite cam timing adjustment over a range of 20 degrees, and the ability to alter the cam timing without removing the gears.

Any high-performance engine should have the cam precisely degreed-in, ensuring the valve events are timed as intended. With the COMP adjustable drive, Aschtgen simply slacked the cam gear fasteners and dialed the cam timing to an installed centerline of 108 degrees.

Any high-performance engine should have the cam precisely degreed-in, ensuring the valve events are timed as intended. With the COMP adjustable drive, Aschtgen simply slacked the cam gear fasteners and dialed the cam timing to an installed centerline of 108 degrees.

The small dome, big displacement, and compact combustion chambers of the Trick Flow cylinder heads add up to a compression ratio of 11:1. (We’ll have a lot more on these killer flowing heads in our next installment.) That compression will ensure that the engine will live happily with pump gas, while the big cubes, ample airflow, and the generous cam timing are in place for serious output.

The small dome, big displacement, and compact combustion chambers of the Trick Flow cylinder heads add up to a compression ratio of 11:1. (We’ll have a lot more on these killer flowing heads in our next installment.) That compression will ensure that the engine will live happily with pump gas, while the big cubes, ample airflow, and the generous cam timing are in place for serious output.