How To Install Nitrous Nozzles - Hot Rod Magazine

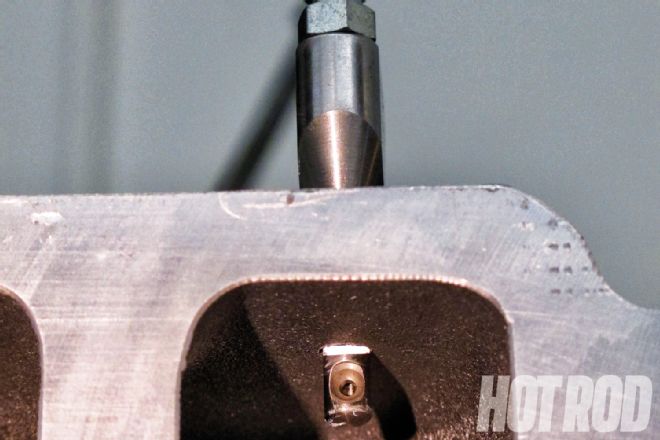

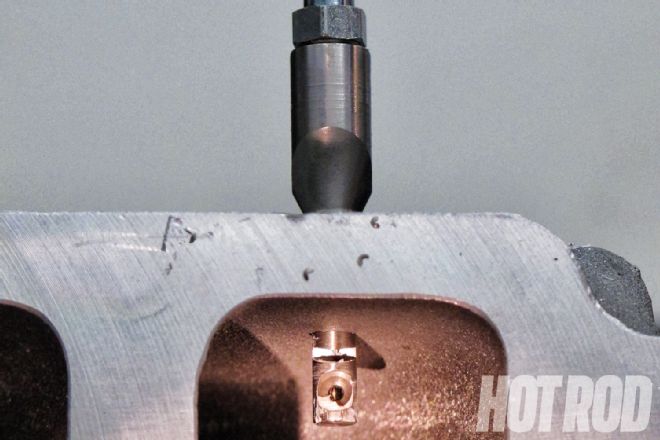

01. Most nitrous nozzles use 1⁄16-inch NPT tapered fittings. Drilling the pilot holes for these is the riskiest part of the install. Find the center of each intake runner and punch it. If you’re using 90-degree nozzles (like we did), drill the intake 90 degrees to the runner using a 0.242-inch (or letter “C”) drill bit. Common annular-style nozzles require the holes to be drilled in the runner at a 30-degree angle.

02. Be sure to lubricate the 1⁄16-NPT tap with light oil and work slowly as the aluminum can gall and snap the small tap.

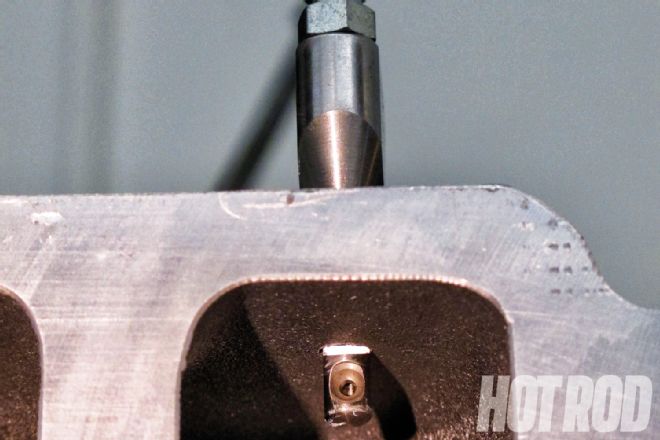

03. Install the nozzles after coating the threads with Teflon paste. Wipe the excess paste from nozzle and runner wall.

04. Thread the nozzle until both the fuel and nitrous ports clear the runner wall. This nozzle isn’t threaded in far enough.

05. This is more like it.

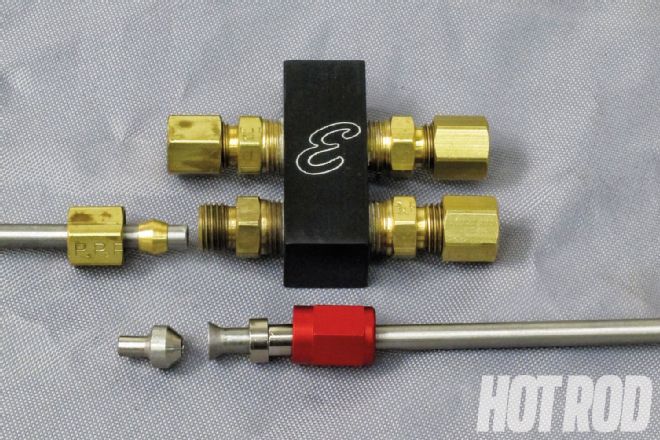

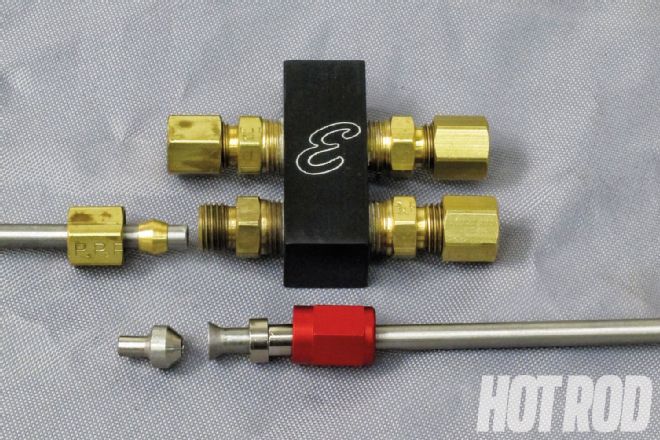

06. Most direct-port systems, like this one from Edelbrock, include stainless steel hard lines that are already flared on the nozzle end to make assembling the system easier. An inexpensive tubing bender makes quick work of forming the lines.

07. The opposite end connects to a distribution manifold using a nut and collet assembly.

08. Chris Starkweather of B1 Racing makes it look easy. The tubing supports the solenoids, and the entire system fits beneath a drop-base air cleaner and clears the throttle linkage on a Victor Jr. intake manifold.

01. Most nitrous nozzles use 1⁄16-inch NPT tapered fittings. Drilling the pilot holes for these is the riskiest part of the install. Find the center of each intake runner and punch it. If you’re using 90-degree nozzles (like we did), drill the intake 90 degrees to the runner using a 0.242-inch (or letter “C”) drill bit. Common annular-style nozzles require the holes to be drilled in the runner at a 30-degree angle.

01. Most nitrous nozzles use 1⁄16-inch NPT tapered fittings. Drilling the pilot holes for these is the riskiest part of the install. Find the center of each intake runner and punch it. If you’re using 90-degree nozzles (like we did), drill the intake 90 degrees to the runner using a 0.242-inch (or letter “C”) drill bit. Common annular-style nozzles require the holes to be drilled in the runner at a 30-degree angle.

02. Be sure to lubricate the 1⁄16-NPT tap with light oil and work slowly as the aluminum can gall and snap the small tap.

02. Be sure to lubricate the 1⁄16-NPT tap with light oil and work slowly as the aluminum can gall and snap the small tap.

03. Install the nozzles after coating the threads with Teflon paste. Wipe the excess paste from nozzle and runner wall.

03. Install the nozzles after coating the threads with Teflon paste. Wipe the excess paste from nozzle and runner wall.

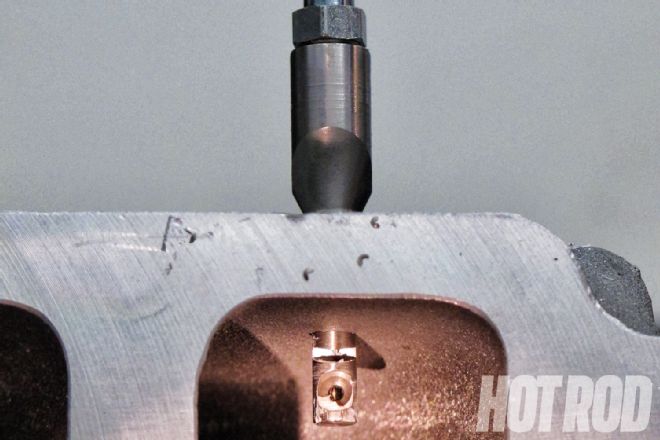

04. Thread the nozzle until both the fuel and nitrous ports clear the runner wall. This nozzle isn’t threaded in far enough.

04. Thread the nozzle until both the fuel and nitrous ports clear the runner wall. This nozzle isn’t threaded in far enough.

05. This is more like it.

05. This is more like it.

06. Most direct-port systems, like this one from Edelbrock, include stainless steel hard lines that are already flared on the nozzle end to make assembling the system easier. An inexpensive tubing bender makes quick work of forming the lines.

06. Most direct-port systems, like this one from Edelbrock, include stainless steel hard lines that are already flared on the nozzle end to make assembling the system easier. An inexpensive tubing bender makes quick work of forming the lines.

07. The opposite end connects to a distribution manifold using a nut and collet assembly.

07. The opposite end connects to a distribution manifold using a nut and collet assembly.

08. Chris Starkweather of B1 Racing makes it look easy. The tubing supports the solenoids, and the entire system fits beneath a drop-base air cleaner and clears the throttle linkage on a Victor Jr. intake manifold.

08. Chris Starkweather of B1 Racing makes it look easy. The tubing supports the solenoids, and the entire system fits beneath a drop-base air cleaner and clears the throttle linkage on a Victor Jr. intake manifold.