John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

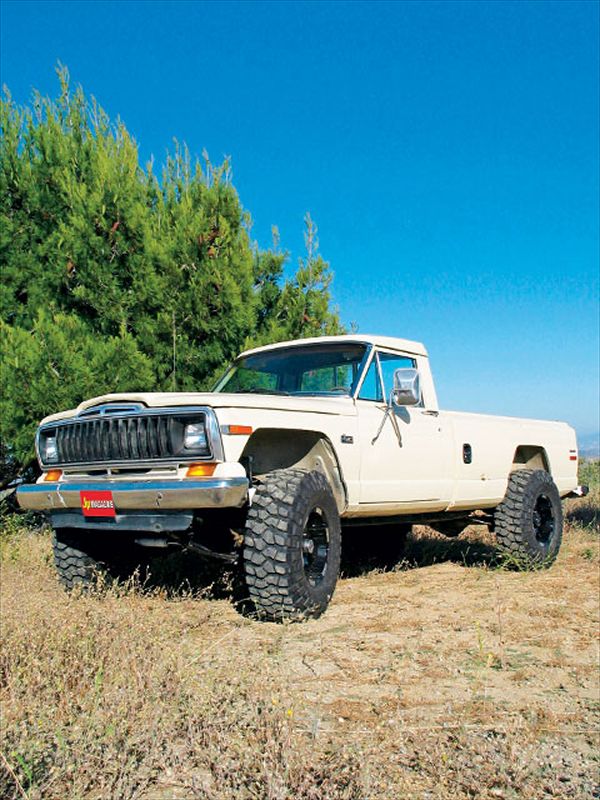

We weighed our options of keeping the stock, boring, brick-stiff suspension and getting a cement spine implant or installing Softride leaf springs, which would lift our J-20 4 inches to fit 37-inch tires. Guess which option we took? Last issue we showed you the installation and tricks for the front of the Jeep. This month we'll show you some tips out back along with our tire fitment solutions all around.

PhotosView Slideshow

PhotosView Slideshow