If you had a chance to see last month’s issue of STREET RODDER, you would have seen Part 1 of the story of how Walden Speed Shop in Pomona, California, was in the process of scratchbuilding a chassis and steel coupe body (with styling cues from both a 1932 and 1933 Ford) for Fred Warren.

Part 1 covered the chassis and the initial build, including how the firewall, quarter-panels, roof insert, and most of the rest of the body was formed by the team at Walden (Walden, Wesley Kent, Blake Tomlinson, and Matt Bryant) out of a stack of 4x8 sheets of cold-rolled steel.

In Part 2 we’ll examine the integral rollcage incorporated into the body, how the doors were made, and see the car in its final metal state. After Walden finished the body, Warren brought it back to his home in Ohio and prepped it for the 2013 Detroit Autorama, where it was on display (still in metal) next to his Ridler-winning coupe as part of the 50th anniversary of the Don Ridler Memorial Award at the show.

1| Here’s where we left off last month, with the car sitting on the ground for the first time after being built. It’s fairly complete, but there is still a lot to make.

1| Here’s where we left off last month, with the car sitting on the ground for the first time after being built. It’s fairly complete, but there is still a lot to make.

2| Next on the agenda was to make the inner structure out of tubing, which necessitated the removal of the drivetrain.

2| Next on the agenda was to make the inner structure out of tubing, which necessitated the removal of the drivetrain.

3| Made from 1.25-inch, 0.120-wall DOM tubing and bent on a hydraulic tubing bender, this inner structure was put in place to provide structural rigidity and added safety.

3| Made from 1.25-inch, 0.120-wall DOM tubing and bent on a hydraulic tubing bender, this inner structure was put in place to provide structural rigidity and added safety.

3|

3|

3|

3|

4| More bracing was added with the fabbing of the inner decklid panel, which also had several lightening holes added, too.

4| More bracing was added with the fabbing of the inner decklid panel, which also had several lightening holes added, too.

5| Similar to the way Ferrari doors and decklids were made in the ’50s, an inner tubing structure was formed for Warren’s decklid, to which an out flange (about 3 inches wide) was added. After the decklid’s skin is rolled out, the edge of the skin will fold over the outside edge of the flange, securing it in place. The inner structure will remain as well.

5| Similar to the way Ferrari doors and decklids were made in the ’50s, an inner tubing structure was formed for Warren’s decklid, to which an out flange (about 3 inches wide) was added. After the decklid’s skin is rolled out, the edge of the skin will fold over the outside edge of the flange, securing it in place. The inner structure will remain as well.

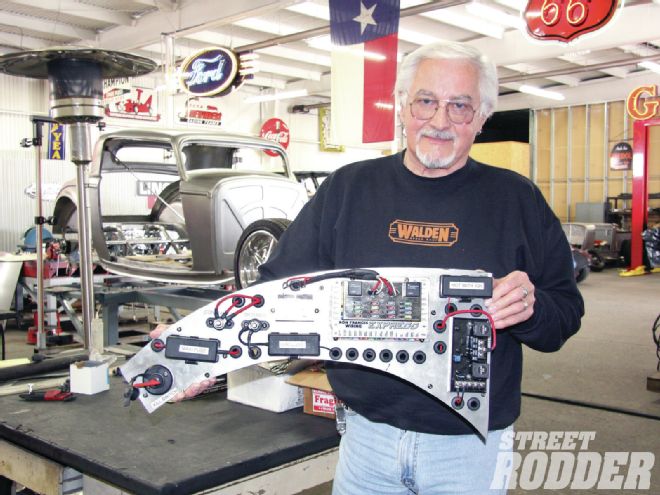

6| Warren likes doing electrical, and he made up several phenolic (non-conductive) panels to hold the necessary components, such as the Express wiring box from Ron Francis, fuses, kill switch, and so on. This one will fit inside the driver’s quarter-panel.

6| Warren likes doing electrical, and he made up several phenolic (non-conductive) panels to hold the necessary components, such as the Express wiring box from Ron Francis, fuses, kill switch, and so on. This one will fit inside the driver’s quarter-panel.

7| Even the floor is thing of beauty! The notch in the floor above the centersection of rearend is where the Vintage Air A/C system will fit.

7| Even the floor is thing of beauty! The notch in the floor above the centersection of rearend is where the Vintage Air A/C system will fit.

8| The detail in the trans tunnel was made the same way the firewall was done—on the Pullmax with forming dies and wooden bucks.

8| The detail in the trans tunnel was made the same way the firewall was done—on the Pullmax with forming dies and wooden bucks.

9| Countersunk bolts hold the floor to the chassis after the tunnel has been spot-welded in place.

9| Countersunk bolts hold the floor to the chassis after the tunnel has been spot-welded in place.

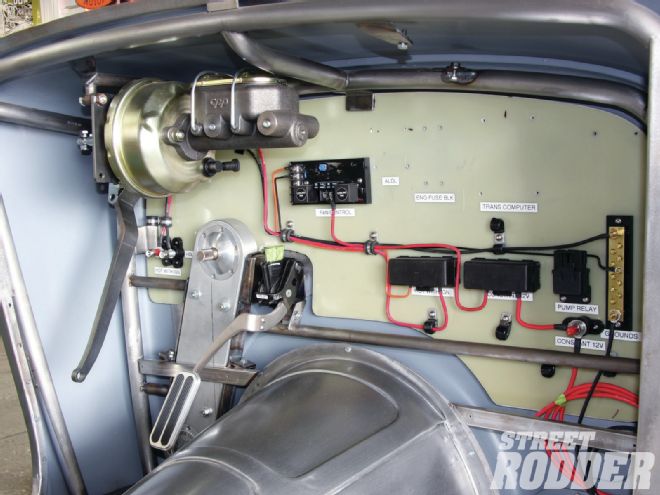

10| Another of Warren’s non-conductive electrical boards is found under the cowl, plus you can see where the Wizard steering drop and 90-degree master cylinder booster from Kugel Komonents are mounted.

10| Another of Warren’s non-conductive electrical boards is found under the cowl, plus you can see where the Wizard steering drop and 90-degree master cylinder booster from Kugel Komonents are mounted.

Warren does plan to paint it, but he’s still deciding on colors, so in the meantime he’ll be content in driving the car (probably for a year or so) in metal and work out any bugs it might have before blowing it apart for paint. STREET RODDER will let you know when it’s finished, as it should be just as impressive in paint as it is in metal.

11| Walden designed the door to hang on two hinges instead of three, but reinforced the lower hinge to eliminate any flex from when the door is open.

11| Walden designed the door to hang on two hinges instead of three, but reinforced the lower hinge to eliminate any flex from when the door is open.

12| Walden built everything you see here, including the inner structure, to which a ’32 Ford three-window regulator (from Vintique) was attached. With four turns of the window crank the glass is either up or down.

12| Walden built everything you see here, including the inner structure, to which a ’32 Ford three-window regulator (from Vintique) was attached. With four turns of the window crank the glass is either up or down.

12|

12|

13| The coupe is also getting a set of these Walden X-braces (for added safety and rigidity), which Walden also sells to other builders.

13| The coupe is also getting a set of these Walden X-braces (for added safety and rigidity), which Walden also sells to other builders.

14| This bulkhead separates the seating area from the trunk, and the “V” in the panel is the return for the A/C system. Dynamat was used throughout the car’s interior, too.

14| This bulkhead separates the seating area from the trunk, and the “V” in the panel is the return for the A/C system. Dynamat was used throughout the car’s interior, too.

15| Flooring made from Baltic Birch plywood was carved with passages so the car’s electrical lines could run through them.

15| Flooring made from Baltic Birch plywood was carved with passages so the car’s electrical lines could run through them.

16| The dash is from Brookville, but the height was shortened and the reveal along the bottom edge was reshaped.

16| The dash is from Brookville, but the height was shortened and the reveal along the bottom edge was reshaped.

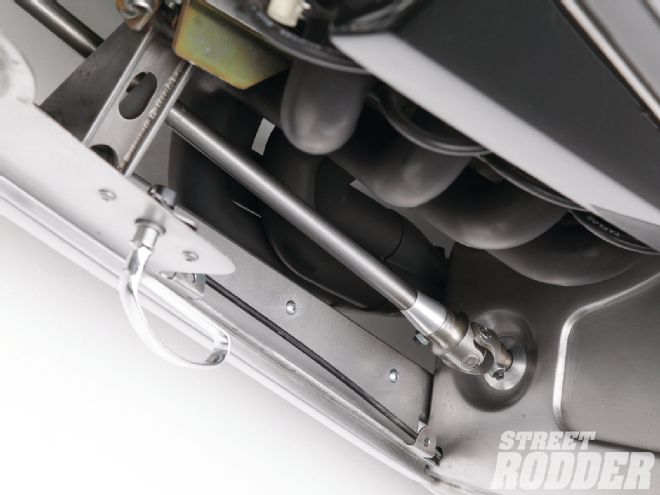

17| The lower output of the Wizard steering includes a one-off aluminum sleeve from Walden’s to hide the shaft’s splines. Bobby Walden fabbed the car’s headers, too.

17| The lower output of the Wizard steering includes a one-off aluminum sleeve from Walden’s to hide the shaft’s splines. Bobby Walden fabbed the car’s headers, too.

18| Another neat item on the coupe is the rear nerf bar, which tucks in close and flows in the same shape as the rear apron, giving the appearance of a roll pan.

18| Another neat item on the coupe is the rear nerf bar, which tucks in close and flows in the same shape as the rear apron, giving the appearance of a roll pan.

19| Walden ordered an oversize piece of metal stamped with ’33 Ford louvers from Rootlieb, then cut and shaped them to fit Warren’s car. Check out the cool blister made for the upper control arm.

19| Walden ordered an oversize piece of metal stamped with ’33 Ford louvers from Rootlieb, then cut and shaped them to fit Warren’s car. Check out the cool blister made for the upper control arm.

20| The tubular structure under the decklid will remain exposed even after the car is painted. Walden made a wooden buck to create the shape for the fuel cell, which is made out of stainless steel.

20| The tubular structure under the decklid will remain exposed even after the car is painted. Walden made a wooden buck to create the shape for the fuel cell, which is made out of stainless steel.

21| Warren’s coupe is a combination of both ’32 and ’33 Ford styling cues, and Walden Speed Shop was able to expertly blend the two looks together into one impressive design.

21| Warren’s coupe is a combination of both ’32 and ’33 Ford styling cues, and Walden Speed Shop was able to expertly blend the two looks together into one impressive design.

22| Walden narrowed the ’64 Thunderbird seats to create the special seating in the coupe. All of the car’s garnish moldings were made at Walden as well.

22| Walden narrowed the ’64 Thunderbird seats to create the special seating in the coupe. All of the car’s garnish moldings were made at Walden as well.

22| The steering column came from ididit, and the gauges are through Classic Instruments.

22| The steering column came from ididit, and the gauges are through Classic Instruments.

23| It’s high tech (big-inch billet wheels, IFS/IRS, an LS3 under the hood), but also traditional in many ways (hood louvers, exposed hinges, and door handles). Some say it would be a shame to paint it, but gloss might just be the cherry on the sundae—we’ll have to wait and see how it turns out!

23| It’s high tech (big-inch billet wheels, IFS/IRS, an LS3 under the hood), but also traditional in many ways (hood louvers, exposed hinges, and door handles). Some say it would be a shame to paint it, but gloss might just be the cherry on the sundae—we’ll have to wait and see how it turns out!