Total Cost Involved Engineering recently introduced their new coil spring independent front suspension with a long list of improvements over previous designs. Included is a new standard or power rack-and-pinion steering gear and a lifetime warranty on all TCI Engineering–manufactured parts.

Total Cost Involved Engineering recently introduced their new coil spring independent front suspension with a long list of improvements over previous designs. Included is a new standard or power rack-and-pinion steering gear and a lifetime warranty on all TCI Engineering–manufactured parts.

With the initial growth of our hobby came an entirely new industry offering products that made street rods easier to build, more comfortable to drive, and safer, too. When Ed Moss, founder of Total Cost Involved Engineering, introduced a reproduction Model A frame in 1974 it was not only revolutionary, it was the beginning of a long line of quality chassis parts.

Unquestionably one of the most popular suspension components to appear on the street rod scene was the Pinto/Mustang II front suspension kit. When they were first introduced, many in the hobby were skeptical. How could a suspension from a subcompact car be up to the rigors of street rod use? It didn't take long for that question to be answered. The Ford frontend had stout spindles with wheel bearings that were larger than the Nova clips that were being installed at the time. Even with the demise of the Pinto, Mustang II components were readily available, installation kits were affordable, and the rack-and-pinion steering simplified installations. Most importantly it was an independent front suspension system that worked extremely well.

Like most items that have come to the street rod market, a variety of improvements were made in Mustang II IFS kits over the years. Larger disc brakes became available, tubular upper A-arms and full lower A-frame kits that eliminated the strut rods (and the problems associated with their frame brackets cracking and breaking off when improperly welded) were introduced. Then, as original parts began to be scarce, the manufacturers stepped up and reproduced everything needed, including spindles and rack-and-pinion steering in both manual and power configurations. Today there's no need to search for original parts as these frontends come as complete assemblies and are made entirely from aftermarket components.

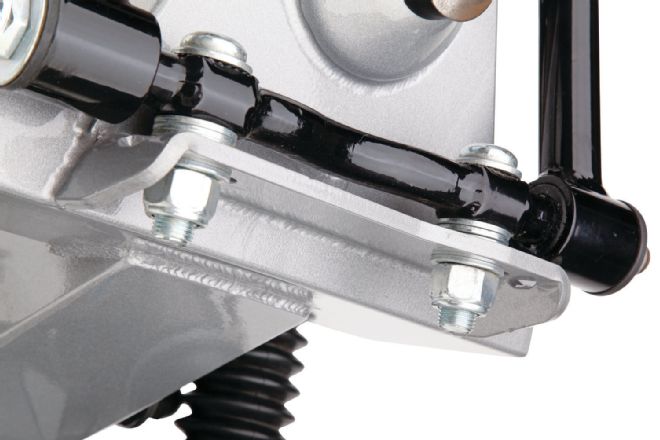

TCI Engineering’s IFS uses shims to adjust camber rather than slots in the upper spring plate. Upper A-arms are made from 1-inch od DOM (drawn over mandrel) tubing.

TCI Engineering’s IFS uses shims to adjust camber rather than slots in the upper spring plate. Upper A-arms are made from 1-inch od DOM (drawn over mandrel) tubing.

While there were a number of aftermarket improvements made to the original frontend's design, there was one undesirable element that often remained—the method of adjusting caster and camber. Slots in the upper mounting plates allowed the top A-frame shafts to be moved to facilitate alignment. Unfortunately, the T-bolts securing the shafts could slip, especially on nicely painted or powdercoated frames. One pothole can knock the frontend out of alignment—and if you drive your street rod you'll no doubt find potholes and other obstacles that seem to have been placed as a result of an alignment shop conspiracy.

Not long ago Sal Solorzano, general manager and vice president of TCI Engineering, decided it was time to introduce a new coil spring IFS that had all of the pluses of earlier designs, but none of the minuses. The first thing the engineering staff addressed was the method of alignment—the spring towers were redesigned by doing away with the commonly used adjustment slots and adding vertical plates to serve as attachment points for the upper A-frame shafts. When the frontend is aligned shims are sandwiched between the shafts and plates, eliminating the possibility of the adjustment slipping.

TCI Engineering has made changes in other areas as well. The suspension geometry has been revised to enhance handling and the lower control arm mounts have been redesigned and now have a 1-1/4 inch pin running through the crossmember for increased strength and durability. The upper and lower control use Energy Suspension urethane bushings and are said to be the strongest on the market. To further increase safety and longevity, only American-made screw-in upper and lower ball joints are used with pull out ratings of 28,000 and 32,000 pounds, respectively.

Slots in the vertical plates allow for caster adjustments but can’t slip like horizontal slots can. The upper shaft is angled to provide the proper antidive characteristics during braking.

Slots in the vertical plates allow for caster adjustments but can’t slip like horizontal slots can. The upper shaft is angled to provide the proper antidive characteristics during braking.

In order to tailor their IFS to individual customer needs, there are a number of options. Rodders can choose stock or dropped spindles, disc brakes with Ford or Chevy bolt patterns, coil springs with specially designed shock with more travel than OEM designs, or coilovers, to name a few.

TCI Engineering has taken a good thing a made it better by taking the best parts of a proven design and applying their experience and engineering expertise to eliminate its shortcomings. The result is independent front suspension redefined. Take a look and see if you don't agree.

Here the alignment shims can be seen between the upper shaft.

Here the alignment shims can be seen between the upper shaft.

Optional are TCI Engineering’s coilover retrofit kit. A variety of other options are available, including air springs, bigger brakes and powdercoated components.

Optional are TCI Engineering’s coilover retrofit kit. A variety of other options are available, including air springs, bigger brakes and powdercoated components.