Now that we have discussed the theory behind supercharging and introduced you to Gear Head Designs’ supercharger kit for Pontiacs in the primer article, we can move on to preparing our Pontiac engine for supercharging, setting up the dyno, and dyno testing.

When contemplating upgrading to a supercharger, many aspects need to be considered, not the least of which is that the engine needs to be blower friendly. Here are a few points to consider before you bolt on a supercharger kit, and how we approached them with the Mule:

Is the Pontiac mechanically sound enough to take the added cylinder pressure?

Prior to bolting on the blower we had performed a leakdown, cranking and running compression tests, and a bubble test on the Mule, so we knew it was healthy.

What is the compression ratio?

Project Pure Poncho was built with a 9.1:1 compression ratio, so in theory it would be able to accept moderate levels of boost. If your engine is 10:1 or greater with iron heads, then it most likely would not be the best idea to put a supercharger on it, even if you limited the boost to 5 psi. The only exception would be if your Pontiac had a bulletproof rotating assembly and you were willing to use 100-octane fuel.

Is the rotating assembly (pistons, rods and crankshaft) up to the task?

A supercharger places more load on the snout of the crankshaft and the front main cap. It could take up to 100 hp or more to turn a blower at high rpm and boost levels, and this needs to be recognized. Any weakness there will become apparent very quickly, as the crankshaft will see a load in a region it’s not designed for.

Our forged rotating assembly was not a source of trepidation. It’s comprised of stout pieces, and though it’s meant for a normally aspirated application, we felt confident in its durability when exposed to moderate boost pressure. The only concern is that when bad things happen, they do so very quickly in a forced-induction engine. If the tune-up wanders near the line, it would be very possible that a ring land would disconnect from a piston and wreck the engine. So keep this in mind when using forced induction—safety trumps power when it comes to the tune.

Is the cam profile good for a blower?

Superchargers are sensitive to the overlap of the camshaft. If both valves are kept open, the boost pressure goes out the exhaust instead of being trapped in the cylinder. A cam profile that works great on a drag engine will usually have poor results with a supercharger. The Mule was designed with a cam grind of minimal overlap, since it is meant to be street friendly. It should be able to build boost easily.

Is the fuel delivery stout enough?

A typical dyno fuel system was not going to be sufficient for a forced-induction application. The fuel pressure regulator needs to be able to add one pound of fuel pressure for each pound of boost. Likewise, the fuel pump must to be able to maintain the volume at the higher pressure. A standard carburetor uses 6-7 psi of fuel pressure and according to Gear Head Designs, the three pulleys they sent us would be approximately 5, 10 and 15 psi. Thus, a fuel pump that would maintain flow up to 22 psi (7 plus 15) would be required, along with a boost sensitive pressure regulator. We installed both.

Will a new carburetor be required?

The Gear Heads kit is a blow-through design—the carburetor is pressurized, so a standard version will not work without a good deal of modification. (This is in contrast to a draw-through system that places a plenum for the supercharger to provide forced air under the carburetor.)

To resolve this issue, we turned to Quick Fuel Technology (QFT) and the company’s 750-cfm blow-through street/strip carburetor. It features blower- specific annular discharge boosters with additional holes to guarantee enough fuel flow. The metering block is machined to accommodate larger main wells. Other changes are to the throttle body. It has relief slots to direct fuel to the intake manifold and not out the shaft bushing. In addition, the throttle shafts are round instead of the normal flat stock. This is to prevent bending under boost pressure. A Nitrofil float replaces a brass style that may crush under pressure. The power valve has no back-pressure blow-out protection, since that would not allow it to work with forced induction.

Will the ignition need to be upgraded?

The ignition system needs to be strong enough to arc the spark plug under the higher cylinder pressure. A street car would require a boost-retard system that we did not employ on the dyno, since we were only testing under full load. It’s not just to keep abnormal combustion at bay, but also as the VE is increased, the turbulence in the cylinder improves and less timing is required to make peak power. A boost retard system would allow the engine, when used on the street, to enjoy an efficient spark advance curve under vacuum to atmospheric pressure, and then remove a minimum of 1 degree advance for every pound of boost.

Do I need a different spark plug heat range?

You want the spark plug to not hold an excessive amount of heat, and be responsible for igniting the gasoline prior to the discharge of the ignition coil. Identify the heat range of the spark plug that is in the Pontiac now, and then go a few steps colder to help keep abnormal combustion away.

Craig used a special tool to confirm the heat range of the plug that was already in the Mule and then went two heat ranges colder. The Pontiac had Autolite 26 plugs; he switched to Autolite 24, and tightened the gap to 0.035 from 0.045. The wider gap makes the engine more prone to misfire due to the added turbulence and pressure from the blower.

Further Considerations

There were a few other things that we integrated into our testing that may or may not apply to a street application.

HPP wanted to identify the discharge temperature of the air from the supercharger and also in the plenum of the intake manifold. We would know the dyno room temperature, and then with the other data, we would be able to confirm if the blower was working in an acceptable adiabatic range. The influence of an intercooler was also one of the test protocols. Craig placed the second temperature probe under the divider in the plenum of the intake manifold so that it would be accurate and not disturb fuel or airflow.

Our plan was to run the engine without any cooling effect for the air and then introduce two different methods. The first would be a Snow Performance Stage 2 Boost Cooler methanol injection system. It includes a 3-quart reservoir, UHO (Ultra High Ouput) electric pump, different flow rate nozzles, a programmable Digital Variable Controller to tune the amount of injection, installation hardware and instructions, and an 8-ounce bottle of Boost Juice concentrate (mix is 50/50 water and methanol).

The theory of the methanol injection is to provide a cooling effect to the charge through the latent heat of vaporization. Methanol and water will evaporate, and this process removes heat from the air. It is the same basic theory that allows a living being to perspire and be cooled on a hot summer day. The controller allows the amount of methanol sprayed to be varied by the duty-cycle of the pump, along with a set pressure for boost.

A traditional air-to-air heat exchanger plumbed in between the blower discharge and the carburetor hat was to be the next method of intercooling. The methanol injection system would be turned off. Gear Head Designs provided a CXRacing intercooler that measures 24 inches wide by 12 inches tall by 4 inches thick.

We felt it was important to try two different cooling methods and to be able to identify an actual heat drop with a thermocouple. In our use, the engine would only see short bursts of peak power on the dyno. A street/strip Pontiac with this kit would have to live under more severe conditions with a closed hood and high ambient temperature. This would almost make some style of cooling necessary for the best results, but based on Gear Heads data, the system can be used safely without any charge air cooling.

The Results

The Mule fired right up with the QFT blow-through carburetor and idled perfectly with the load of the Paxton Novi 1500 blower. With the engine running, we visually checked the belt tension and all the brackets for movement. Everything looked fine, but subsequently the belt came loose as it stretched and needed to be tightened during our dyno session. This is not unusual with a new belt on a fresh installation.

RaceKrafters did install a linear air/fuel meter, since we would not be able to monitor brake specific fuel consumption (BSFC) due to the need for two flow meters when using a return fuel system. The boost sensitive regulator employed a return line to the fuel cell that a standard fuel pressure regulator does not.

We did immediately notice that the supercharger carburetor was rich at idle with an 11.3:1 air/fuel ratio. We were told by QFT that it was set this way, and Craig knew he would be able to lean out the idle circuit if it were a street engine. For the dyno, the rich mixture was just fine. We were not going to idle it long enough to do any harm or foul the plugs.

Our first test would have the 4.00-inch-diameter pulley (the least boost), no air cooling, and 92-octane pump gas. The specification predicted 5 psi of boost, so the timing was retarded from its previous 32 degrees BTDC to 27 degrees BTDC. Another full pull would be done with this setup, and then any tuning changes or decisions would be made.

The third protocol would be to introduce the methanol injection with this calibration, and then shut it off and move up to the next smaller pulley (3.25 inches). The smaller pulley was supposed to produce between 8 and 10 psi of boost. It would be tested with and without the chemical intercooler. Depending on the results and the engine’s health after these tests, we could then go to the smallest pulley and perform all the steps over again.

With the first full pull, it was easy to see the Mule loved the Gear Heads supercharger. It made a peak torque of 632.1 lb-ft and 596.1 hp on pump gas with an average boost pressure of 3.609 psi and a maximum of 5.66 psi. The QFT carburetor was very rich (which means safe) under full load with an air/fuel ratio of around 9.7:1. The engine had 27 degrees of total timing.

The maximum blower discharge temperature was 148 degrees F with a dyno cell of 96 degrees F. With no cooling, the plenum temperature was 88 degrees F. The rich air/fuel ratio was acting as a chemical intercooler and doing an excellent job of removing heat from the compressed air. This is the real benefit of a carburetor over an EFI system. The phase change of the fuel in the plenum provides cooler charge air. The temperature of the charge was actually 8 degrees F lower than the ambient temperature in the dyno room.

After a backup pull, with such sterling results and nothing broken, we decided to leave the tune alone. The Pontiac made more power than we had estimated, and we were very happy with the rich mixture. We did not want to risk hurting a piston by going too lean.

The next step was to evoke the methanol injection system. With it on and timing bumped to 30 degrees, the air/charge temperature only dropped about 2 degrees F to about 86 degree F, and the power stayed about the same. This is no reflection on the system, but is a result of the efficient annular discharge booster in the QFT carburetor and the extremely rich mixture. If we would have leaned the carburetor, then the methanol injection could be used to bring the air temperature back down, and a more aggressive tune-up and higher power could be realized. But we felt it unnecessary to push the envelope for just a few more ponies.

Satisfied with the performance, we moved to the 3.25-inch-diameter pulley and higher boost. For this test, Craig drained the fuel cell and poured in 100-octane Rockett Brand street gas. We did not know how much boost the smaller pulley would make and we wanted an insurance policy.

We thought the Mule was stout before, but the new pulley ratio really woke it up. With this setup, the discharge temperature from the blower went up to 208 degrees, and with no chemical intercooler, the plenum air temperature went up to just around 90 degrees F.

The cooling effect of the rich mixture was still in play, but the engine did pop a little at around 4,500 rpm since it went even richer than before. We could not get a real clean pull. Craig decided that we would need to lean the carburetor slightly and replaced the 74/82 jets with 72/80 jets. The timing was still at 30 degrees and the methanol was turned on for safety with the elevated discharge temperature from the blower.

Project Pure Poncho returned the favor of a slightly leaner mixture (10.5:1) with peak torque of 680.2 ft-lb and 647.4 hp! This is from a stock ’75 block, 6X head 455. The plenum temperature with the Snow Performance injection came down to 82 degrees F, and the blower discharge went up to around 212 degrees F.

Concerned about the cylinder pressure and the stress on the crankshaft, we did not try the smaller pulley. The final test was to install the air-to-air intercooler with the 3.25-inch-diameter pulley.

With everything plumbed in place, we started the pull, and then at 4,000 rpm, the engine went lean (16:1) and started to buck and pop. Bob was running the dyno and he quickly got out of the throttle. After spending an hour trying different things, the engine would not take any load with the intercooler in place. Craig put it back to the way it was and it made 647 hp again with no fuss.

Paxton and Gear Head Designs believe the resistance from the intercooler was robbing boost. Their recommendation is to run a smaller pulley to increase the boost and/or run a smaller intercooler. Gear Head Designs has a smaller CXRacing intercooler on the way for a future test.

Regardless, we had a solid day of testing with very good numbers and no breakage. There is no doubt that the Gear Heads supercharger kit is an excellent system. When installed on a properly prepared engine, it can produce power and reliability that was previously unheard of. Regarding the Mule, it allowed an already great performing engine put out an additional 150-plus horsepower and 125-plus lb-ft of torque on a conservative tune—quite an accomplishment for a bolt-on kit.

16. For the test with the 3.25-inch-diameter pulley, Craig filled the fuel cell with 100-octane Rockett Brand gasoline.

16. For the test with the 3.25-inch-diameter pulley, Craig filled the fuel cell with 100-octane Rockett Brand gasoline.

17. The CXRacing intercooler seems to be too big for our application. To use one, we have to install a smaller pulley to increase boost and/or get a smaller intercooler.

17. The CXRacing intercooler seems to be too big for our application. To use one, we have to install a smaller pulley to increase boost and/or get a smaller intercooler.

HPP Engine Buildup Worksheet

Engine Displacement: 467 ci

Bore/Stroke: 4.185 / 4.250-in

Bore/Stroke ratio: 0.98:1

Rod/Stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Deck height: 10.205-in

Crank: Butler/Eagle forged

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Bearings: Clevite, plain shell, tri-metal

Pistons: Butler/Ross forged flat-top with valve reliefs

Piston-to-deck height: 0.010-in below

Piston pins: Ross, 0.990-in floating, 0.155-in wall

Method used to retain pins in pistons: Spiro Locks

Rings: Total Seal, moly top, ductile second, 3-piece oil, 1⁄16, 1⁄16, 3⁄16-in

Rod bolts and head bolts: ARP

Balancing specs: Internal

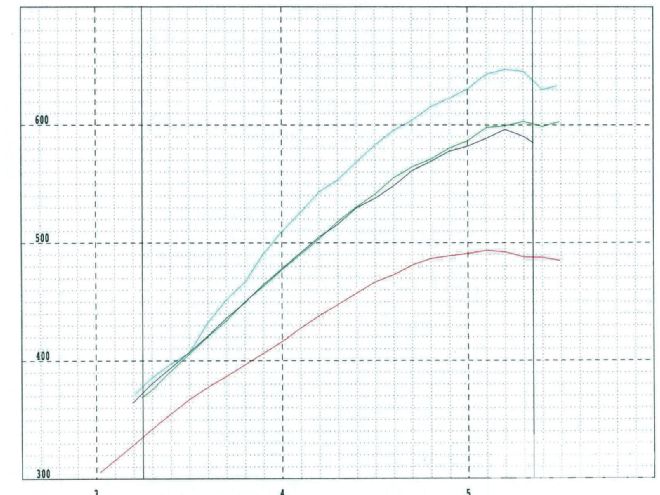

Corrected Horsepower 18. The red line represents a normally aspirated pull on 92-octane from our previous oil test. Blue is the baseline with the supercharger, 4.00-inch pulley, 92-octane, and no methanol injection; green is the 4.00-inch pulley, 92-octane, with methanol injection; aqua is the 3.25-inch pulley, 100-octane fuel, and methanol injection.

Corrected Horsepower 18. The red line represents a normally aspirated pull on 92-octane from our previous oil test. Blue is the baseline with the supercharger, 4.00-inch pulley, 92-octane, and no methanol injection; green is the 4.00-inch pulley, 92-octane, with methanol injection; aqua is the 3.25-inch pulley, 100-octane fuel, and methanol injection.

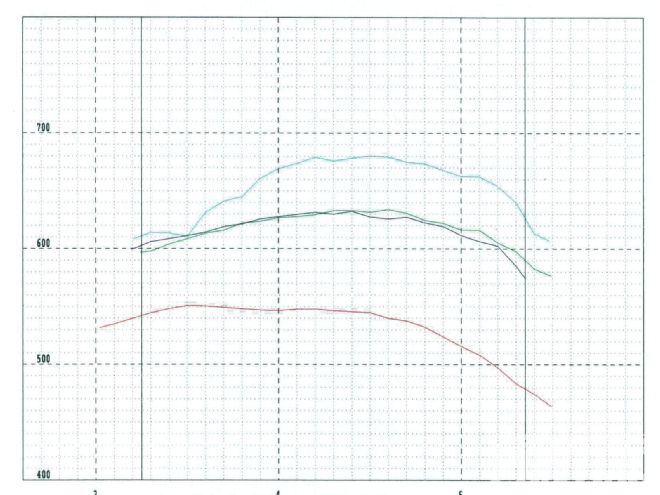

Corrected Torque 18. The red line represents a normally aspirated pull on 92-octane from our previous oil test. Blue is the baseline with the supercharger, 4.00-inch pulley, 92-octane, and no methanol injection; green is the 4.00-inch pulley, 92-octane, with methanol injection; aqua is the 3.25-inch pulley, 100-octane fuel, and methanol injection.

Corrected Torque 18. The red line represents a normally aspirated pull on 92-octane from our previous oil test. Blue is the baseline with the supercharger, 4.00-inch pulley, 92-octane, and no methanol injection; green is the 4.00-inch pulley, 92-octane, with methanol injection; aqua is the 3.25-inch pulley, 100-octane fuel, and methanol injection.

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road Race Series 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2 ccs

Maximum flow at 28 inches of pressure

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job

Intake: 45, 60, 75, and 82-deg, 82 is hand-blended into 75-deg.

Exhaust: 45-deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valve Guides: K-line bronze liner

Valve Seals: Steel/Viton

Rocker Studs: ARP 7⁄16-in

Rocker Arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 3/8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration At 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe Separation Angle: 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 137-lb/in

Open Pressure: 290-lb/in

Timing Chain: Cloyes double roller

Induction

Carb: Quick Fuel Technology 750-cfm, set up for blow-through supercharger

Intake Manifold: Edelbrock Torker II

Supercharger: . . Gear Head Designs Paxton Novi 1500

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5 mm

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32-in

Collector Size: 3.00-in

Gaskets

Brand: Fel-Pro

Parts Sources

Engine Components: Summit Racing Equipment www.summitracing.com

Reciprocating Assembly: Butler Performance www.butlerperformance.com