On a stock 327 Chevy with a 0.447-inch-lift cam, will installing 1.6:1 roller-tip rockers make that much of a difference over the stock 1.5:1 stamped rockers?

Brian Dias, Madera California

Comp Cams Pro Magnum full-roller rocker arms offer less weight, a more accurate ratio, and reduced friction. For any given engine's rocker-arm design, shortening the distance from the fulcrum (rocker-stud pivot) to the pushrod tip increases the ratio. Here, a 1.52:1 rocker is on the left; the 1.6:1 version is at right.

Comp Cams Pro Magnum full-roller rocker arms offer less weight, a more accurate ratio, and reduced friction. For any given engine's rocker-arm design, shortening the distance from the fulcrum (rocker-stud pivot) to the pushrod tip increases the ratio. Here, a 1.52:1 rocker is on the left; the 1.6:1 version is at right.

There are several broad rules of thumb that provide clues to whether increasing rocker-arm ratio will prove to be a performance boon with a given engine, cylinder head, and camshaft combination. Generally speaking (and remember, there are exceptions to every rule), the smaller the cam, the greater the performance gain from increasing rocker-arm ratio. The better the cylinder head, the more you can expect from high-ratio rockers. The larger the valves, the greater the improvement. These factors are interrelated.

The intake- and exhaust-valve heads present a restriction to airflow into and out of the ports. There has to be a certain minimum amount of valve opening to overcome the restriction. Dividing the cam's valve lift (including rocker ratio) by valve diameter yields what's known as the lift/diameter (L/D) ratio, the percentage of lift to valve diameter. According to Comp Cam's lobe designer Billy Godbold, L/D for a high-performance street engine should be at least 25 percent, but "28 to 30 percent is better for hard-core performance." Pure race engines will want 35 percent or even higher. The really neat thing about this rule of thumb is that it's applicable to any engine; from a snowmobile to a gigantic Marine diesel, it scales required lift to the valve size.

Assuming your 327 has 1.94-inch intake and 1.50-inch exhaust valves, and the cam develops 0.447-inch valve lift with the stock 1.5:1 rockers, the L/D ratio would be:

L/D (intake) = 0.447 ÷ 1.94 = 0.230 = 23%

L/D (exhaust) = 0.447 ÷ 1.50 = 0.298 = 29.8%

This is low on the intake side but OK on the exhaust side. If on a budget, consider trying the high-ratio rockers on the intake side only. But let's assume an upgrade to 1.6:1 rockers across the board. To find the new L/D ratio, first divide the valve lift by the existing 1.5:1 rocker ratio to obtain the cam's lobe lift, then multiply the lobe lift by the new rocker ratio (1.6:1), and finally, divide the new product by the valve size, as before:

L/D (int.) = [(0.447 / 1.50) x 1.60)] / 1.94 = 0.246 ? 24.6%

L/D (exh.) = [(0.447 / 1.50) x 1.60)] / 1.50 = 0.318 ? 31.8%

Substituting 1.6:1 rockers for 1.5:1 rockers turns a 0.447-inch-lift cam into a 0.477-inch-lift cam, increasing the intake and exhaust L/D ratio to around 25 and 32 percent, respectively. The higher rocker ratio also develops several more degrees of duration at the valve. Therefore, high-ratio rockers, particularly on the intake, should be a viable, cost-effective upgrade--at least up to the point at which they exceed the flow capacity of the ports in the heads.

Besides the potential power benefits of an increase in rocker ratio, roller rockers have several additional power-adding advantages compared with a stamped rocker. The advertised ratio of aftermarket roller-tip rockers is more accurate than the claimed ratio of typical stock stamped rockers. In other words, stock rockers can vary and are often less (rarely more) than their advertised ratio. Second, the premium, true roller-style rocker that adds a rollerized fulcrum (pivot) in addition to the roller tip offers a significant friction reduction. Together, these combine to add some additional power beyond what the ratio change itself brings to the table.

The accompanying graphs illustrate the results of installing better rockers on a Chevy 350 equipped with aftermarket Trick Flow 23-degree heads with 2.02/1.60-inch valves that flowed 250 cfm at 0.500-inch valve lift on the intake port and 183 cfm at 0.500-inch valve lift on the exhaust side. A 750-cfm Speed Demon carb atop an Edelbrock Performer RPM intake metered the fuel, while valve actuation was handled by a Comp Cams Xtreme Energy XE268H dual-pattern hydraulic flat-tappet with 224/230-degrees duration at 0.050-inch tappet lift and 0.477/0.480-inch valve lift with 1.5:1 rockers. (The lift increases to 0.509/0.512 with 1.6:1 rockers.)

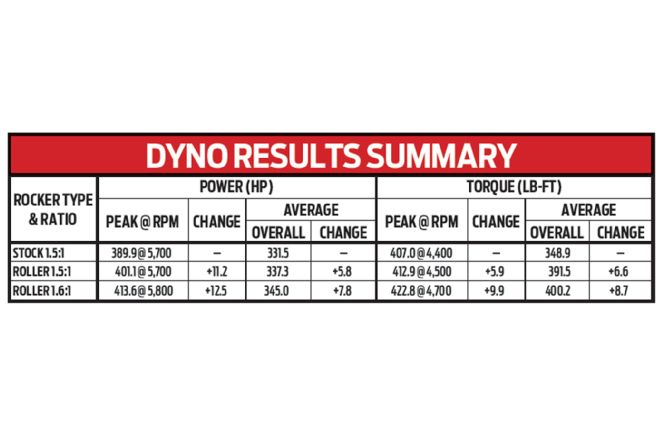

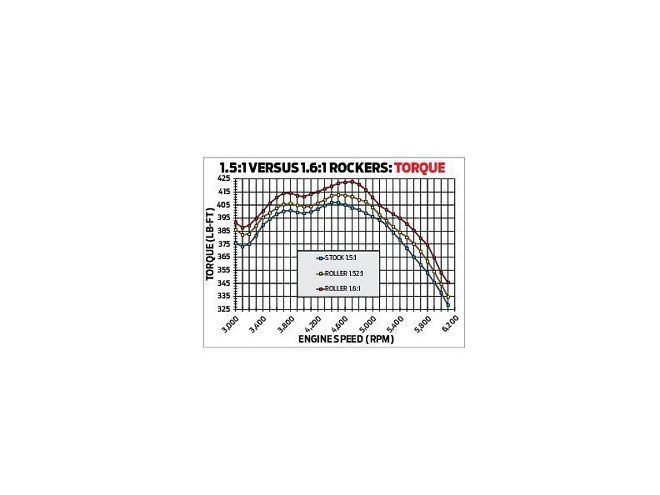

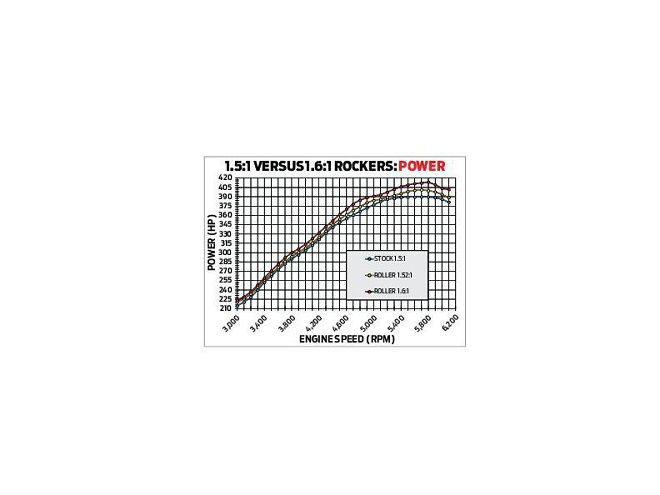

The engine was tested on Westech Performance's SuperFlow dyno using stock GM 1.5:1 stamped rockers with pivot-ball fulcrums, 1.52:1 full roller rockers, and 1.6:1 full roller rockers. Merely changing from the stock stamped rockers to full roller rockers with approximately the same advertised ratio was worth about 11 hp and 6 lb-ft, verifying the friction reduction and greater stability of a full rollerized rocker configuration. Moving from 1.52:1 full roller to 1.6:1 full roller rockers was worth another 12-1/2 hp and 10 lb-ft. Overall, the engine gained nearly 24 hp and 16 lb-ft over the baseline stock rocker configuration, raising peak output from 390 hp and 407 lb-ft to 414 hp and 423 lb-ft.

Compared with your 327, the test 350 had 23 more cubic inches, better heads, and a larger cam with more base lift. According to the theory, the larger cam should be less responsive to higher-ratio rockers, but that in turn would be canceled out to some extent by the higher-flowing heads. You didn't say what heads you are using, but decent '60s-era heads with 1.94/1.50-inch valves and a good valve job might flow around 200 and 135 cfm on the intake and exhaust sides, respectively--much less than the Trick Flow Heads used in the heads. Still, I'd say your 327 is looking at a conservative estimate of a 10 to 15 hp increase from a rocker-arm swap.

An additional caution: Going to high-ratio rockers is not always a simple bolt-on. Even at your mild performance level, the pushrods may bind or rub on the close-tolerance pushrod holes in heads without screw-in studs and guideplates, or they may rub against the guideplates on those heads machined for guideplates. You will have to cycle the engine through the complete opening and closing cycle for all valves and check this visually. On guideplate-equipped heads, you can modify the plates if needed for clearance, or procure adjustable plates (such as Comp Cams PN 4835-8). On heads with close-tolerance pushrod holes, the heads must be removed and the holes elongated as necessary to avoid contaminating the engine with metal shavings. But if you need to go that far, why not put in a better cam? Du-oh-- mission creep!

More radical engines than yours may experience additional problems when increasing rocker ratio, including piston-to-valve interference, rocker arm-to-valvespring retainer interference, valvespring-to-valveguide or seal interference, and overall valvetrain geometry issues. Mallory ZC Distributor Conversion

Putting higher-ratio rockers on engines more radical than Dias' mild 327 can cause valvetrain geometry problems, piston-to-valve interference, or clearance problems between the rocker, spring retainer, valveguides, and valve seals. On this Vortec head, the reference mark on the valve-stem tip (arrow) indicates that the stock-length pushrods are too short.

Putting higher-ratio rockers on engines more radical than Dias' mild 327 can cause valvetrain geometry problems, piston-to-valve interference, or clearance problems between the rocker, spring retainer, valveguides, and valve seals. On this Vortec head, the reference mark on the valve-stem tip (arrow) indicates that the stock-length pushrods are too short.

Mallory ZC Distributor Conversion

I want to convert an old Mallory ZC distributor to electronic ignition. It's in a '50 flathead. Is there a provider that can supply the kit?

James B. Knaus, Gibraltar, MI

Unfortunately, I can't find anyone making a dedicated conversion kit for such an old application--not even Mallory itself. Crane Cams does offer several universal XR700 FireBall optically triggered kits. From the looks of it, Crane PN 700-0231 might do the job. It has adjustable, slotted mounting brackets. Download the XR700 illustrated instructions from Crane's website to see if it might meet your needs. Otherwise, you're looking at a complete modern electronic distributor from leading aftermarket companies like MSD or Roto-Faze. Either way, you need to move up to a 12-volt electrical system. For example, the XR700's operating voltage is listed as 6 to 18 volts, but your original 6-volt system may drop below 4 volts under crank.

Replacing the stock 1.5:1 stamped steel rockers with full-roller 1.52:1 rockers on a 350 Chevy equipped with Trick Flow Heads and a Comp XE268H cam was worth 11 hp and 6 lb-ft of torque. Compared with the stock rocker baseline, moving to 1.6:1 rockers was worth 24 hp and 16 lb-ft.

Replacing the stock 1.5:1 stamped steel rockers with full-roller 1.52:1 rockers on a 350 Chevy equipped with Trick Flow Heads and a Comp XE268H cam was worth 11 hp and 6 lb-ft of torque. Compared with the stock rocker baseline, moving to 1.6:1 rockers was worth 24 hp and 16 lb-ft.