No matter what kind of rules are written to keep the costs of racing down, there are some facets of stock car racing that are going to be expensive no matter what you do. This is particularly true when it comes to the engine. Even if you’re racing a crate engine class, any engine is a complex piece of machinery with lots of moving parts which require an extremely precise fit and finish. That type of stuff just costs money.

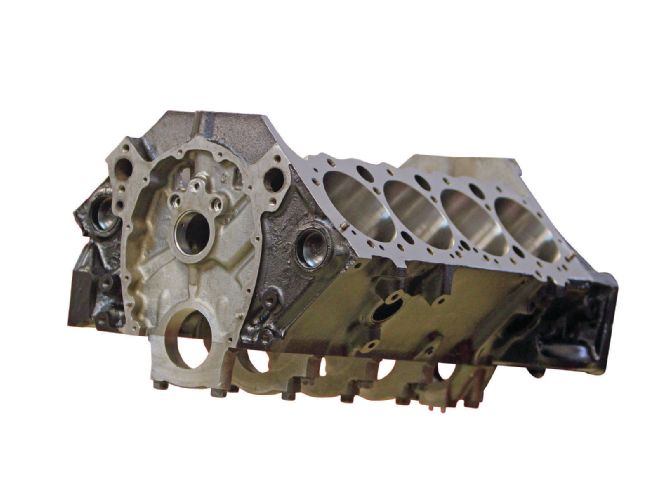

This is our Chevy small block that we use as a dyno mule ready for a new rotating assembly. What did it take to get it to this point? Glad you asked.

This is our Chevy small block that we use as a dyno mule ready for a new rotating assembly. What did it take to get it to this point? Glad you asked.

If you race in a built motor class, the up-front costs are likely even higher. But the costs almost always evens out in the long run because the higher quality parts you will normally use in a built race motor will be a higher quality than you will find in most crates—this is true even if you’re building a Pure Street race engine—so they will last longer, perform better, and be much less likely to blow up at the worst possible time.

The key to saving a buck when it comes to your racing engine is to do at least some of the work yourself. After all, your time may be valuable, but at least nobody is charging you for it. So whatever you can take off of your engine builder’s plate and do for yourself is that much more that won’t be reflected on the bill.

Of course, there are some things that are best left to the engine builder with a dedicated machine shop and all the cool specialized tools that come with it. In this article, we’ll take an in-depth look at preparing the engine block for a race engine build. Some things require specialized machining equipment, which should be left to your trusted engine builder. We’ll take a look at exactly what these are, what they should cost and how they will help your engine perform at its best. We’ll also take a look at which steps are critical and which you can sometimes get by without, but honestly, if you’re attempting to race at your highest level, doing everything you can to make sure your engine block is absolutely perfect is always a good idea.

And then there are some operations that don’t require anything more than handtools. You may want to consider doing some of these yourself, either before or after you take the block to your engine builder. Almost all the steps we’ll discuss are valid whether you’re prepping a brand-new block straight out of the speed parts catalog, attempting to salvage an old soldier out of the junkyard, or simply going through a rebuild.

For this story we spent a lot of time at KT Engine Development which was kind enough to share with us the typical costs for most of the steps involved. Your local engine builder may have a different pricing schedule, and in fact, KT Engines owner Ken Troutman says he often charges less than the prices quoted depending on the shape of the block, but these should be considered an industry standard.

What’s It Gonna Cost Me?

After a brief survey, here’s what we’ve determined are average prices for some of the most common tasks when it comes to prepping an engine block.

Teardown and Inspection $150 Bore and Hone $250 Add Torque Plates $50 Deck the Block $200 Line Hone $225 Install Cam Bearing and Plugs $50 Final Wash $100